Arc welding control device

A technology of arc welding and control unit, which is applied in arc welding equipment, devices for supplying/removing shielding gas, manufacturing tools, etc. It can solve the problems of time spent on maintaining equipment, achieve the effect of improving maintenance and ensuring reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

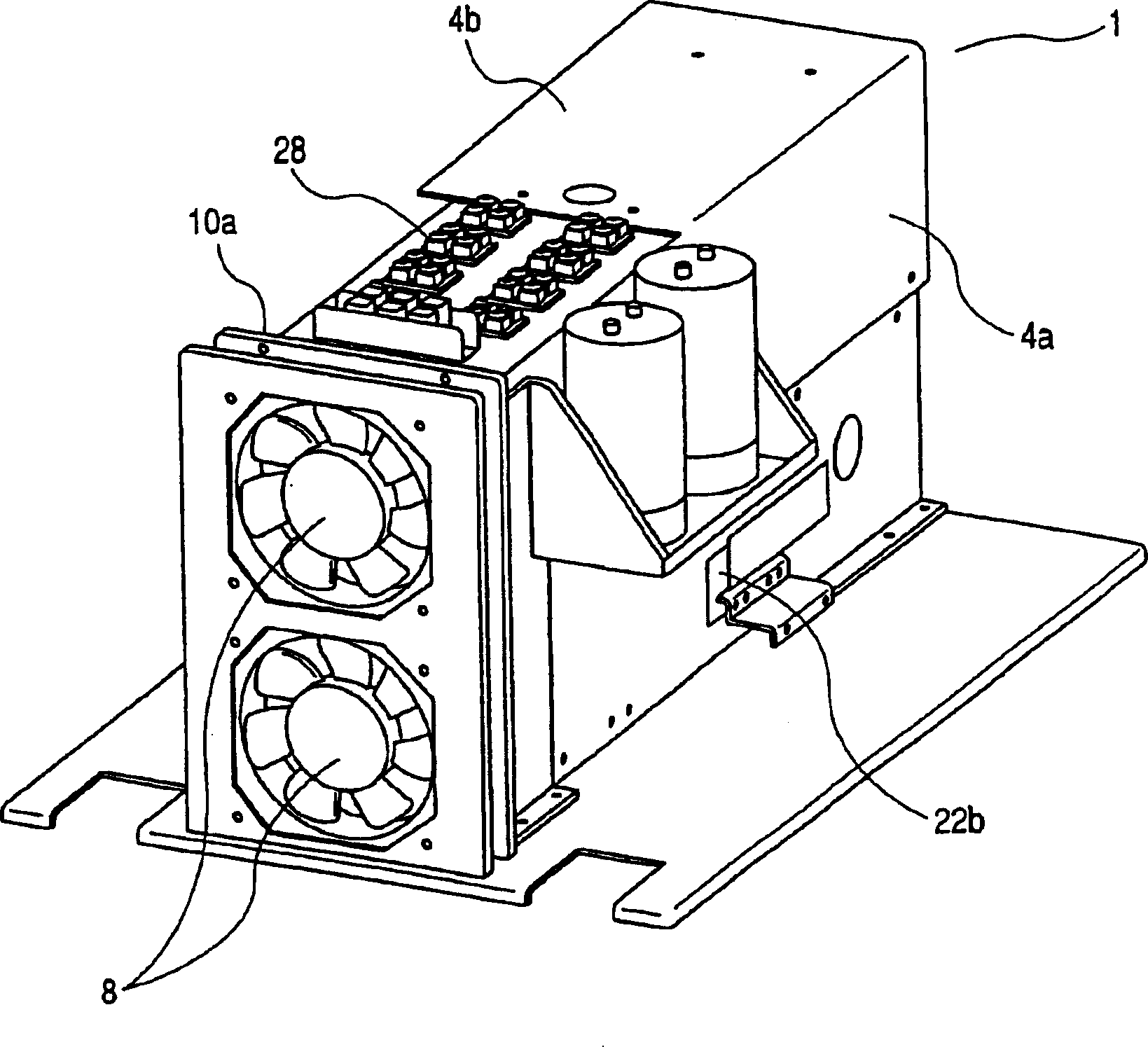

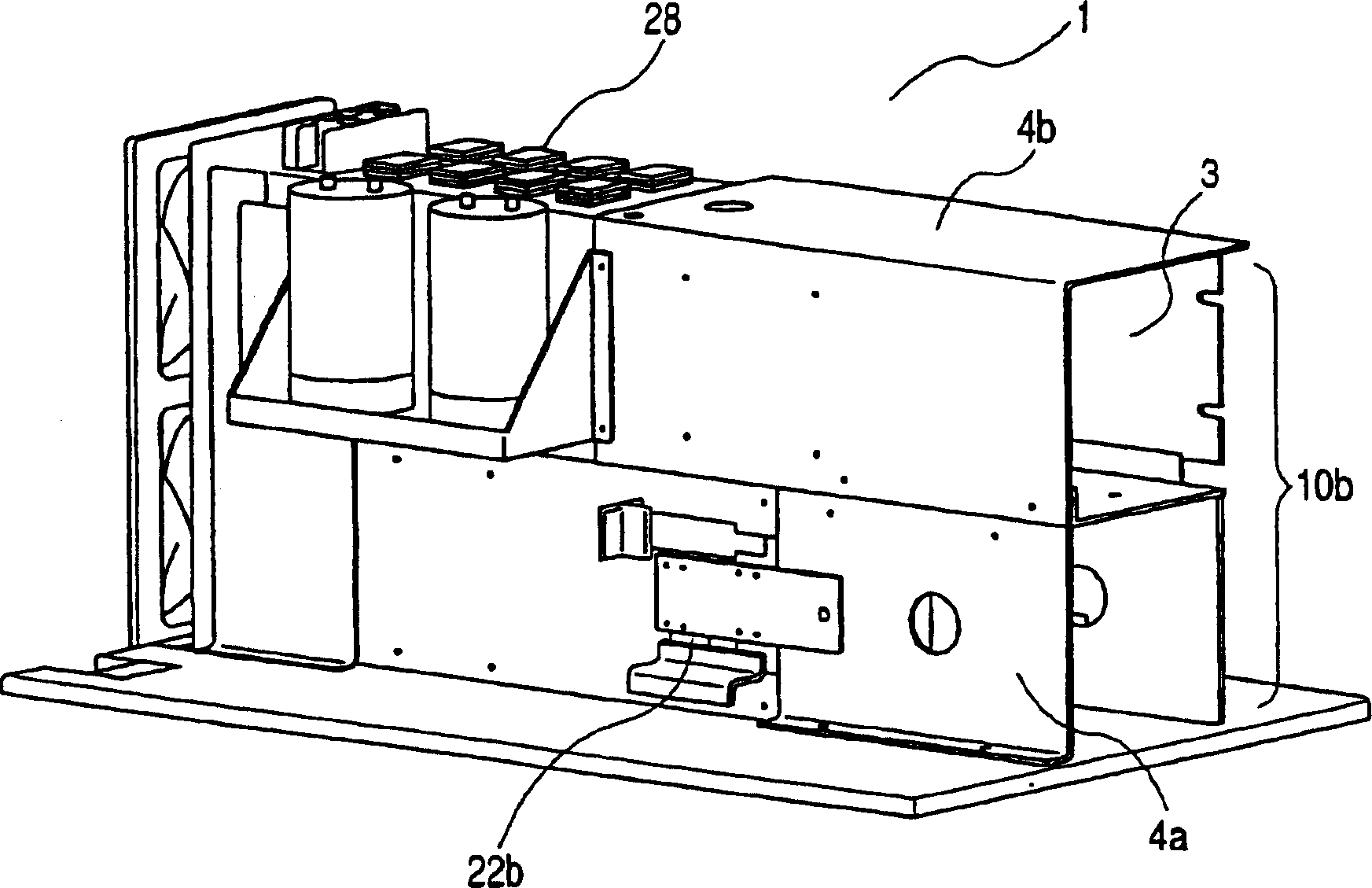

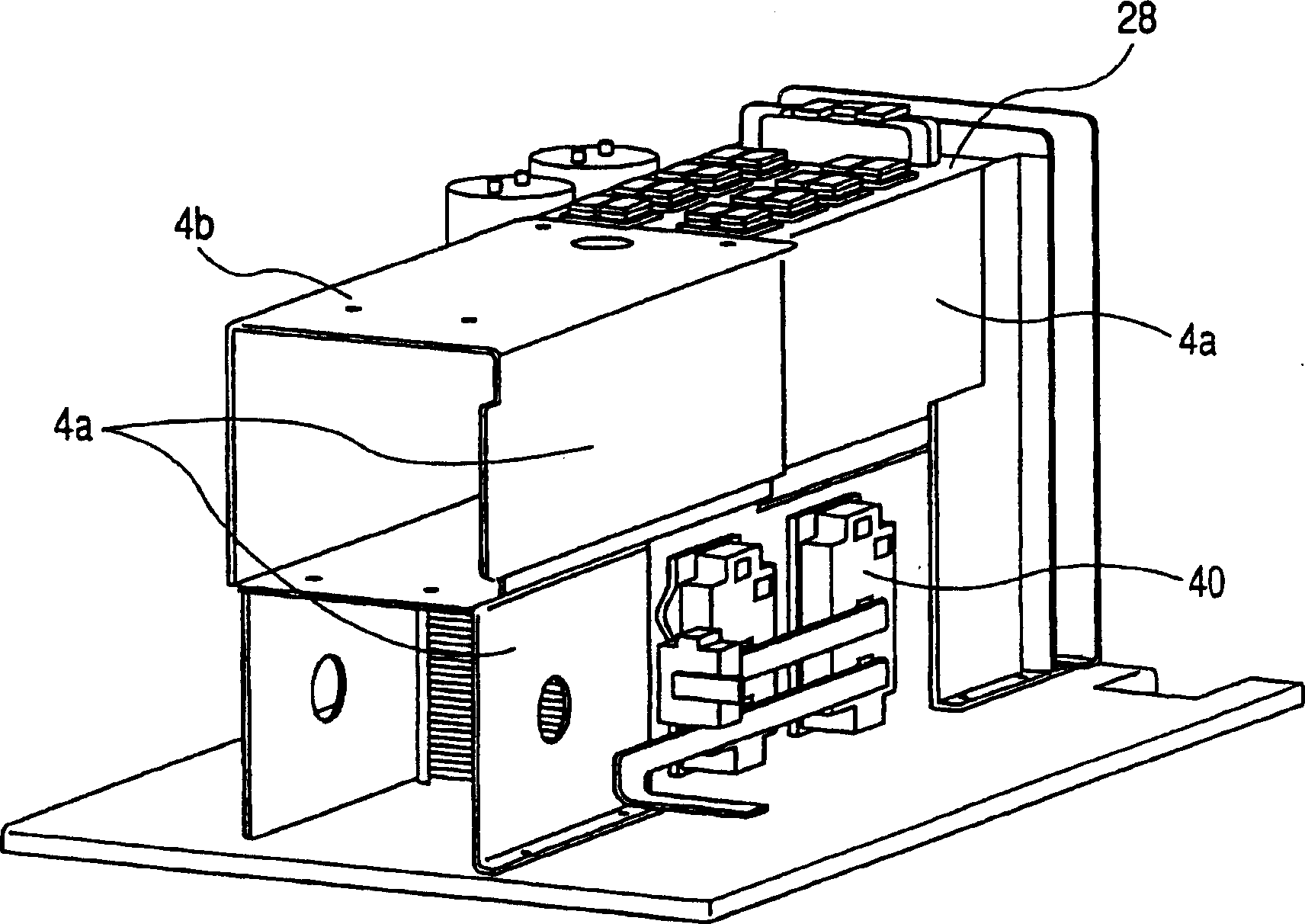

[0016] First, refer to Figure 5 , to briefly describe the circuit structure of the arc welding control unit according to this embodiment of the present invention. Figure 5 is a circuit diagram of the circuit configuration of the arc welding control unit according to this embodiment. Figure 5 , a portion shown by a single-dot chain line and denoted by reference numeral 20 is a primary side inverter circuit (inverter circuit), 28 denotes a power transistor used as an inverter (switching device) in the primary side inverter circuit 20, 21 Denotes a main transformer, a portion shown by a two-dot chain line and denoted by reference numeral 22 is a secondary side main circuit, 23 denotes a DC reactor, and 34 denotes a control circuit.

[0017] Next, the operation of this embodiment will be briefly described with reference to the above-described circuit configuration. The electric power supplied from the commercial power source 25 is rectified by the primary rectifying diode 26 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com