Al<4>SiC<4> and Al composite reinforced silicon carbide honeycomb ceramic and preparation method thereof

A silicon carbide honeycomb and composite reinforcement technology, which is applied in the field of honeycomb ceramics, can solve the problem of poor thermal shock resistance, thermal fatigue resistance and working reliability of wall-flow silicon carbide honeycomb ceramics, micropore size and uneven distribution, and product Poor performance and other problems, to achieve the effect of easy molding, uniform micropore size and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

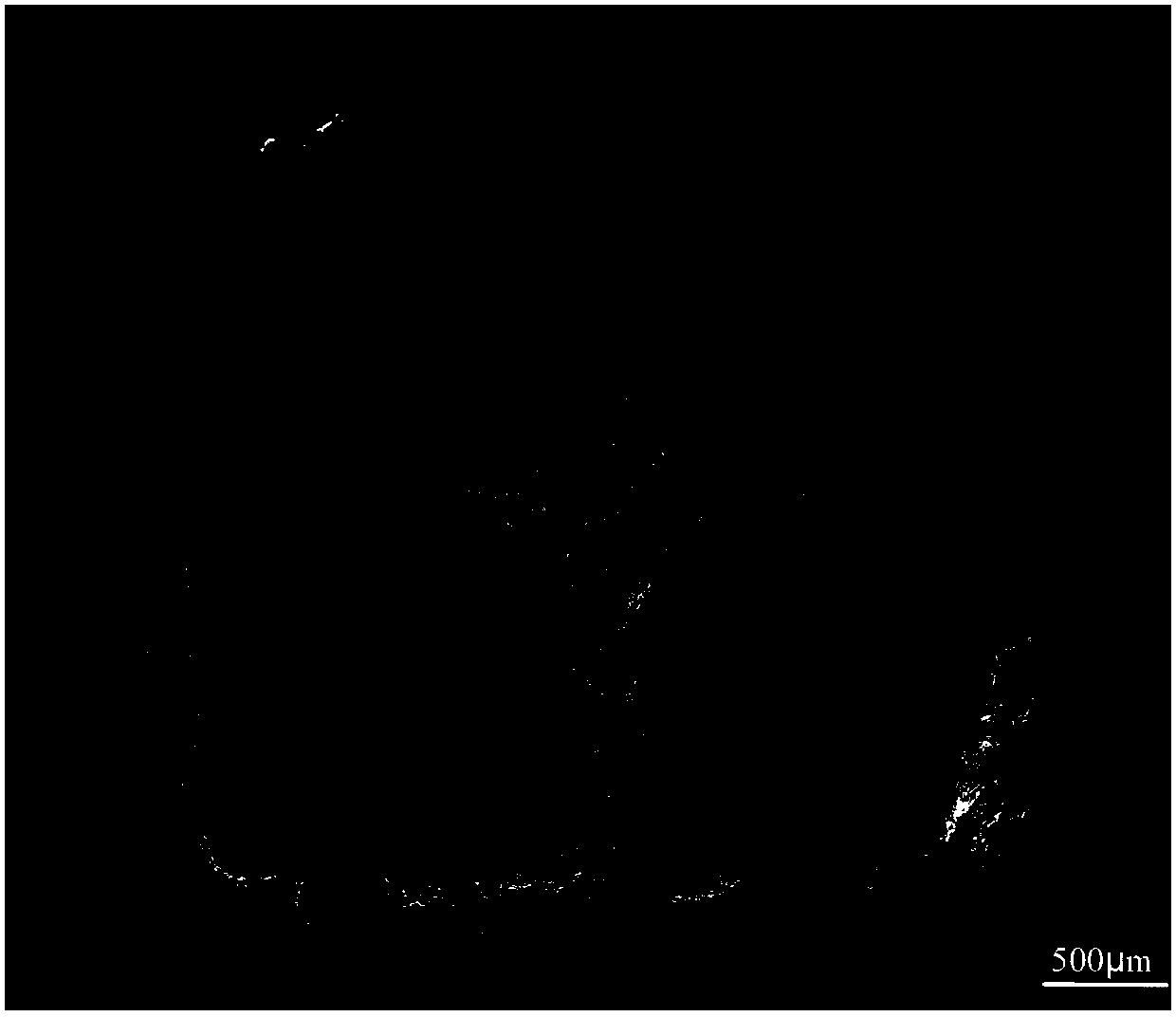

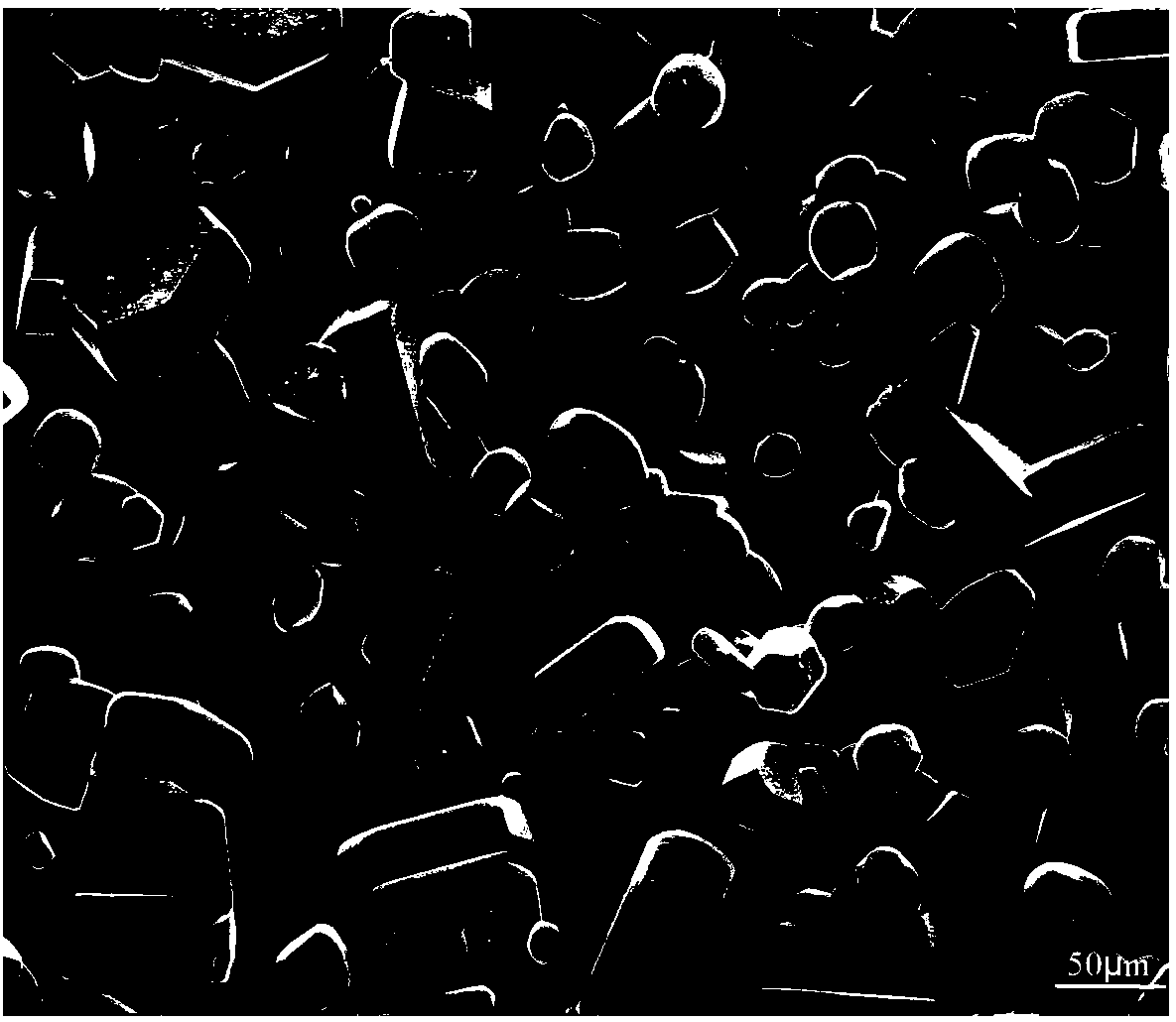

Image

Examples

Embodiment 1

[0040] a kind of Al 4 SiC 4 And Al composite reinforced silicon carbide honeycomb ceramics and a preparation method thereof. The steps of the preparation method described in this embodiment are:

[0041] Step 1, mixing the main material, sintering aid and binder evenly to obtain a mixture;

[0042] The main ingredients include 75wt% silicon carbide powder A, 15wt% silicon carbide powder B, 5wt% Al 4 SiC 4 and 5wt% Al powder;

[0043] The sintering aid is a metal oxide, and the amount of the sintering aid is 7wt% based on the quality of the main material;

[0044] The binding agent is obtained by dissolving cellulose, surfactant, vegetable oil and glycerin into water of equal quality and stirring evenly. Based on the quality of the main material, the consumption of cellulose is 7.5wt%, and the consumption of surfactant 3wt%, the consumption of vegetable oil is 1.5wt%, and the consumption of glycerol is 1wt%;

[0045] Step 2. Pour the mixture into a vacuum extruder to for...

Embodiment 2

[0050] a kind of Al 4 SiC 4 And Al composite reinforced silicon carbide honeycomb ceramics and a preparation method thereof. The steps of the preparation method described in this embodiment are:

[0051] Step 1, mixing the main material, sintering aid and binder evenly to obtain a mixture;

[0052] The main ingredients include 85wt% silicon carbide powder A, 5wt% silicon carbide powder B, 5wt% Al 4 SiC 4 and 5wt% Al powder;

[0053] The sintering aid is a metal oxide, and the amount of the sintering aid is 9wt% based on the quality of the main material;

[0054] The binding agent is obtained by dissolving cellulose, surfactant, vegetable oil and glycerin into water of equal quality and stirring evenly. Based on the quality of the main material, the consumption of cellulose is 7.5wt%, and the consumption of surfactant 4wt%, the consumption of vegetable oil is 2wt%, and the consumption of glycerol is 2.5wt%;

[0055] Step 2. Pour the mixture into a vacuum extruder to form...

Embodiment 3

[0060] a kind of Al 4 SiC 4 And Al composite reinforced silicon carbide honeycomb ceramics and a preparation method thereof. The steps of the preparation method described in this embodiment are:

[0061] Step 1, mixing the main material, sintering aid and binder evenly to obtain a mixture;

[0062] The main ingredients include 80wt% silicon carbide powder A, 8wt% silicon carbide powder B, 6wt% Al 4 SiC 4 and 6wt% Al powder;

[0063] The sintering aid is a metal oxide, and the amount of the sintering aid is 13wt% based on the quality of the main material;

[0064] The binding agent is obtained by dissolving cellulose, surfactant, vegetable oil and glycerin into water of equal quality and stirring evenly. Based on the quality of the main material, the consumption of cellulose is 7.5wt%, and the consumption of surfactant 3.5wt%, the consumption of vegetable oil is 3wt%, and the consumption of glycerol is 3wt%;

[0065] Step 2. Pour the mixture into a vacuum extruder to for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com