Green forging process method of transition segment

A process method and transition section technology, applied in the field of forging, can solve the problems of long production cycle, huge difference in the body of the forgings in the weld area, poor organizational uniformity, etc. The effect of the production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] A forging process method for a transition section, comprising the following steps:

[0050] (1) According to the size of the finished forging in the transition section, the size of the rolled blank is reversely calculated through the design machining allowance, sampling allowance and forging heat consumption data;

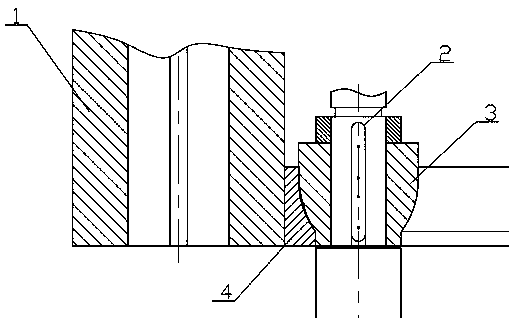

[0051] (2) Design the profiling rolling die and forging process parameters according to the size of the blank, and determine the process parameters such as the weight of the raw material steel ingot;

[0052] (3) Re-inspect the purchased raw materials, analyze their chemical composition, and select qualified products for backup;

[0053] (4) According to the heating process, put the steel ingot into the furnace and heat it to about 1200 ° C, and the holding time is ≥ 4 hours;

[0054] (5) After the steel ingot is released from the furnace, according to the forging process, carry out rounding, hot water riser, pier thickening, punching, and hole expansion; ...

Embodiment 2

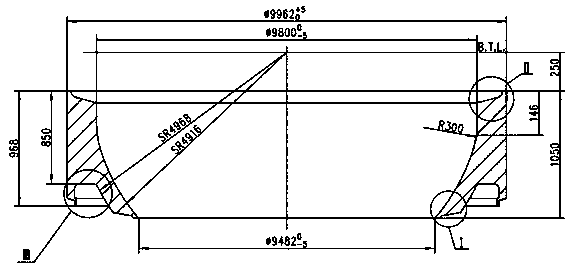

[0063] The applicant undertook a ¢9962 / ¢9482×1050mm transition section forging of 12Cr2Mo1V material ordered by a customer. image 3 .

[0064] Implementation of the present invention comprises the following steps:

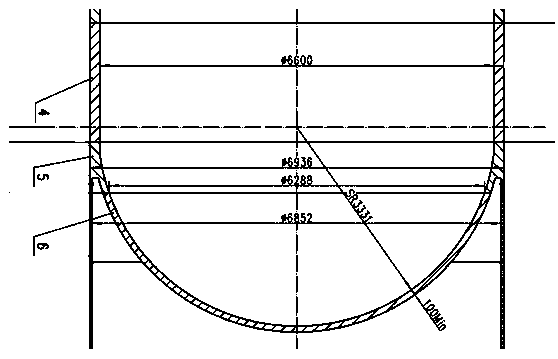

[0065] (1) According to the size of the finished forging in the transition section, the size of the rolled blank is reversely calculated through the design machining allowance, sampling allowance and forging heat consumption data, see Figure 4 ; (The size of the forging rolling blank is the red part, and the finished product size is the white part)

[0066] (2) Design profiling rolling dies and forging process parameters according to the size of the blank, and determine the process parameters such as the weight of the raw material steel ingot; the weight of the forged piece during rolling is calculated to be about 76 tons, and the weight of the purchased raw material steel ingot is about 95 to 100 tons. In the traditional free forging method, the weight of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com