Hinge beam integral die-forging and forming combined die and hinge beam machining method thereof

A combined mold and hinge beam technology, which is applied in the field of forging and pressing, can solve problems such as cracking damage and stress concentration of hinge beams, and achieve the effects of prolonging service life, avoiding stress concentration, and improving material utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

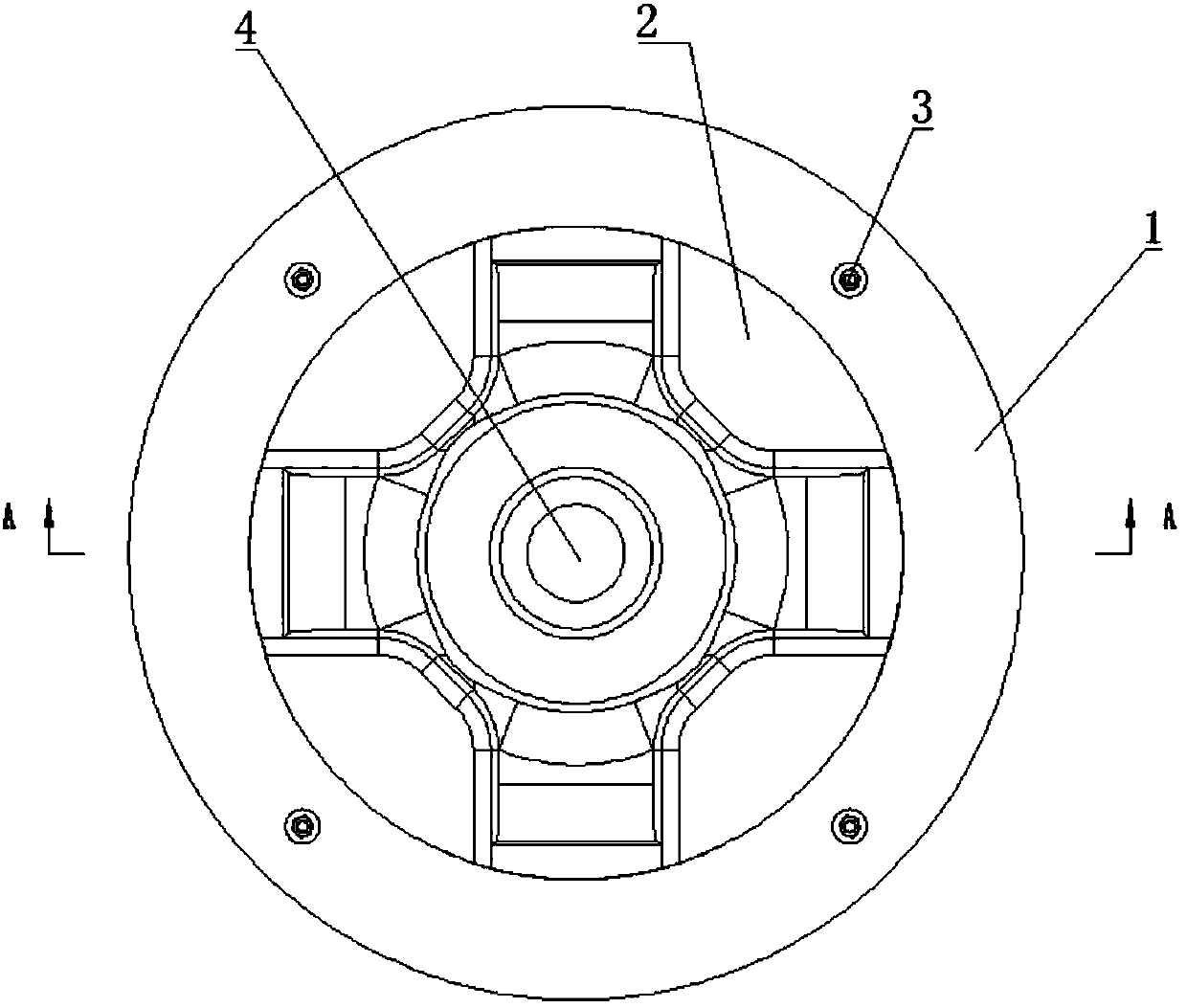

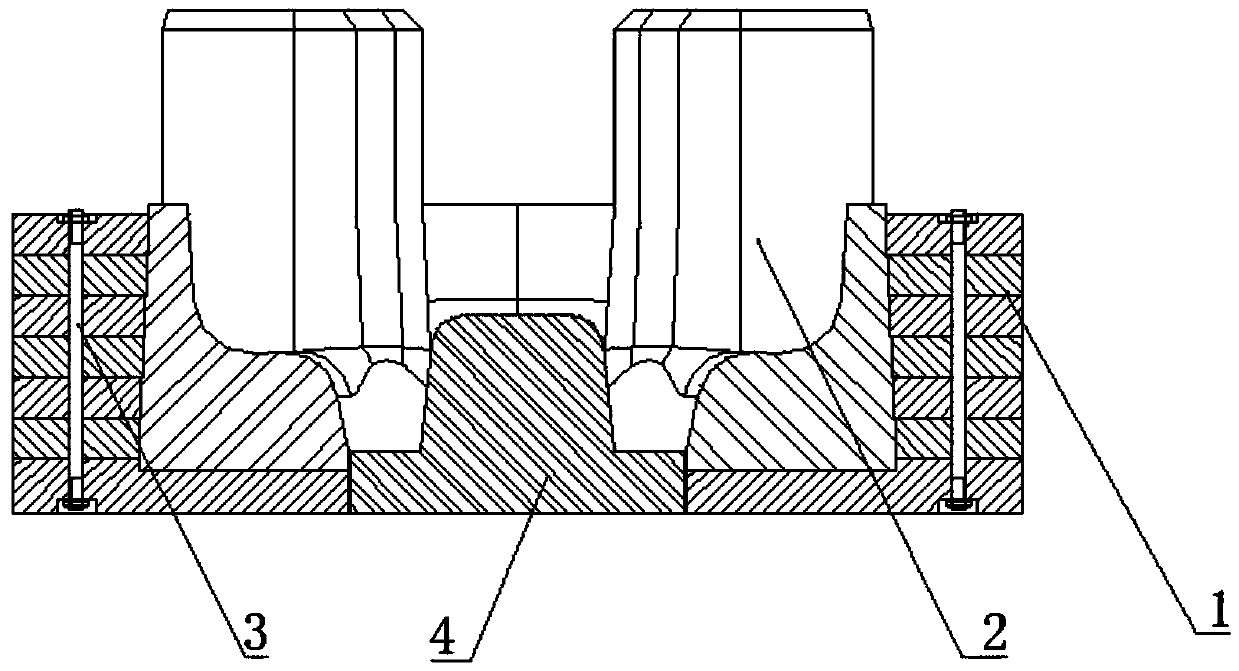

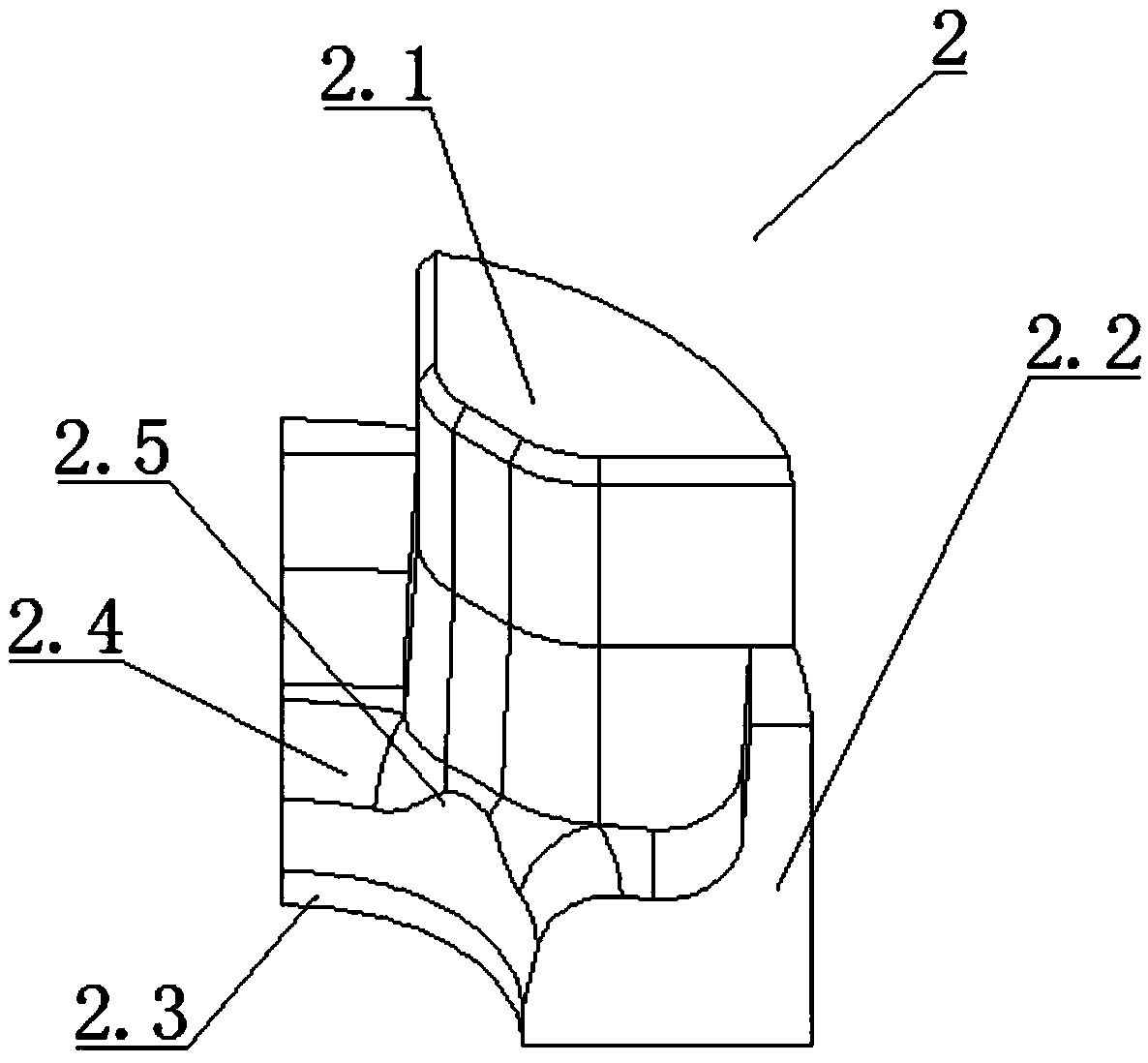

[0032] A kind of combined mold for integral die forging of hinged beam ( Figure 1-Figure 3 ), comprising a die and a punch; said die comprises an outer hoop plate group 1 fixed together by a screw 3, four die petals 2 and a central punch 4; said outer hoop plate group 1 It consists of a multi-layer outer hoop plate ring and an outer hoop bottom plate. The outer hoop bottom plate has a circular center hole and a raised bottom plate ring on the top surface of the outer hoop bottom plate; the center punch 4 is a cylindrical punch at the bottom The bottom plate and the upper truncated punch protrusion are composed, and the punch protrusion is coaxial with the punch bottom plate; the die petal body 2 is formed by a fan-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com