Method and device for low-temperature refining of beef tallow

A tallow, low temperature technology, applied in the field of tallow low temperature smelting device, can solve the problems of low work efficiency, product pollution, high labor intensity, etc., and achieve the effect of reducing labor intensity, ensuring safety and hygiene, and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

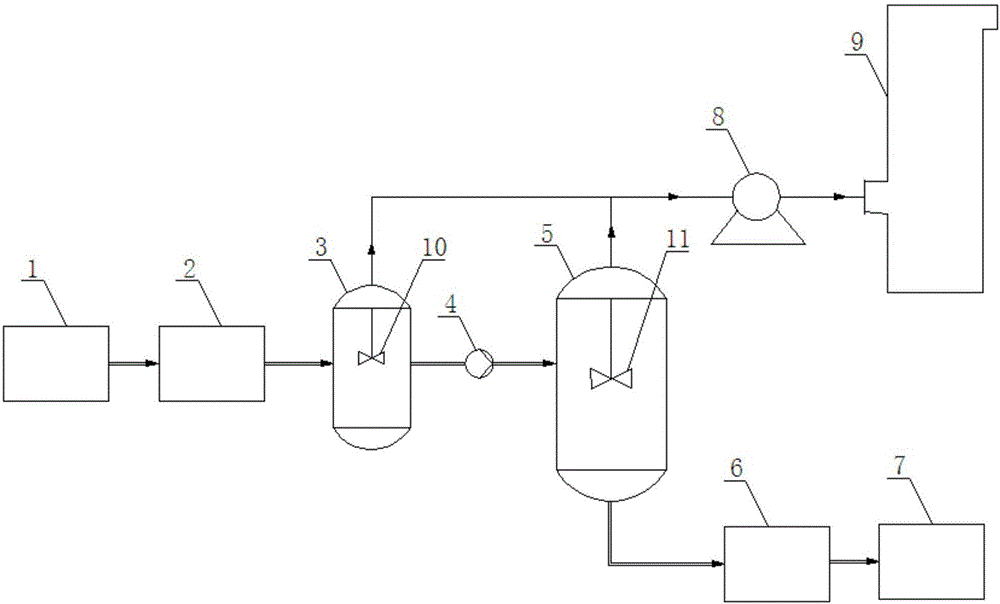

[0020] Such as figure 1 As shown, a low-temperature smelting device for butter includes a feeder 1, a grinder 2, a preheating tank 3, a meat slurry pump 4, a melting tank 5, a suspension tank 6, a centrifuge 7, a vacuum pump 8 and a washing device 9 , the feeder 1 is connected to the grinder 2, the grinder 2 is connected to the preheating tank 3, the preheating tank 3 is connected to the middle part of the smelting kettle 5 through the meat slurry pump 4, and the smelting kettle 5 The bottom is connected to the suspension tank 6, the suspension tank 6 is connected to the centrifuge 7, the top of the preheating tank 3 and the top of the smelting kettle 5 are connected to the washing device 9 through a vacuum pump 8, and the inside of the preheating tank 3 and the melting kettle 5 Heating devices are respectively provided, and stirring devices 10 and 11 are respectively provided in the preheating tank 3 and the smelting kettle 5 .

Embodiment 2

[0022] A method for low-temperature smelting of tallow using the tallow low-temperature smelting device described in Embodiment 1, comprising the following steps:

[0023] (1) Inject crude oil into preheating tank 3 and smelting kettle 5 respectively, open the heating device and stirring device 10 of preheating tank 3;

[0024] (2) When the temperature of the preheating tank 3 is raised to 50-100° C., start the mincer 2 first, then start the feeding machine 1, and start feeding, and the butter raw material enters the preheating tank 3 after being crushed by the mincer 2;

[0025] (3) After the material in the preheating tank 3 is heated to the initial melting state, turn on the vacuum pump 8, and then turn on the heating device and the stirring device 11 of the smelting kettle 5;

[0026] (4) Open the meat slurry pump 4 to send the material into the smelting kettle 5, and keep the temperature of the smelting kettle 5 at 100-120° C. for smelting for 30-60 minutes;

[0027] (5)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com