Equipment for welding vertical rod and buckling disc of scaffold and method for welding scaffold

A technology of welding equipment and scaffolding, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of difficulty in mass production, poor precision, low efficiency, etc., to meet mass production and improve processing Effects on Accuracy and Productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

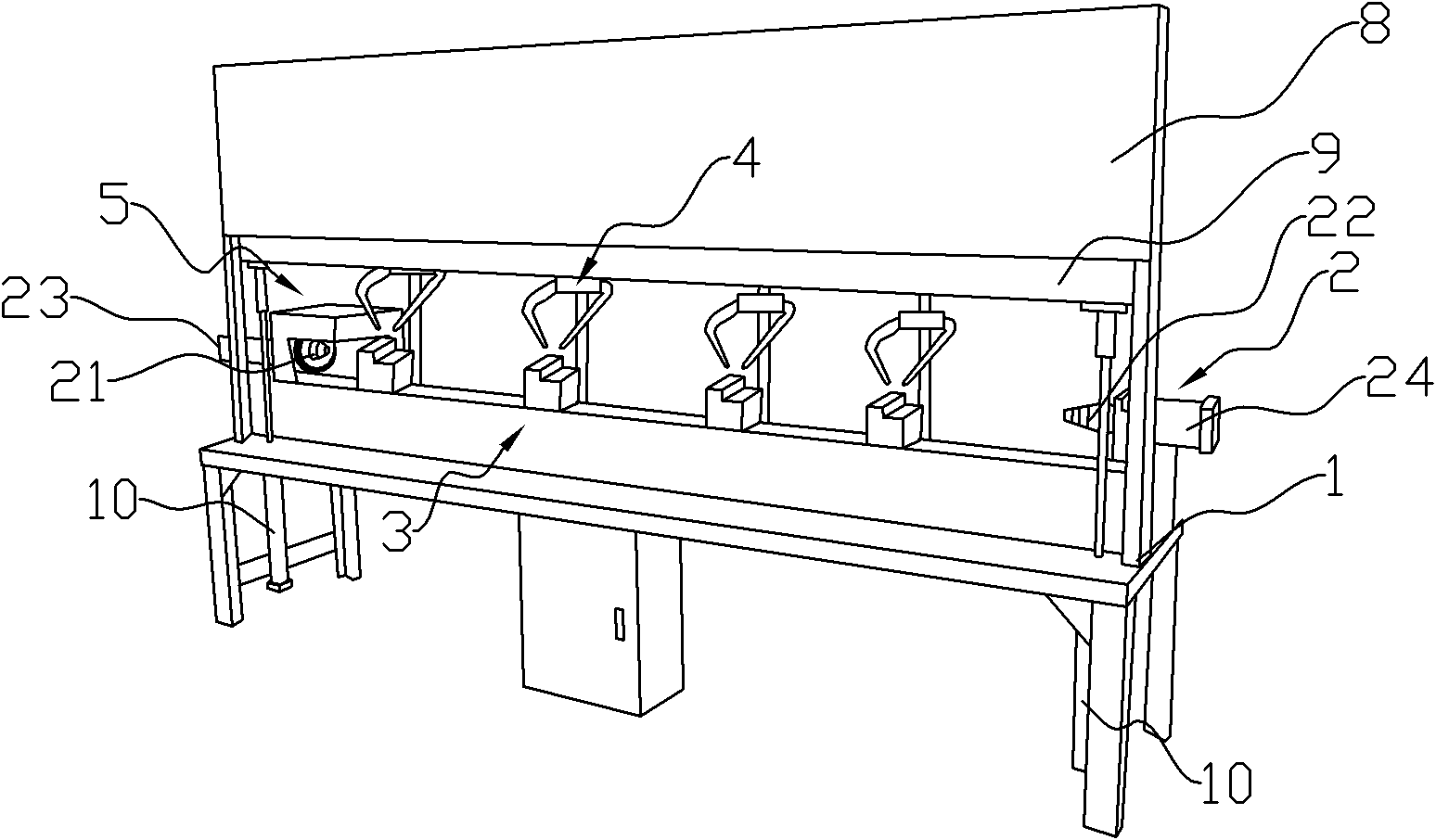

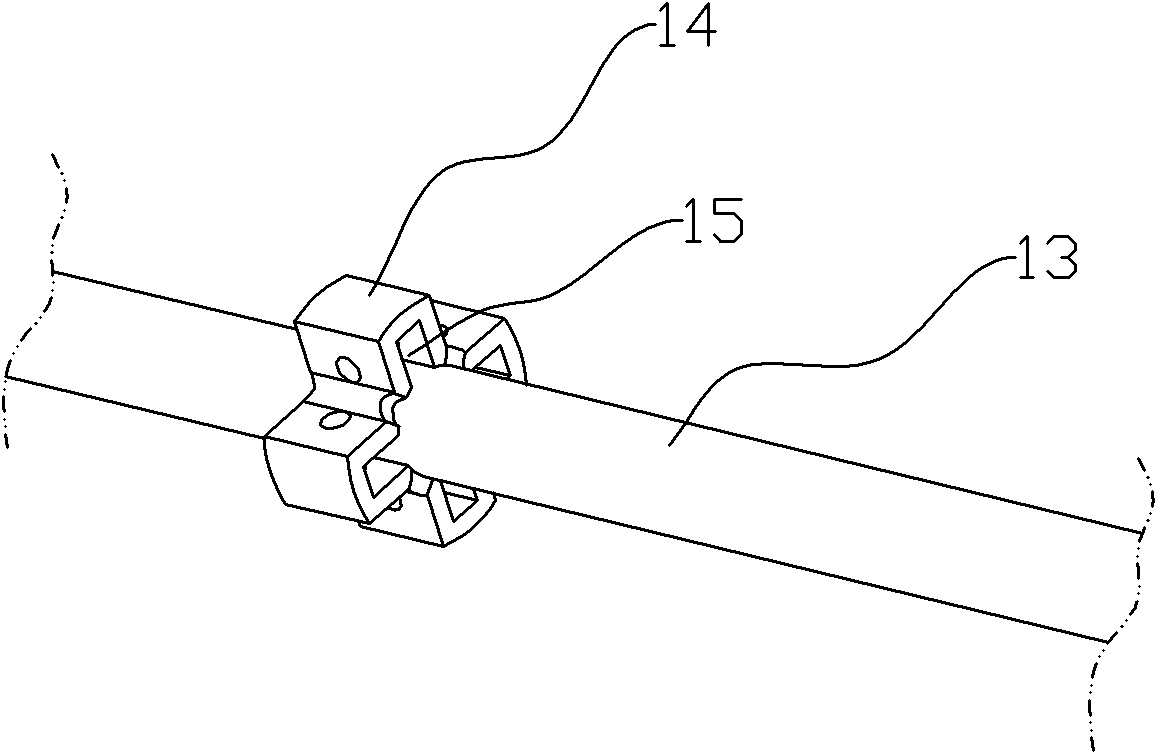

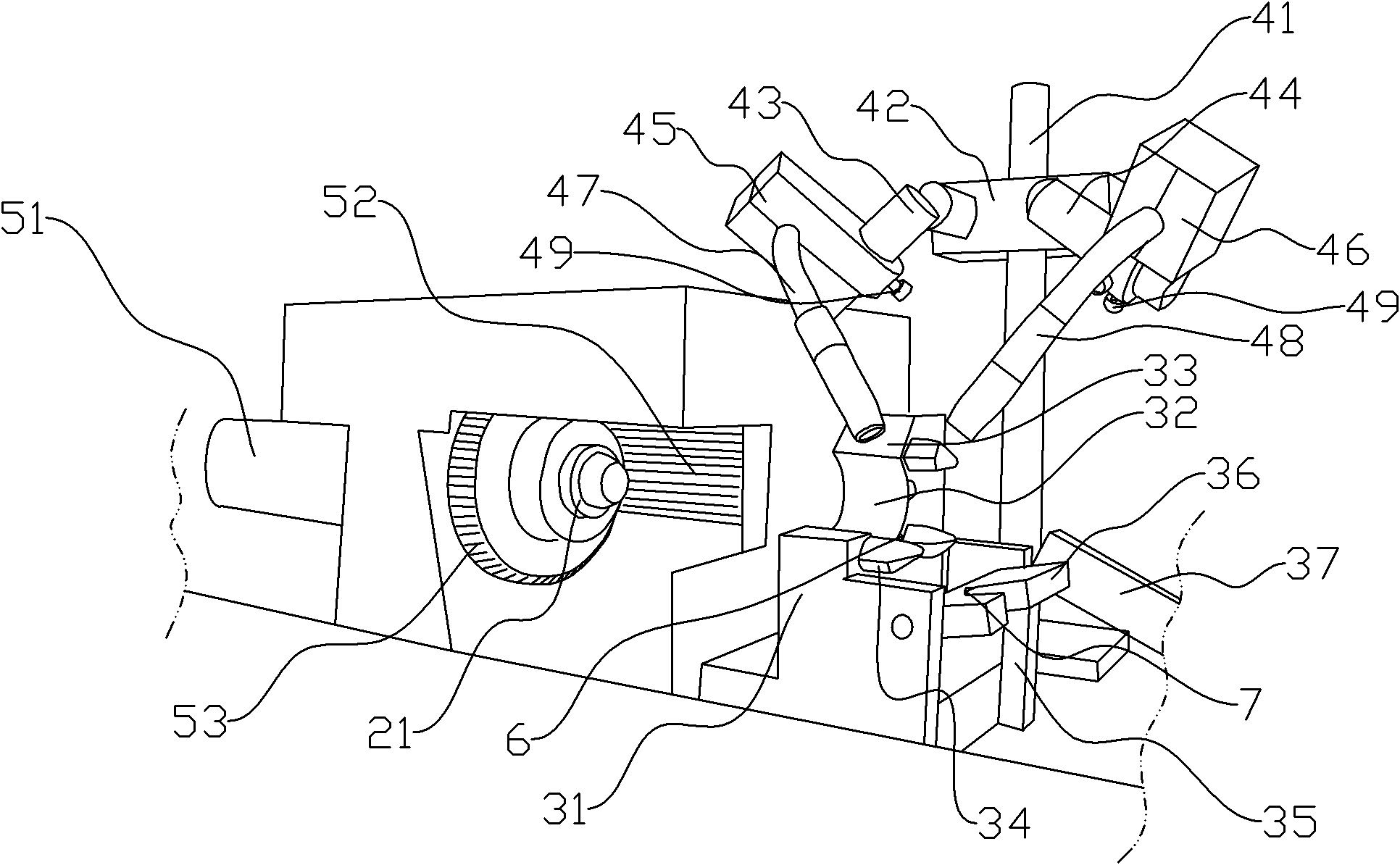

[0032] refer to figure 1 , a scaffold pole buckle plate welding equipment of the present invention, comprising a frame 1, the frame 1 is respectively provided with a pole positioning mechanism 2 and a buckle plate positioning mechanism 3, above the buckle plate positioning mechanism 3 is installed For the welding device 4, the frame 1 is also provided with a power mechanism 5 that drives the vertical rod to rotate through the vertical rod positioning mechanism 2. This scaffold pole buckle plate welding equipment clamps and positions the vertical pole 13 and the buckle plate 14 through the pole positioning mechanism 2 and the buckle plate positioning mechanism 3, and uses the welding device 4 to weld the side of the buckle plate 14 and the vertical pole 13. , and the power mechanism 5 drives the vertical pole to turn over automatically, realizing the replacement of manual welding, improving the processing accuracy and production efficiency, and meeting the needs of mass product...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com