Method of producing polyaluminum chloride with wasted anthraquinone regeneration agent

A polyaluminum chloride and regeneration agent technology, applied in the chemical field, can solve the problems of complex production process and high cost, and achieve the effects of simple process, improved efficiency and accelerated dissolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The method of utilizing waste anthraquinone regeneration agent of the present invention to prepare polyaluminum chloride comprises the following steps:

[0033] A, 500g discarded anthraquinone regeneration agent is mixed with 50g activated carbon and then ground into 500 mesh fine powder, and 100g diesel oil is added, and the mixture is obtained after fully stirring; the anthraquinone regeneration agent is sodium hydroxide supported on activated alumina balls;

[0034] B. Pass the mixture obtained in step A into air at 700°C for aerobic roasting for 3 hours, so that the combustion agent is burned, and then the activated carbon is burned to generate heat to decompose the remaining impurities, and the roasted material is obtained after the combustion is complete;

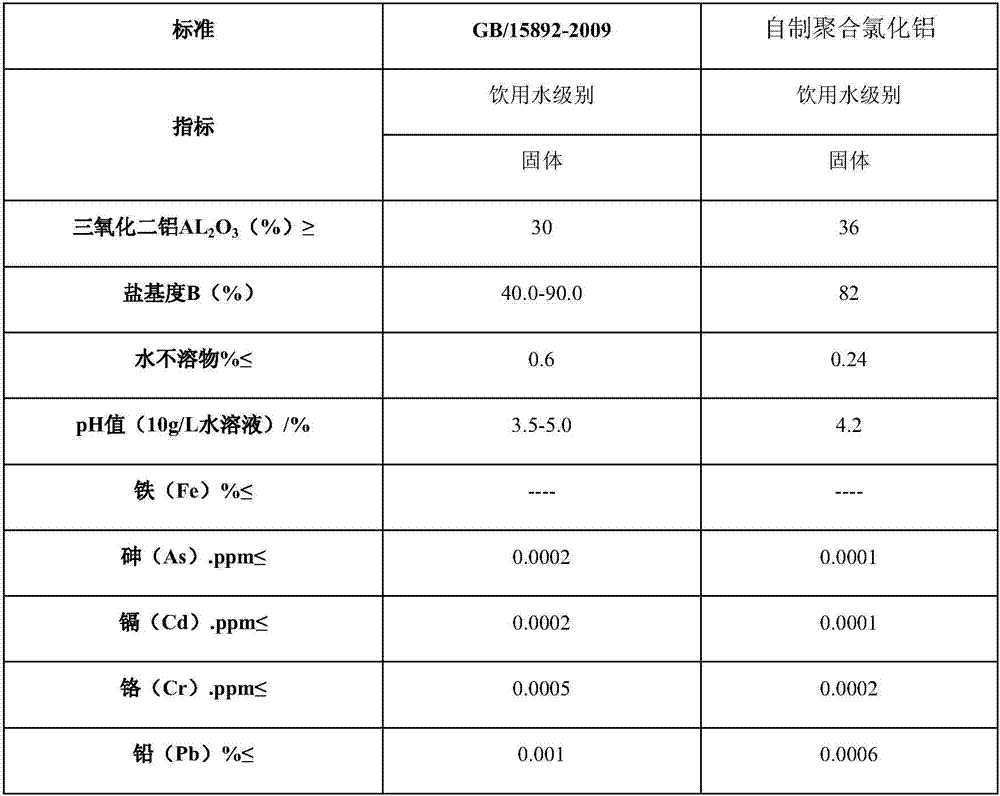

[0035] C. Under 3 atmospheric pressures, mix the calcined material in step B with 25% hydrochloric acid in a molar ratio of 1:5, and perform a stripping reaction for 1 h to strip the alumina to obtain a strippin...

Embodiment 2

[0038] The method of utilizing waste anthraquinone regeneration agent of the present invention to prepare polyaluminum chloride comprises the following steps:

[0039] A. Mix 600g of discarded anthraquinone regeneration agent with 100g of activated carbon and grind it into a 300-mesh fine powder, add 200g of gasoline, and stir thoroughly to obtain the mixture; the anthraquinone regeneration agent is sodium hydroxide supported on activated alumina balls;

[0040] B. Pass the mixture obtained in step A into oxygen at 750°C for aerobic roasting for 2 hours, so that the combustion agent is burned, and then the activated carbon is burned to generate heat to decompose the remaining impurities, and the roasted material is obtained after the combustion is complete;

[0041] C. Under 4 atmospheric pressures, the calcined material in step B is mixed with 30% hydrochloric acid in a molar ratio of 1: 4.5 by mass fraction, and the stripping reaction is carried out for 6 hours to strip the a...

Embodiment 3

[0044] The method of utilizing waste anthraquinone regeneration agent of the present invention to prepare polyaluminum chloride comprises the following steps:

[0045] A, 600g discarded anthraquinone regeneration agent is mixed with 150g activated carbon and ground into 200-mesh powder, sprayed with 300g kerosene, and fully stirred to obtain the mixture; the anthraquinone regeneration agent is sodium hydroxide supported on activated alumina balls;

[0046] B. Pass the mixture obtained in step A into air at 650°C for aerobic roasting for 4 hours, so that the combustion agent is burned, and then the activated carbon is driven to burn, generating heat to decompose the remaining impurities, and the roasted material is obtained after the combustion is complete;

[0047] C. Under 6 atmospheric pressures, mix the calcined material in step B with 37.5% hydrochloric acid in a molar ratio of 1:6 in mass fraction, and carry out a stripping reaction of 6 hours to strip out alumina to obtai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com