Waste gas treatment system for dolomite sand calcination rotary kiln

A waste gas treatment and dolomite sand technology, which is applied in waste heat treatment, lighting and heating equipment, furnace components, etc., can solve problems such as direct discharge, high temperature of waste gas, and large dust content, so as to reduce operating costs and improve economic benefits , the effect of prolonging the use time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

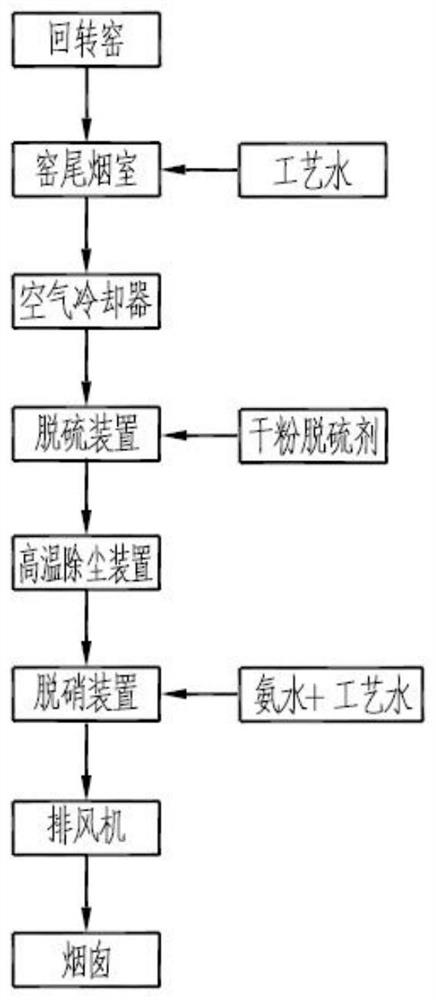

[0019] Such as figure 1 As shown, this embodiment provides a dolomite sand calcination rotary kiln exhaust gas treatment system, including a kiln tail smoke chamber, an air cooler, a desulfurization device, a high-temperature dust collection device, a denitrification device, an exhaust fan, and a chimney; the kiln tail smoke The chamber inlet is connected to the above-mentioned rotary kiln, the outlet of the above-mentioned kiln tail smoke chamber is connected to the above-mentioned air cooler, and the above-mentioned air cooler is connected to a cooling fan through an air pipe, and the outlet of the above-mentioned air cooler is connected to the above-mentioned desulfurization device, and the above-mentioned desulfurization device is connected to a Desulfurization agent injector, the outlet of the desulfurization device is connected to the above-mentioned high-temperature dust collection device, the outlet of the above-mentioned high-temperature dust collection device is conne...

Embodiment 2

[0026] This embodiment provides a process for treating waste gas using the dolomite sand calcined rotary kiln waste gas treatment system in Example 1:

[0027] The waste heat flue gas with a temperature of 450-500°C enters the kiln tail smoke chamber through the tail of the rotary kiln, and after settling part of the large particle dust, it enters the air cooler through the pipeline. -400℃, the cooled flue gas is discharged from the top of the air cooler, and enters the desulfurization device through the pipeline. Enter the dry desulfurization device for desulfurization reaction, form desulfurization gypsum and settle into the ash hopper to collect or enter the high-temperature dust removal device with the flue gas to collect dust. The temperature of the flue gas after dust collection is 330-380°C, and the dust concentration is less than 10mg / m 3 , the flue gas after dust collection and purification enters the denitrification device, and the denitrification adopts the selectiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com