Dual-body water conservancy power generation ship

A power generation ship and water conservancy technology, which is applied to special-purpose ships, warships, motor vehicles, etc., can solve the problems of not being able to become a functional power supply, and achieve the effects of low cost, wide application, and high power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below in conjunction with accompanying drawing and embodiment the present invention is described in detail:

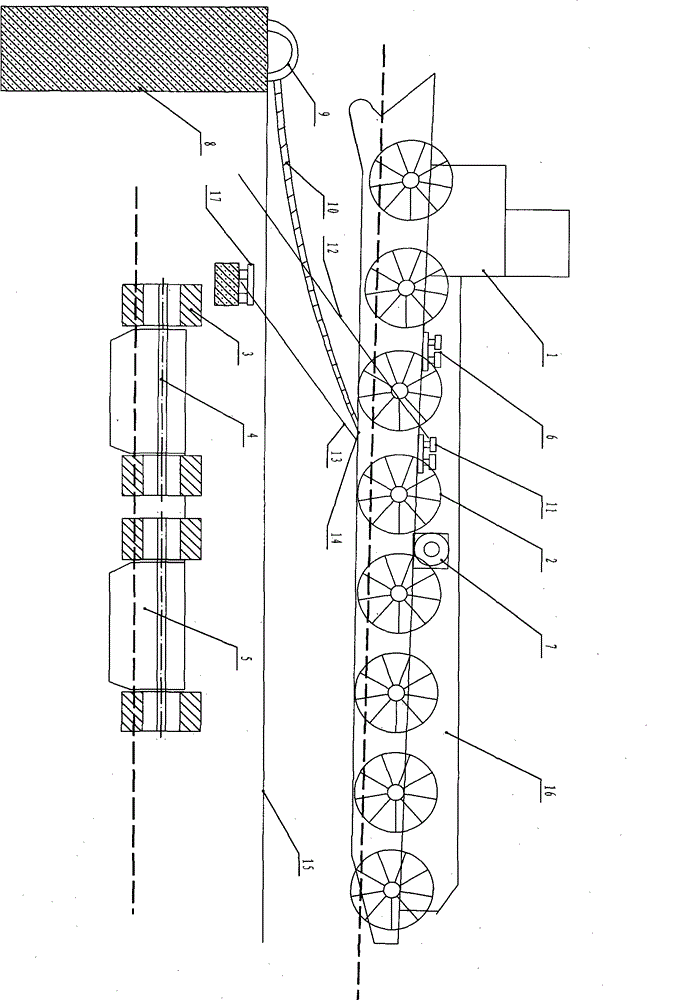

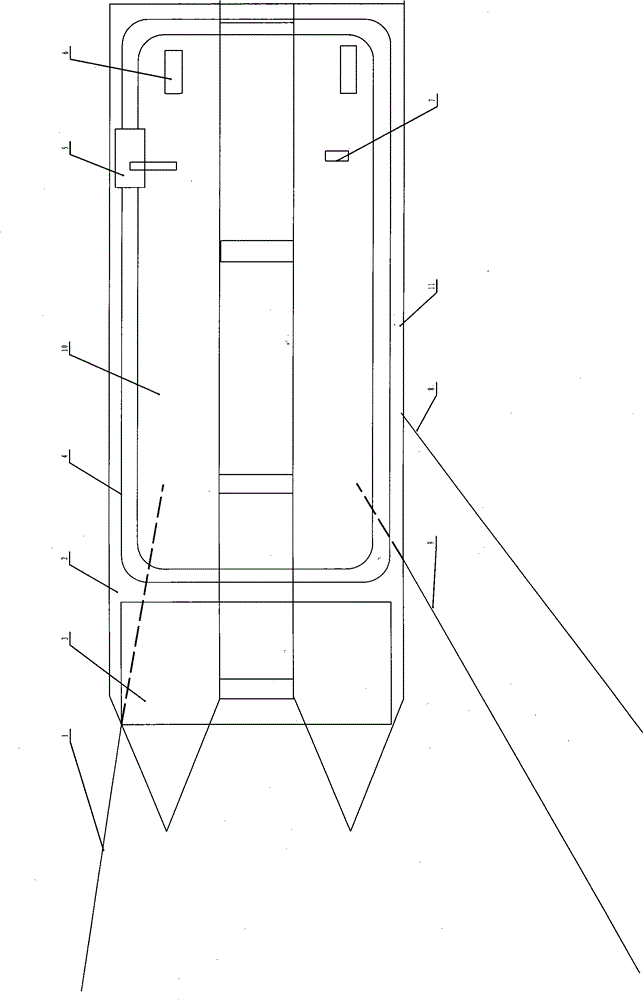

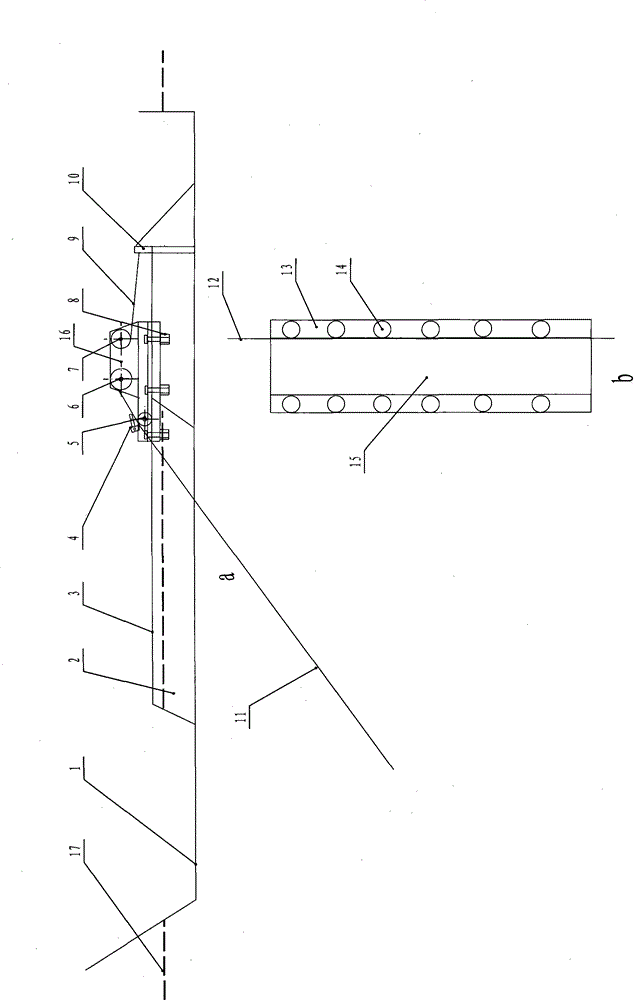

[0018] Such as figure 1 As shown, the present invention includes: a traction and fixing system, a control system, a power transmission system, and a maintenance monitoring system.

[0019] Traction fixed system: Dam building power generation depends on the water drop to determine the unit installed capacity. The non-dam hydropower generating ship of the present invention depends on the traction capacity to determine the unit (ship) installed capacity. Anchor built at the bottom of the river ( figure 1 / 8 below is omitted as 1 / 8) and the shore anchor (1 / 17) forms a triangular three-dimensional traction structure through the anchor chain (1 / 10) and (1 / 13) knotted double ship keel hanging point (1 / 14), so that The power generation ship is positioned in the torrent, so that the multiple sets of paddle wheels (1 / 2) and (1 / 3) arranged on both sides of the hull are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com