Fresh food cold-chain logistics automatic sealing and packaging system

A cold chain logistics and automatic sealing technology, which is applied in packaging, transportation packaging, transportation and packaging, etc., can solve the problems of inability to carry out efficient vacuum processing, inability to meet mass production, and reduced work efficiency, so as to achieve high packaging continuity , fast packing speed and good packing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in further detail below in conjunction with the accompanying drawings.

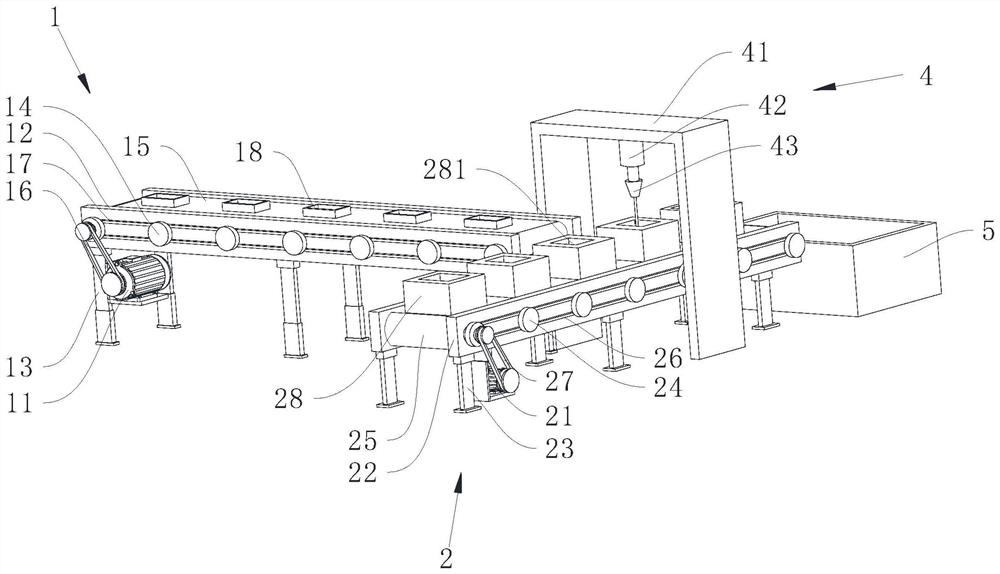

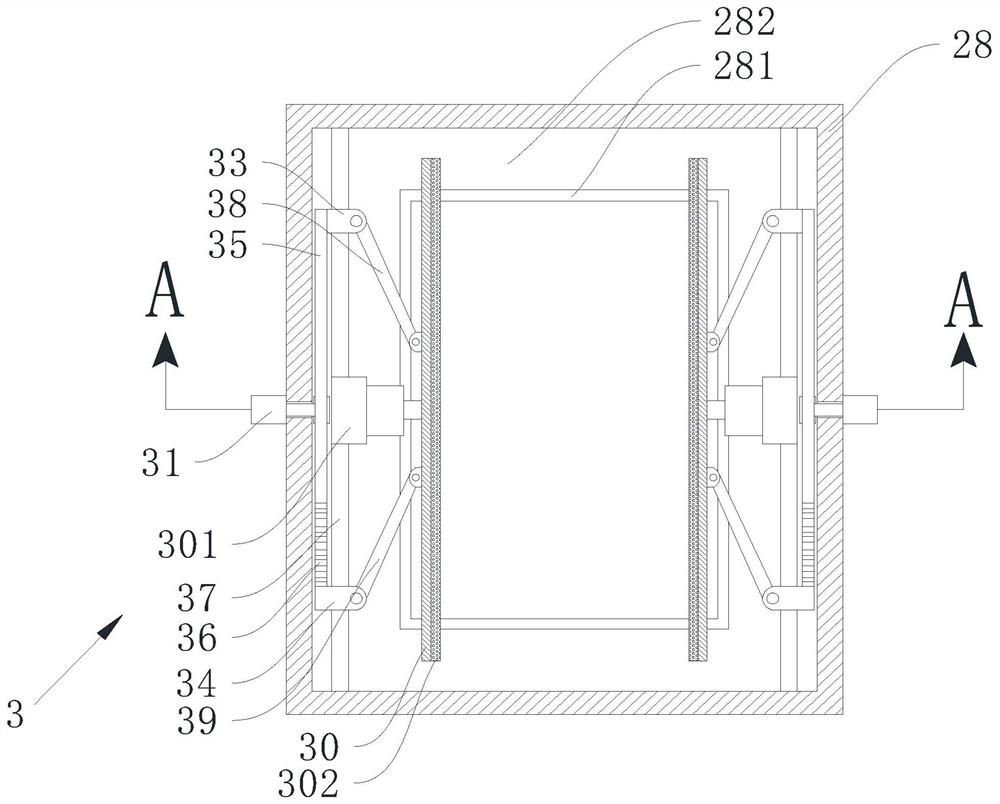

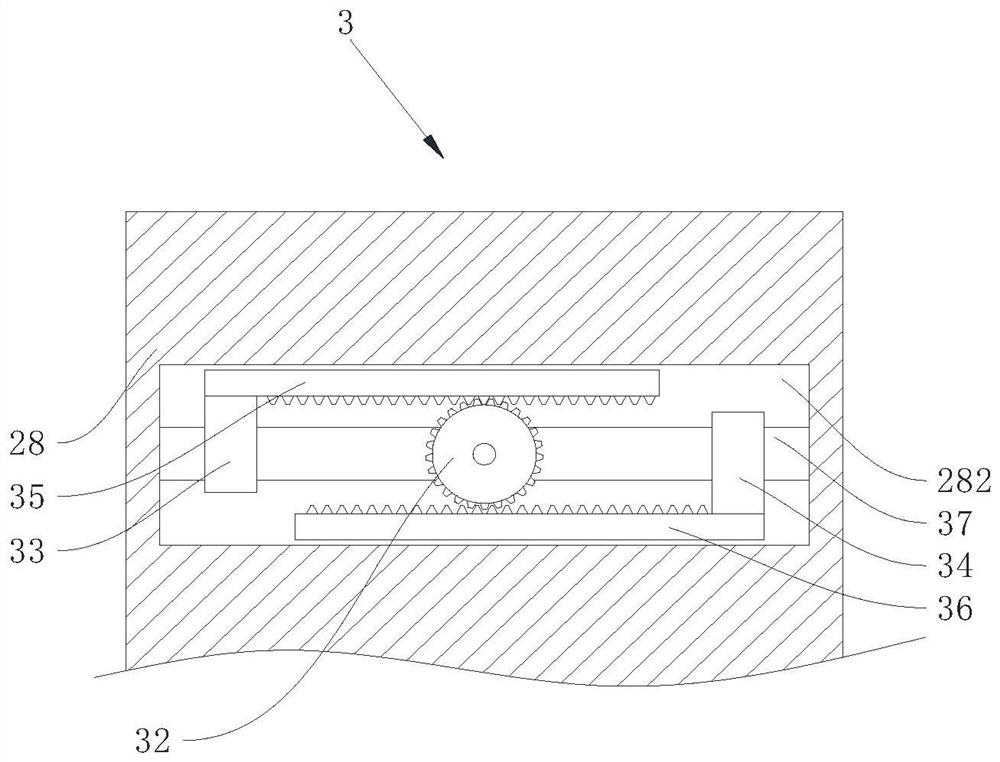

[0029] refer to figure 1As shown, it is a fresh cold chain logistics automatic sealing packaging system disclosed by the present invention, which includes a first transmission mechanism 1, a second transmission mechanism 2, an extrusion device 3 and an extraction device 4; During use, the operator places fresh food in the placement box 18, and then the No. 1 drive motor 11 starts to transport the No. 1 drive roller 14 with the placement box 18 above the No. 1 conveyor belt 15 to move forward. When the No. 1 conveyor belt 15. When transporting the storage box 18 and continuing to move forward, the fresh food in the storage box 18 will fall into the packaging box 28 at this time. Since the operator has set the vacuum packaging bag in the installation groove 281 in advance, the fresh food produced at this time Fresh food will fall into the vacuum packaging bag,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com