Hot repairing method of molten steel cylinder

A technology for molten steel tanks and residual steel, which is applied in the direction of casting molten material containers, metal processing equipment, casting equipment, etc., can solve the problems of high labor intensity and low operating efficiency, achieve improved operating efficiency, improve the effect of residual steel treatment, and suppress The effect of tank temperature drop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

[0029] A hot repair method for a molten steel tank according to the present invention comprises the following steps:

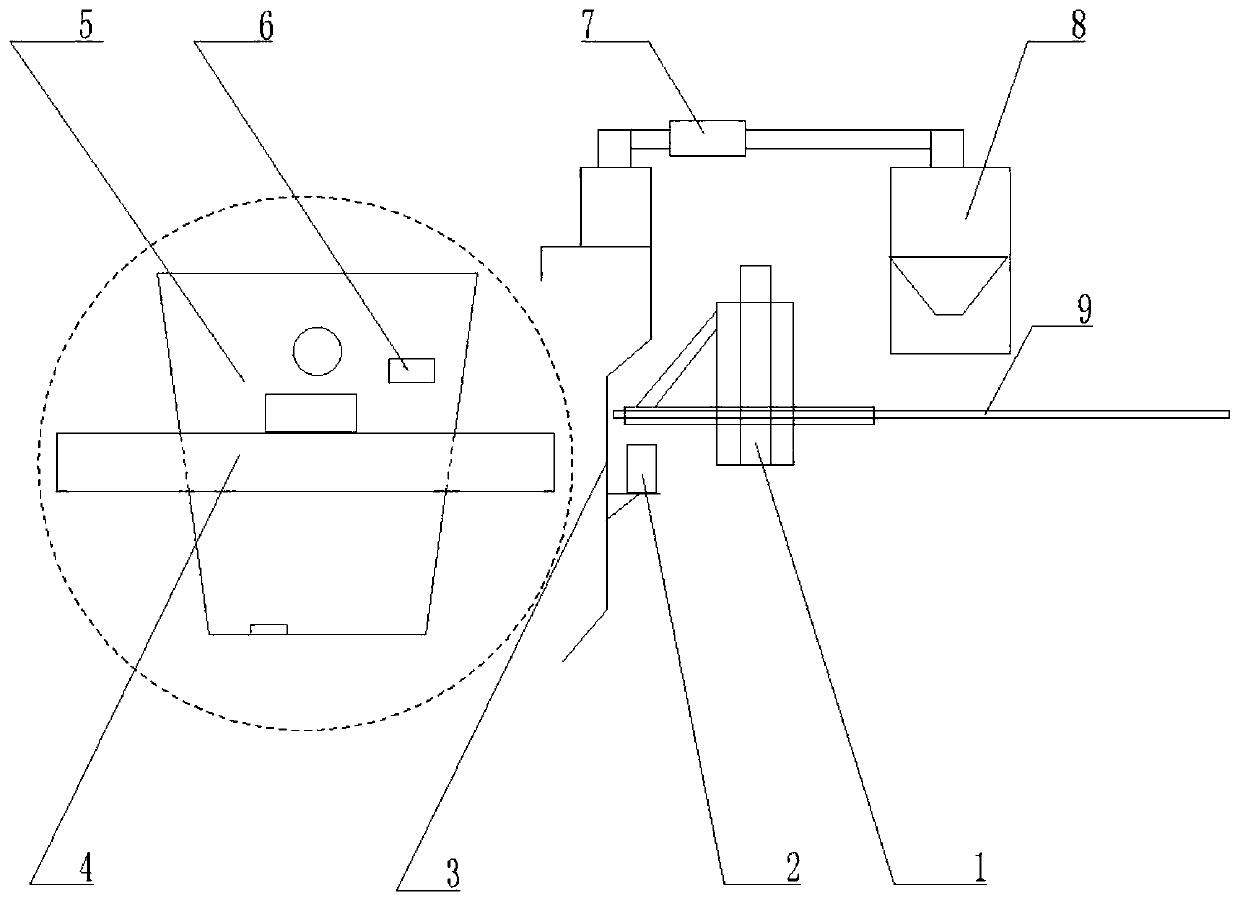

[0030] 1) if figure 1 As shown, the molten steel tank is in place: the molten steel tank 5 to be repaired is hoisted by the crane and vertically seated on the turning device 4;

[0031] 2) Tank number identification of molten steel tank 5: the label 6 set on the tank body of molten steel tank 5 is automatically identified by the tag reader, and the read information is uploaded to the control system to realize automatic tracking of molten steel tank 5;

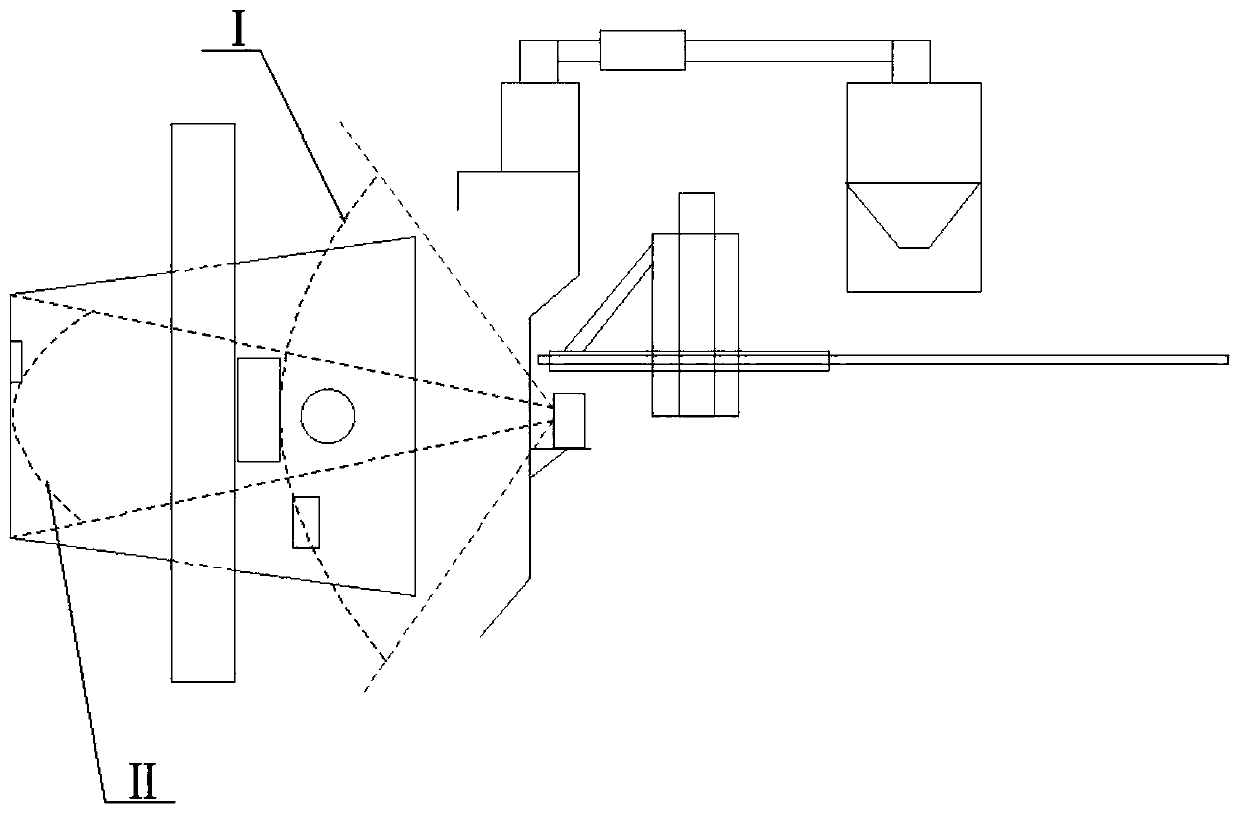

[0032] 3) if figure 2 As shown, the molten steel tank 5 is overturned: the molten steel tank 5 is turned over 90° by the overturning device 4, so that the mouth of the tank faces the horizontal direction, and then locked by a mechanical locking mechanism;

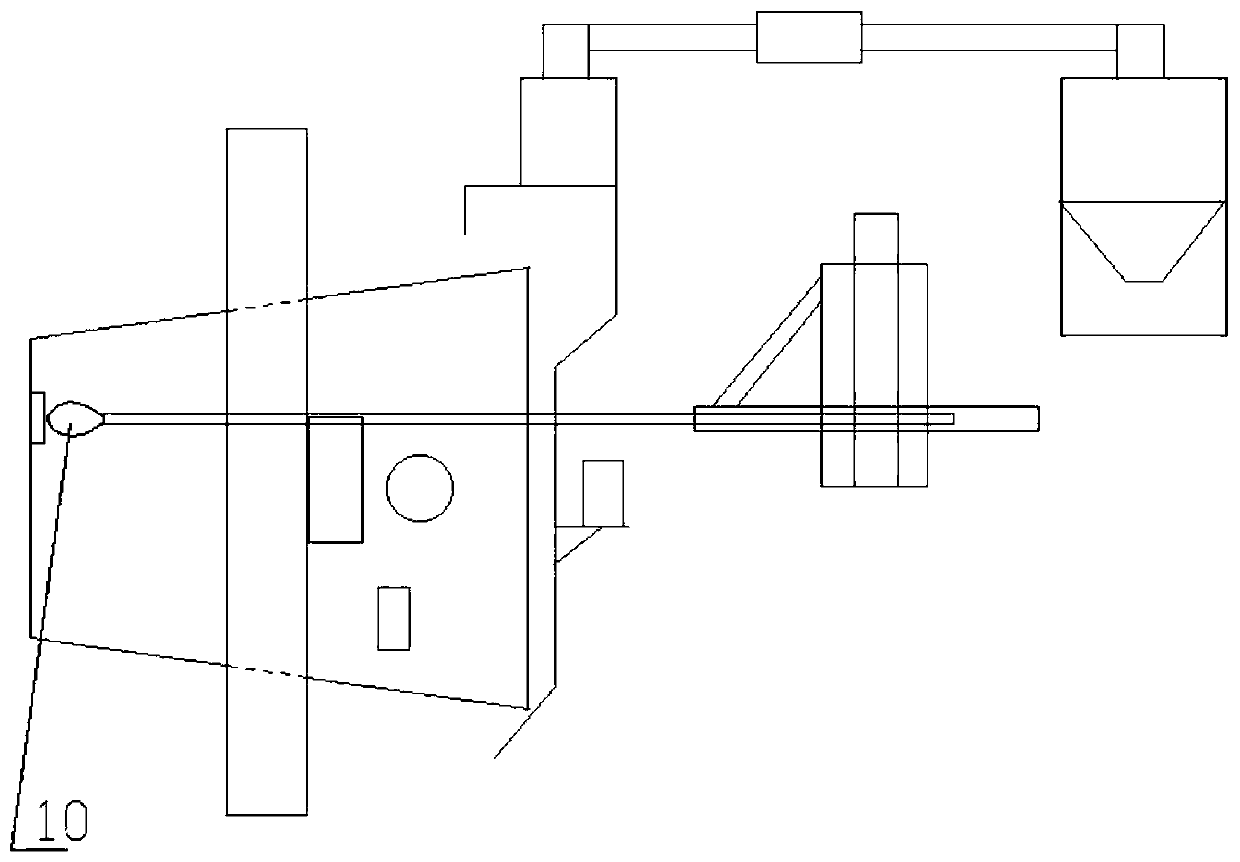

[0033] 4) Tank linin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com