Diamond tool bit bevel face grinding device

A diamond cutter head, grinding technology, applied in the direction of grinding drive device, grinding machine parts, grinding/polishing equipment, etc., can solve the problems of low production efficiency, unable to meet social needs, etc. Compact structure and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

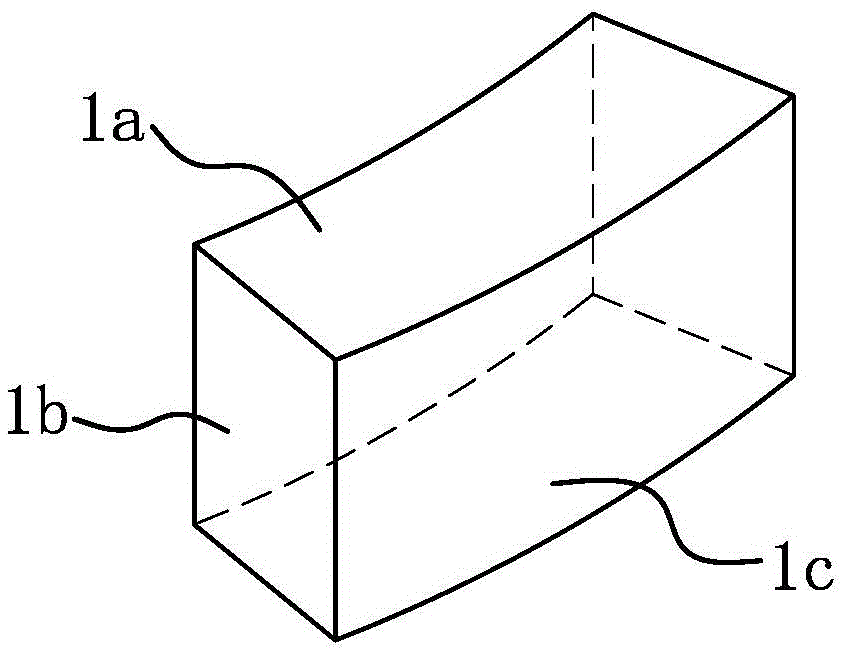

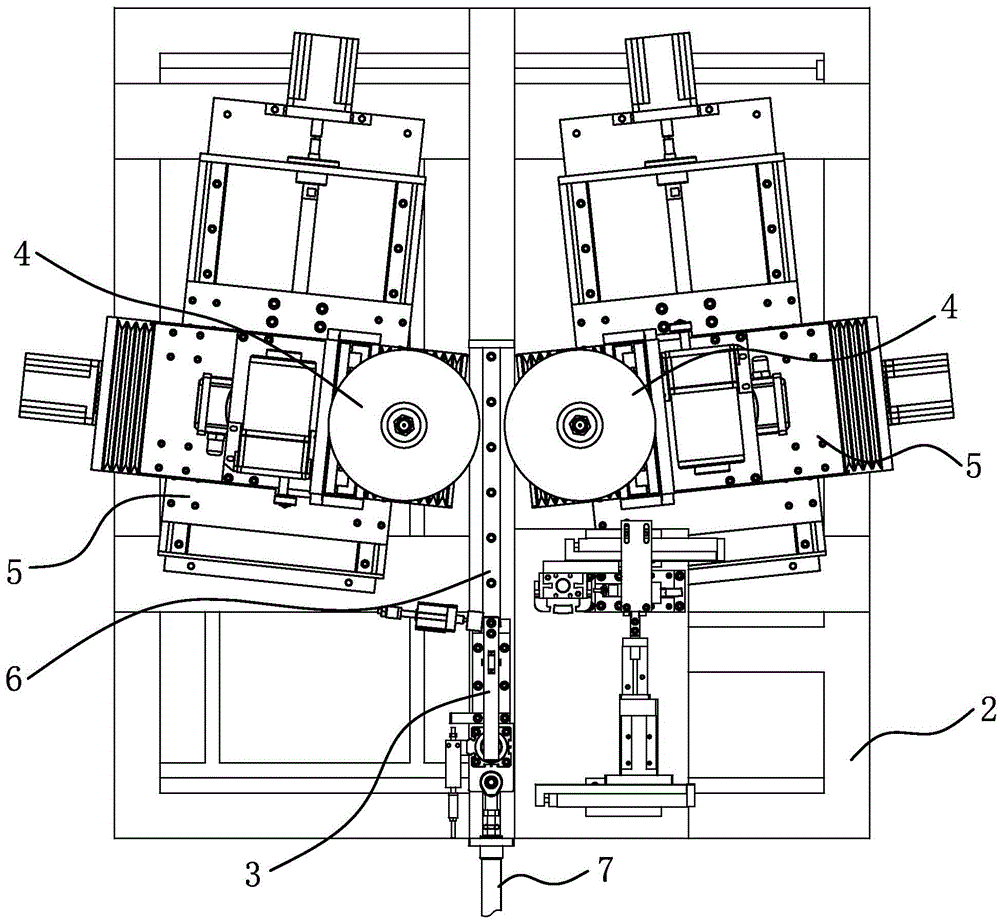

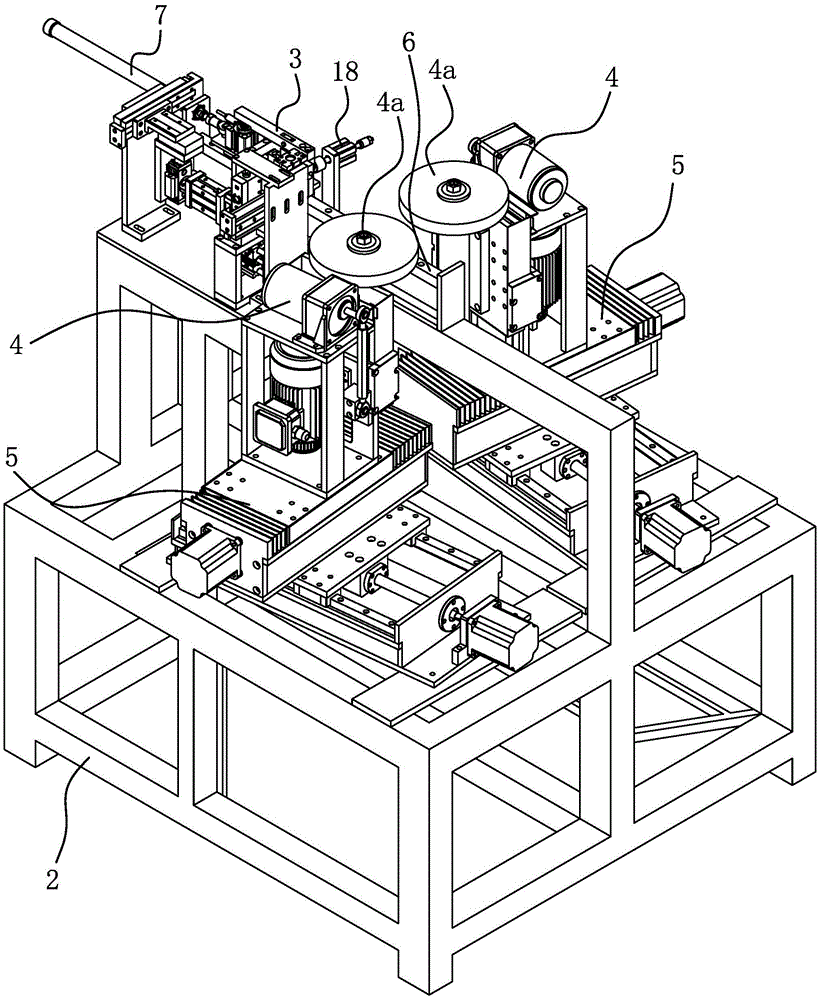

[0036] The grinding device for the beveled surface 1b of the diamond segment includes a frame 2 , a clamp 3 , a grinding mechanism 4 and a feeding mechanism 5 .

[0037] The clamp 3 is arranged on the frame 2 for clamping the diamond segment 1 . In order to facilitate grinding, after the diamond cutter head 1 is clamped, the cutter face of the diamond cutter head 1 faces upward, the bottom face faces, the inner face faces outward, and the two slopes 1b are located outside the fixture 3 . In order to improve the positioning accuracy, the bottom surface of the diamond segment 1 has been machined by grinding. The fixture 3 includes a base 3a, on which a support block 3b for supporting the bottom surface of the diamond cutter head 1 is fixed, on which a pressure rod 3c is hinged, and one end of the pressure rod 3c is connected with a pressure rod for mortgaging the diamond blade surface. block; the base 3a is inherently connected to the other end of the pressure rod 3c and can ma...

Embodiment 2

[0049] Compared with the present embodiment, the difference lies in that the base 3a of the clamp 3 is fixed on the frame 2; other structures are the same, and will not be repeated here.

Embodiment 3

[0051] Compared with the first embodiment, this embodiment also has the following structure: the frame 2 is provided with a fifth linear guide rail 8 perpendicular to the fourth linear guide rail 6, and the slider of the fifth linear guide rail 8 is provided with a first pneumatic clamp Head 9, the frame 2 is provided with the feeding cylinder 10 that is connected with the first pneumatic chuck 9 and can drive the first pneumatic chuck 9 to move; between the third drive assembly 7 and the base 3a of the clamp 3, there is a The gripper 3 avoids the escape cylinder 11 of the movement track of the first pneumatic chuck 9 , and the third drive assembly 7 and the gripper 3 are connected through the avoidance cylinder 11 .

[0052] The diamond segment 1 is first clamped by the first pneumatic chuck 9 . Specifically, the first pneumatic chuck 9 is clamped on the two slopes 1 b of the diamond bit 1 . In order to put the diamond bit 1 clamped by the first pneumatic chuck 9 into the cl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com