Transverse air curtain for laser welding and use method thereof

A technology of laser welding and air curtain, which is applied in the direction of laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of affecting the laser welding effect, polluting the protective lens, and bursting of the optical lens, so as to achieve long-term stable work and avoid pollution , strong practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific embodiment of the present invention is further described below in conjunction with accompanying drawing:

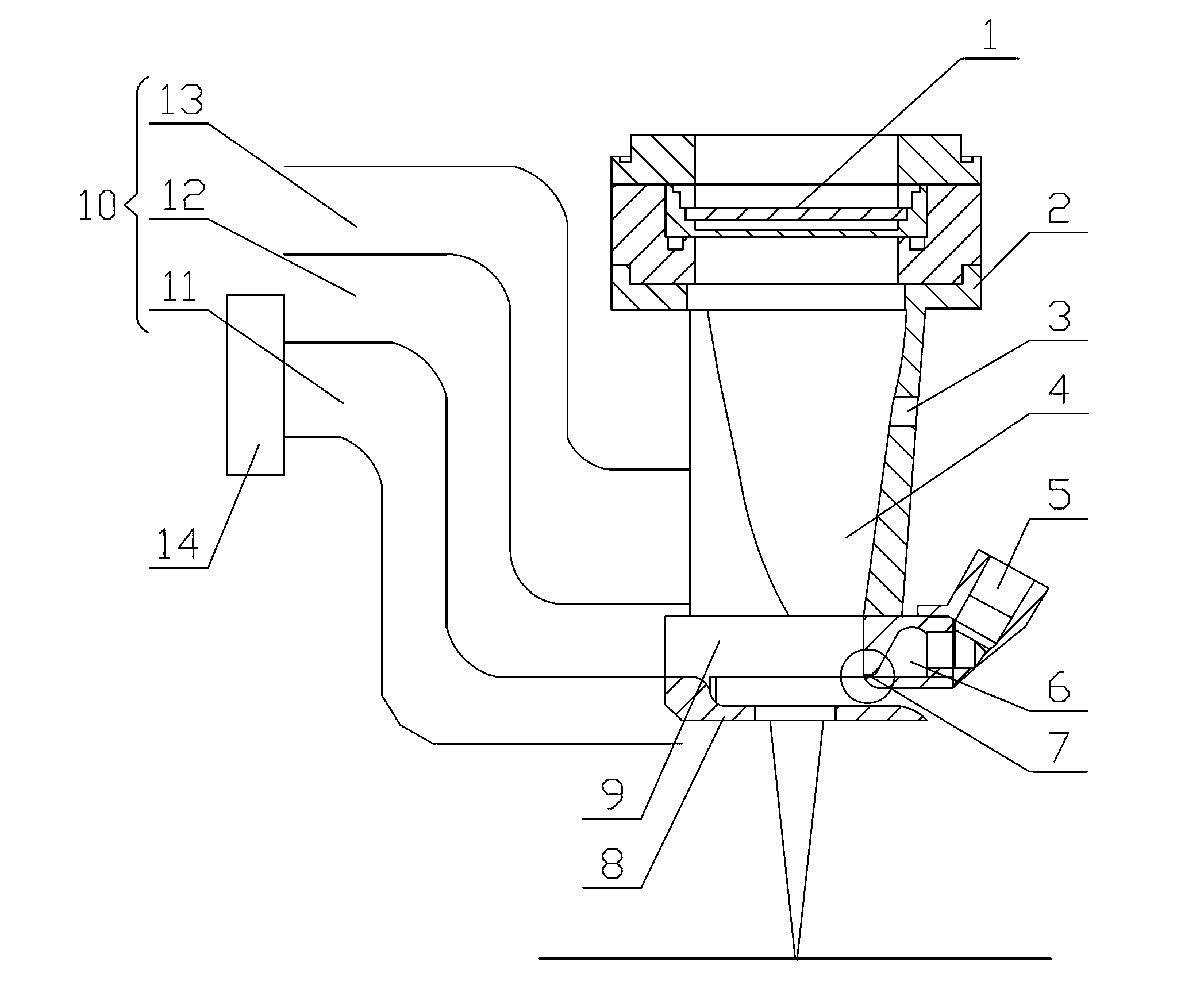

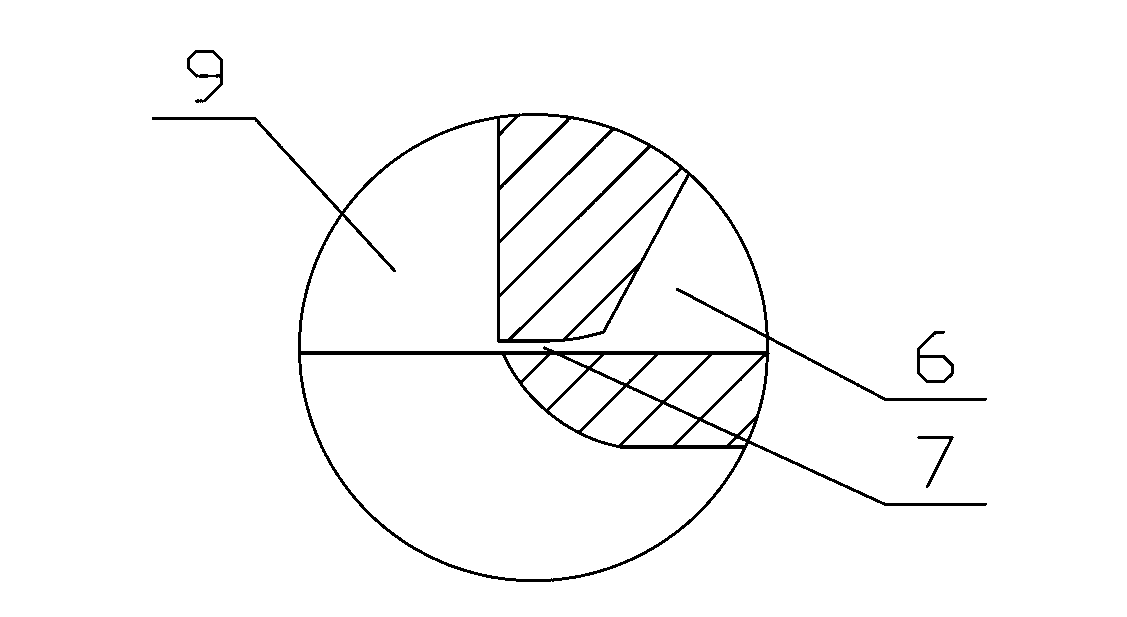

[0020] Such as figure 1 As shown, a horizontal air curtain for laser welding of the present invention includes a window protective mirror 1, an air curtain bracket 2, an anti-splash plate 8, an air curtain connecting plate 9 and an air guide tube 10, and the top of the air curtain bracket 2 is provided with a window protective mirror 1. The bottom of the air curtain support 2 is connected to the anti-splash plate 8 through the air curtain connecting plate 9, and one side of the air curtain support 2 and the air curtain connecting plate 9 is provided with an air guide tube 10; the air guide tube 10 includes a welding smoke discharge channel 11 , compressed air discharge channel 12 and compensation gas discharge channel 13, wherein the other end of the welding smoke discharge channel 11 is connected to the welding smoke absorber 14; the other side of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com