Submerged automatic arc welding tool for segment-shaped seal head

A technology of automatic welding and spherical shape, applied in welding equipment, arc welding equipment, manufacturing tools, etc., can solve the problems of large welding fume, low welding efficiency, poor working environment, etc., and achieve low welding fume pollution and high welding efficiency , good weld quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

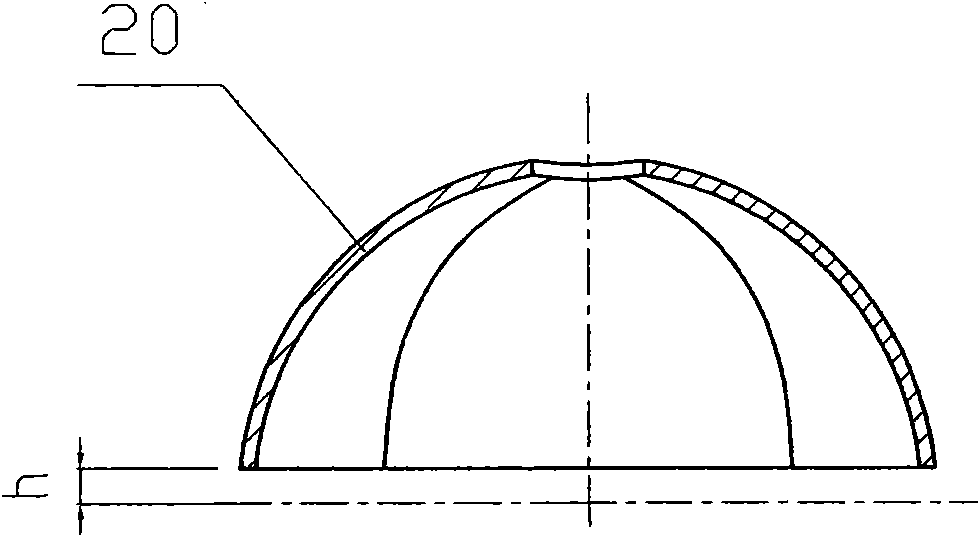

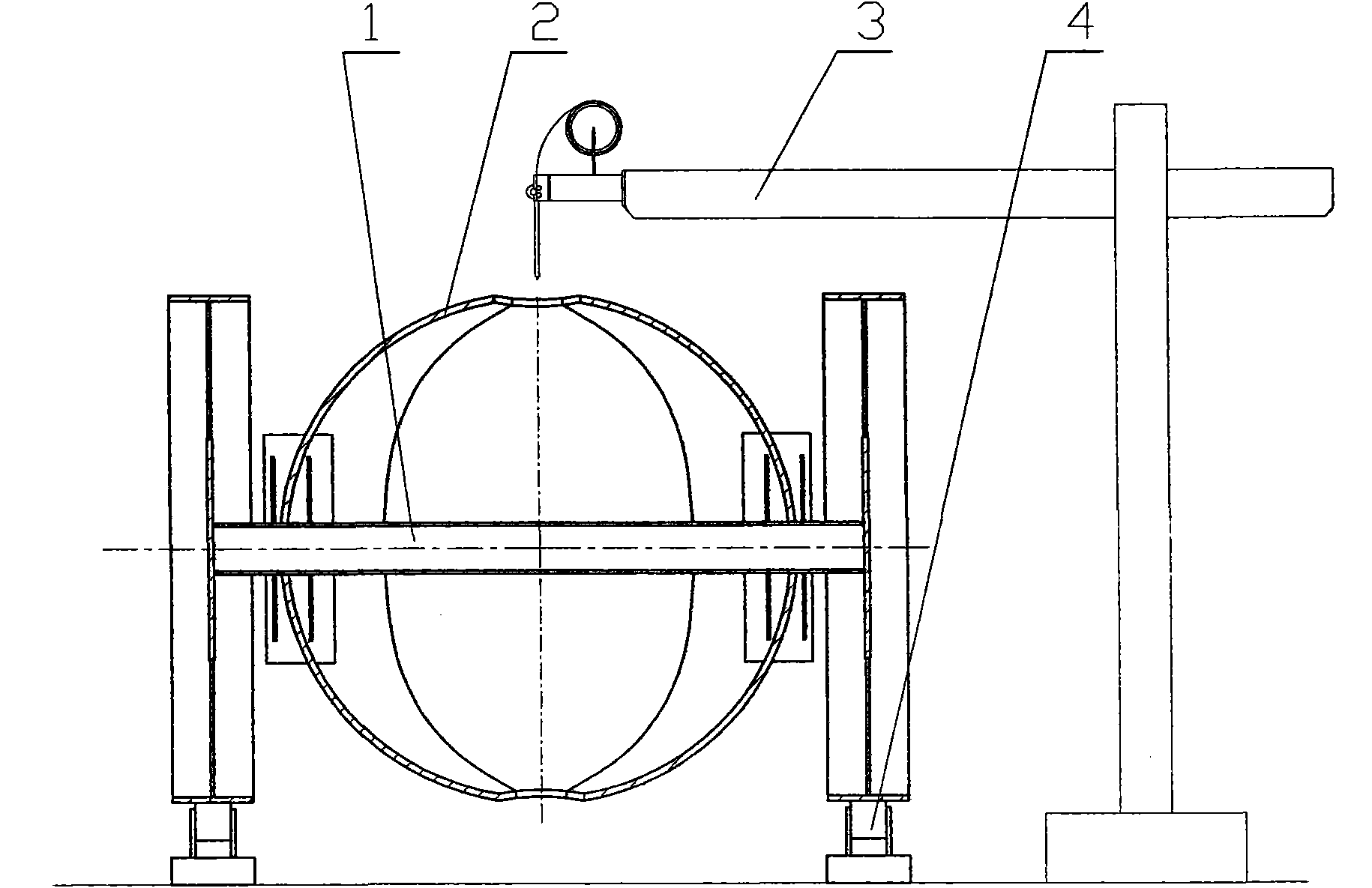

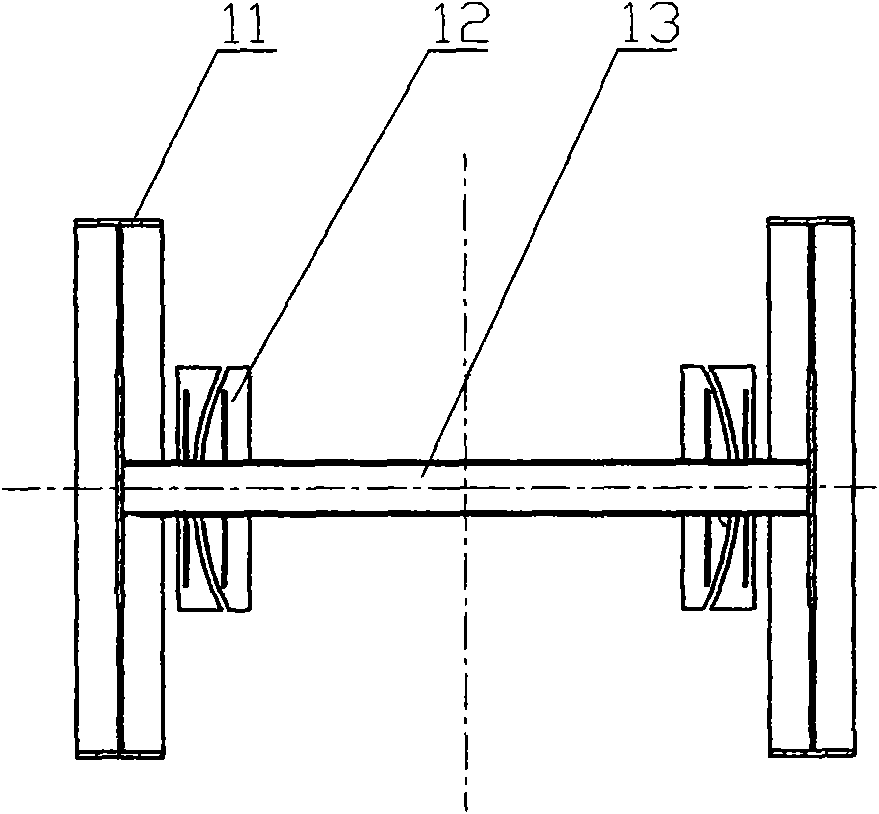

[0025] Such as figure 1 , 2 , 3, 4, 5, 7, 8, and 9, a submerged arc automatic welding tool 1 for a spherical head is composed of two runners 11, a worktable 13, and eight sets of fixed splints 12. The two runners 11 are respectively fixed on the two ends of the workbench 13, and the eight groups of fixed splints 12 are respectively symmetrically arranged on the upper and lower planes of the workbench 13 close to the runners 11, and the workbench 13 The thickness H is equal to 2 times of the spherical segment h of the spherical segmental head 20 (ie H=2h), and the two runners 11 are placed on the rollers 4 respectively, and the rollers 4 are driven by a motor and a reducer.

[0026] Such as Figure 6 , 10 , 11, and 12, the fixed splint 12 is composed of a front splint 121 with a circular arc, a rear splint 122 with a circular arc and a rib 123, and the front splint 121 with a circular arc and the rear splint with a circular arc The arc of 122 coincides with the spherical sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com