Underground pipeline waste gas leakage early warning and treatment system and method

An underground pipeline and processing system technology, applied in the field of underground pipeline waste gas leakage early warning and processing system, can solve the problems of low processing efficiency, difficult to locate the leakage point, difficult to collect, etc., and achieve high collection efficiency, low cost and good processing effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

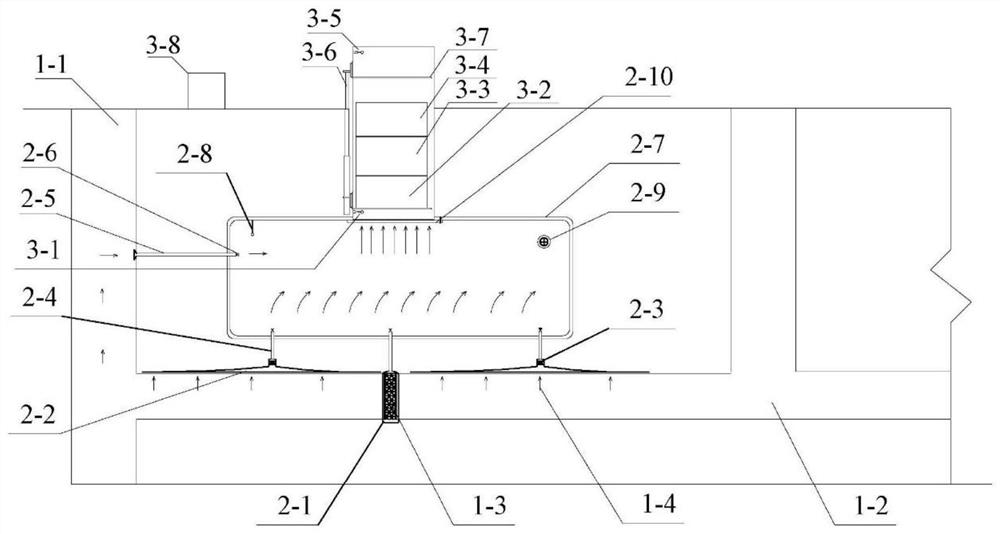

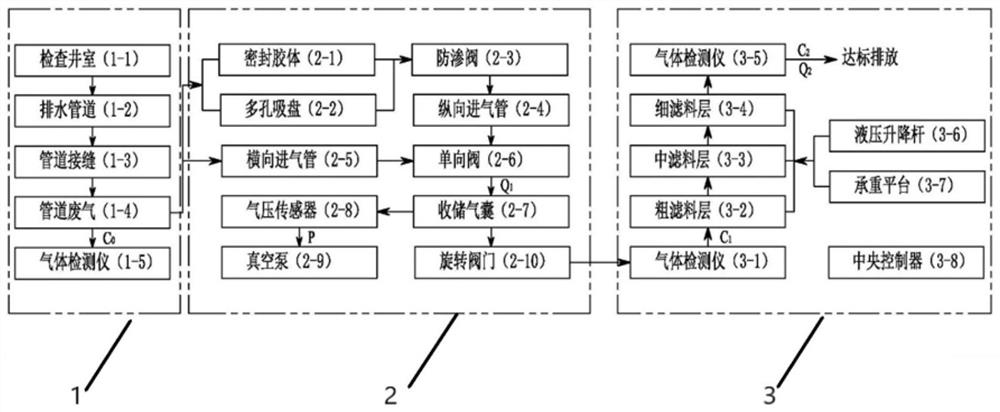

[0089] refer to Figure 1-5 As shown, an underground pipeline exhaust gas leakage early warning and treatment system of the present invention includes three subsystems: an underground pipeline exhaust gas leakage early warning system 1 , an exhaust gas collection system 2 , and an exhaust gas treatment system 3 . Wherein the underground pipeline exhaust gas leakage early warning system 1 includes an inspection well room 1-1, a drainage pipeline 1-2, a pipeline joint 1-3, and pipeline exhaust gas 1-4.

[0090] Exhaust gas collection system 2 includes sealing colloid 2-1, porous suction cup 2-2, anti-seepage valve 2-3, longitudinal air intake pipe 2-4, horizontal air intake pipe 2-5, one-way valve 2-6, storage air bag 2- 7. Air pressure sensor 2-8, vacuum pump 2-9, rotary valve 2-10. The storage air bag 2-7 is arranged above the drainage pipe 1-2, and the horizontal and vertical air intake pipes are arranged between the drainage pipe 1-2, and the storage air bag 2-7 is provided...

Embodiment 2

[0135] Others are the same as embodiment 1.

[0136] Odor Pollutant H 2 The maximum allowable emission concentration of S is 0.15mg / m 3 , then K=1.93>0.99, then it is determined that the treated pipeline exhaust gas 1-4 does not meet the standard and prohibits discharge, and at the same time the initial concentration of pipeline exhaust gas 1-4 is C 1 and emission concentration C 2 Carry out comparative judgment, judge whether to need to replace filter material layer, its judgment method is as formula 5.

[0137]

[0138] Note: η: Exhaust gas removal rate, dimensionless;

[0139] H in the treated pipeline exhaust gas 1-4 2 S emission concentration, take 0.29mg / m 3 ;

[0140] H in pipeline exhaust gas 1-4 2 S initial concentration, take 1.0mg / m 3 ;

[0141] NH in the treated pipeline exhaust gas 1-4 3 Emission concentration, take 0.38mg / m 3 ;

[0142] NH in pipeline exhaust gas 1-4 3 Initial concentration, take 7.0mg / m 3 ;

[0143] CH in the treated ...

Embodiment 3

[0148] Others are the same as embodiment 2.

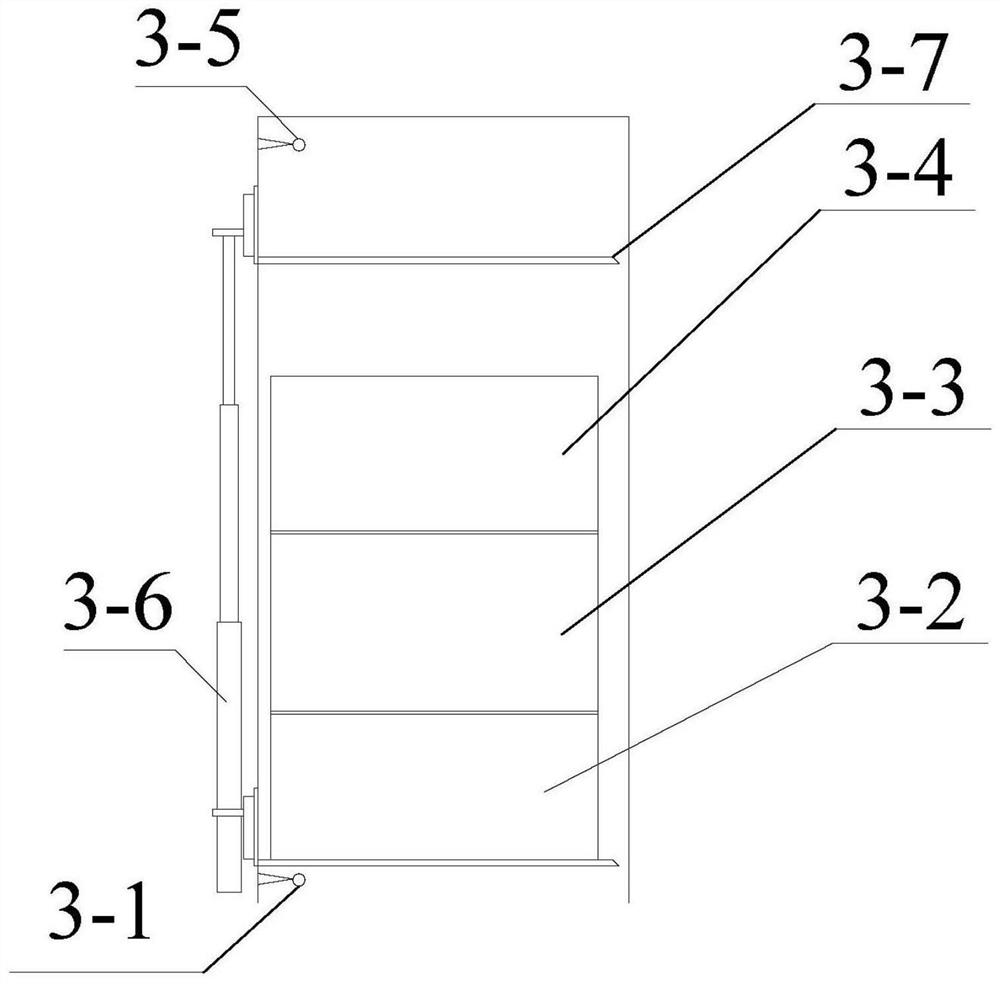

[0149]CH in pipeline exhaust gas 1-4 4 The initial concentration is 0.7mg / m 3 , after calculating η=0.5<0.63, the central processing unit 3-8 determines that the filter material needs to be replaced, the signal is transmitted to the hydraulic lifting rod 3-6, and the hydraulic lifting rod 3-6 starts to lift the load-bearing platform 3-7 above the ground, The replaced filter material layer needs to be removed for harmless treatment, and the new filter material layer is stacked from bottom to top as coarse filter material layer 3-2, medium filter material layer 3-3, and fine filter material layer 3-4 .

[0150] Example 2

[0151] Others are the same as embodiment 1.

[0152] Step 4) central processing unit 3-8 is to initial concentration C 1 , emission concentration C 2 Correlation analysis with filter particle size d, T 1 The time calculation formula is shown in Equation 6.

[0153]

[0154] Note: Y: The emission concentr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com