Engine oil pan

An engine oil and casing technology, which is applied to oil pans, engine components, machines/engines, etc., can solve the problems that non-metallic impurities such as sludge cannot be effectively treated, and the oil pan is large in size, so as to improve filtration efficiency and Lubricant cleanliness, reduced filling volume, and the effect of avoiding cavitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

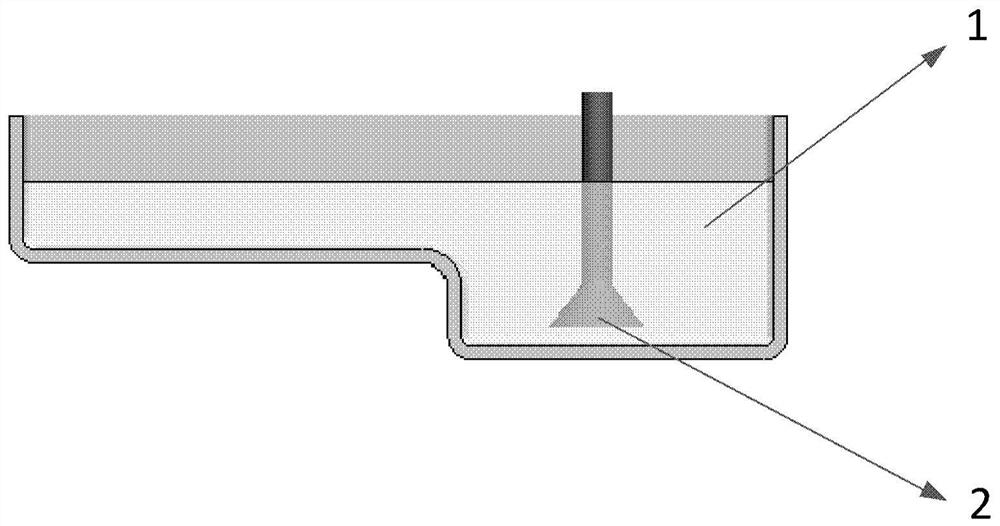

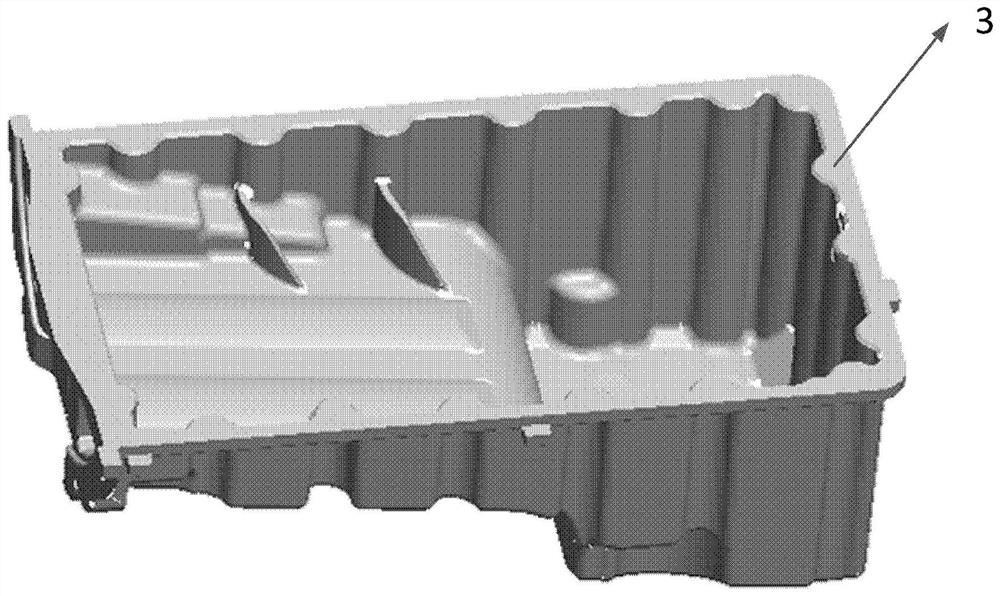

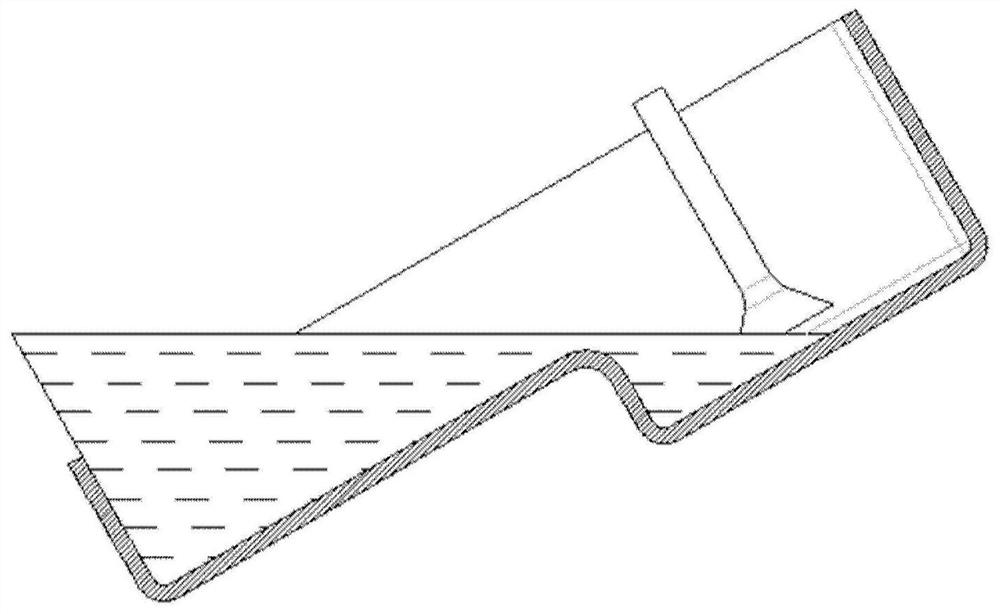

[0060] The present disclosure provides an engine oil pan, the engine oil pan can have a relatively small volume capacity under the premise of ensuring the capacity, can avoid lubricating oil suction, and can effectively filter lubricating oil impurities .

[0061] In the process of realizing the present disclosure, the inventors found that during the normal driving process of the car, there will be different postures such as climbing, downhill, sideways, etc., but the engine oil is in a liquid state. The surface is always kept level, and the oil sump needs to be designed for the boundary according to the actual worst conditions. Usually, the oil pan is designed with the car tilting 30° in the eight directions of forward, rear, left, right, left front, right front, left rear and right rear respectively as the maximum tilting attitude of the engine. Since the oil suction port is arranged in the oil sump cavity, the oil suction port must always be below the lubricating oil liqui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com