Idler wheel switch blade chain pulling device and manufacturing and installing technology of idler wheel switch blade chain pulling device

The technology of a knife chain catcher and roller, which is applied in the field of ship anchors, can solve the problems of large structural type of the chain catcher body, inaccurate cutting, friction between the anchor chain and the roller gate knife chain catcher, etc., so as to reduce the work of the berth The effect of reducing the amount and waste return, avoiding secondary cutting, and shortening the shipbuilding cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The technical solutions of the present invention will be further specifically described below in conjunction with the accompanying drawings and specific embodiments.

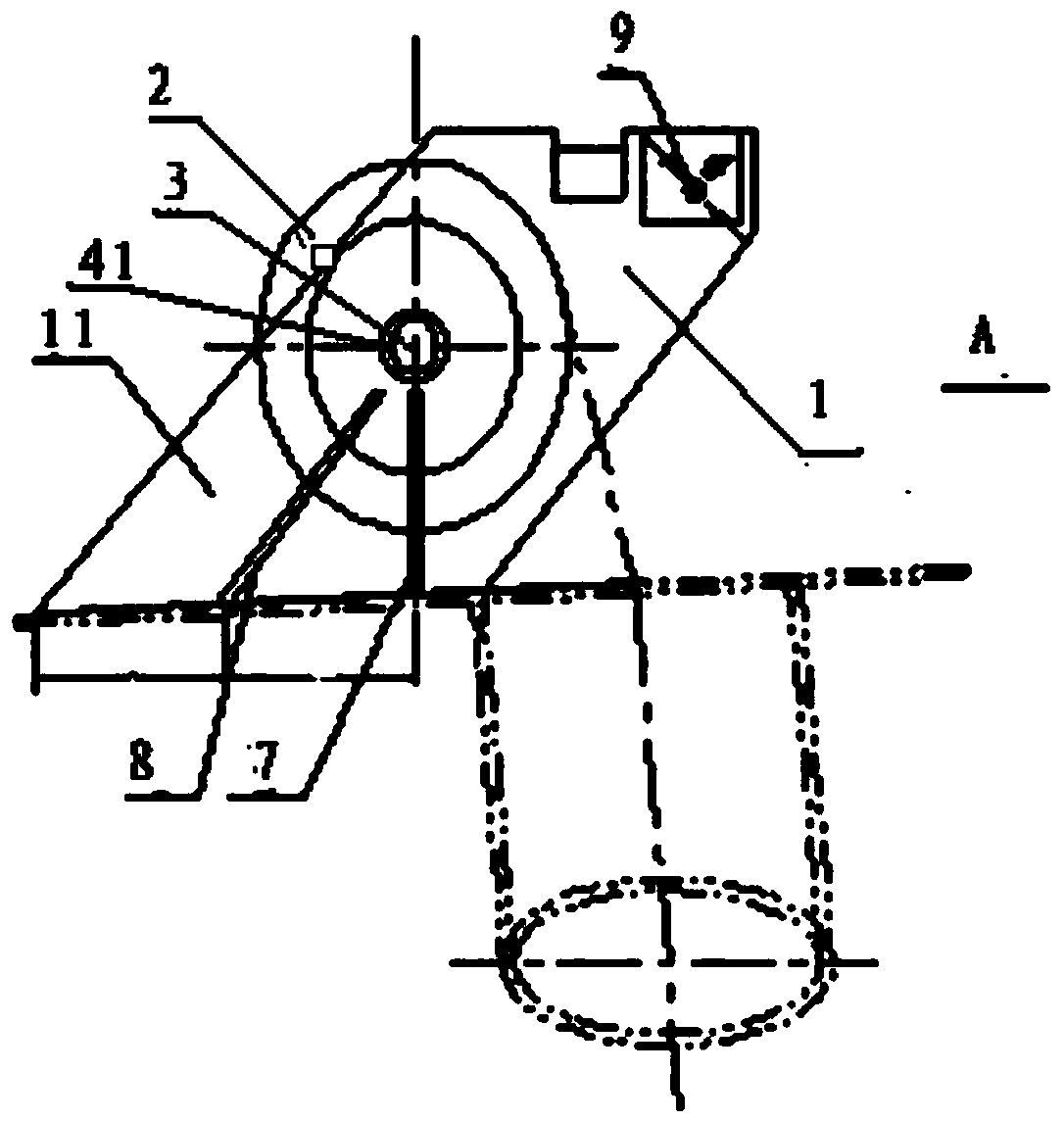

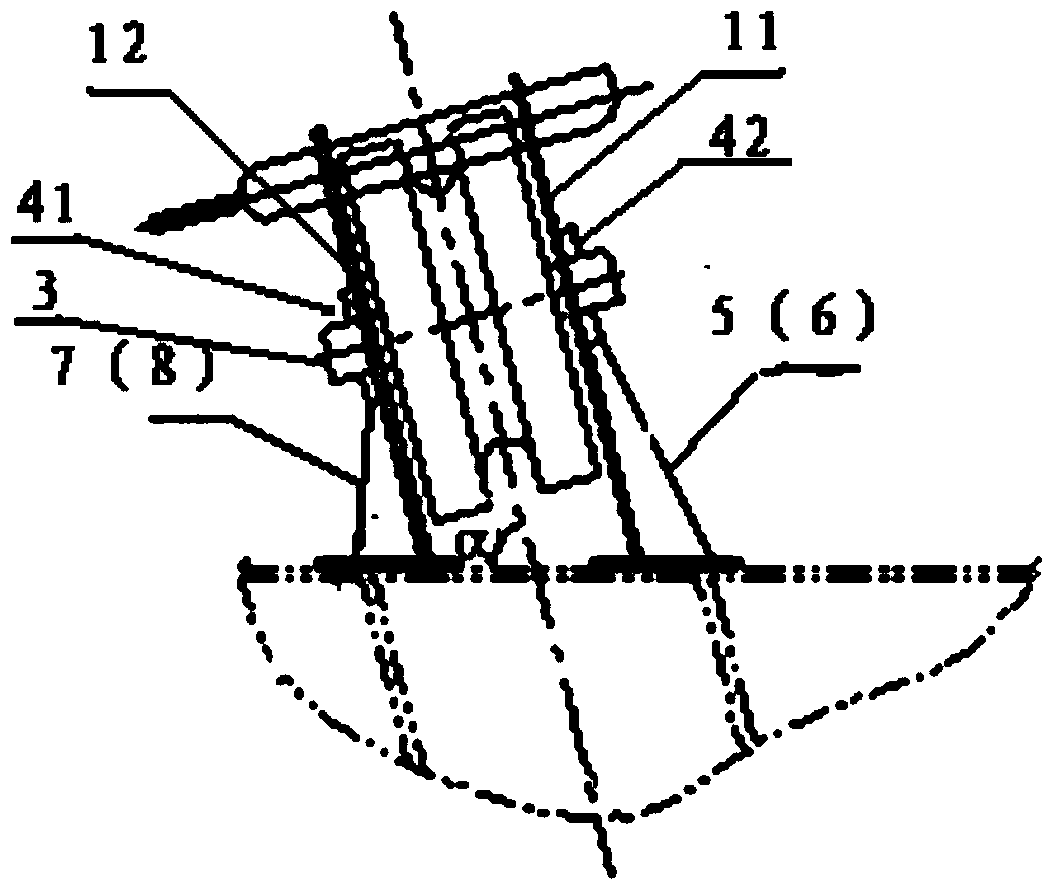

[0017] In the construction of a cruise ship, the roller brake knife chain device was chosen, such as figure 1 and figure 2 As shown, the roller brake knife chain device includes a roller 2 installed in the body 1, and a roller shaft 3 is arranged inside the roller 2, and the two ends of the roller shaft 3 pass through the left and right side plates of the body with left bushings 41 respectively. , the right bushing 42 is fixed, and the first toggle plate 5 and the third toggle plate 6 are also installed on the outside of the left side plate 11 of the body, and the second toggle plate 7 and the third toggle plate are also installed on the outside of the right side plate 12 of the body. Four toggle plates 8; the first toggle plate 5 and the second toggle plate 7 are located on the vertical plane of the ax...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com