Scene explosive mixed loading equipment

A technology for mixing explosives and charges on site, which is applied in mine charge blasting and mining mining, can solve the problems of uneven charging and feeding, discontinuous charge, and uneven material-gas ratio, etc., and achieve low labor intensity, The effect of increasing the charging efficiency and accurate mixing ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings.

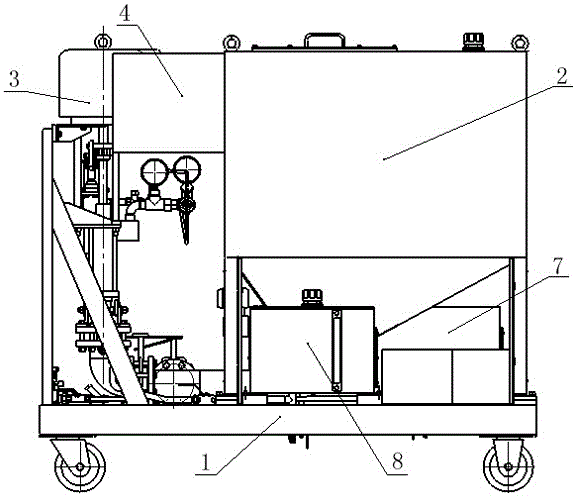

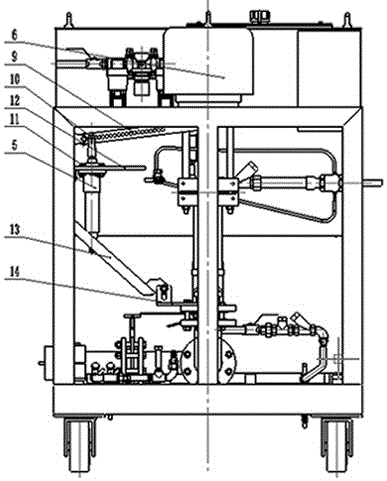

[0020] Such as figure 1 , figure 2 As shown, an on-site mixed explosive charging equipment includes an underframe 1, a matrix silo 2, a sensitizer box 7, and a pumping system 3. The base material bin 2 is installed on the upper part of the chassis 1, and the sensitizer box 7 is arranged at the middle and lower part of the chassis 1.

[0021] The pumping system 3 includes a substrate pump 6 , a sensitizer pump 5 , a connecting rod 9 , a pin shaft 10 , a bracket 13 , a connecting block 12 , a mounting plate 14 , and bolts 11 . The piston rod of the matrix pump 6 is connected with the connecting rod 9 through the pin shaft 10 , and the other end of the connecting rod 9 is connected with the bracket 13 through the pin shaft 10 , and can make the connecting rod 9 move around the upper part of the bracket 13 . A connecting block 12 is provided in the middle of the bracke...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com