Preparation method for silicone oil clutch housing

A technology for silicone oil clutches and housings, which is applied in the field of preparation of silicone oil clutch housings. It can solve the problems of easy formation of sand holes in castings, easy occurrence of pores, and influence on use, and achieve the effects of avoiding sand hole defects, saving raw materials, and facilitating demoulding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

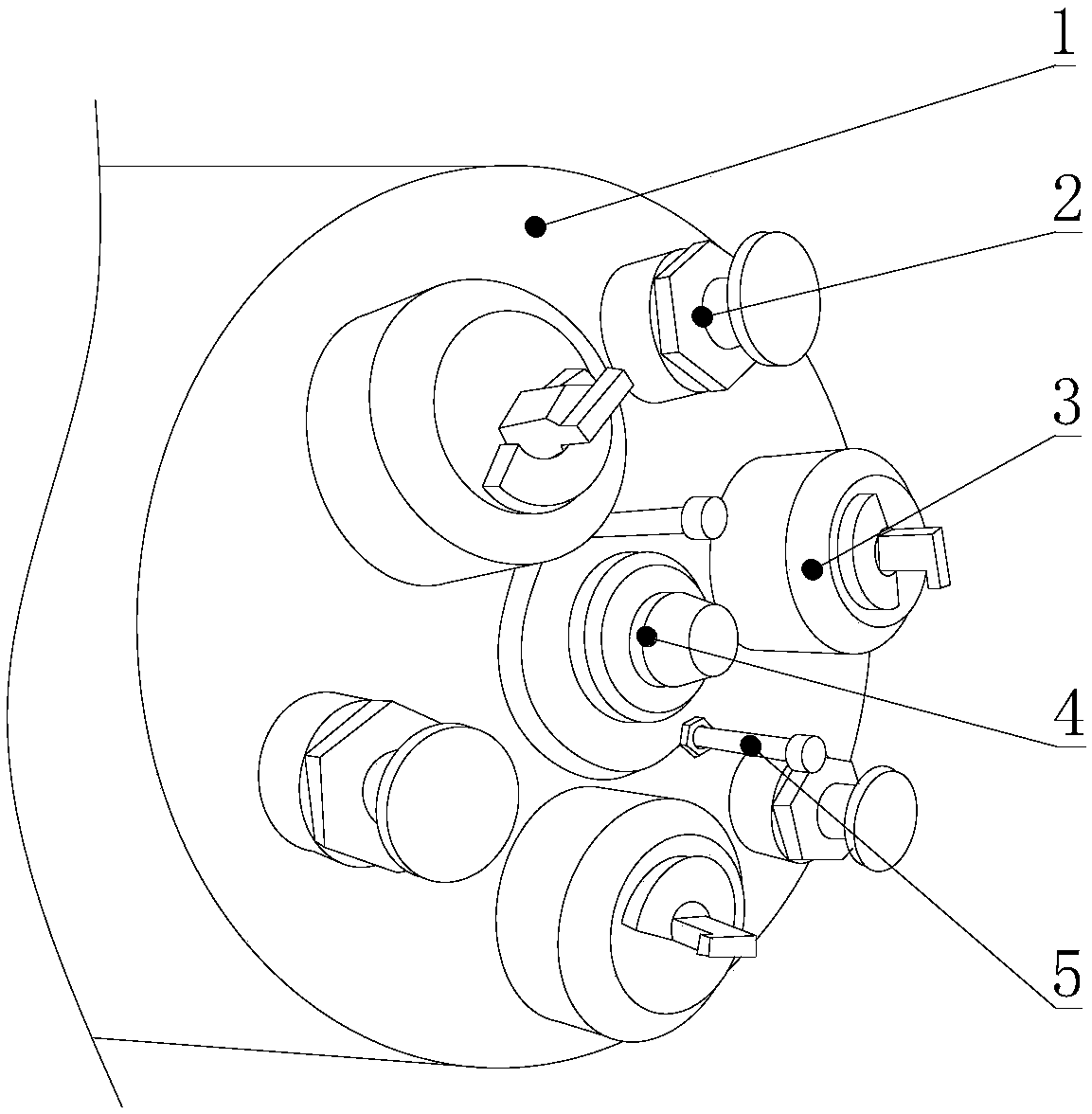

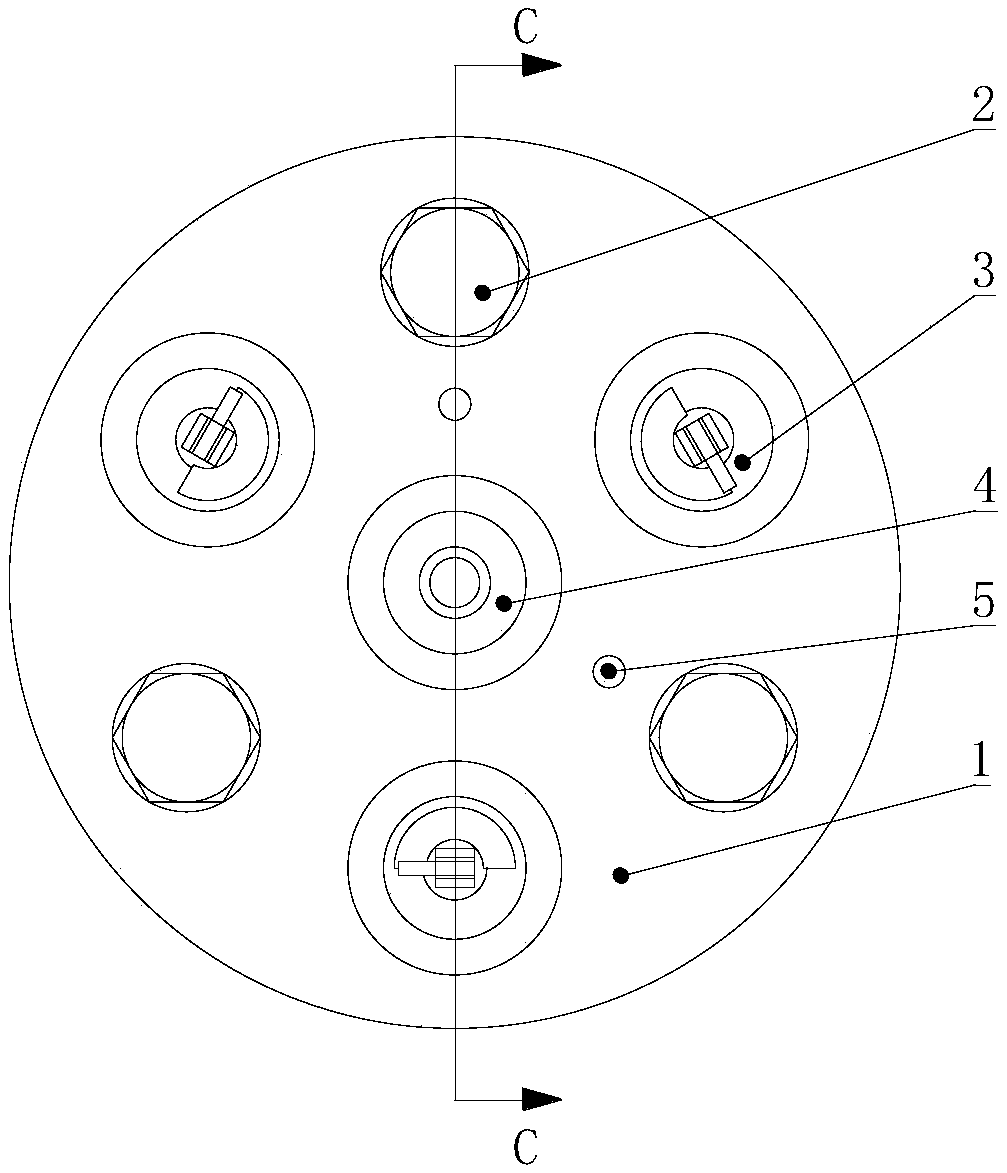

[0045] Below in conjunction with accompanying drawing, the present invention is described in further detail:

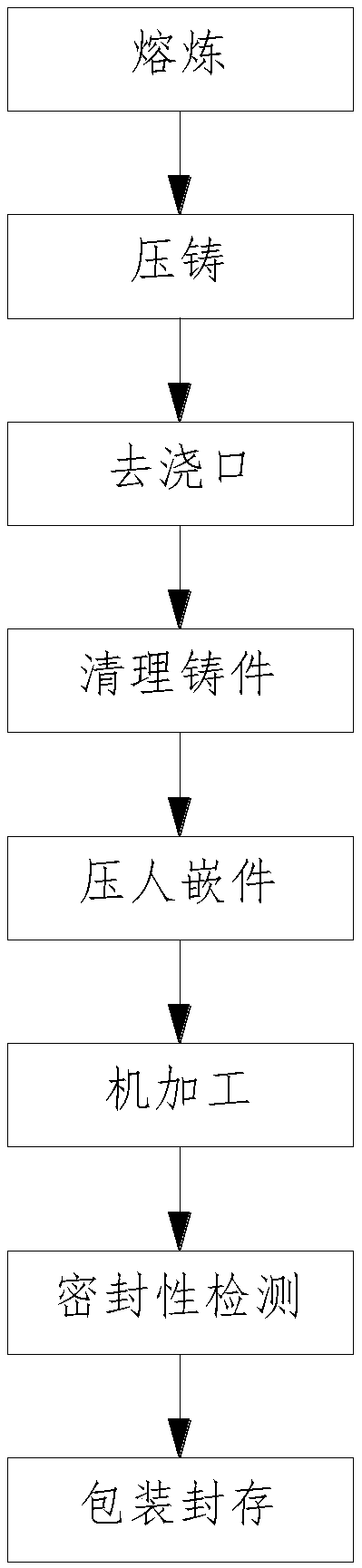

[0046] Such as image 3 Shown, a kind of preparation method of silicone oil clutch housing comprises the following steps:

[0047] S1. Smelting molten steel; put the steel material into the steelmaking furnace for smelting to form molten steel that meets the casting requirements, and provide qualified raw materials for the casting 15. During the smelting process, the volume fraction ratio of new and old materials is 60:40. Slag agent 1‰ (volume fraction), and then smelted to 720°C±10°C.

[0048] S2, pouring molten steel into the forming mold for die-casting; after the male template (movable template 11) and female template (fixed template 21) of the forming mold are closed, the movable mold core 12 fixed on the movable template 11 and fixed on the fixed template 21 The fixed mold core forms a cavity consistent with the shape of the casting 15, and the casting 15 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com