Double-submerged-arc-welding thermal curing gasket welding flux for marine thick steel plate and preparing method for double-submerged-arc-welding thermal curing gasket welding flux

A double-sided submerged arc and thermal curing technology, which is applied in arc welding equipment, welding equipment, welding equipment, etc., to achieve good welding quality, beautiful shape, and stable welding arc

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The preparation method of the double-sided submerged arc welding heat-curing liner flux for marine thick steel plates comprises the following steps:

[0033] Step 1, first dry mix the powders of the components of the basic flux, dry mix evenly, add potassium sodium water glass for wet mixing, then granulate, bake at 200°C for 1 hour, and after screening, heat at 600-800°C Sinter for 2 hours, cool with the furnace, and pass through a 10-mesh to 50-mesh sieve to obtain the basic flux.

[0034] Step 2, use a curing agent accounting for 1-3% of the total weight of the basic flux to prepare an aqueous solution with a concentration of 44%, put it into a glass bottle and seal it for storage; put the resin accounting for 5-15% of the total weight of the basic flux into In a mortar, use a pestle to grind into a powder sample, and pack it into a bag and seal it.

[0035] Step 3, heat the basic flux obtained in step 1 at 180°C for 30 minutes, immediately spread the resin powder t...

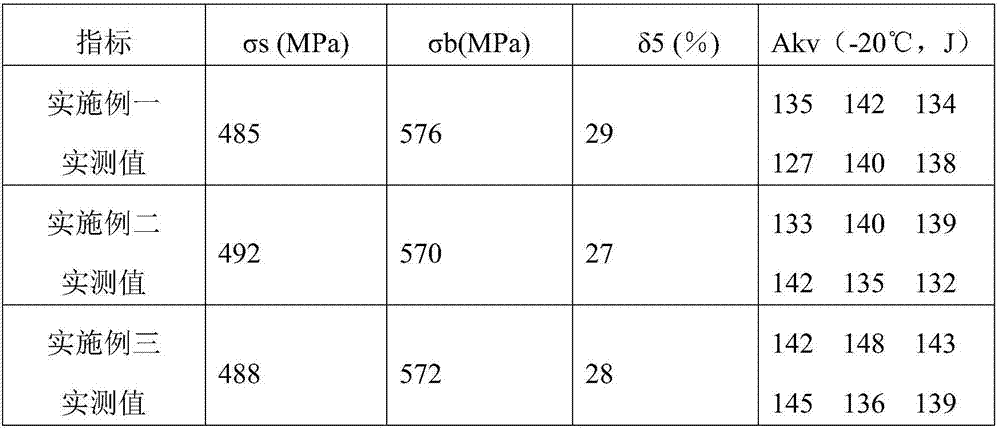

Embodiment 1

[0039] A heat-cured backing flux for double-sided submerged arc welding of marine thick plates, the heat-cured backing flux is composed of basic flux, resin and curing agent, and the basic flux is composed of the following raw materials in weight percentage: magnesia: 28%; silicon Greystone: 22%; Alumina: 20%; Fluorite: 14%; Marble: 5%; Rutile: 5%; Ferrosilicon: 3%; Ferromanganese: 3%.

[0040] The preparation method of the heat-cured backing flux is to firstly dry mix the powders of all components of the basic flux, dry mix evenly, add water glass for wet mixing, then granulate, bake at 200°C for 1 hour, screen, and 600- Sinter at 800°C for 2 hours, cool with the furnace, and pass through a 10-mesh to 50-mesh sieve to obtain the basic flux. Then use 1-3% of curing agent accounting for the total weight of the basic flux to prepare an aqueous solution with a concentration of 44%, and put it into a glass bottle for sealed storage. Put the resin accounting for 5-15% of the total...

Embodiment 2

[0042] A heat-cured backing flux for double-sided submerged arc welding of marine thick plates, the flux is composed of basic flux, resin and curing agent, and the basic flux is composed of the following raw materials in weight percentage: magnesia: 30%; wollastonite: 20% %; Alumina: 22%; Fluorite: 12%; Marble: 4%; Rutile: 7%; Ferrosilicon: 3%; Ferromanganese: 2%.

[0043] The preparation method of the heat-cured backing flux is to firstly dry mix the powders of all components of the basic flux, dry mix evenly, add water glass for wet mixing, then granulate, bake at 200°C for 1 hour, screen, and 600- Sinter at 800°C for 2 hours, cool with the furnace, and pass through a 10-mesh to 50-mesh sieve to obtain the basic flux. Then use 1-3% of curing agent accounting for the total weight of the basic flux to prepare an aqueous solution with a concentration of 44%, and put it into a glass bottle for sealed storage. Put the resin accounting for 5-15% of the total weight of the basic f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com