Method for pressing circular tubes by oil press

A technology of hydraulic presses and round pipes, applied in the directions of presses, manufacturing tools, etc., can solve the problems of long ship manufacturing cycle, idle plate rolling machine equipment, low utilization rate of plate rolling machine, etc., to reduce equipment configuration requirements and shorten construction period. , the effect of reducing shipbuilding costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

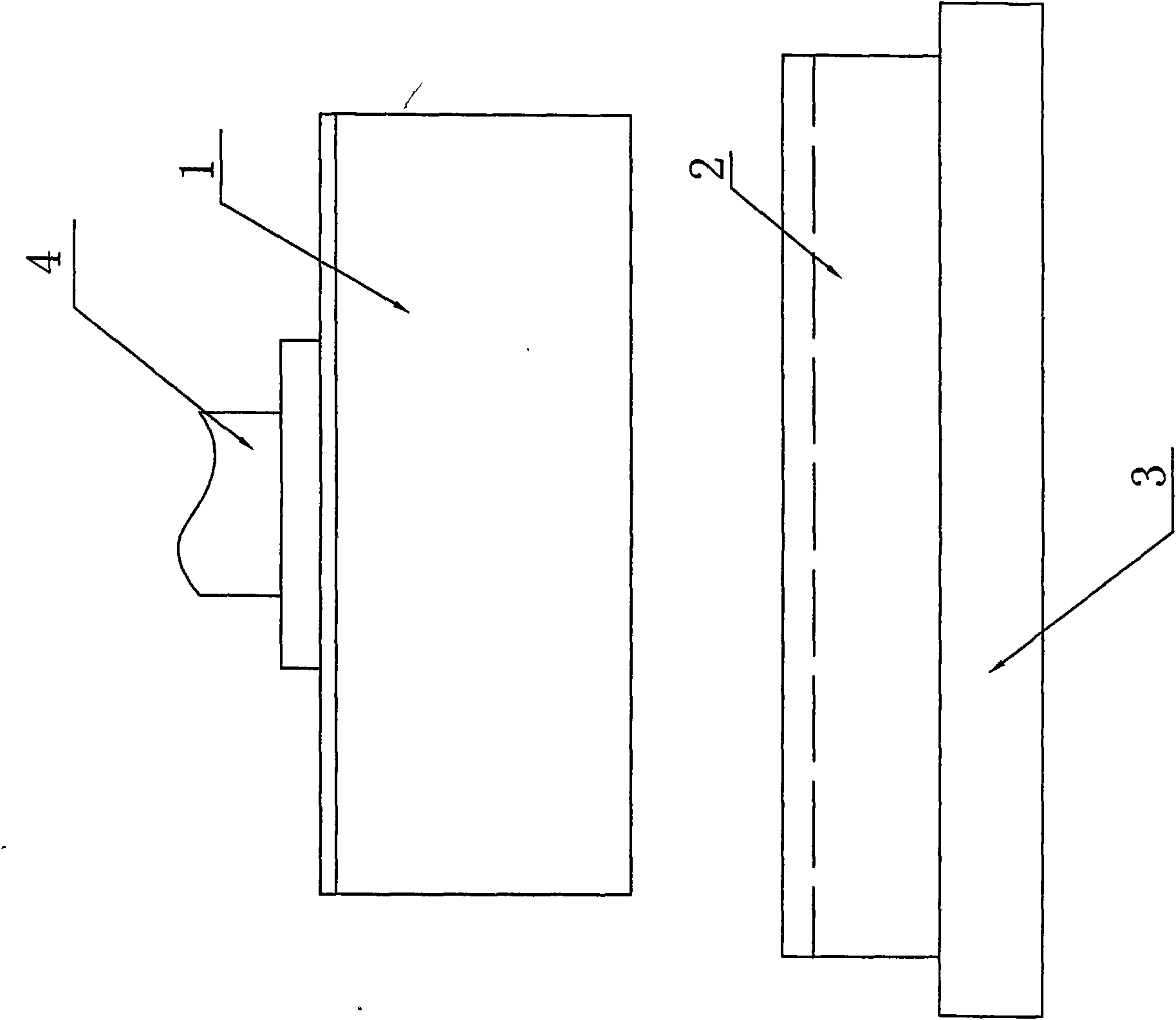

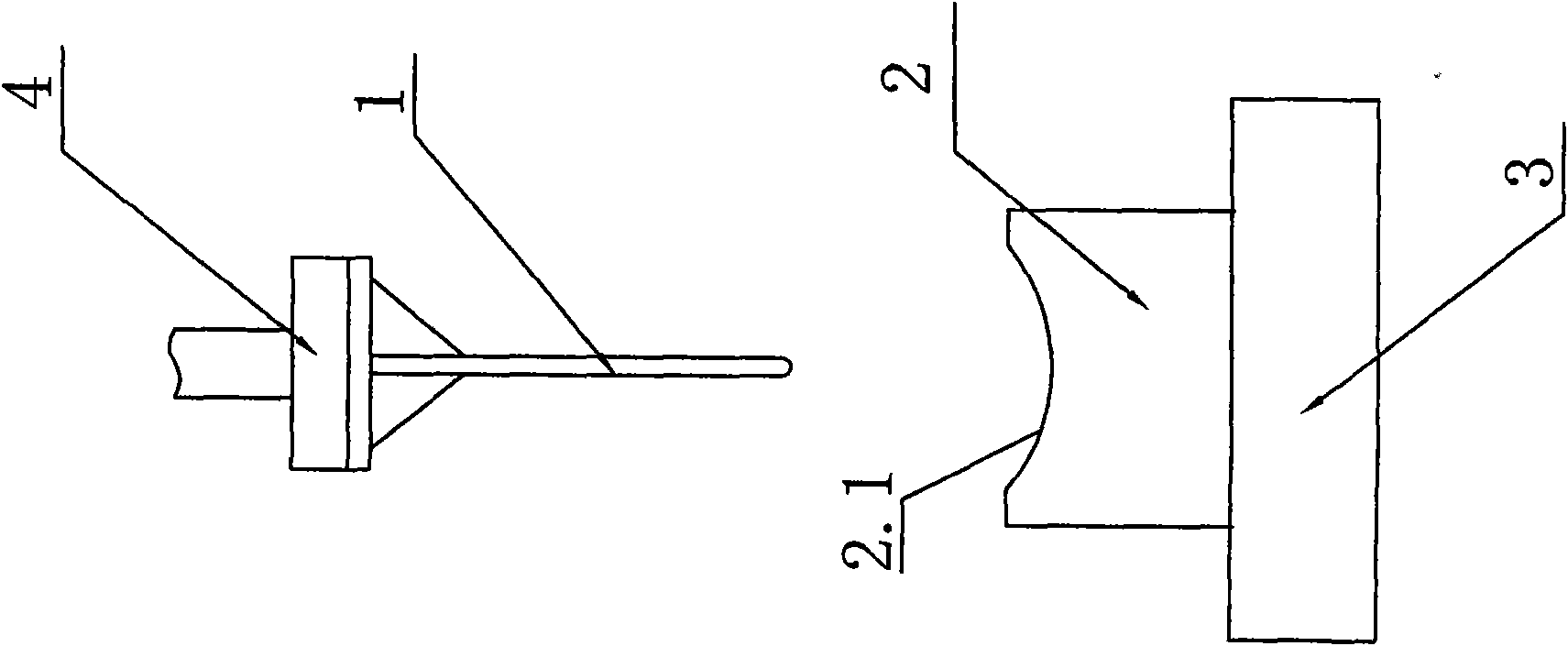

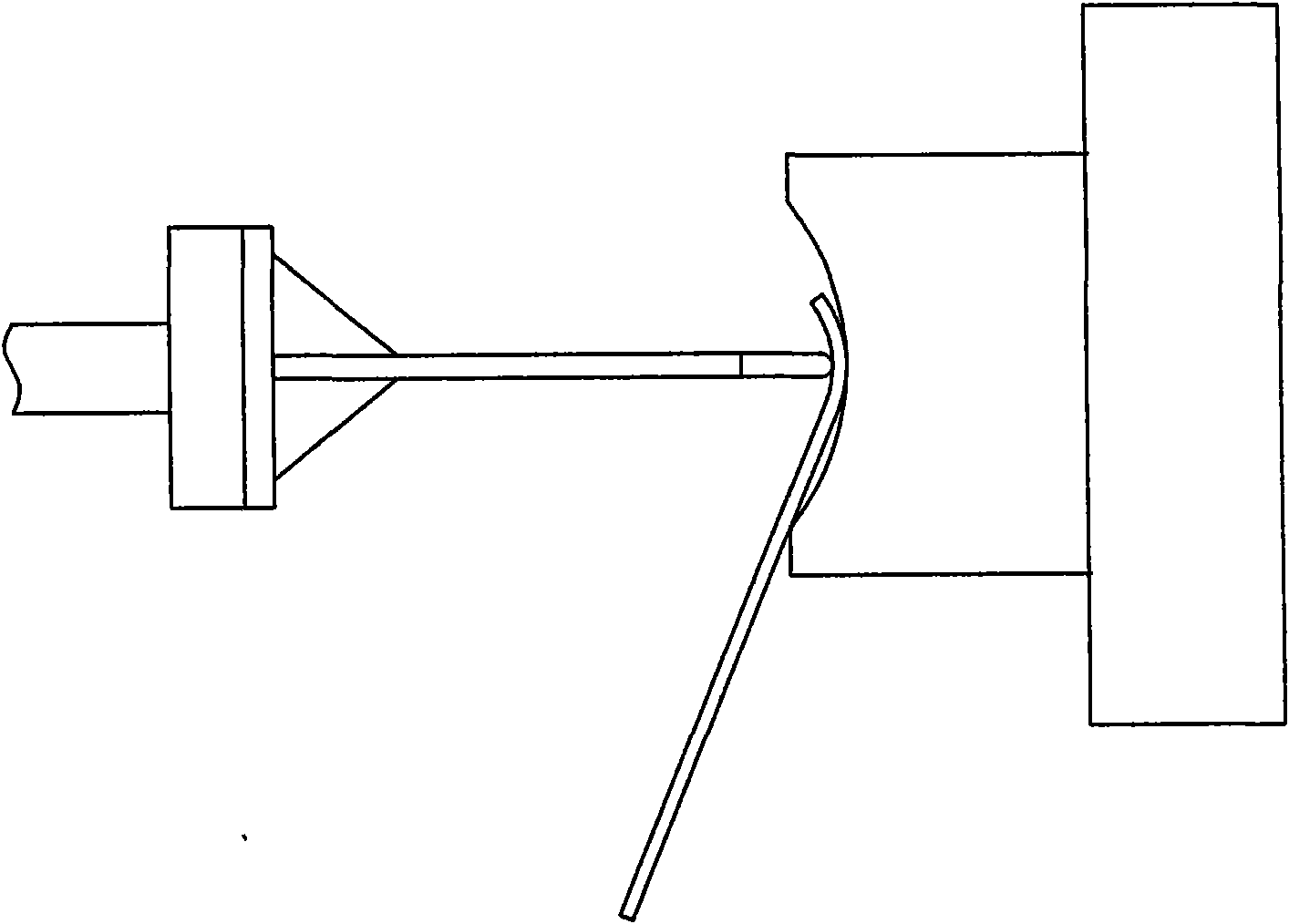

[0022] see Figure 1~2 , the present invention relates to a kind of method that utilizes hydraulic press to press circular pipe in shipbuilding process, and this method comprises:

[0023] Step 1. According to the pressure index of the hydraulic press and the working stroke between the pressure head and the pressing platform, design the upper mold 1 and the lower mold 2. The upper mold 1 is in the shape of a strip. Usually the length of the upper mold 1 is 2000mm, and the material is 16Mn. It is 2500mm, and it is made by splicing steel plates for ships. The lower mold 2 is placed below the upper mold 1, and the upper end surface of the lower mold 2 is arranged as an arc-shaped groove 21 corresponding to the diameter of the round tube to be pressed. Connect and fix the upper mold 1 and the pressure head 4 of the hydraulic press with a turnbuckle, and lock the lower mold 2 with a limit block on the pressing platform 4 of the hydraulic press, and then drive the upper mold downwa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com