Novel universal flexible arm

A flexible and arm technology, applied in the field of new universal flexible arms, can solve the problem that the welding fume collector cannot weld large workpieces and cannot be used at a long distance, and achieves the effect of meeting the requirements of welding dust removal and having a wide range of applications.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

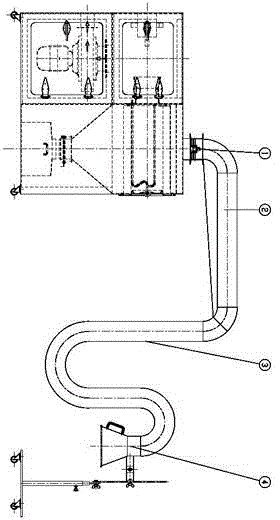

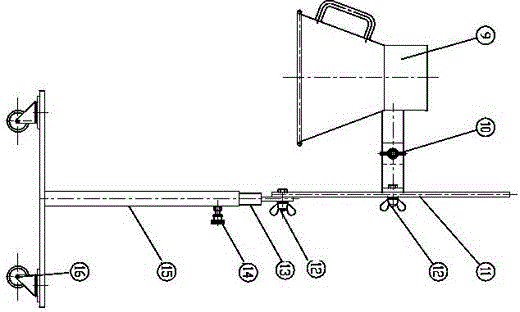

[0018] Such as Figures 1 to 3 As shown, the present invention can be used with a vacuum cleaner, and consists of three parts: a rotary connector 2, a flexible arm 3, and a mobile dust collection cover 4. One end of the rotary connector 2 can be fixed on the vacuum cleaner 1, and the other end is connected to the flexible arm 3. The suction port of the mobile dust collection hood 4 can change with the movement of the welding station.

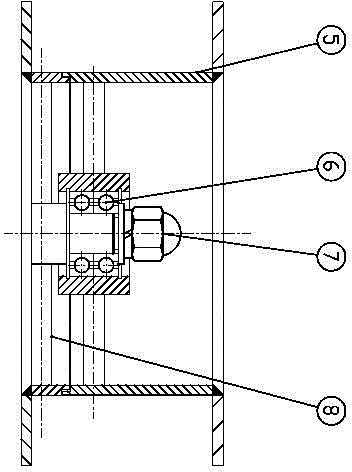

[0019] Such as figure 2 As shown, the rotary connector 2 is composed of an upper connector 5, a bearing 6, a lock nut 7, and a lower connector 8. The upper connector 5 can rotate along the rotation axis of the lower connector 8. The outer ring of the upper connector 5 is a seamless pipe, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com