Patents

Literature

35results about How to "Reduce labor capacity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

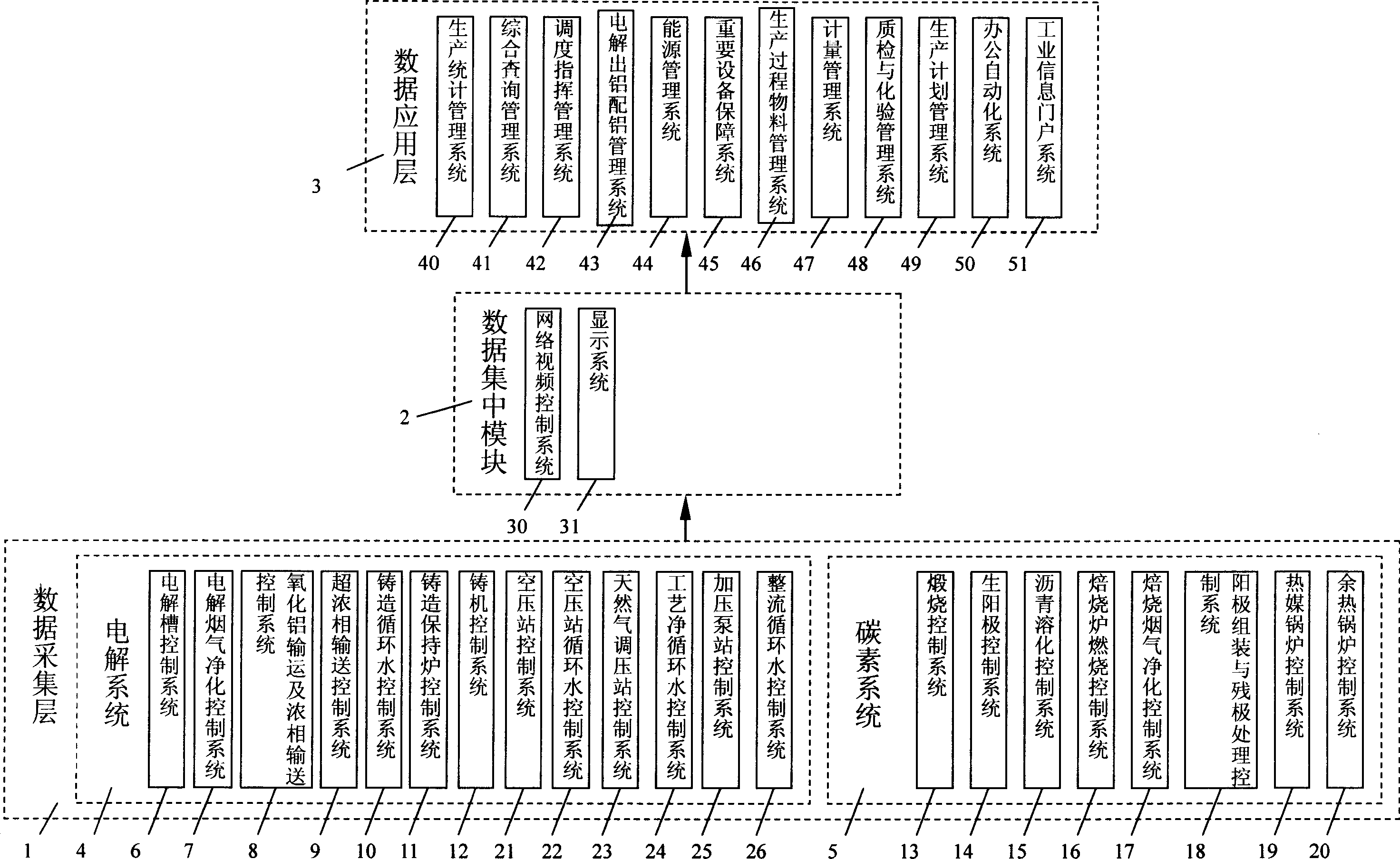

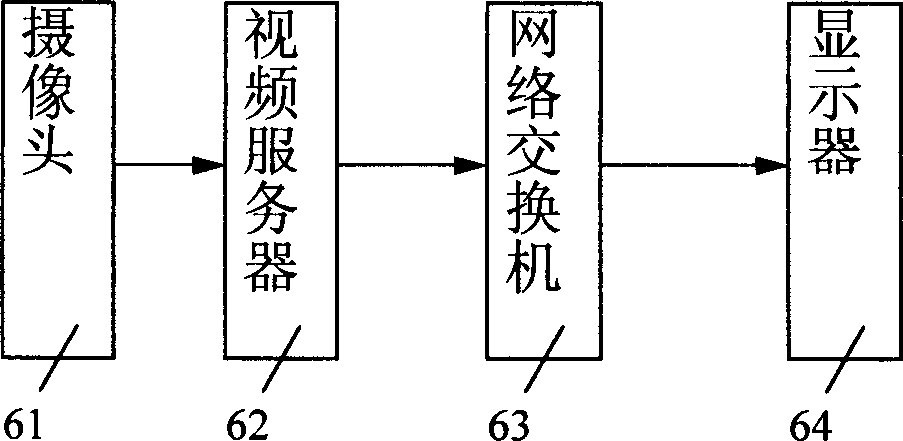

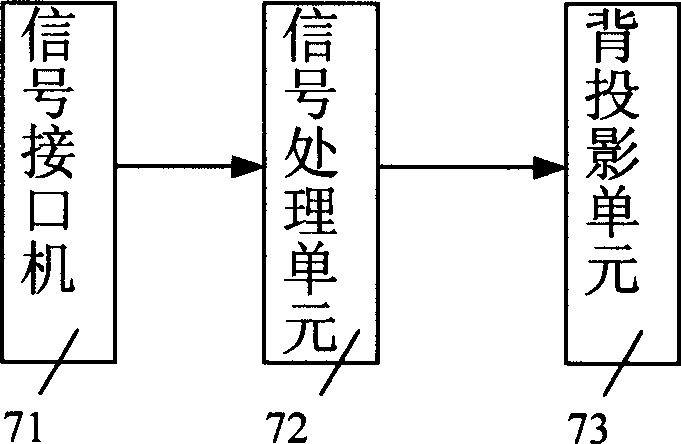

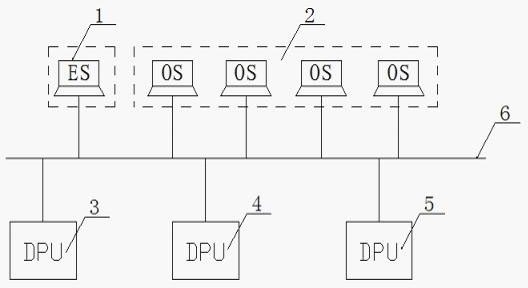

Electrolytic aluminium production management control integrated system

The production-management-control one-piece integrated system for aluminum electrolysis comprises: a data acquisition layer that connects to the control system with a electrolysis system and a carbon-element system by a communication control interface with protocol conversion, data insulation and data buffer, real-time acquires data to convert into uniform format and send to data concentration layer by Ethernet; a data concentration layer that processes, treats, analyzes, stores and releases the data, transfers to data application layer, and sends data among systems according to process request; and a data application layer that builds the opposite application system for the production management according to data information. This invention realizes information centralized management.

Owner:北京华深科技发展有限公司

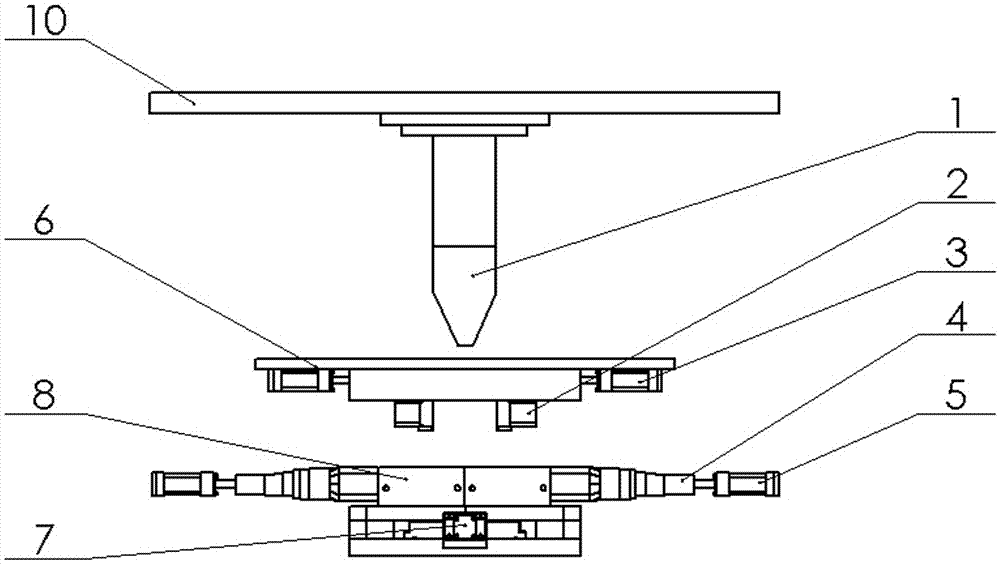

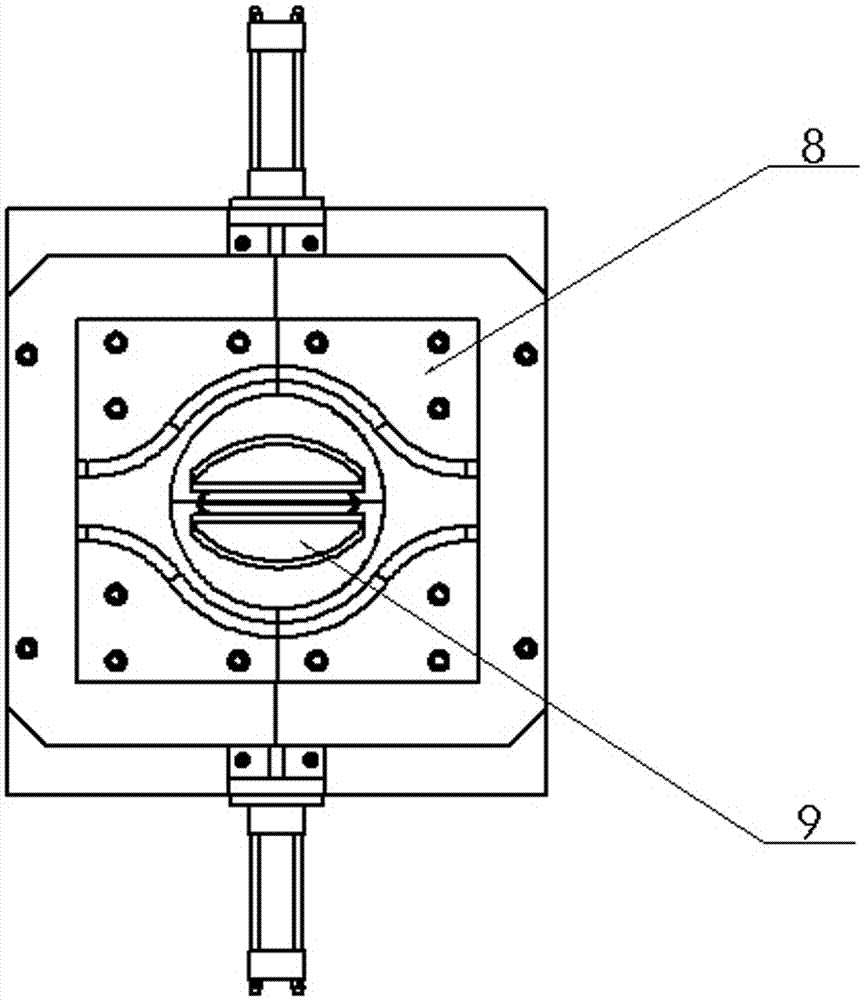

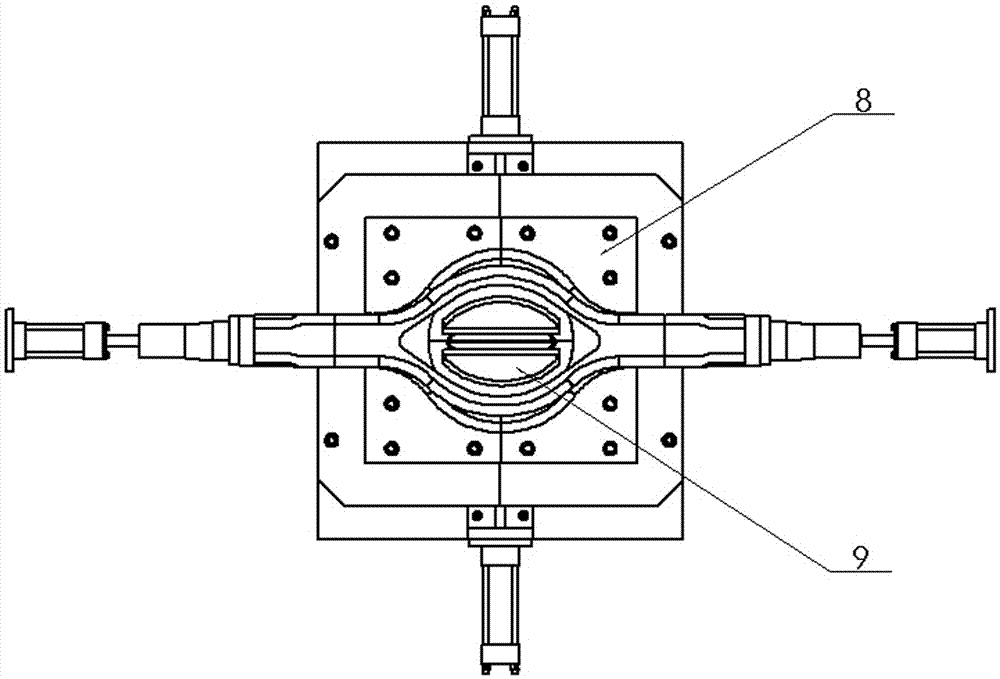

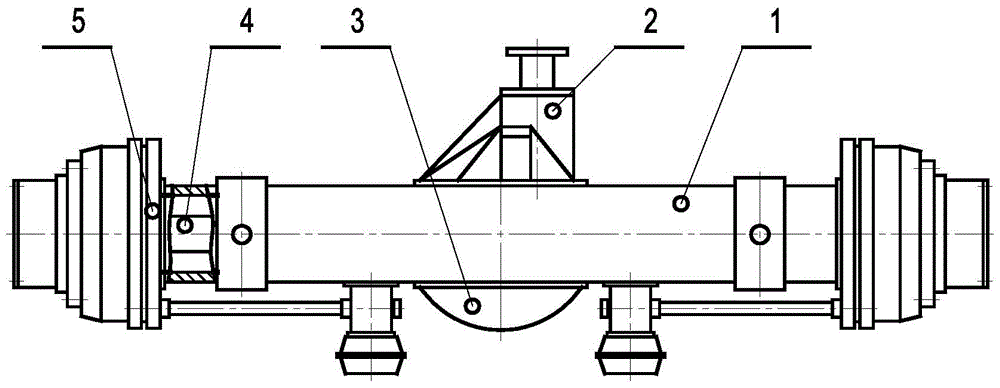

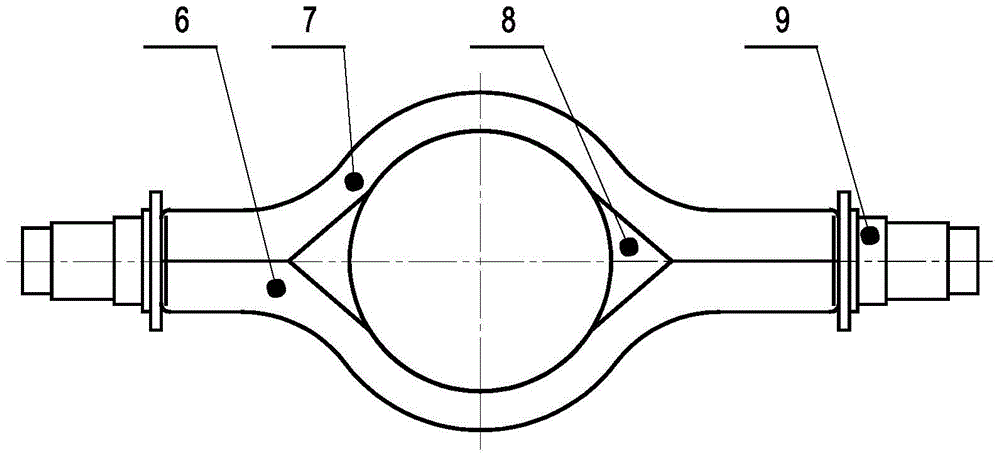

Forming method for banjo axle housing

ActiveCN105436350AEliminate product defectsImprove product qualityShaping toolsEngine componentsHydraulic cylinderEngineering

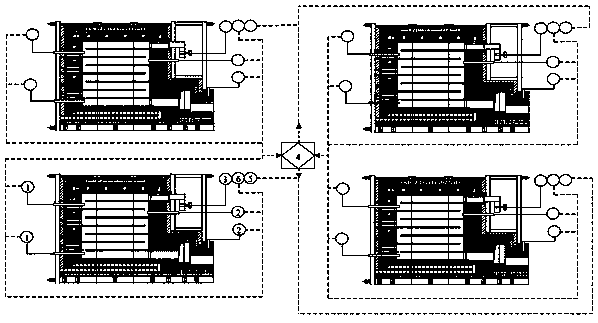

The invention discloses a forming method for a banjo axle housing. The forming method includes the following steps of (S1) blanking, (S2) extrusion of a shaft head, (S3) square pushing, (S4) manufacturing of a process groove, (S5) heating of a workpiece, (S6) radial expansion, (S7) shaping and (S8) upward resetting of a lower press sliding block and taking-out of the workpiece. According to the (S6), a wedge punch penetrates through a central hole of the lower press sliding block, pushes two radial expansion core molds to expand the radial direction of a workpiece central hole and axially squeezes the workpiece synchronously. According to the (S7), two axial shaping core molds are attached, the lower press sliding block moves downwards to enable the axial shaping core molds to be inserted into the position between two radial shaping core molds, an upper press sliding block moves downwards, and the wedge punch is inserted into the position between the two axial shaping core molds to shape the workpiece central hole and axially squeeze a hydraulic cylinder for axial limitation. The forming method integrates heat expansion and shaping, work procedures are reduced, a process chain is shortened, and the outline size accuracy is obviously improved.

Owner:吴志强 +1

Technique for conditioning crude gas from gas making stove for coal dry distillation

ActiveCN1727449AReduce resistanceEliminate the ills that spread into the atmosphereCombustible gas purificationTarAmmonia

Owner:鞍钢集团工程技术有限公司

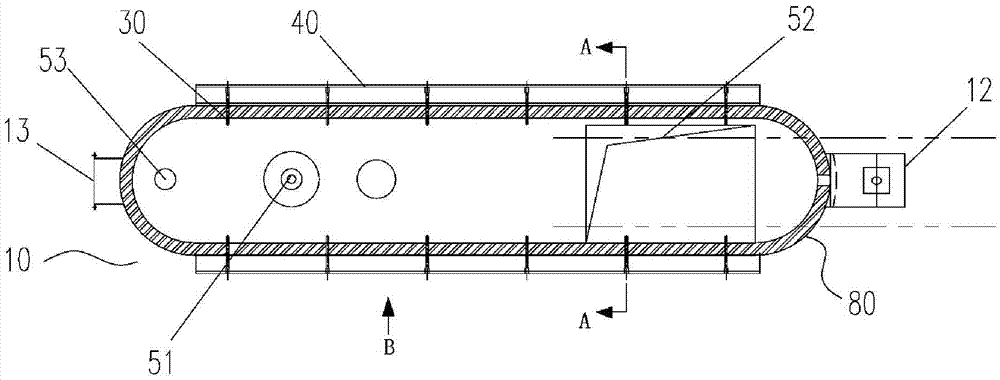

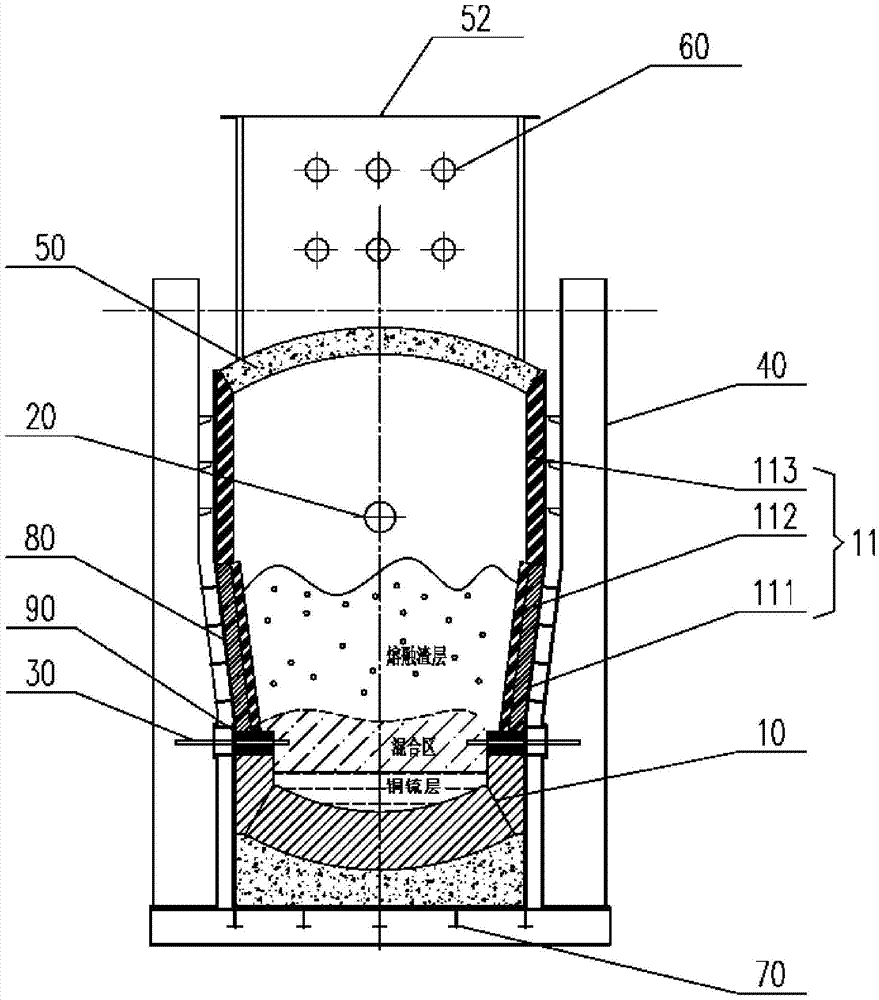

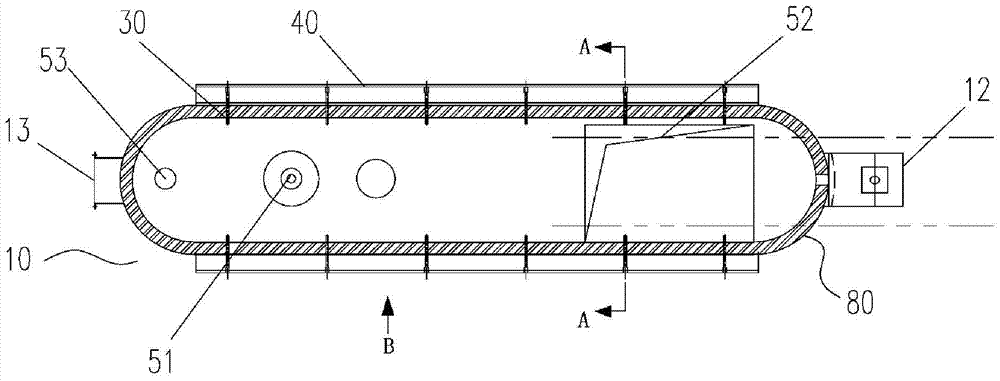

Method for treating copper concentrate through improved side blowing molten pool melting furnace

InactiveCN105441694ACompact processReduce manufacturing costRotary drum furnacesCrucible furnacesMelting tankSlag

The invention provides a method for treating copper concentrate through an improved side blowing molten pool melting furnace. The method comprises the steps that the copper concentrate is put into the improved side blowing molten pool melting furnace, meanwhile, a fusing agent is added, multi-channel spraying guns arranged on the two sides of the molten pool melting furnace spray oxygen rich gas and fuel into a molten pool mixed area of the molten pool melting furnace with the flowing speed being 180 m / s to 280 m / s, and therefore materials in the molten pool melting furnace have the molten pool melting reaction and generate copper matte and melting slag, wherein, the molten pool mixed area contains copper matte and melting furnace slag at the same time; and the melting slag is discharged out of a slag outlet of the molten pool melting furnace, and the copper matte is discharged out of a metal discharging opening of the molten pool melting furnace. The copper concentrate melting method which is compact in process, small in fixed number of workers needed for a job, good in environment friendliness and low in production cost.

Owner:CHINA ENFI ENGINEERING CORPORATION

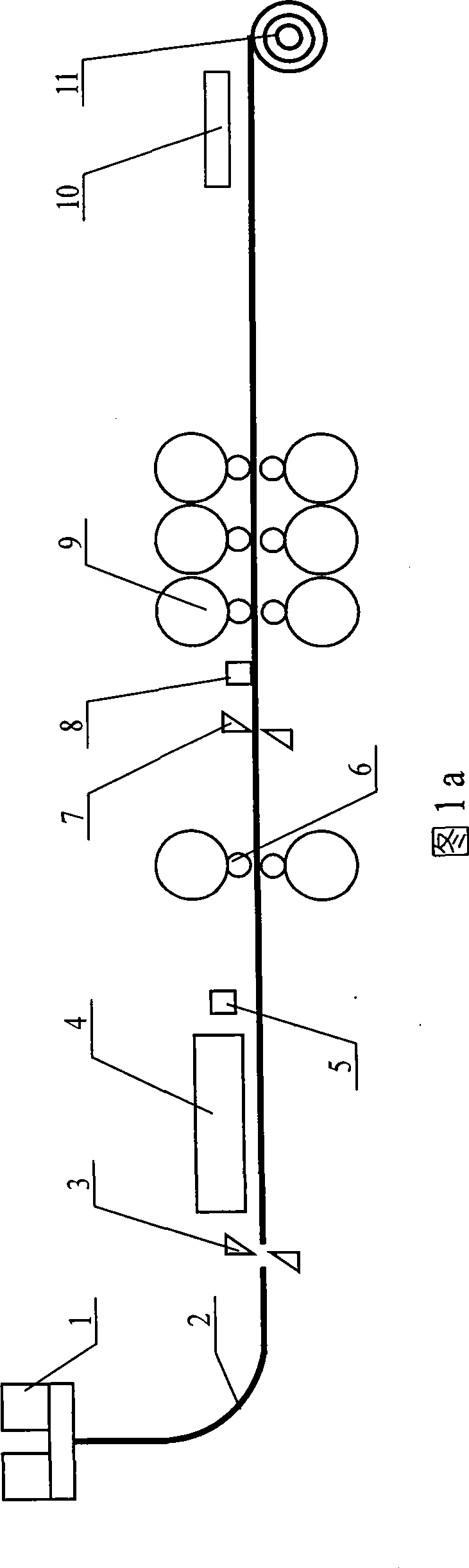

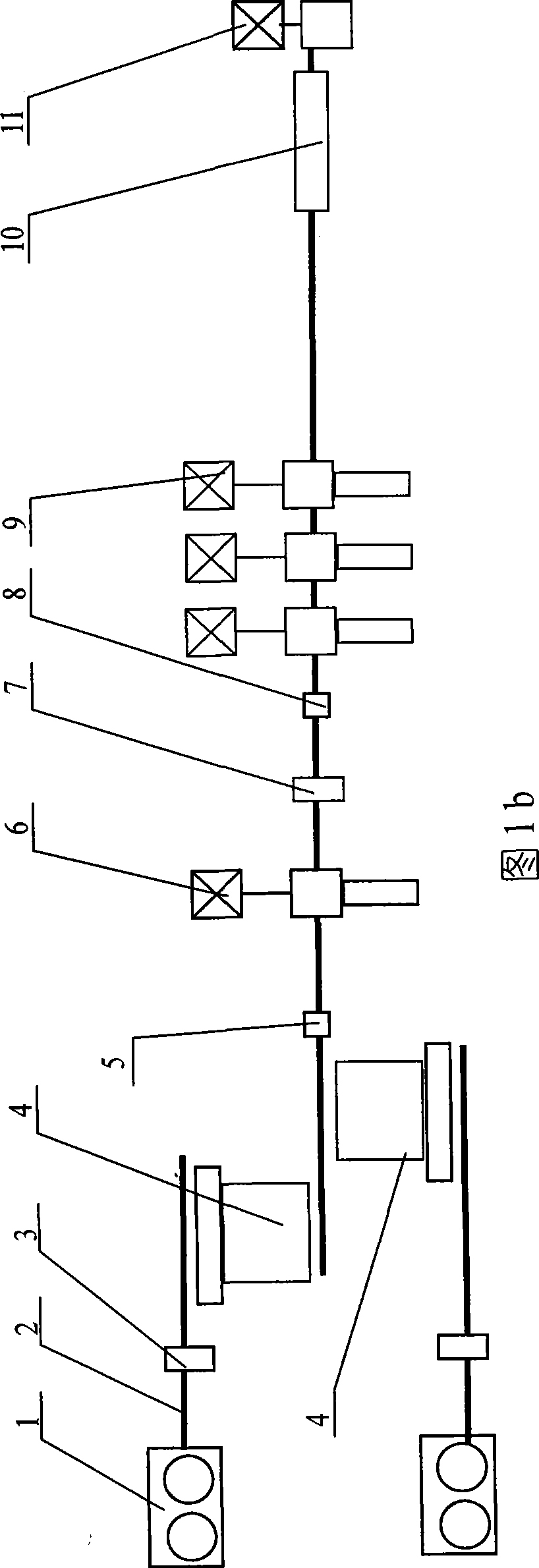

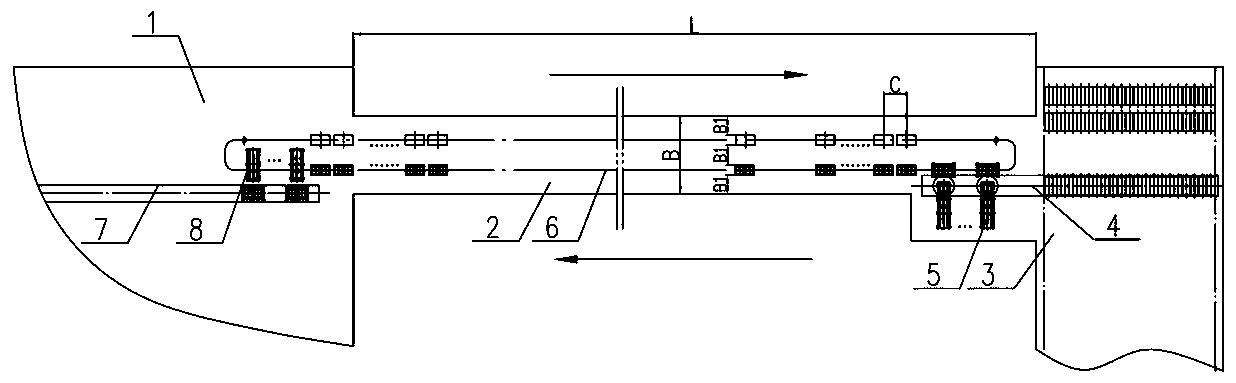

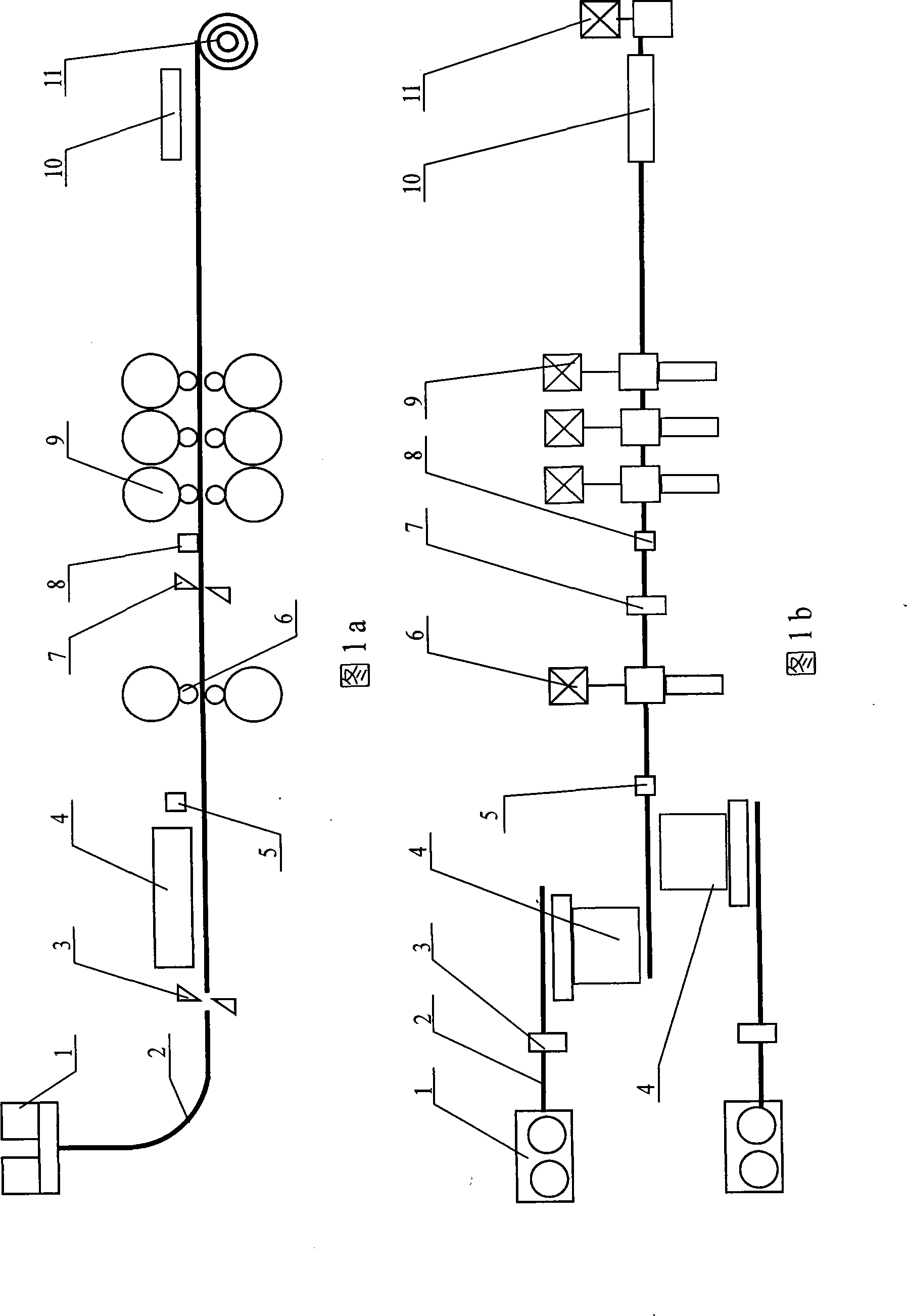

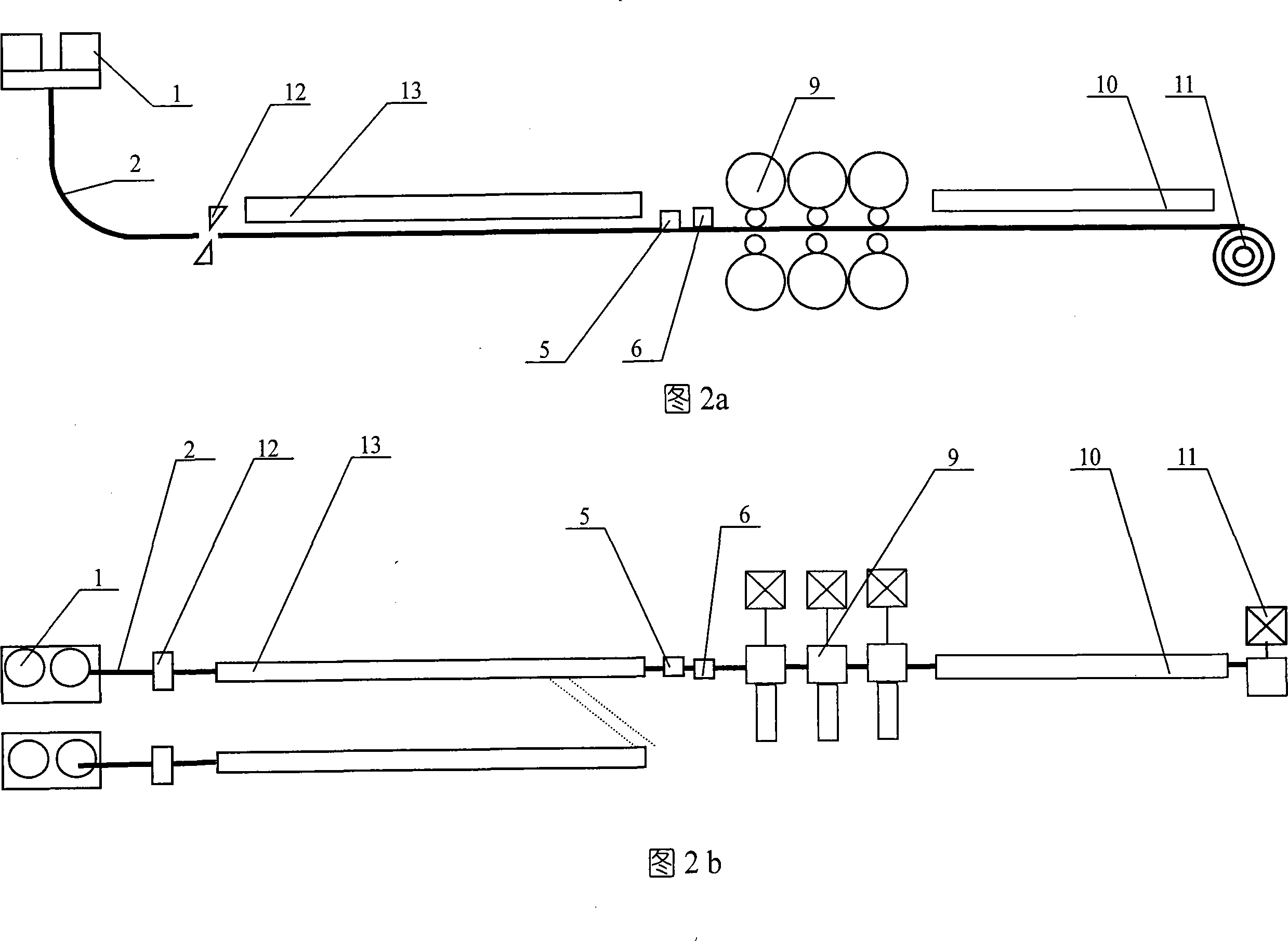

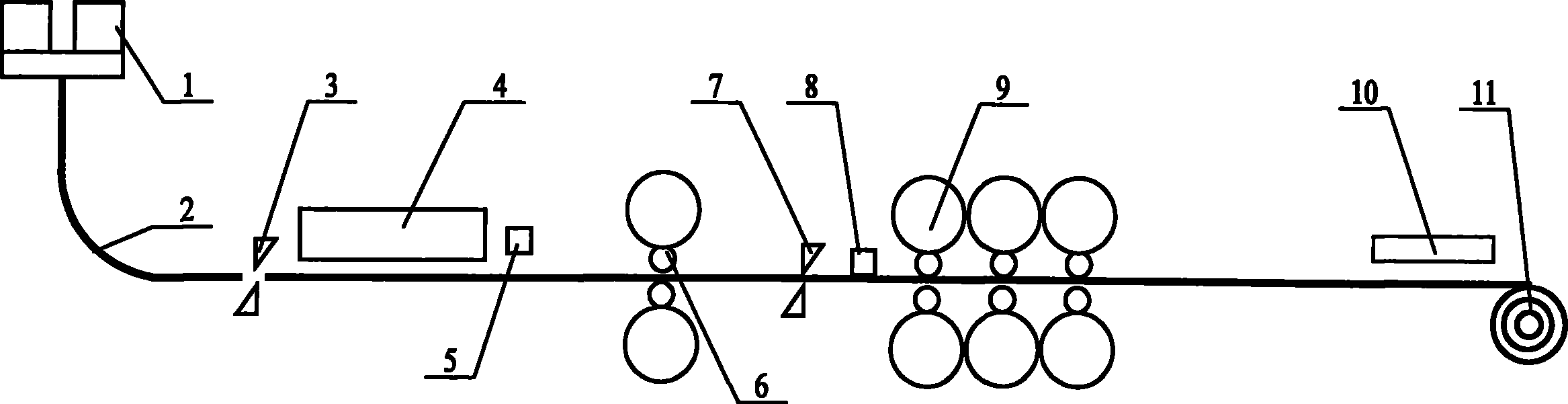

Technique method of thin middle plate continuous casting and rolling production

ActiveCN101391264AIncrease production capacityFull production capacityTemperature control deviceFurnace typesThick plateSingle plate

The invention belongs to the technical field of molding, in particular to a technique method of thin plate continuous casting and tandem rolling, namely effective thin plate process (ETPP). The invention is composed of a conticaster and a rolling mill. Casting plate blanks are broken by the conticaster, a heating furnace is adopted to heat the plate blanks to a set temperature 1050-1200 DEG C, and then the plate blanks are delivered out through a roller way; iron scale on the surface of the plate blanks is removed by high-pressure water; the plate blanks are rolled by the rolling mill set and are performed with laminar flow cooling through a laminar flow cooling device; the slab bands are cooled to a target temperature of 550-780 DEG C and are coiled by a recoiling machine; and the rolling finished products can be delivered in whole coils or can be delivered through being cut into single plate or single stack by a transverse cutting unit. The process flow of the invention has simple equipment components, high production efficiency and little investment. The process of the invention can be applied to the construction of a newly-built or reconstructive medium-thick plate rolling mill.

Owner:CISDI ENG CO LTD

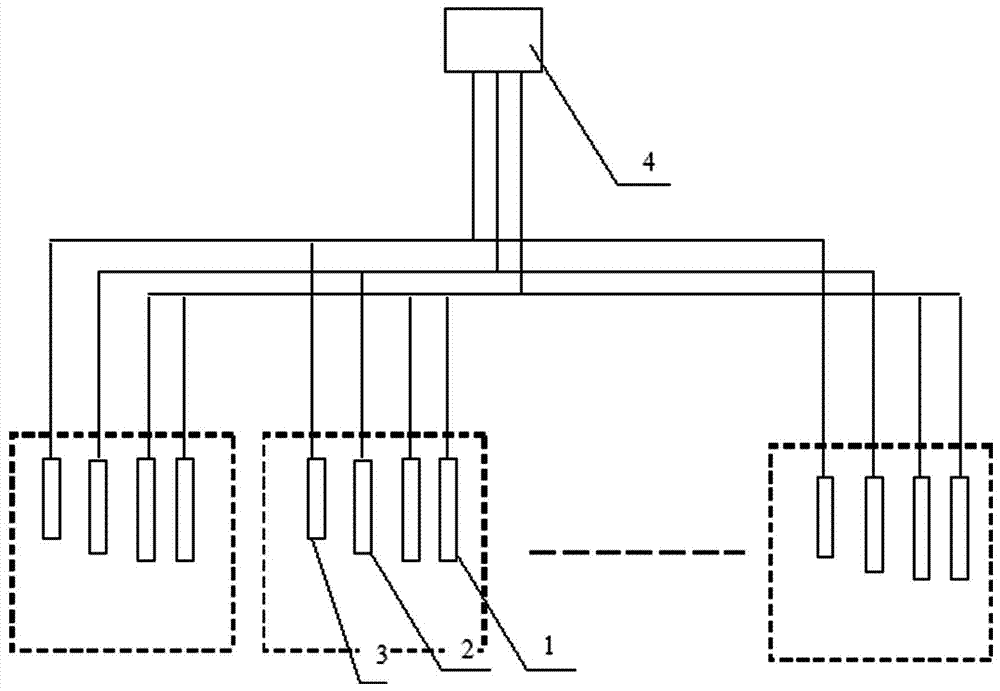

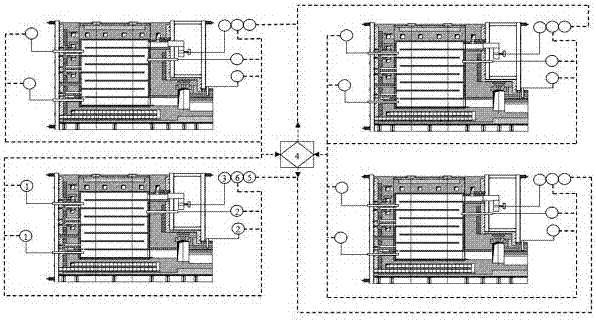

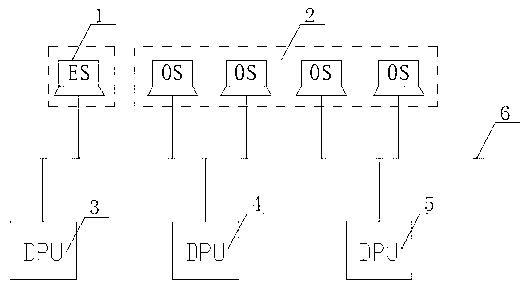

Pot calciner flue temperature automatic control system

ActiveCN107238283AImprove production stabilityImprove uniformityVertical furnacesAutomatic controlControl system

The invention relates to a pot calciner, in particular to a pot calciner flue temperature automatic control system. The pot calciner flue temperature automatic control system comprises bottom layer local control systems and an upper layer central control system. Each pot calciner in a calcinating workshop is provided with one local control system. The local control systems are connected to the upper layer central control system through a network communication system, so that unified management and control over the bottom layer systems are achieved. The pot calciner flue temperature automatic control system has the advantages and effects that temperature distribution of all flues of each pot calciner in the calcinating workshop is precisely controlled, and further, and unified management for all detection and control data of the whole workshop can be achieved; and the system can be used for replacing manual temperature regulation, decreasing the manpower quota and improving the pot calciner production stability and product quality uniformity, furthermore, fluctuations of flue temperatures within target ranges can be precisely controlled, the overheating phenomenon is prevented, and the service lives of the pot calciners are greatly prolonged.

Owner:SHENYANG ALUMINIUM MAGNESIUM INSTITUTE

Cyclone treatment technique of nickel-containing electroplating wastewater

InactiveCN104724864AIncrease current densityIncrease workloadPhotography auxillary processesWater contaminantsElectroplating wastewaterImpurity

The invention discloses a cyclone treatment technique of nickel-containing electroplating wastewater. By adopting a cyclone technique which is completely different from the traditional technique for electrodepositing nickel, the current efficiency can reach 90% above which is much higher than 75% in the traditional nickel electrodeposition. The current density is 600-800 A / m<2> which is more than twice higher than that of the traditional technique. Besides, the nickel product produced by the technique has the advantages of stable quality and low requirements for impurity content in the catholyte. The technique can decrease civil engineering investment, and has the advantages of low production cost, high degree of mechanization, low workshop labor requirement, low worker labor intensity and the like.

Owner:江苏地一环保科技有限公司

Production process of hollow brick and porous brick from coal gangue

The invention relates to a production process of a hollow brick or a porous brick from coal gangue. The hollow brick or the porous brick is good in heat preservation performances, but is complex in production process, and meanwhile, qualities of the bricks burned through different processes are quite different. The production process includes the steps of: (1) primary crushing; (2) secondary crushing; (3) aging: aging raw materials after the secondary crushing for 1-1.5 months; (4) moulding; (5) drying; and (6) calcination: pulling dried green bodies of the bricks out and directly calcining the green bodies in a calcining kiln. In the process, a one-time palletizing and burning process is employed, wherein the moulded green bodies are directly palletized on a kiln car and then are subjected to continuously drying and calcination, so that an operation of palletizing the moulded green bodies on a drying car and then unloading the dried green bodies can be avoided, thereby simplifying the process. The production process reduces required workers, is convenient for production management and can increase labor productivity.

Owner:任云辉

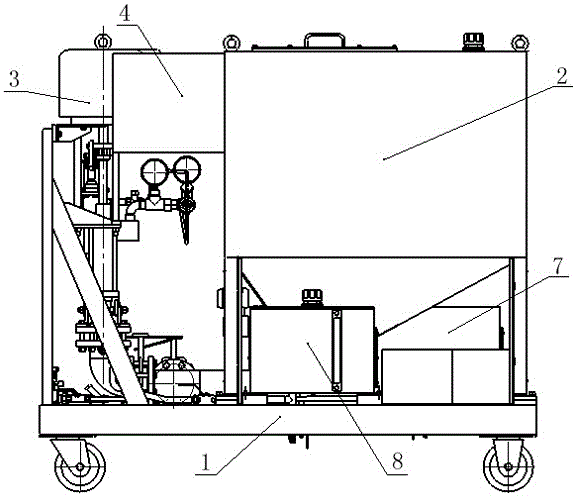

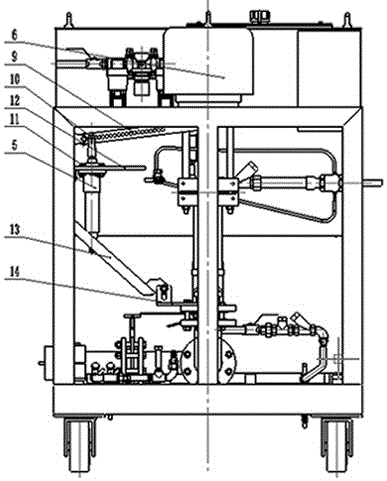

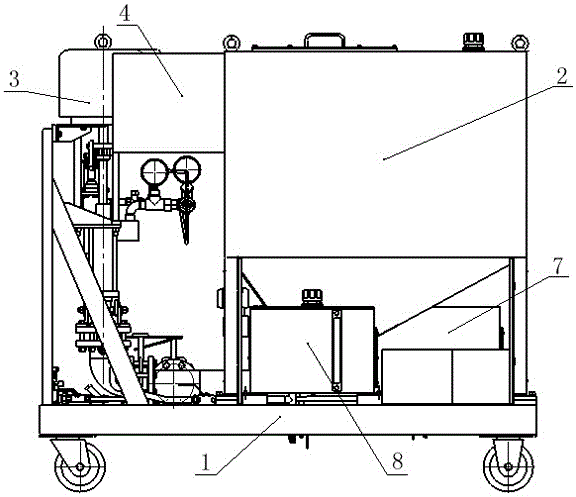

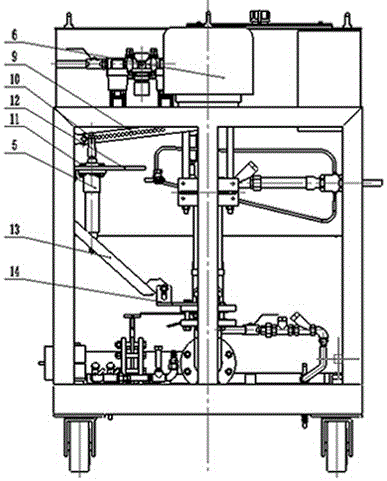

Scene explosive mixed loading equipment

The invention relates to scene explosive mixed loading equipment. The scene explosive mixed loading equipment comprises a chassis, a substrate cabin, a sensitizer box and a pumping system, wherein the substrate cabin and the sensitizer box are connected with the pumping system; the pumping system comprises a substrate pump, a sensitizer pump, a connecting rod, a pin shaft, a bracket, a connecting block, a mounting plate and a bolt; a piston rod of the substrate pump is connected with the connecting rod through the pin shaft; the other end of the connecting rod is connected with the bracket through the pin shaft; the connecting block is arranged at the middle part of the bracket; and the sensitizer pump is mounted on the connecting block. The scene explosive mixed loading equipment is simple in structure and continuous in feeding, and greatly reduces the labor intensity of workers when greatly improving the loading efficiency.

Owner:HUNAN KENON SCI & TECH

Hydraulic fracturing comprehensive mechanized continuous mining method for gently inclined hard rocks

PendingCN113153291ADamage stabilityReduce intensityMining devicesDisloding machinesHydraulic fracturingStoping

The invention provides a hydraulic fracturing comprehensive mechanized continuous mining method for gently inclined hard rocks. The hydraulic fracturing comprehensive mechanized continuous mining method for the gently inclined hard rocks comprises the following steps of (1) determining ore block structure parameters; (2) arranging a mining and cutting project, and forming a mining working face; (3) forming fracturing holes in the mining working face; (4) hydraulically fracturing an ore body in the fracturing holes; (5) adopting comprehensive mechanized stoping; and (6) filling a goaf. Compared with the prior art, when the hydraulic fracturing comprehensive mechanized continuous mining method for the gently inclined hard rocks is used for mining the hard rocks, the mining and cutting engineering amount, the fixed number of workers and the ventilation energy consumption are greatly reduced, and the production efficiency is improved.

Owner:CINF ENG CO LTD

Integrated self-adaptive coordinated control system for flue gas denitrification, water-saving and coal-saving of cement plant

InactiveCN102707685AGuarantee normal productionMaximize energy saving benefitsEnergy industryTotal factory controlWater savingFlue gas

The invention discloses an integrated self-adaptive coordinated control system for flue gas denitrification, water-saving and coal-saving of a cement plant. The integrated self-adaptive coordinated control system comprises a centralized control DCS (Distributed Control System) of a clinker line, a flue gas denitrification system, a water-saving system and a cement clinker production coal-saving system and is characterized in that various systems are accessed to the centralized control DCS and used for sharing data by communication and controlling coordination of the integrated structure; the DCS can be used for statistically analyzing and optimally calculating onsite data, and automatically regulating technical parameters, so that the energy-saving benefits of a factory is maximized.

Owner:娄卡奔新能源科技发展(上海)有限公司

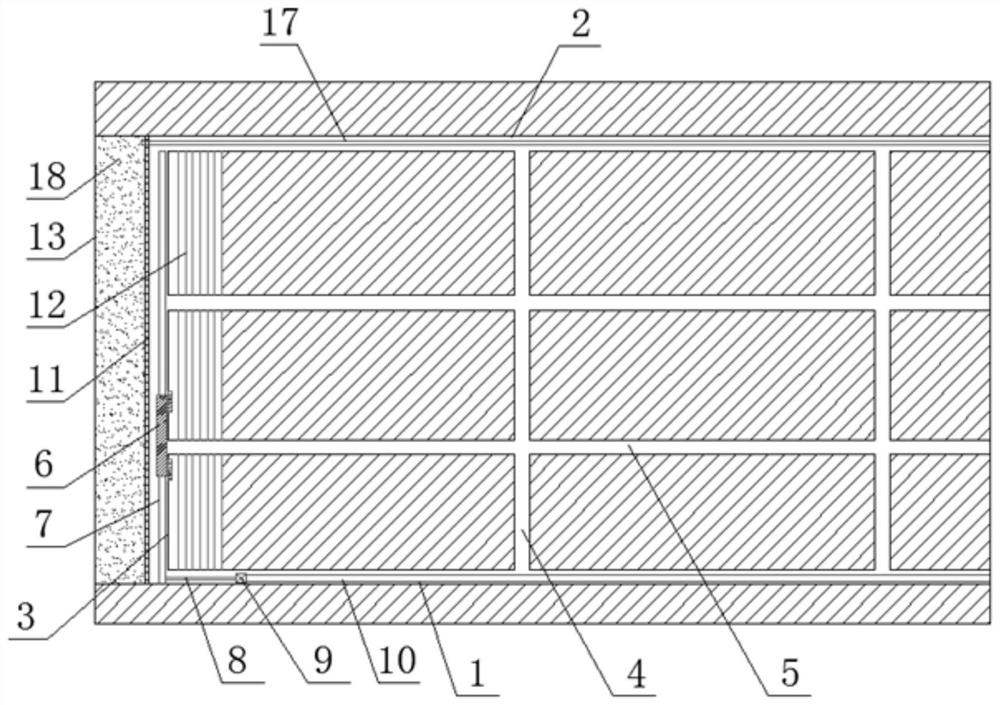

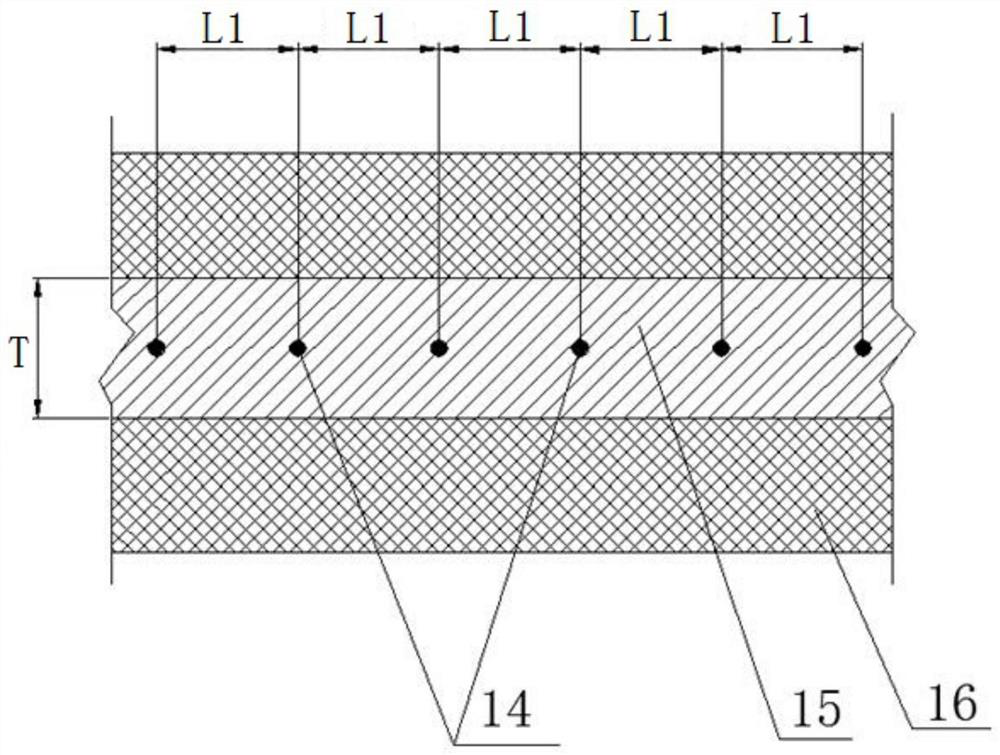

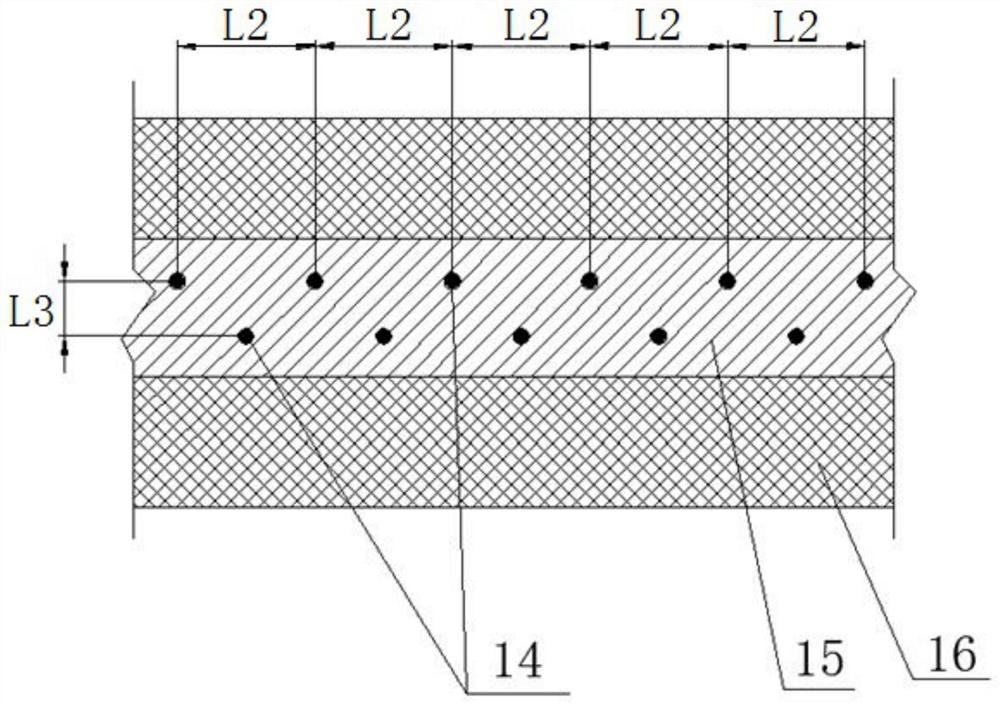

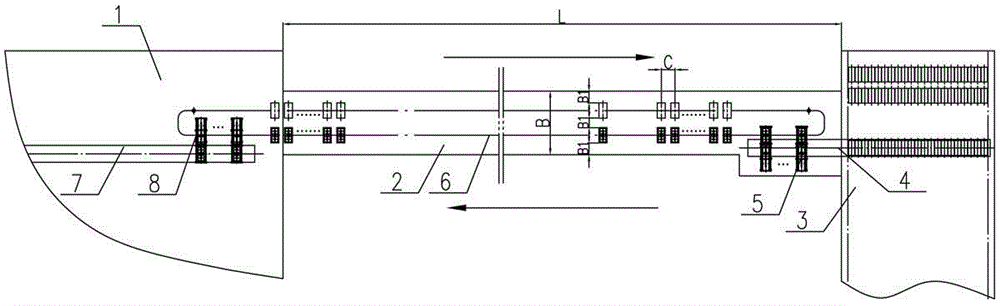

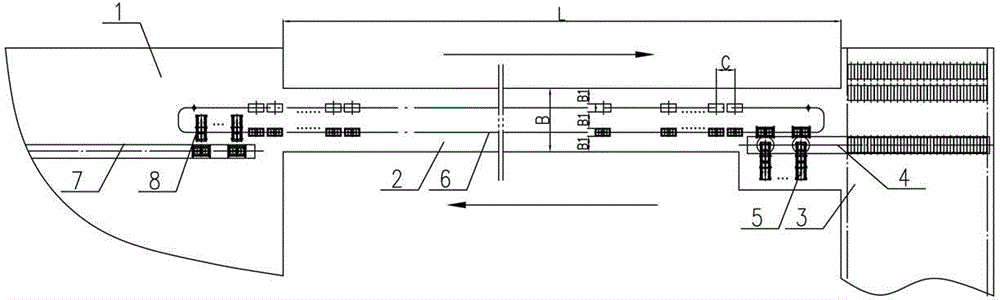

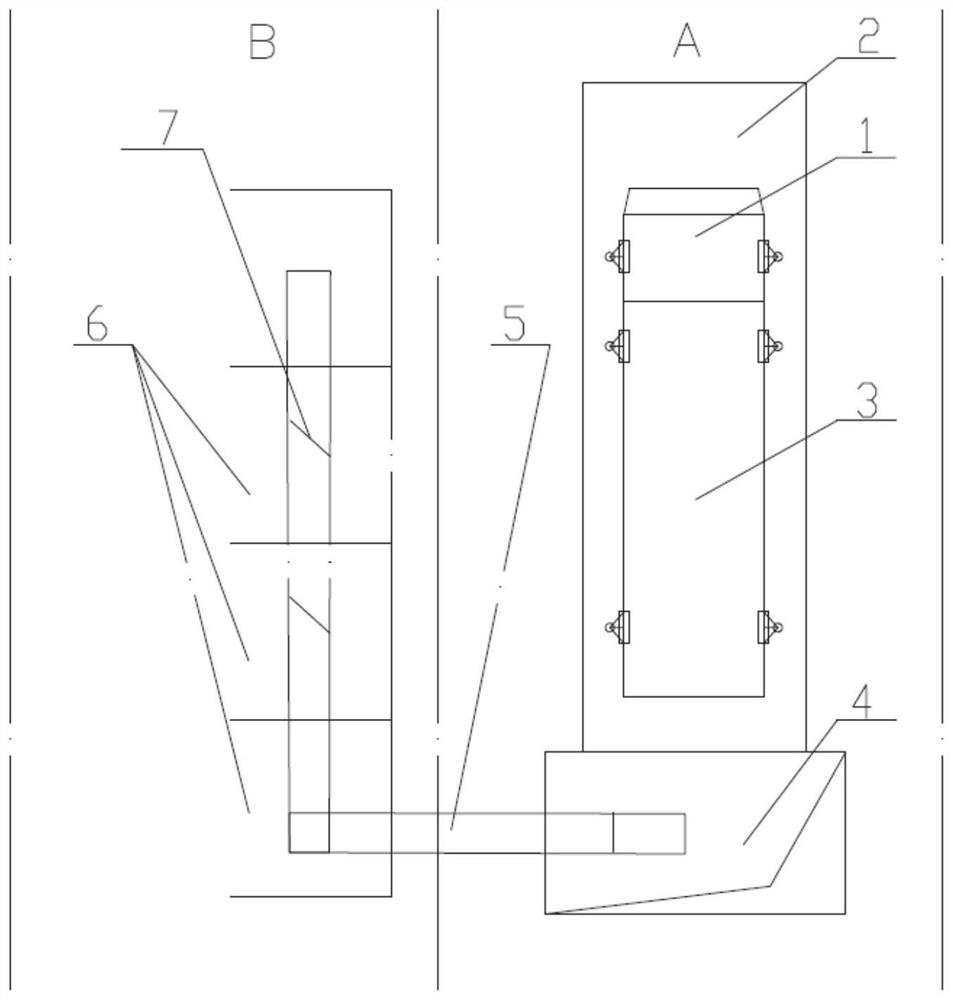

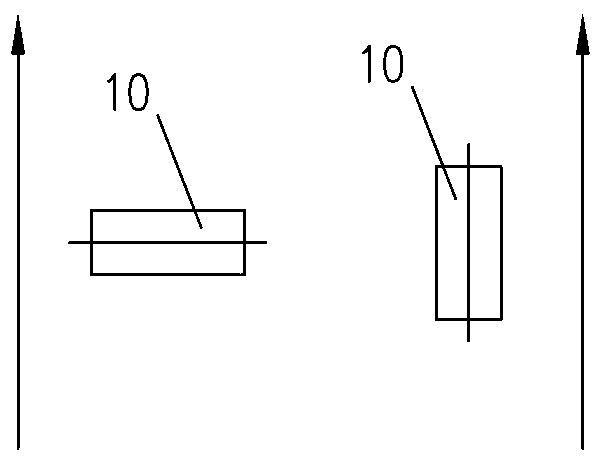

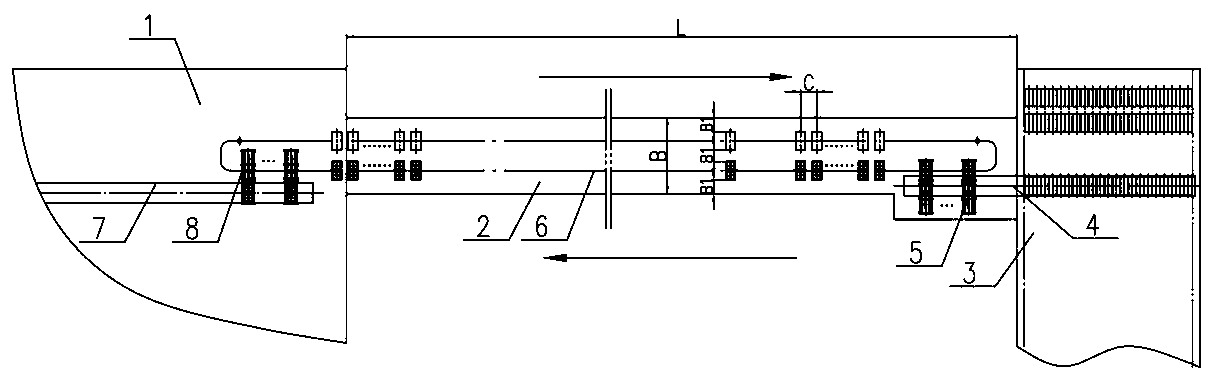

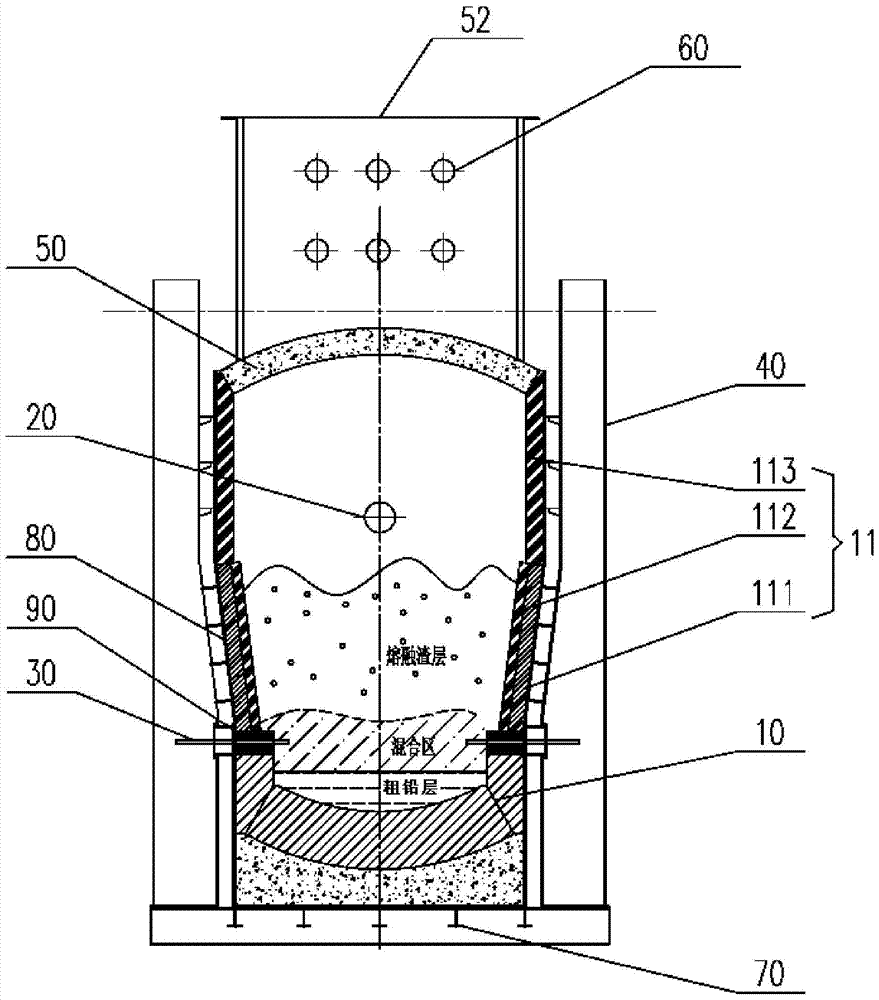

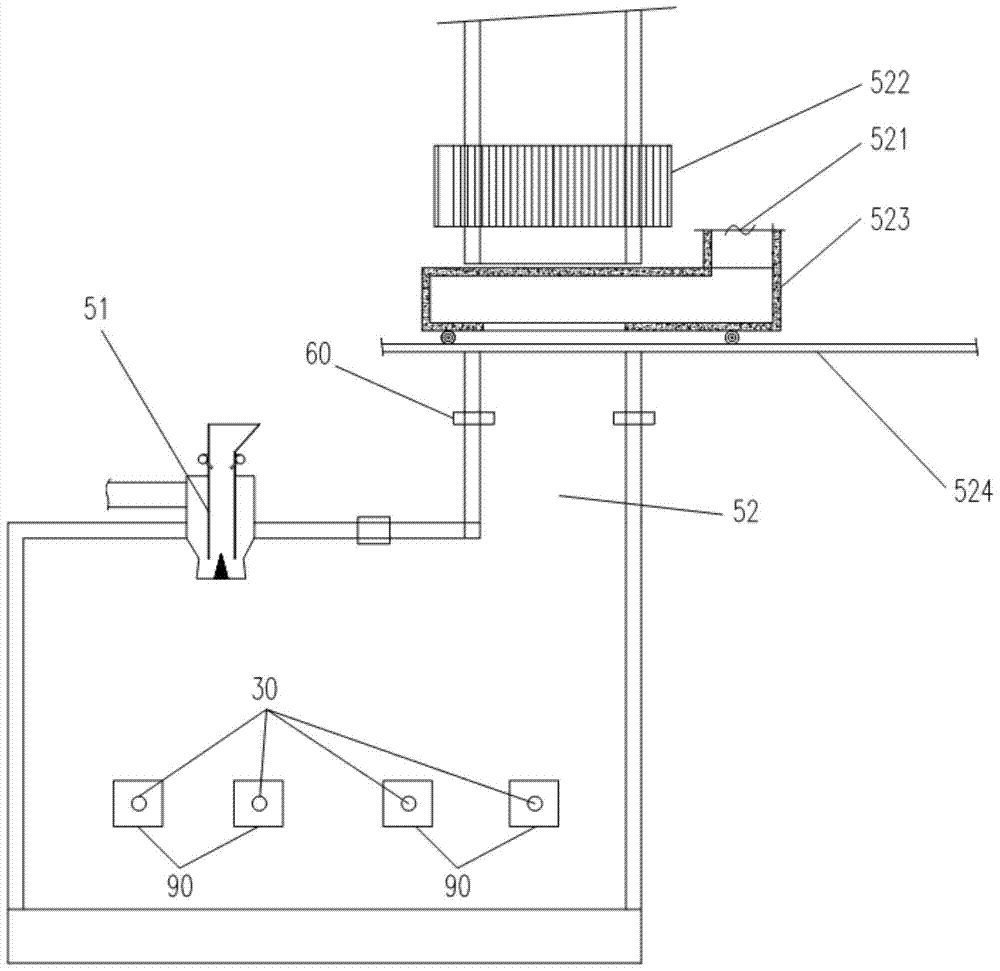

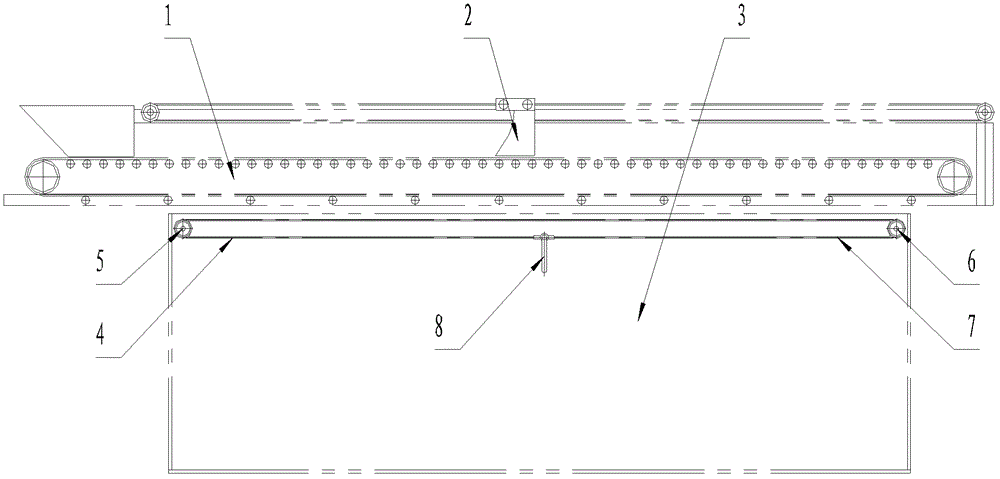

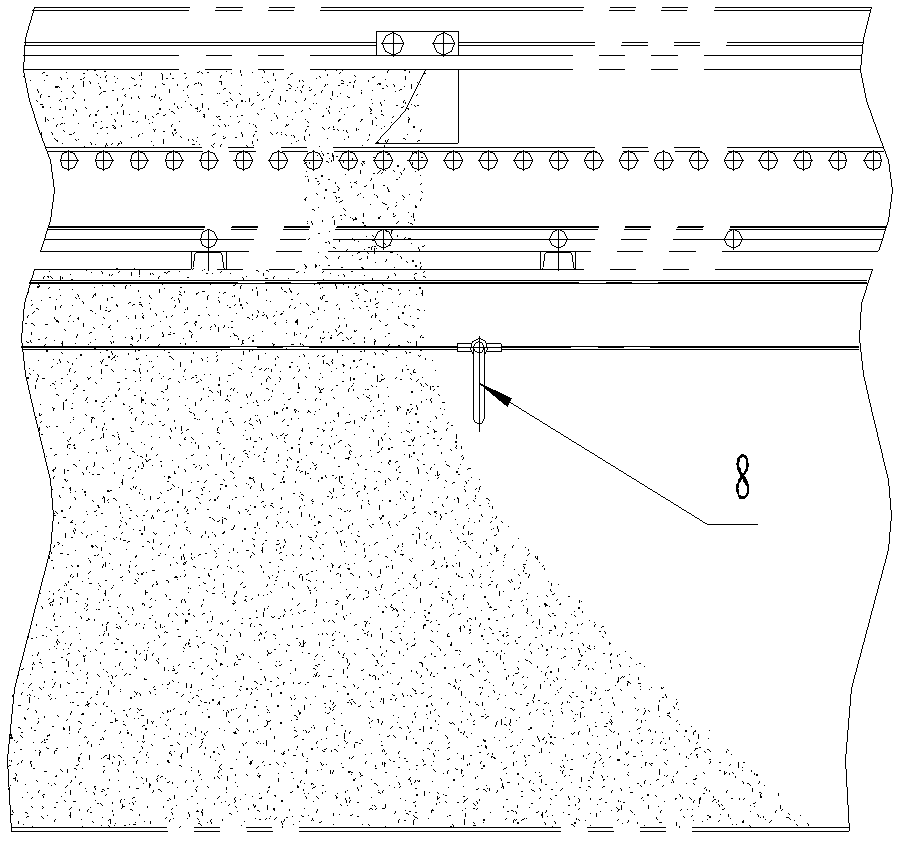

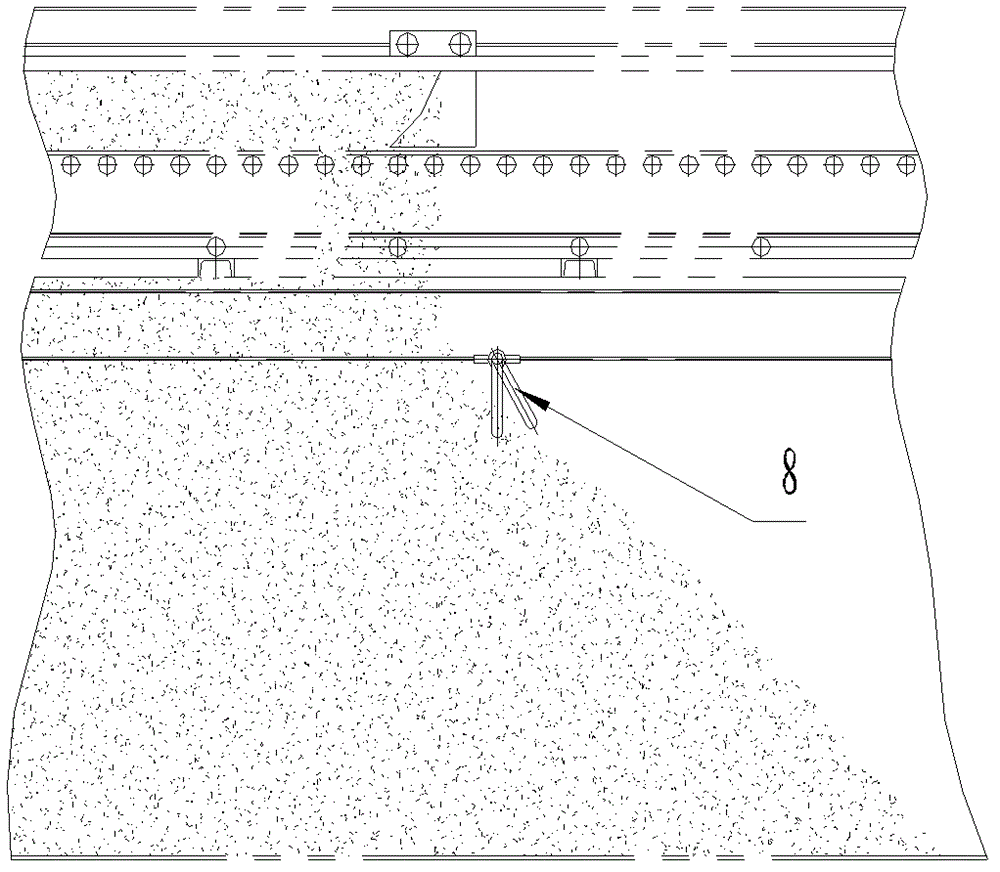

An anode carbon block suspended chain conveying system

InactiveCN106315169AImprove automationImprove mechanical propertiesConveyor partsMechanical conveyorsEconomic benefitsChain conveyor

The invention relates to an anode carbon block conveying system and in particular provides an anode carbon block suspended chain conveying system between an anode carbon block warehouse and an anode assembly workshop of an electrolytic aluminum enterprise. A carbon block conveying gallery is arranged between an anode assembly workshop and an anode carbon block warehouse; an assembly workshop carbon block conveyor and a carbon push-out device are arranged in the anode assembly workshop; a carbon block warehouse carbon block conveyor and a carbon block push-in device are arranged in the anode carbon block warehouse; a suspension type suspended chain conveyor is arranged in the carbon block conveying gallery; lifting tools are arranged under the suspension type suspended chain conveyor. The system can reduce the manpower quotas of enterprises, increase the labor productivity of the enterprises, reduce the engineering construction and production operating costs, reduce the electrolytic aluminum production cost and bring certain economic benefits for the enterprises.

Owner:SHENYANG ALUMINIUM MAGNESIUM INSTITUTE

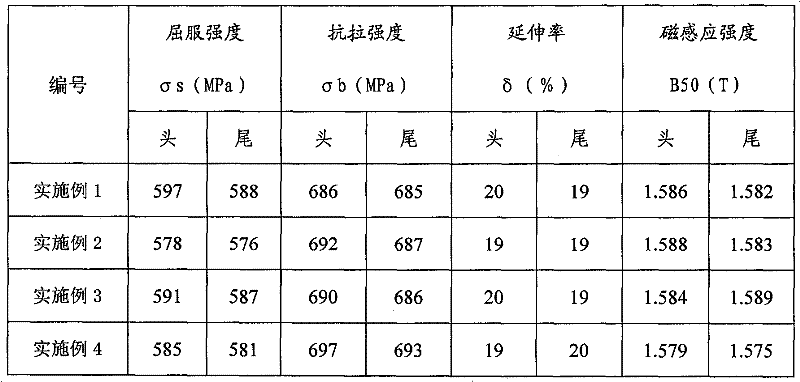

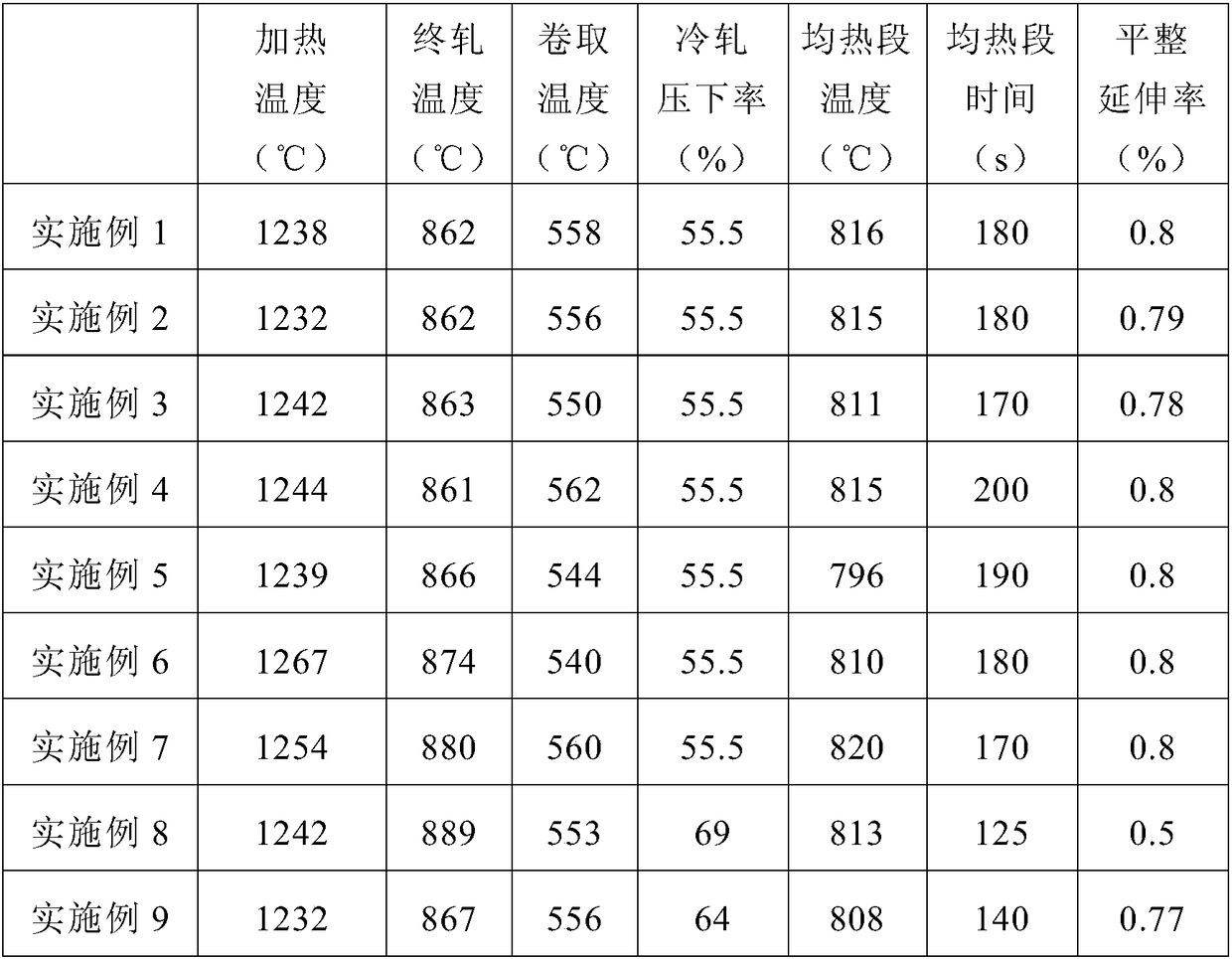

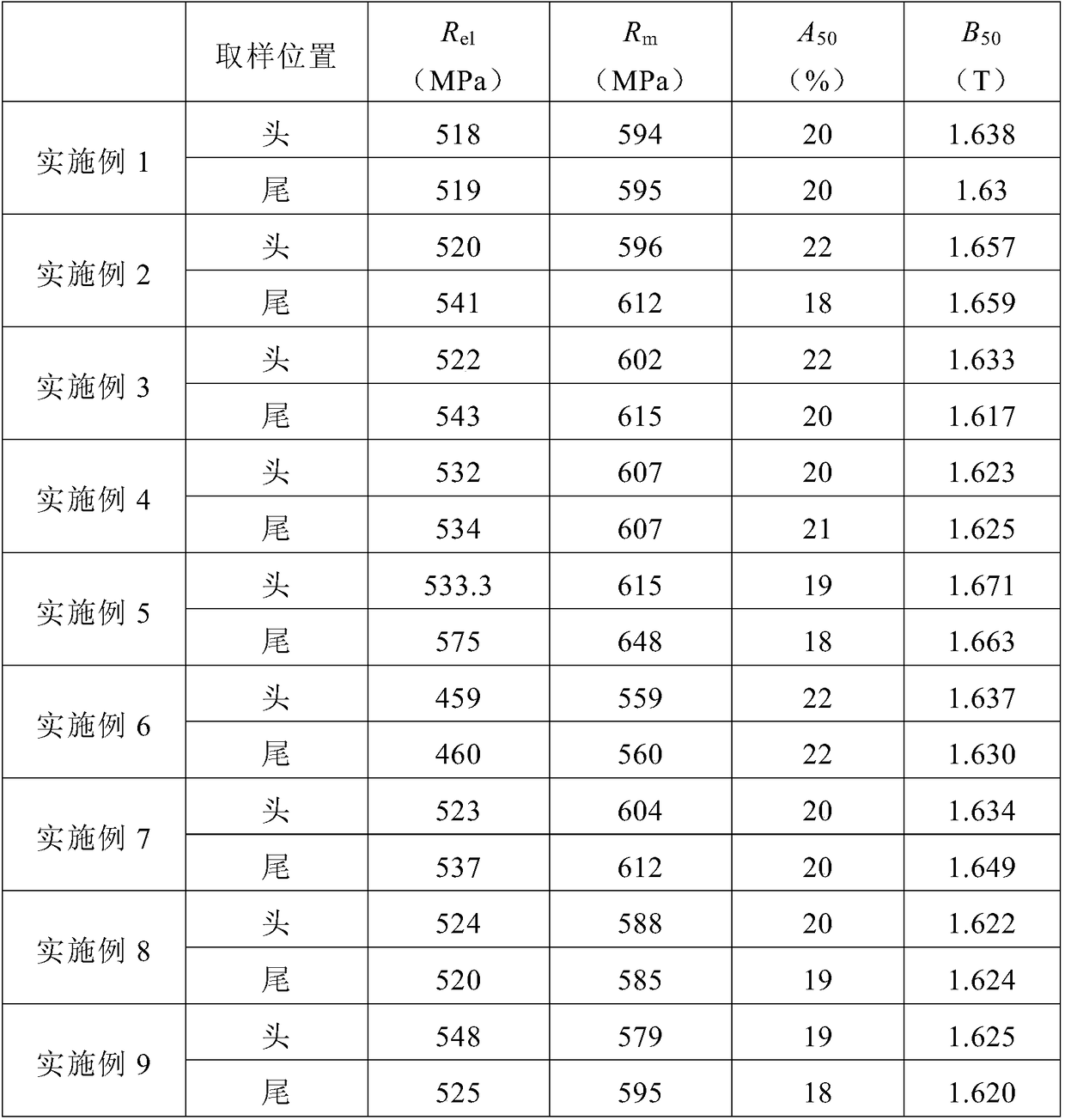

Manufacturing method of 500Mpa-grade cold-rolled magnetic steel

ActiveCN101871076BHigh yield strengthImprove mechanical propertiesTemperature control deviceFurnace typesSheet steelAcid washing

The invention discloses a manufacturing method of 500MPa-grade cold-rolled magnetic steel, which comprises the following steps that: (1) heating a slat to 1200 to 1260 DEG C, then rolling the slab into a steel sheet, the final rolling temperature is 830 to 890 DEG C, and adopting a laminar flow cooling way to cool the steel sheet to 550 to 600 DEG C to be rolled; (2) cooling the steel sheet in anair cooling way, and acid-washing the steel sheet; (3) cold rolling; (4) continuous annealing: the temperature of a uniformly-heated section of an annealing furnace is controlled within the range of 740 to 760 DEG C, the speed of the annealing process section is controlled at the range of 120 to 125 meter per minutes, and the time of the uniformly-heated section is controlled within the range of 230 to 239 s; (5) flattening. The cold-rolled magnetic steel produced with the method has high yield strength which can reach more than 570 MPa, uniform performance, small performance difference, favorable match between the magnetic sensing strength and the strength of the steel plate, favorable shape, high size precision, good surface quality and high yield.

Owner:BAOSHAN IRON & STEEL CO LTD

Multiple-screw extruding device for refining forming of regenerated rubber powder and refining method

ActiveCN105599166AImprove the level of technologyAvoiding Contamination ConundrumsHigh intensityDisadvantage

The invention relates to a multiple-screw extruding device for refining forming of regenerated rubber powder and a regeneration method, and adopts special screws to distribute homodromous / heterodromous parallel structures, triangular structures and cylindrical structures. Through the decomposing of traditional technical effect, closed and continuous refining forming of regenerated rubber powder is realized through different types of thread elements, and the disadvantages of serious pollution, low labor efficiency, high intensity and low automation degree of the traditional open production technology are effectively avoided.

Owner:CHINA RUBBER RESOURCE REGENERATION QINGDAO

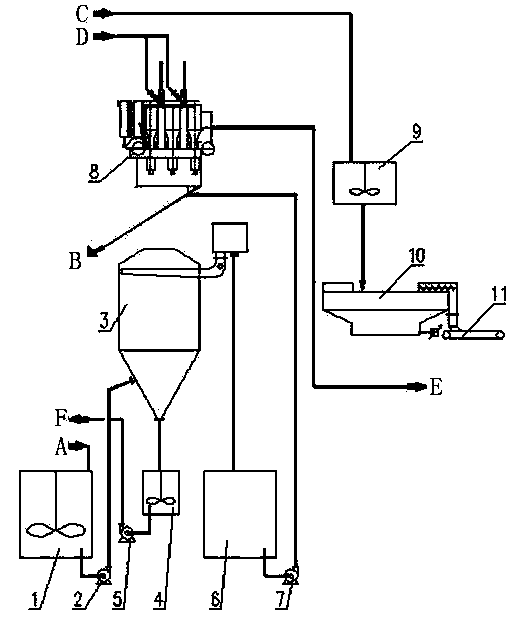

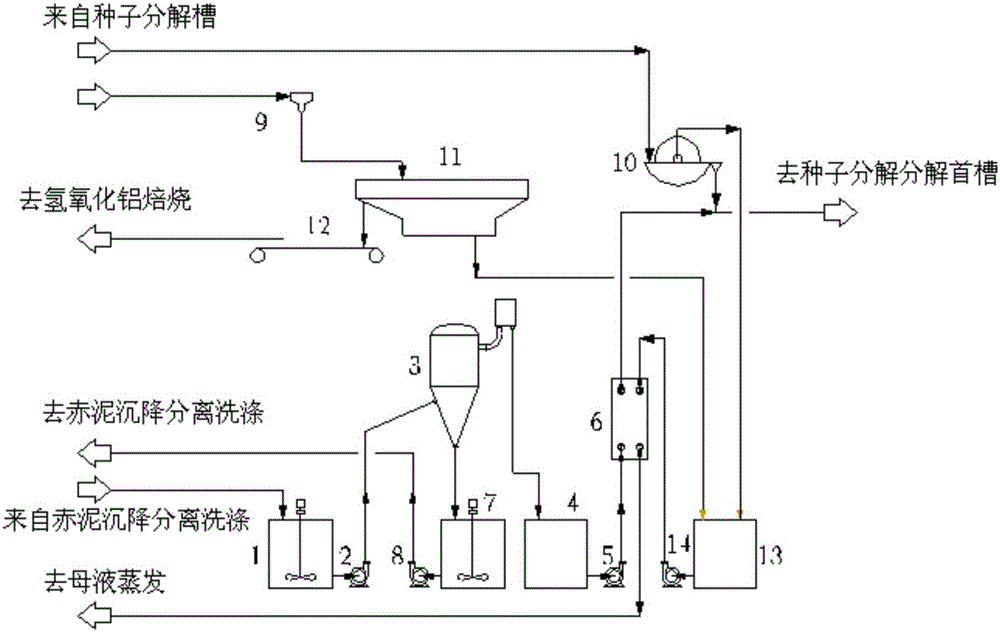

Filtration-integration integrated plant and method for producing aluminum oxide by Bayer process

The invention belongs to the field of mineral processing, and particularly relates to a filtration-integration integrated device and method for producing aluminum oxide by a Bayer process. In the device, a crude liquid tank is connected with a leaf filter through a crude liquid pump, the bottom of the leaf filter is connected with a filter cake tank, and the upper part is connected with a fine liquid tank; the bottom of the fine liquid tank is provided with a fine liquid pump; the fine liquid pump is connected with a vertical disk filter; the filter cake tank is arranged on a 5.000 plane; the lower part of the filter cake tank is provided with a filter cake pump; an aluminum hydroxide slurry tank is arranged above a horizontal disk filter; and the horizontal disk filter is connected with a belt conveyor. The device for aluminum oxide filtration provided by the invention implements filtration-integration integration. The invention reduces the crystal seed tank, mixing unit and other units in the existing device, reduces the corresponding pipelines, valves, pipe fittings and the like, reduces the equipment maintenance and maintenance work load in the device operation process, saves the energy, and lowers the production and labor cost.

Owner:NORTHEASTERN UNIV ENG & RES INST CO LTD +1

Comprehensive filtering process during aluminum oxide production

The invention discloses a comprehensive filtering process during aluminum oxide production. The comprehensive filtering process includes the steps of firstly, rough liquid from a red mud settling separation washing procedure enters a leaf filter through a rough liquid tank and a rough liquid pump; secondly, fine liquid after filtration enters a plate type heat exchanger through fine liquid pump to exchange heat with mother liquor from the mother liquor tank of a seed filtering procedure; thirdly, the bottom flow of the cyclone device of a seed decomposition procedure flows to a flat-plate filter; fourthly, mother liquid obtained through a vertical-plate filter and the flat-plate filter flows to a seed filtering mother liquor tank; fifthly, aluminum hydroxide obtained by the filtering of the flat-plate filter is conveyed to an aluminum hydroxide calcining procedure by a belt conveyor; sixthly, filter cake obtained by the filtering of the leaf filter is conveyed to the red mud settling separation washing procedure. The comprehensive filtering process has the advantages that the procedures are centralized, process flow is shortened, buffer equipment is reduced, and production cost is lowered; centralizing of equipment such as a vacuum pump and an air compressor is achieved, and mutual standby application of equipment is achieved to a certain degree.

Owner:SHENYANG ALUMINIUM MAGNESIUM INSTITUTE

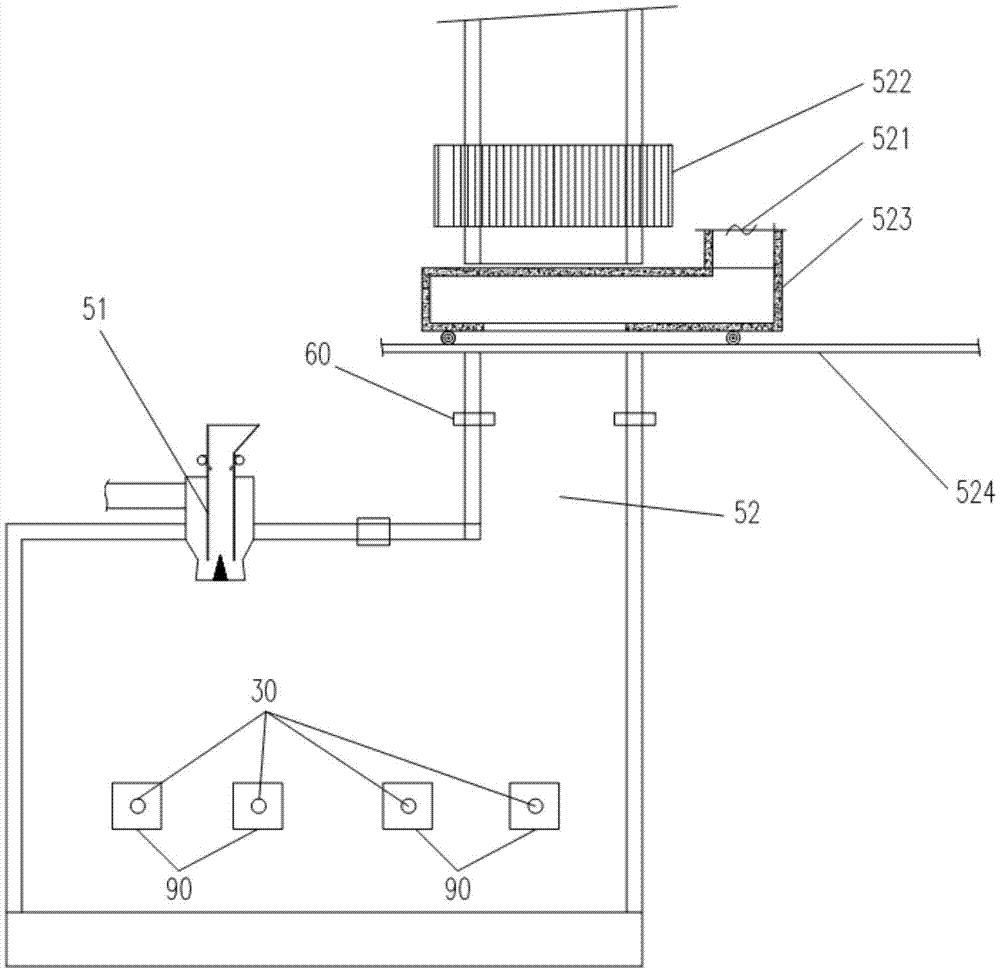

Automatic unloading and warehousing system for pretreatment workshop

PendingCN112875337AReduce manual unloadingReduce labor capacityLoading/unloadingTruckManufacturing engineering

The invention discloses an automatic unloading and warehousing system for a pretreatment workshop. The automatic unloading and warehousing system comprises a truck identification sensor, an automatic unloading device, an unloading pit, an automatic material transportation system, a storage bin and a control system, wherein the unloading pit is mounted at the rear end of the automatic unloading device; the automatic material transportation system is connected with the unloading pit and the storage bin; the automatic material transportation system is arranged above the storage bin; and the truck identification sensor, the automatic unloading device and the automatic material transportation system are connected with the control system. Automatic unloading and warehousing of materials are achieved, the labor intensity of workers is reduced, and the production efficiency is improved.

Owner:SUZHOU INST OF INDAL TECH

A Catenary Conveying System for Anode Carbon Blocks

InactiveCN106315169BImprove automationImprove mechanical propertiesConveyor partsMechanical conveyorsEconomic benefitsChain conveyor

The invention relates to an anode carbon block conveying system and in particular provides an anode carbon block suspended chain conveying system between an anode carbon block warehouse and an anode assembly workshop of an electrolytic aluminum enterprise. A carbon block conveying gallery is arranged between an anode assembly workshop and an anode carbon block warehouse; an assembly workshop carbon block conveyor and a carbon push-out device are arranged in the anode assembly workshop; a carbon block warehouse carbon block conveyor and a carbon block push-in device are arranged in the anode carbon block warehouse; a suspension type suspended chain conveyor is arranged in the carbon block conveying gallery; lifting tools are arranged under the suspension type suspended chain conveyor. The system can reduce the manpower quotas of enterprises, increase the labor productivity of the enterprises, reduce the engineering construction and production operating costs, reduce the electrolytic aluminum production cost and bring certain economic benefits for the enterprises.

Owner:SHENYANG ALUMINIUM MAGNESIUM INSTITUTE

A method for treating regenerated lead using an improved side-blown smelting reduction furnace

The invention provides a method for treating secondary lead through an improved side-blowing smelting reduction furnace. The method comprises the steps that the secondary lead is put into the improved side-blowing smelting reduction furnace, meanwhile, a smelting agent is added, oxygen-enriched gas, a reduction agent and fuel are sprayed into a smelting pool mixing area of the smelting reduction furnace at the flow speed of 180-280 m / s through multichannel spray guns on the two sides of the smelting reduction furnace, so that materials in the smelting reduction furnace are subjected to a smelting reduction reaction, and wet lead and smelting slag are generated; the wet lead and the smelting slag are included in the smelting pool mixing area at the same time; and the smelting slag is discharged out of a slag outlet of the smelting reduction furnace, and the wet lead is discharged out of a metal discharge opening of the smelting reduction furnace. The method for smelting the secondary lead is compact in procedure, small in fixed number of workers, environment-friendly and low in production cost.

Owner:CHINA ENFI ENGINEERING CORPORATION

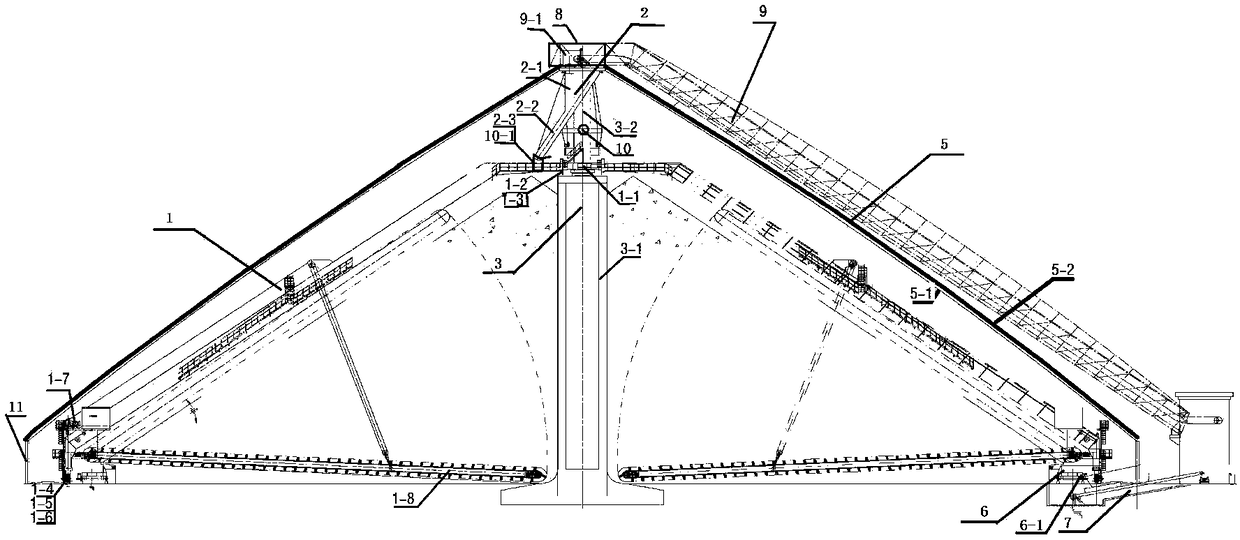

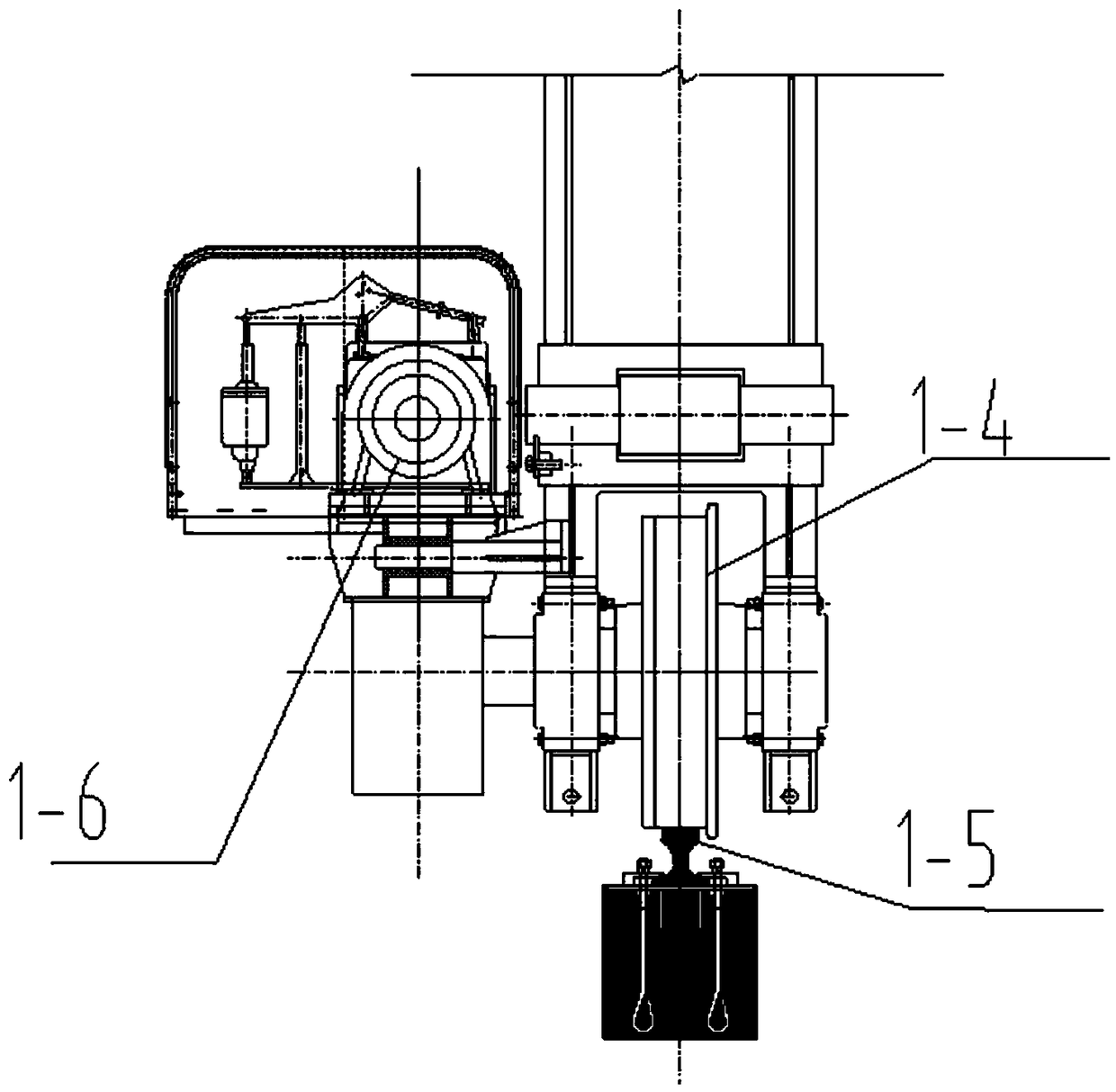

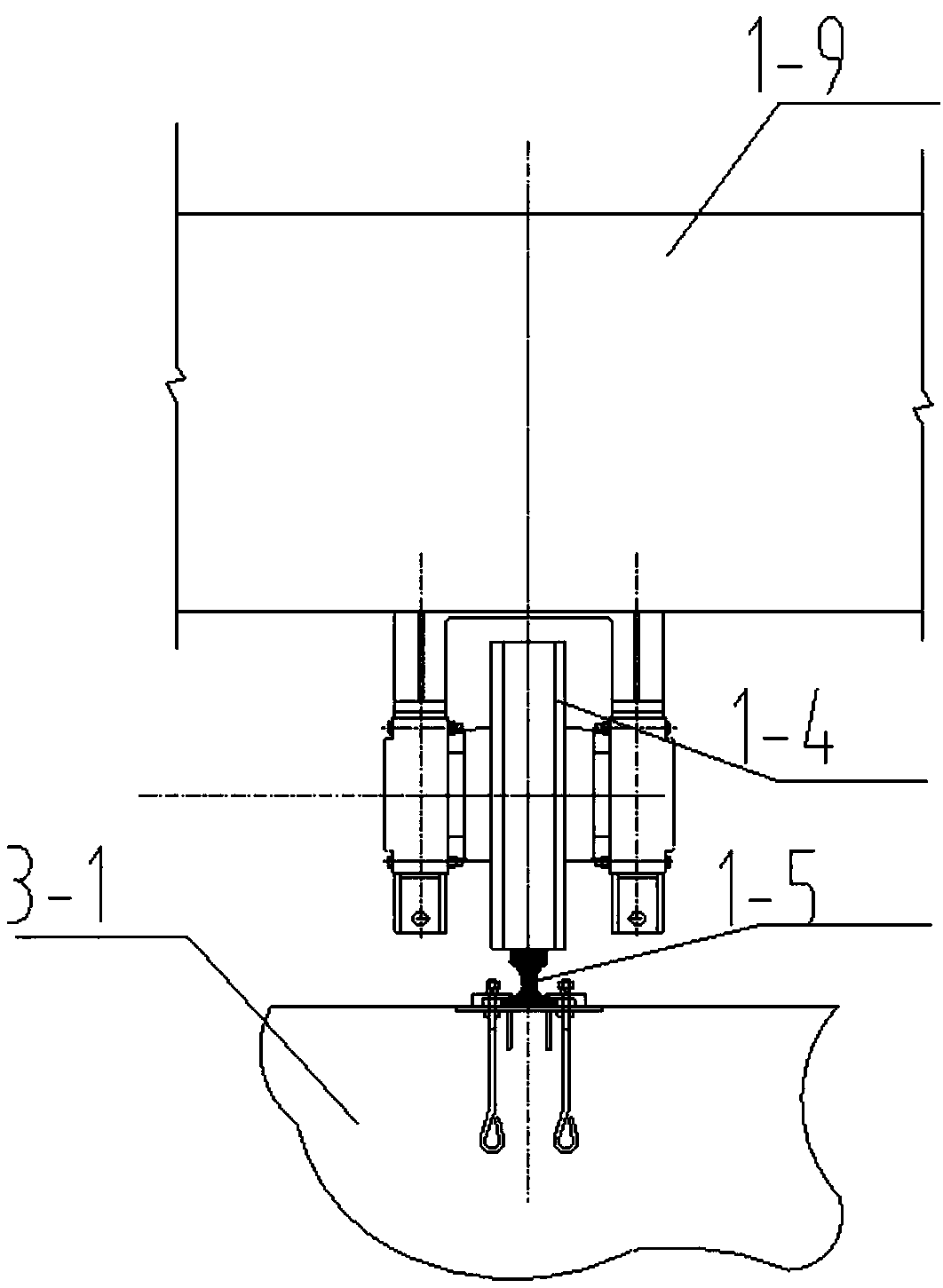

A conical environmental protection stockyard

The invention discloses a conical environment-friendly material field with a sealed cover, and belongs to the technical field of bulk material storage and conveying facilities. The conical environment-friendly material field comprises a scraping plate material taking machine (1), a rotary material distributor (2), a center upright post (3), an annular transfer machine (6), an adhesive tape output machine (7), a transfer station (8), an adhesive tape input machine (9) and an enclosing wall (11), wherein the center upright post (3) is positioned in the center of the material field; the rotary material distributor (2) is connected and fixed with the upper part of the center upright post (3) in a sleeving way; the transfer station (8) is arranged above the rotary material distributor (2); the adhesive tape input machine (9) is connected with the transfer station (8); the top end of the scraping plate material taking machine (1) is positioned under the rotary material distributor (2), and is rotationally connected with the upper part of the center upright post (3); the bottom end of the scraping plate material taking machine (1) is positioned above the annular transfer machine (6); the annular transfer machine (6) is positioned above the adhesive tape output machine (7). The material field is applicable to material storage, piling and taking operation of various bulk materials.

Owner:北京市工业设计研究院有限公司 +1

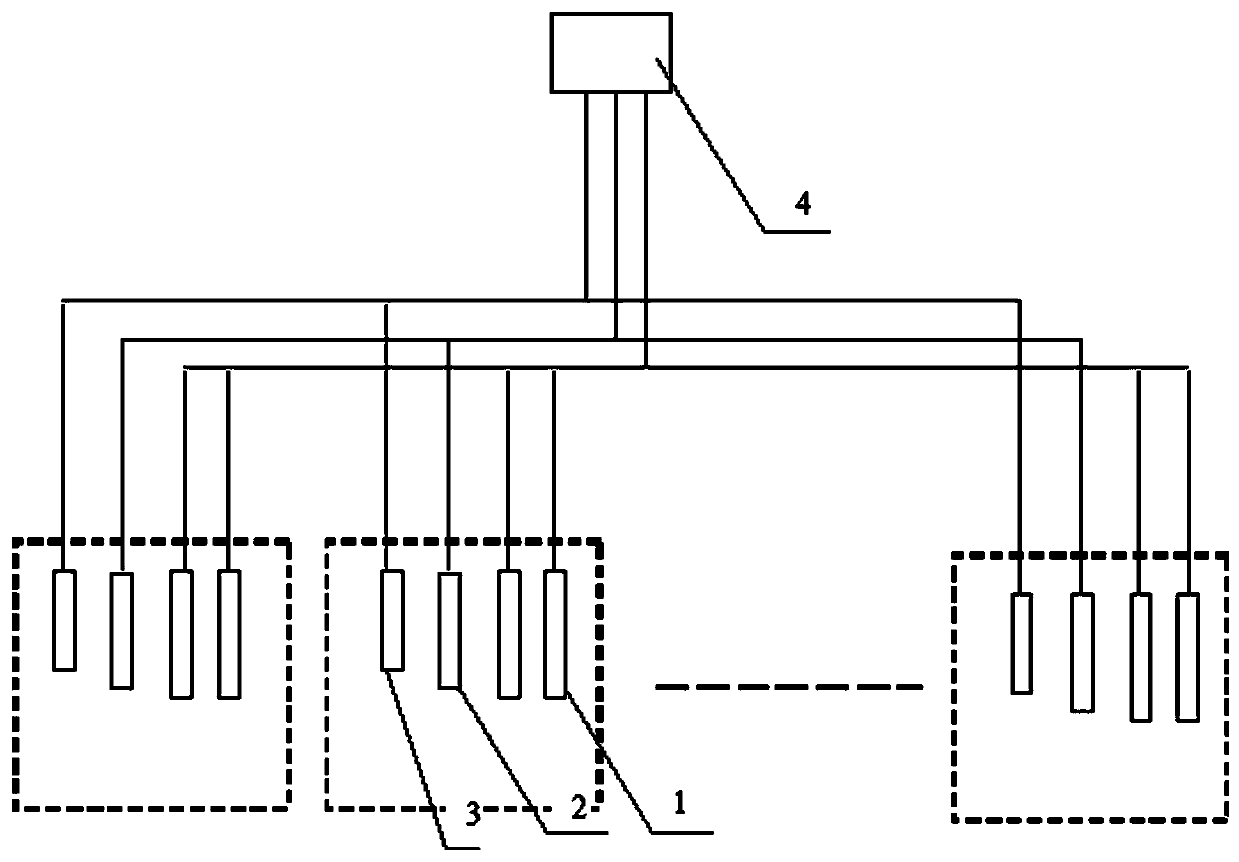

Automatic temperature control system for tank furnace

ActiveCN107238283BImprove production stabilityImprove uniformityVertical furnacesAutomatic controlControl system

The invention relates to a pot calciner, in particular to a pot calciner flue temperature automatic control system. The pot calciner flue temperature automatic control system comprises bottom layer local control systems and an upper layer central control system. Each pot calciner in a calcinating workshop is provided with one local control system. The local control systems are connected to the upper layer central control system through a network communication system, so that unified management and control over the bottom layer systems are achieved. The pot calciner flue temperature automatic control system has the advantages and effects that temperature distribution of all flues of each pot calciner in the calcinating workshop is precisely controlled, and further, and unified management for all detection and control data of the whole workshop can be achieved; and the system can be used for replacing manual temperature regulation, decreasing the manpower quota and improving the pot calciner production stability and product quality uniformity, furthermore, fluctuations of flue temperatures within target ranges can be precisely controlled, the overheating phenomenon is prevented, and the service lives of the pot calciners are greatly prolonged.

Owner:SHENYANG ALUMINIUM MAGNESIUM INSTITUTE

A low-cost cold-rolled magnetic pole steel with a yield strength of 450mpa and high magnetic induction and its manufacturing method

Owner:BAOSHAN IRON & STEEL CO LTD

Multi-screw extrusion device and refining method for refining and molding recycled rubber powder

ActiveCN105599166BImprove the level of automation technologySolve the pollution problemMetallurgyHigh intensity

The invention relates to a multiple-screw extruding device for refining forming of regenerated rubber powder and a regeneration method, and adopts special screws to distribute homodromous / heterodromous parallel structures, triangular structures and cylindrical structures. Through the decomposing of traditional technical effect, closed and continuous refining forming of regenerated rubber powder is realized through different types of thread elements, and the disadvantages of serious pollution, low labor efficiency, high intensity and low automation degree of the traditional open production technology are effectively avoided.

Owner:CHINA RUBBER RESOURCE REGENERATION QINGDAO

Technique method of thin middle plate continuous casting and rolling production

ActiveCN101391264BIncrease production capacityFull production capacityTemperature control deviceFurnace typesThick plateSingle plate

The invention belongs to the technical field of molding, in particular to a technique method of thin plate continuous casting and tandem rolling, namely effective thin plate process (ETPP). The invention is composed of a conticaster and a rolling mill. Casting plate blanks are broken by the conticaster, a heating furnace is adopted to heat the plate blanks to a set temperature 1050-1200 DEG C, and then the plate blanks are delivered out through a roller way; iron scale on the surface of the plate blanks is removed by high-pressure water; the plate blanks are rolled by the rolling mill set andare performed with laminar flow cooling through a laminar flow cooling device; the slab bands are cooled to a target temperature of 550-780 DEG C and are coiled by a recoiling machine; and the rolling finished products can be delivered in whole coils or can be delivered through being cut into single plate or single stack by a transverse cutting unit. The process flow of the invention has simple equipment components, high production efficiency and little investment. The process of the invention can be applied to the construction of a newly-built or reconstructive medium-thick plate rolling mill.

Owner:CISDI ENG CO LTD

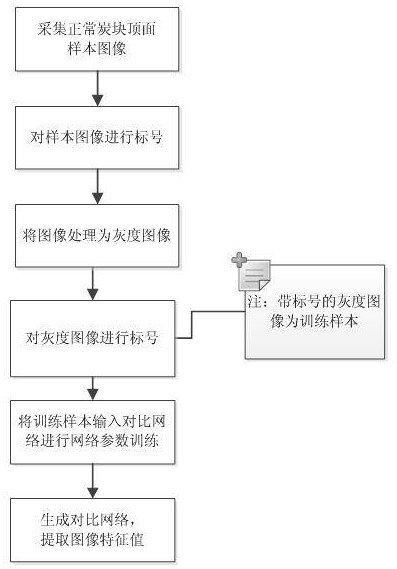

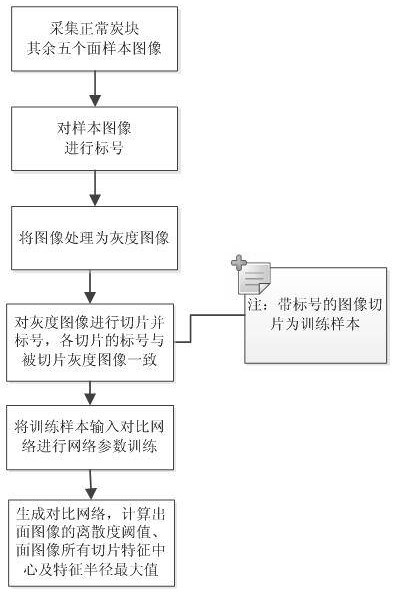

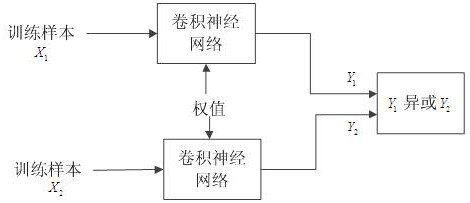

A detection method of raw anode carbon block based on machine vision

ActiveCN109239074BReduce labor capacityThe test result is accurateOptically investigating flaws/contaminationMachine visionMolding machine

Owner:CHINA ALUMINUM INT ENG CORP

Technique for purifying crude gas from gas making stove for coal dry distillation

ActiveCN100463953CReduce resistanceEliminate the ills that spread into the atmosphereCombustible gas purificationTarAmmonia

Owner:鞍钢集团工程技术有限公司

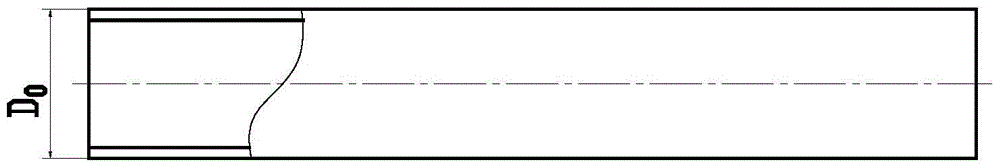

Integral thermal expansion manufacturing method for heavy-duty vehicle drive axle housing

The invention discloses an overall thermal expansion manufacturing method for a heavy-duty car drive axle housing, and overcomes the problems that currently, material utilization rate is low, machinery processing load is heavy, the punching and welding production process chain is long, welding workload is heavy, product rigidity is low, and service life is short. The method includes 1, determining the structural size of a used billet, namely selecting the appropriate expansion ratio according to geometrical features and size parameters of an axle housing to be processed, determining the diameter of the specification of the billet to be D0, the wall thickness to be H0 and the length to be L0; 2, preforming the billet before thermal expansion; 3, cutting prefabricated hole in the middle of the preformed billet, namely cutting axial elongated prefabricated through holes in the bedding face after the middle of the billet is flattened and allowing an upper prefabricated through hole and a lower prefabricated through hole to be centered; 4, preforming in the manner of thermal expansion; 5, forming in the manner of thermal expansion; 6, shaping, namely eliminating drive axle housing lute holes and unrounded degree of a lateral flange after twice thermal expansions and allowing the radius of the large arc of an axle housing transition area to be 200mm.

Owner:JILIN UNIV

A Field Mixed Explosive Charging Equipment

ActiveCN104990468BReduce labor intensityReduce labor capacityBlastingPiston rodElectrical and Electronics engineering

The invention relates to scene explosive mixed loading equipment. The scene explosive mixed loading equipment comprises a chassis, a substrate cabin, a sensitizer box and a pumping system, wherein the substrate cabin and the sensitizer box are connected with the pumping system; the pumping system comprises a substrate pump, a sensitizer pump, a connecting rod, a pin shaft, a bracket, a connecting block, a mounting plate and a bolt; a piston rod of the substrate pump is connected with the connecting rod through the pin shaft; the other end of the connecting rod is connected with the bracket through the pin shaft; the connecting block is arranged at the middle part of the bracket; and the sensitizer pump is mounted on the connecting block. The scene explosive mixed loading equipment is simple in structure and continuous in feeding, and greatly reduces the labor intensity of workers when greatly improving the loading efficiency.

Owner:HUNAN KENON SCI & TECH

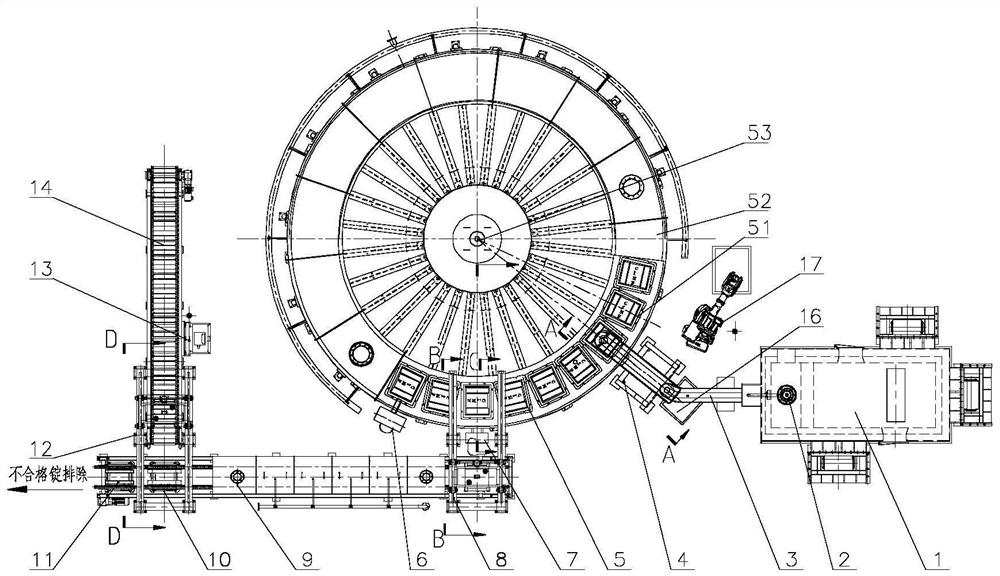

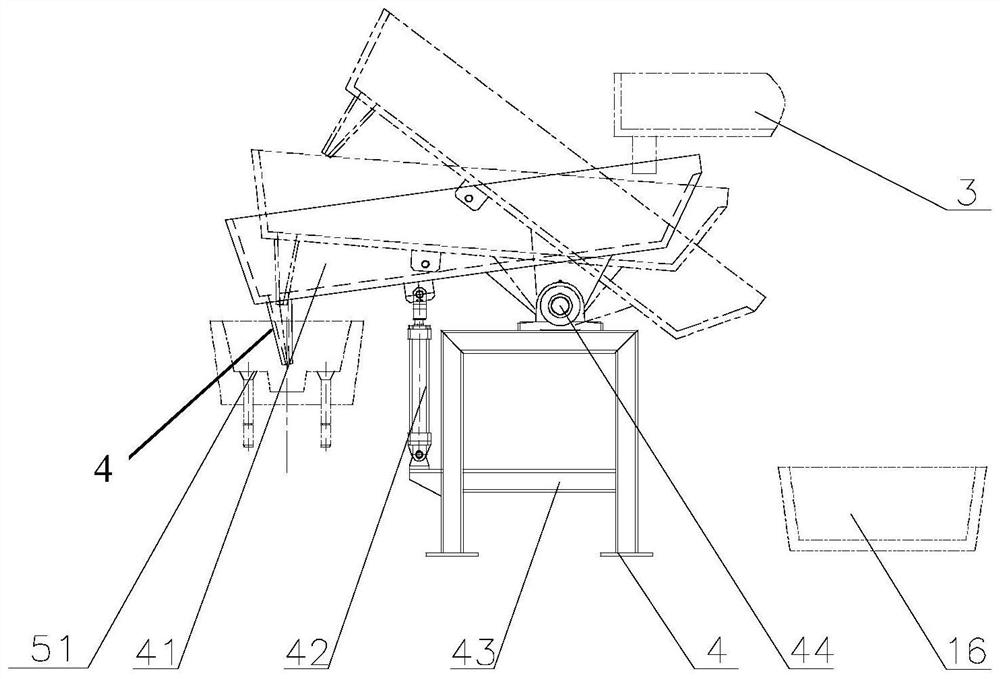

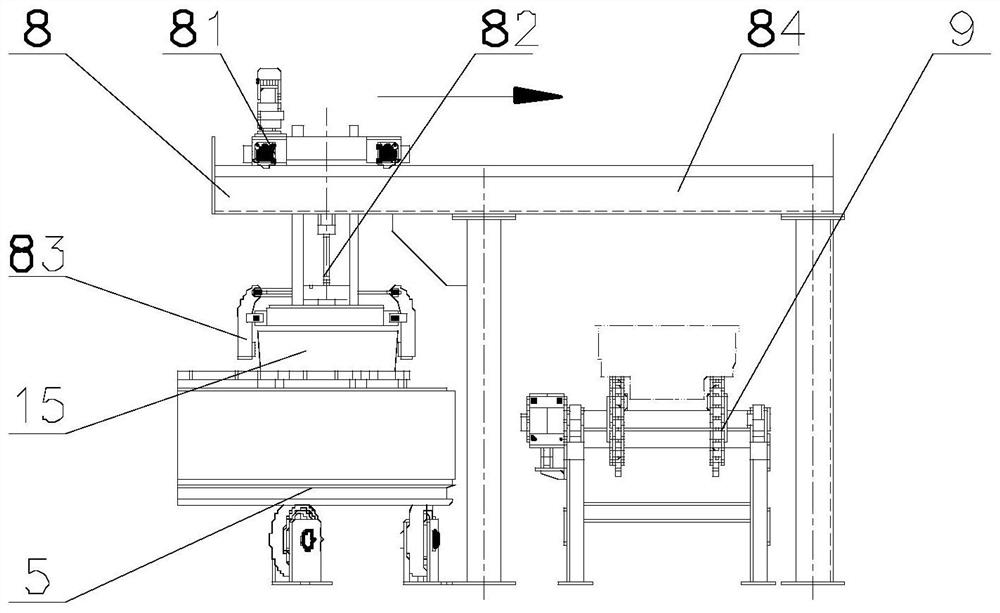

Casting device, ingot casting system and ingot casting method

ActiveCN109676094BHigh degree of automationImprove ingot casting efficiencyIngot casting plantsMolten metal conveying equipmentsIngot castingStructural engineering

The invention relates to a casting device, an ingot casting system and an ingot casting method. The casting device includes a first frame and a first bucket with an open top, the bottom of the first bucket is provided with a hinged seat and a casting nozzle connected with the first bucket, the hinged seat is hinged with the first frame, and the casting nozzle A mold for molding is provided below; a first linear drive part is also included, the lower end of the first linear drive part is hinged to the first frame, and the upper end of the first linear drive part is hinged to the first bucket. The casting device and the ingot casting system of the present invention have a high degree of automation and high ingot casting efficiency; manual stripping is not required, and labor capacity is reduced; the ingot casting system of the present invention has a compact structure and a small footprint.

Owner:CINF ENG CO LTD +1

Bin level measuring device

ActiveCN102951456BImprove working environmentReduce labor capacityLarge containersLoading/unloadingAutomatic controlWorking environment

The invention relates to a measuring device and particularly relates to a box chamber material level measuring device. The box chamber material level measuring device comprises a sensing mechanism which comprises a rocker, a sensor and a fixed base, wherein the rocker is hinged with the fixed base and swings around the fixed base; the sensor is arranged on the fixed base; the sensor can be triggered through the swinging of the rocker; and the sensing mechanism synchronously moves with a discharger of a box chamber material distribution device in a length direction of the box chamber. The box chamber material level measuring device provided by the invention can be used for automatically detecting a material position, so that fixed personnel can be reduced, the automatic control on a discharging process can be realized, the efficiency is high, the charging quality is good, and a working environment of workers can be improved.

Owner:JINING CITY CUSTOMKEY ELECTROMECHANICAL TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com