Corn straw bundling machine

A technology of corn stalks and balers, which is applied in the fields of packaging, agricultural machinery and implements, and applications. It can solve the problems of inability to crush corn stalks, inconvenient transportation of corn stalks, and inability to separate corn stalks, so as to facilitate the baling of corn stalks. The effect of the operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

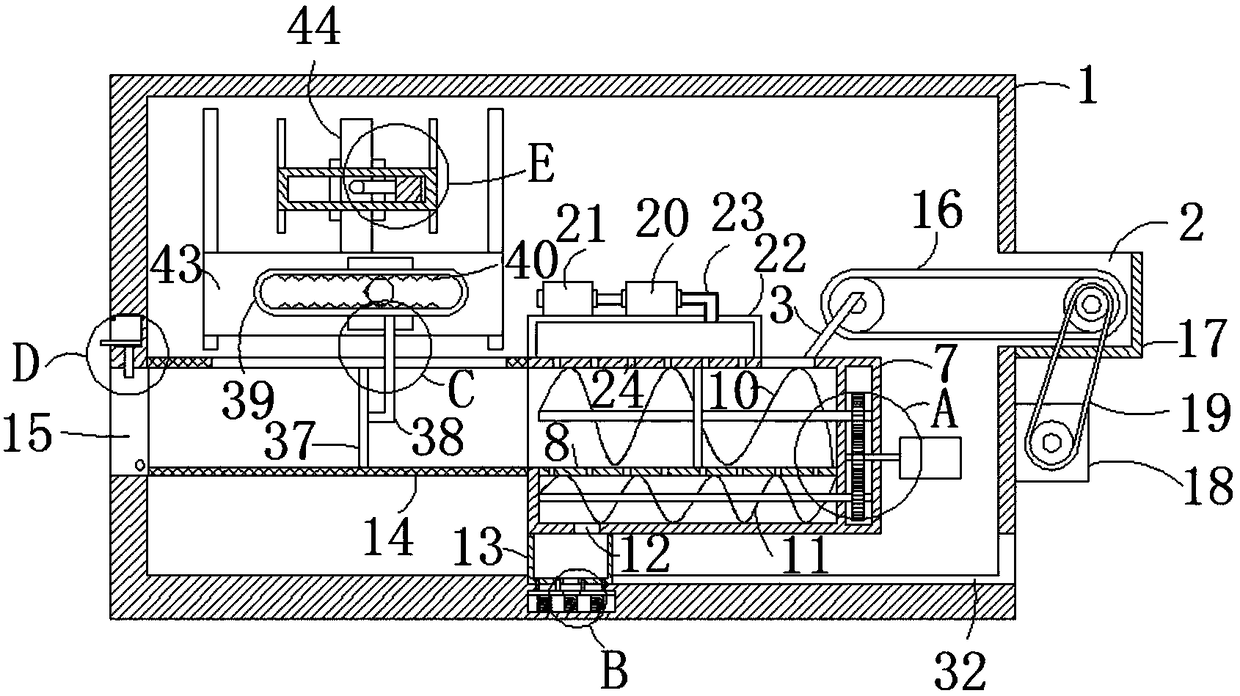

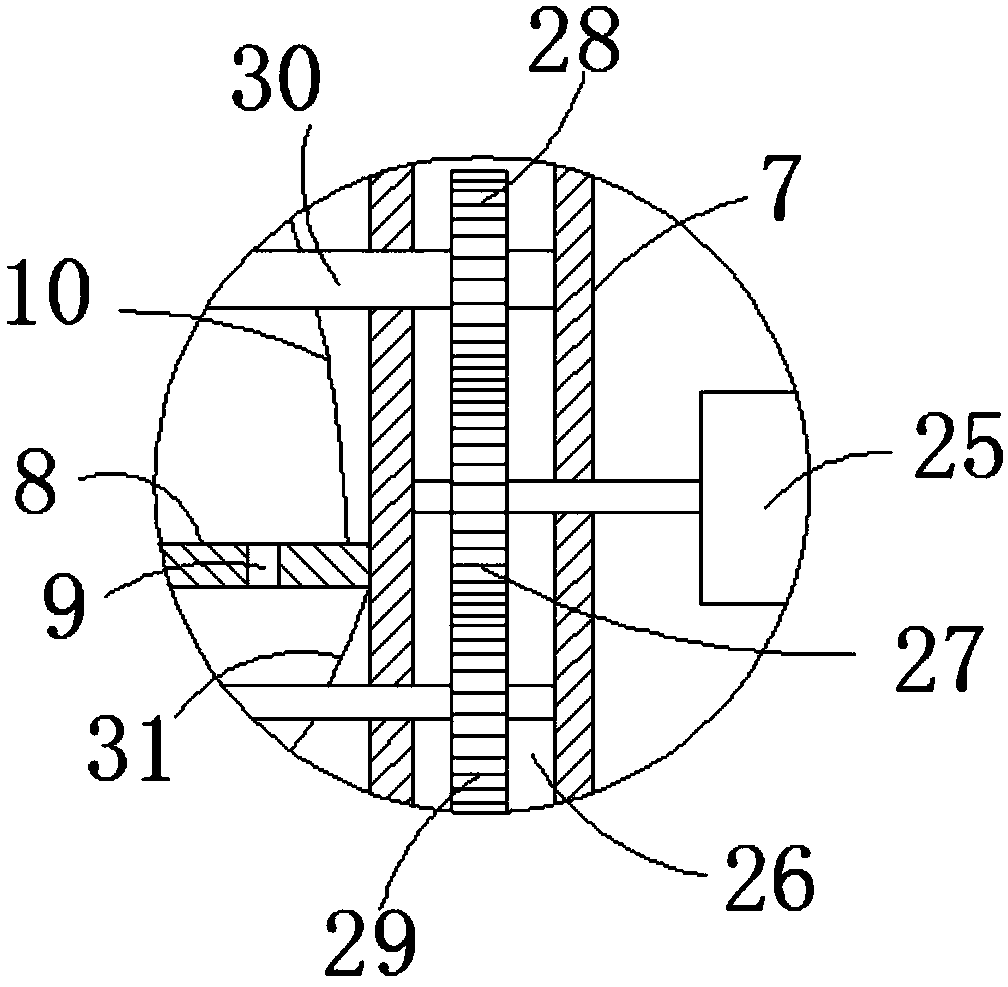

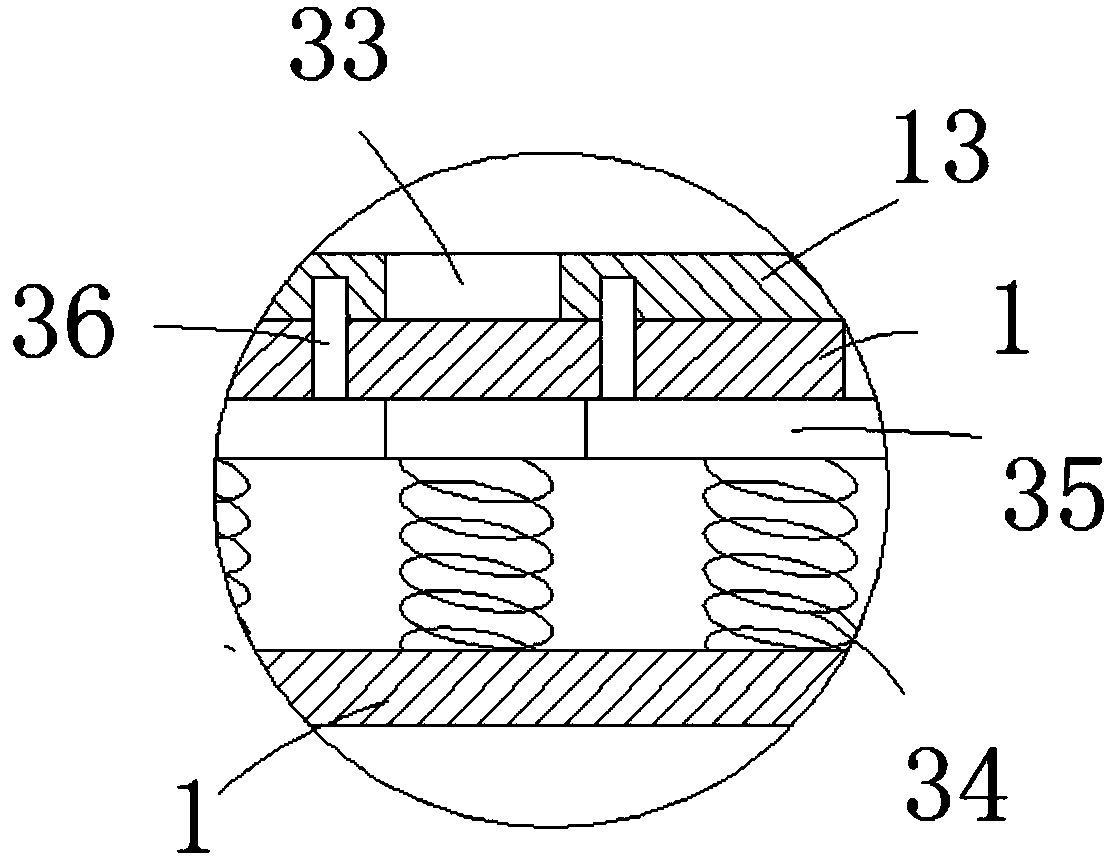

[0024] Such as Figure 1-7 As shown, a corn stalk baler includes a box body 1, the side wall of the box body 1 is provided with a feed port 2, the inside of the box body 1 is provided with a feeding mechanism, and the inner side wall of the box body 1 is fixedly connected with The inclined plate 3 has two baffles 4 fixedly connected to the side wall on one side of the inclined plate 3. Specifically, the two baffles 4 are arranged symmetrically with respect to the inclined plate 3 to facilitate the straw to slide down from the inclined plate 3. The two baffles 4 A plurality of intermediate shafts 5 are fixedly connected between the baffles 4, and a roller 6 is set on the intermediate shaft 5 to reduce the friction between the straw and the inclined plate 3, and facilitate the straw to slide down from the inclined plate 3. The inner wall is fixedly connected with a feeding box 7, and the feeding box 7 is provided with a straw mouth corresponding to the position of the inclined p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com