Patents

Literature

35results about How to "Guaranteed mix ratio" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

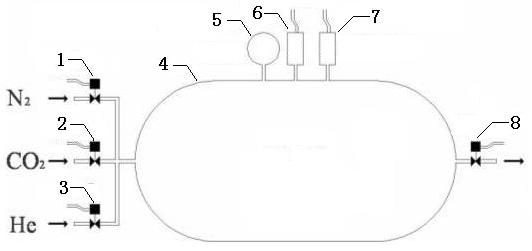

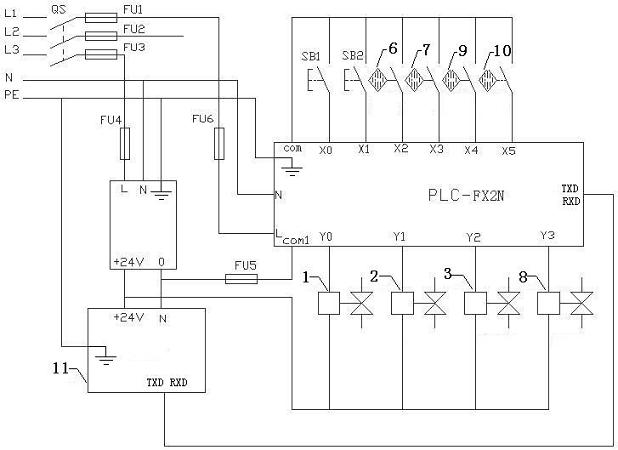

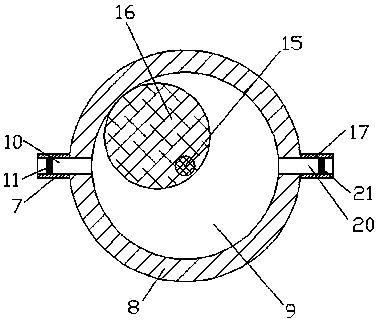

Method and device for mixing various gases according to specified proportion

InactiveCN102631846AGuaranteed mix ratioStable jobLaser detailsMixing gases with gases/vapoursSolenoid valveEngineering

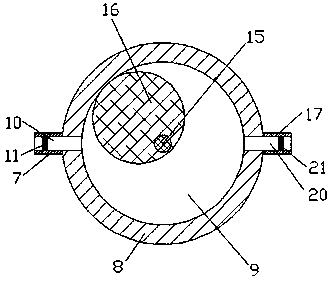

The invention relates to a fast-flow axial CO2 laser, particularly relates to a method and device for mixing gases, and particularly provides a method and device capable of supplying a proper gas proportion to the split-type air supply fast-flow axial CO2 laser. The invention firstly provides solenoid valves which are of the same type and consistent in path flow. The method and the device provided by the invention can control the mixing proportion of various gases according to opening time or opening frequency of different solenoid valves. According to the method and the device provided by the invention, the inconsistency of the path influence on the solenoid valves can be effectively reduced through expansion caused by heat and contraction caused by cold, so as to further reduce the influence caused by heat and contraction caused by cold on the component proportion of mixed gases.

Owner:JIANGSU UNIV

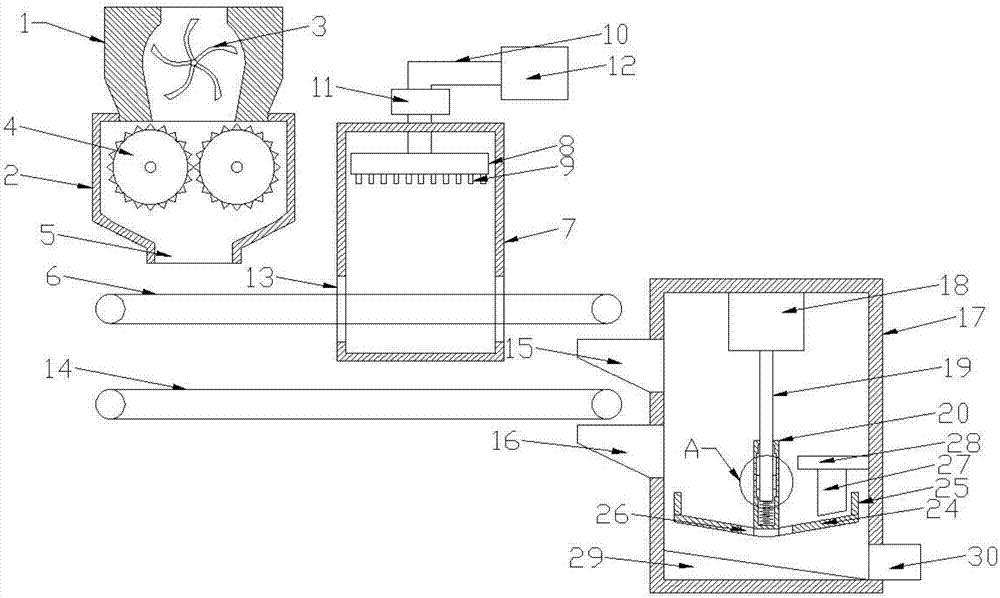

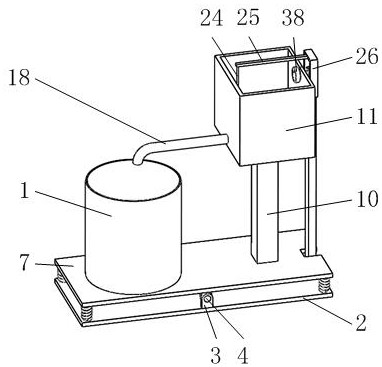

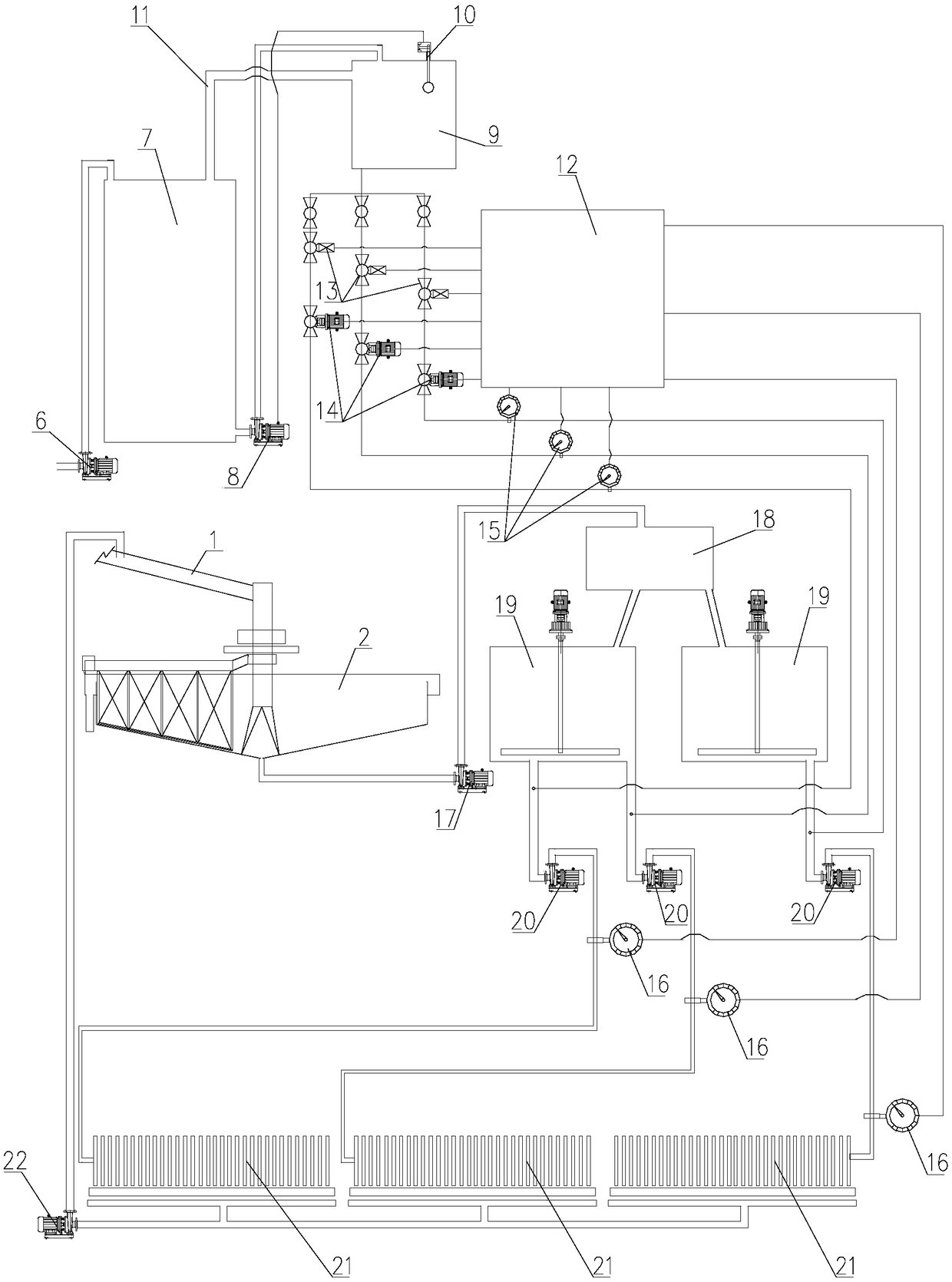

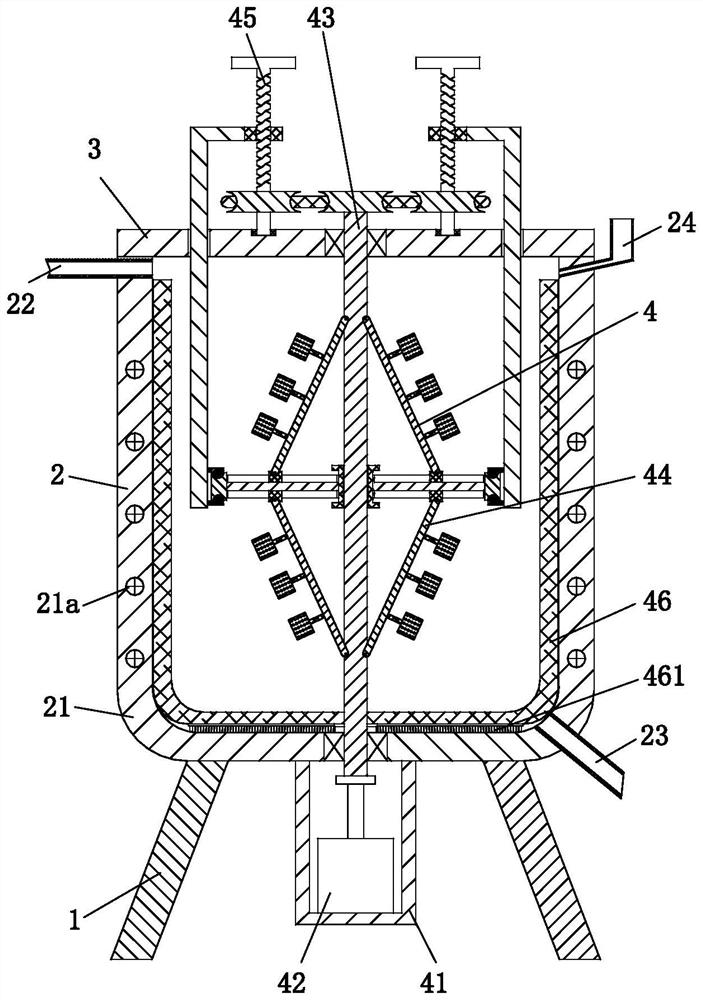

Straw crushing and mixing device for breeding

The invention discloses a straw crushing and mixing device for farming, which comprises a feeding hopper, a crushing box and a mixing box; several cutting blades are installed in the feeding hopper; A horizontal straw conveyor belt is installed below the feeding port, an atomization box is arranged on the right side of the crushing box, and a horizontal feed conveyor belt is arranged below the straw conveyor belt; the lower end of the rotating shaft covers A sleeve is provided, a vertical spring is fixed at the lower end of the rotating shaft, and a vertical chute is provided on the inner wall of the sleeve; a receiving tray is fixed at the lower end of the sleeve; the crushed straw surface There is water vapor attached to it, which can adhere to the feed during mixing, and evenly mix the feed with straw fragments to ensure the mixing ratio of feed and straw; the feeding tray can also move up and down while rotating, so as to realize the vibration of the feeding tray and shake the raw materials. Fall, to facilitate the whereabouts of materials.

Owner:刘志坚

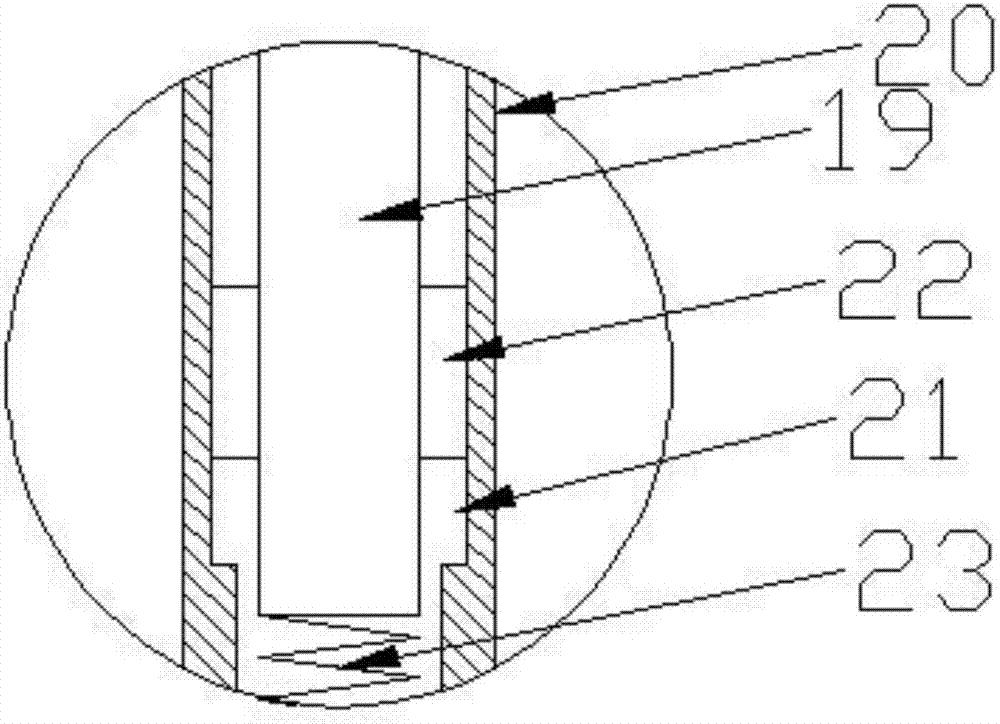

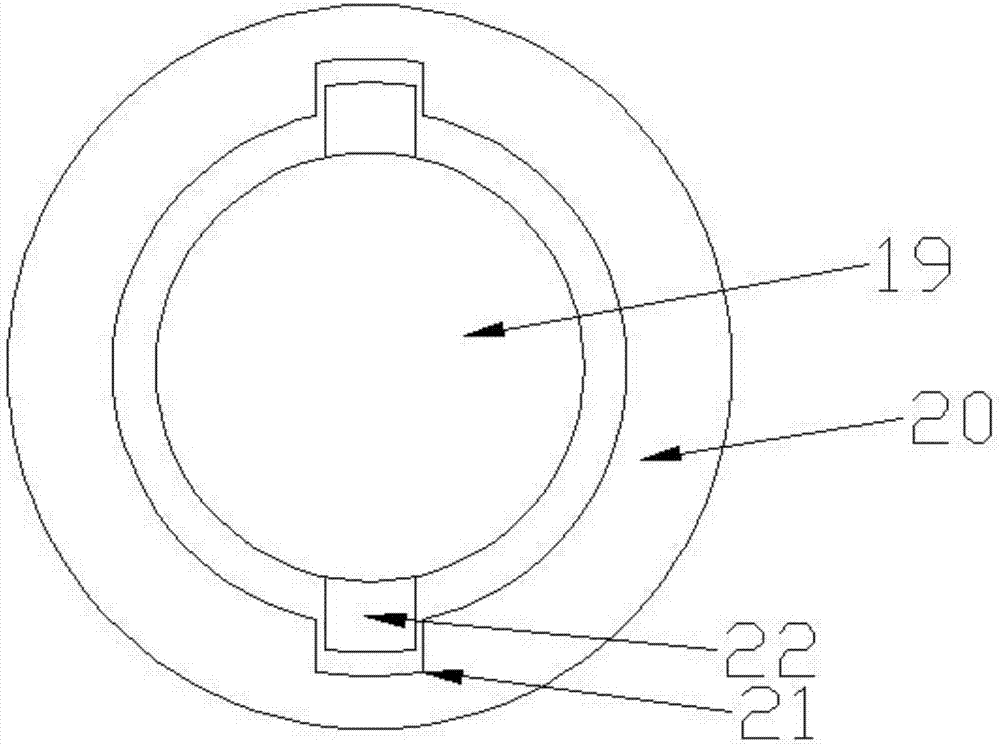

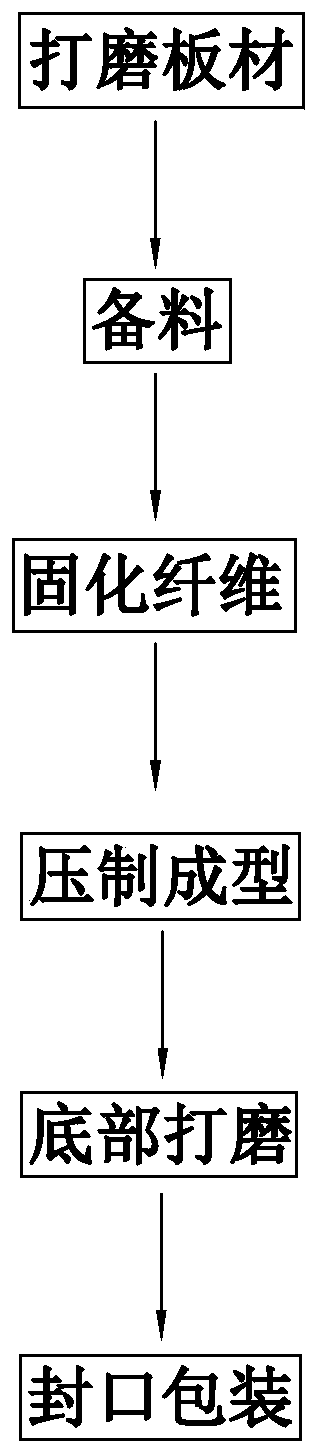

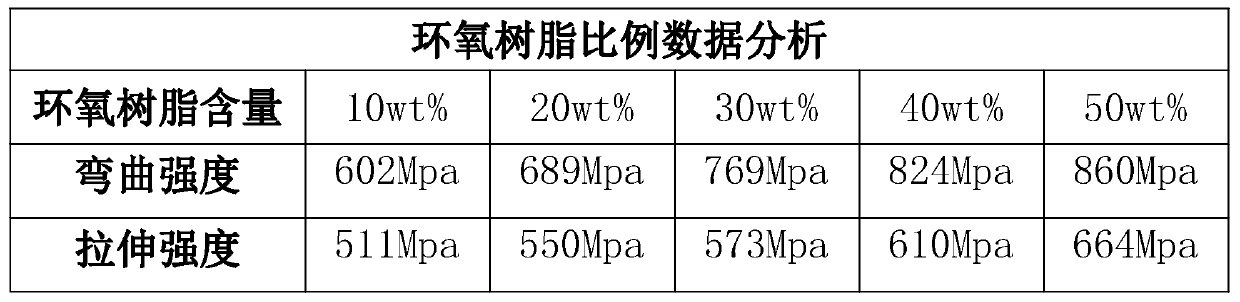

Manufacturing method of snowboard

The invention discloses a manufacturing method of a snowboard. The snowboard sequentially comprises a bottom board, a lower glass fiber board, a board core, an upper glass fiber board and a panel frombottom to top. The production method comprises the following steps: 1, grinding the bottom plate, the plate core and the face plate to the specified thickness and width according to the drawing size;2, preparing glass fibers and epoxy resin, then weighing the epoxy resin and the glass fibers, and keeping the weight ratio of the epoxy resin to the glass fibers at 13: 7; 3, flatly laying the glassfiber cloth on a workbench, uniformly brushing epoxy resin on the glass fiber cloth, putting the glass fiber cloth into a hot press for curing after uniformly smearing, and extruding 20wt% of epoxy resin in the extrusion process; and 4, evenly smearing epoxy resin glue between all layers of materials of the snowboard, placingthe snowboard into a hot press to be extruded after being evenly smeared, and fixing and forming the snowboard along with curing of the epoxy resin. The snowboard has the advantage that the mechanical property of the snowboard is enhanced.

Owner:AOXUE CULTURE COMM BEIJING CO LTD

Immobilized nutrient soil particle as well as preparation method and application thereof

InactiveCN112430172ALoose structureConducive to cultivationExcrement fertilisersBioloigcal waste fertilisersMicrobial agentNutrition

The invention discloses an immobilized nutrient soil particle as well as a preparation method and application thereof, belonging to the technical field of soil. The immobilized nutrient soil particlespecifically comprises the following raw materials in parts by weight: 20-100 parts of river sediments, 10-50 parts of an organic fertilizer, 1-30 parts of a microbial agent and 1-30 parts of a chemical fertilizer. The preparation method comprises the following steps: uniformly mixing the decomposed organic fertilizer with the microbial agent, the dehydrated river sediments and the chemical fertilizer, and successively conducting granulating, drying and hardening to obtain the immobilized nutrient soil particle. When the nutrient soil particle is used, the nutrient soil particle is uniformly spread on the surface of desertified soil, and then turf is spread on the surface of the immobilized nutrient soil particle. According to the method, rich trace elements such as Ca, Mg, Zn, Cu and Fe and organic matters contained in the sediments can be returned to natural environment for circulation again, so an effective way is provided for recycling of the river sediments, and meanwhile, an effective solution is provided for recovery of barren soil and desertified soil.

Owner:天津市滨海新区环境创新研究院

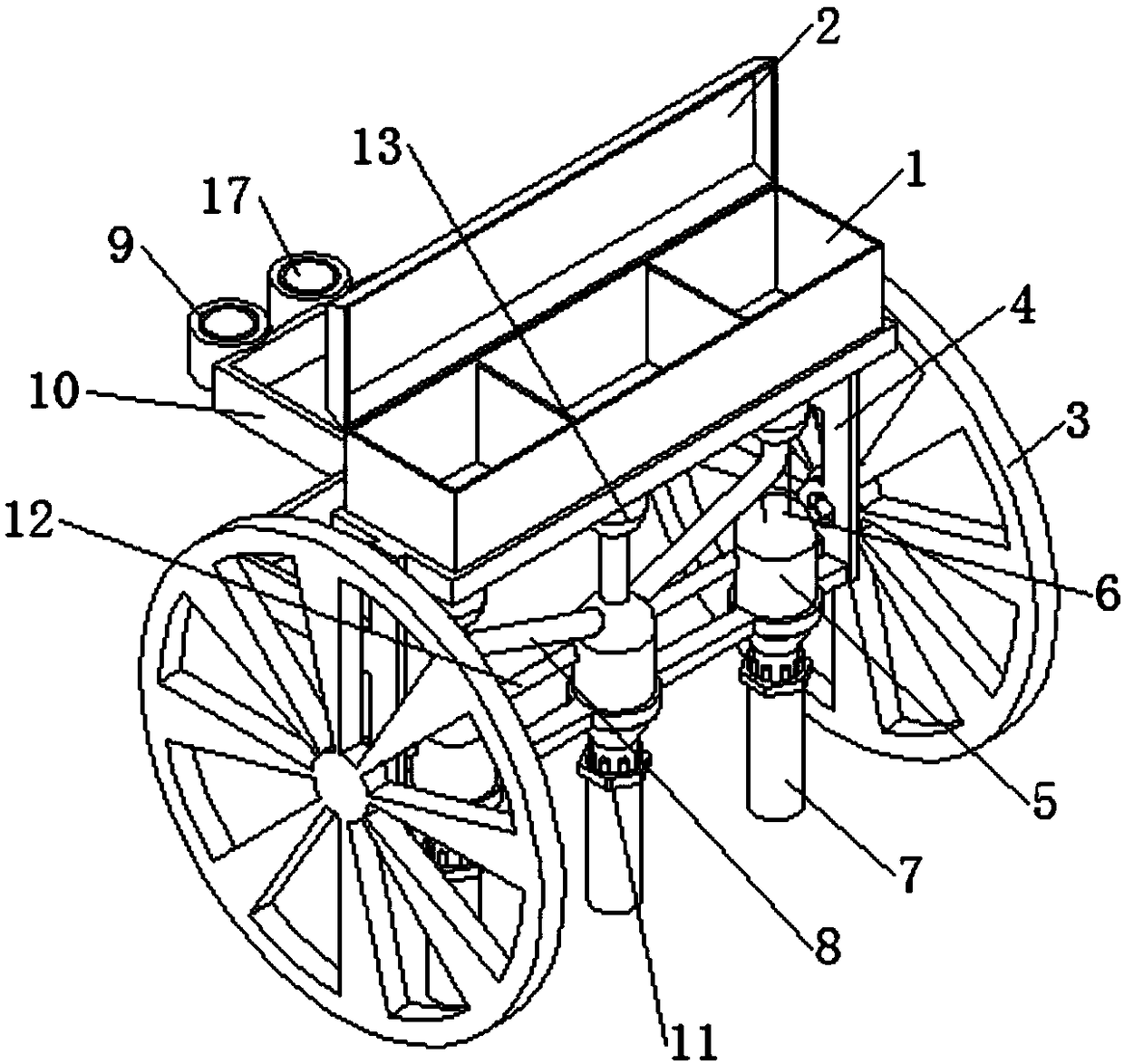

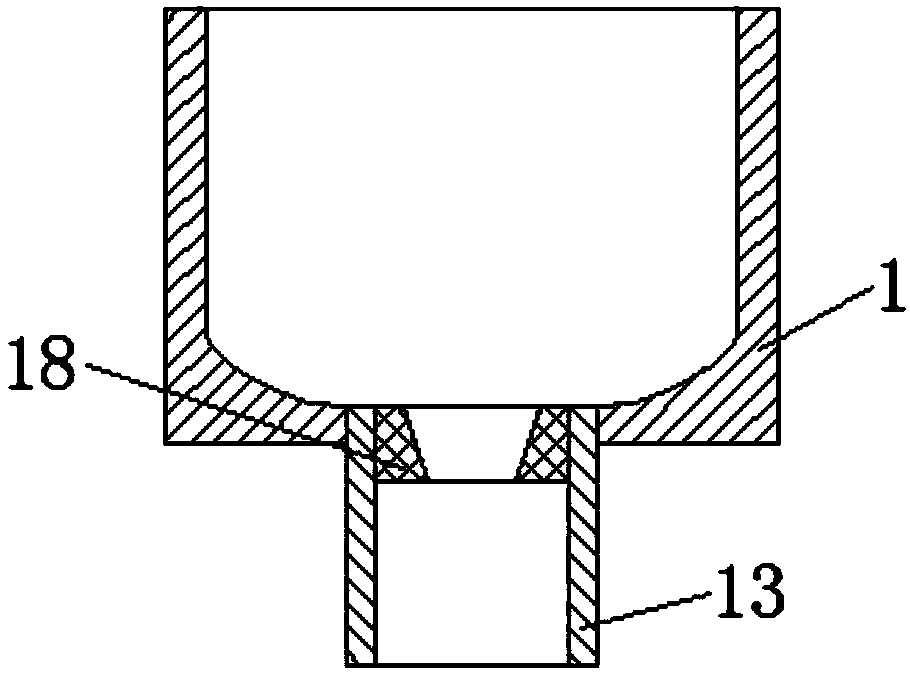

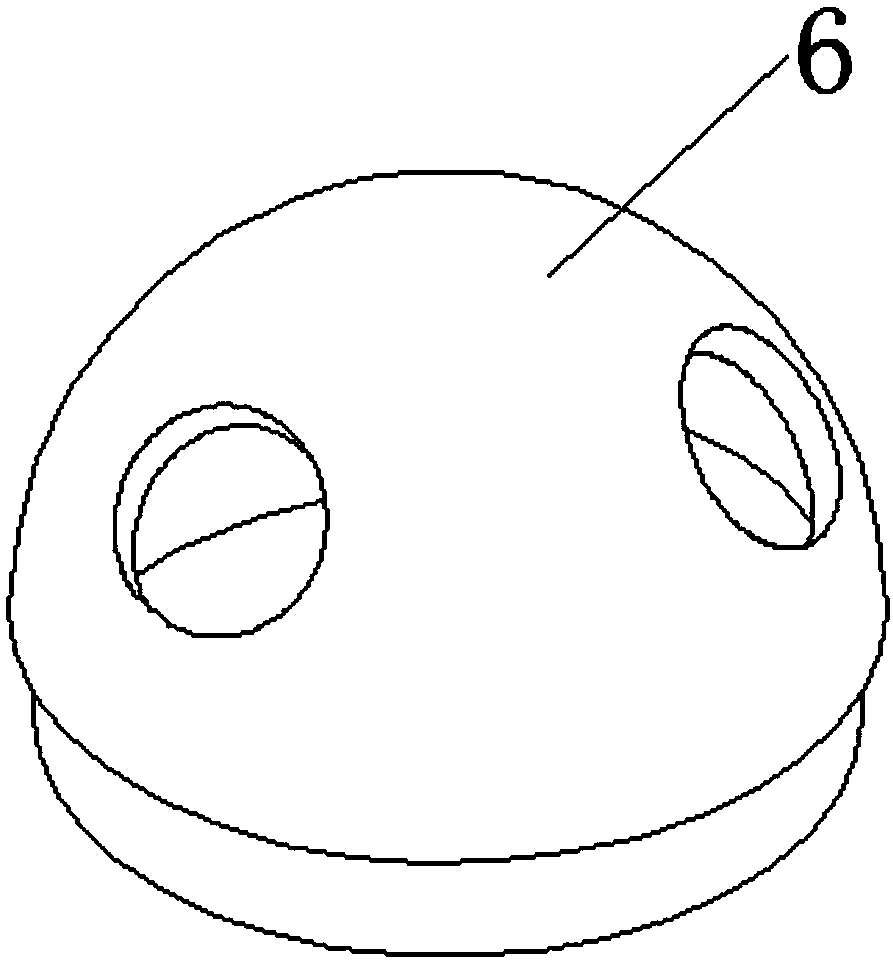

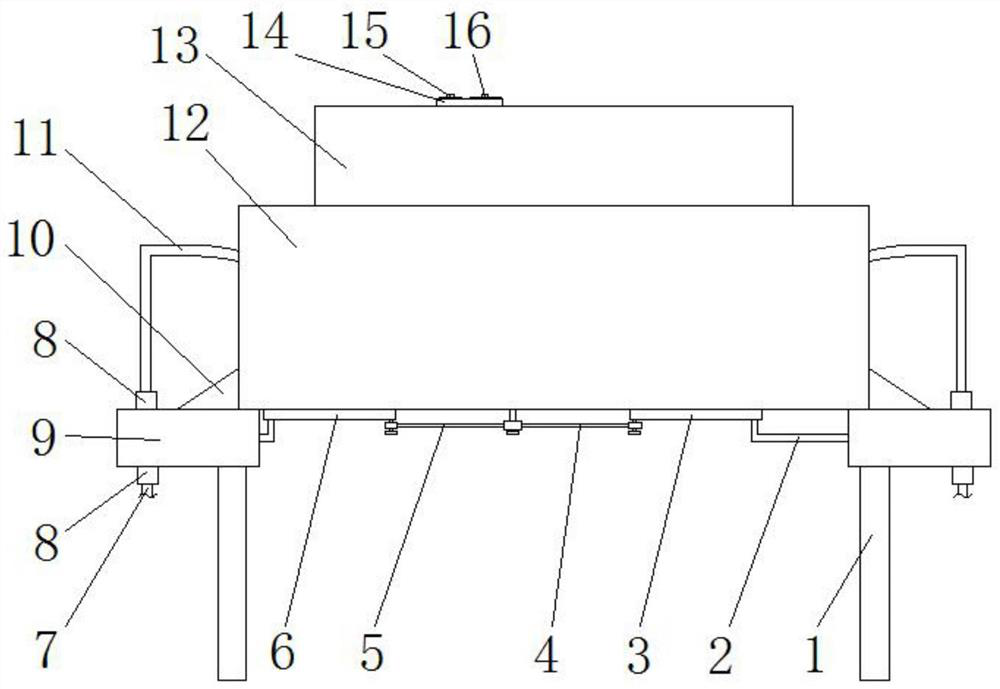

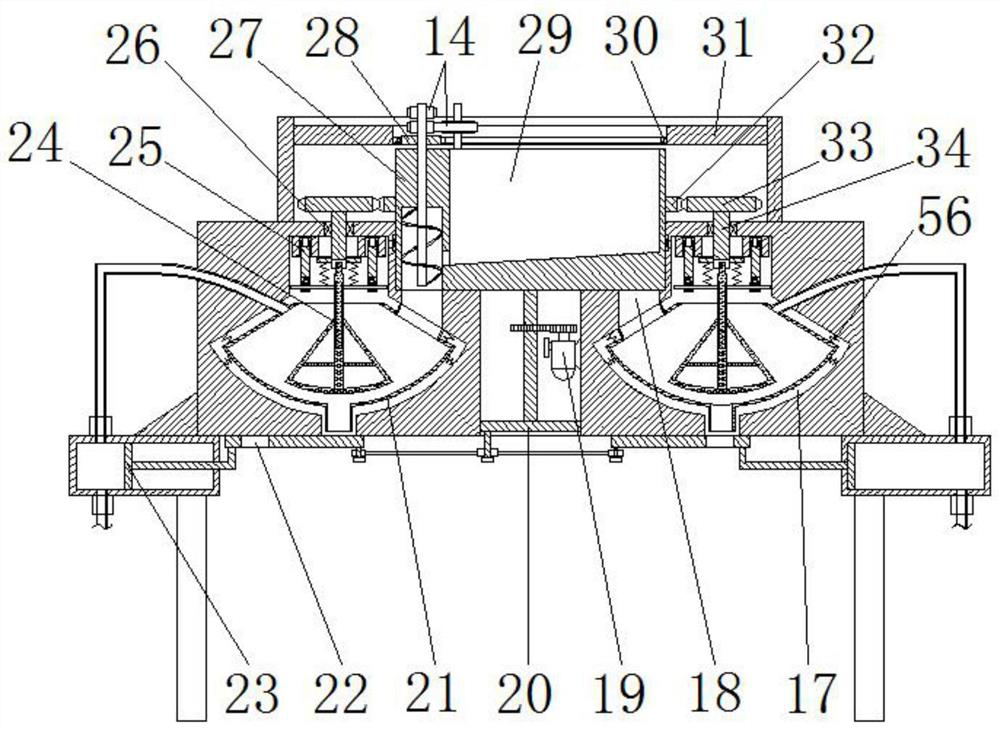

Agricultural fertilizer mixing and throwing device

InactiveCN108738569AWell mixedGuaranteed mix ratioFertiliser distributersAgricultural engineeringTime difference

The invention discloses an agricultural fertilizer mixing and throwing device which comprises a material tank, wherein the material tank is internally partitioned into three containing spaces throughpartition plates; through holes are formed in middle positions of the bottom surfaces of the three containing spaces; preservation cylinders are fixedly mounted below the through holes in the lower ends of the three containing spaces; discharge holes are formed in the lower ends of the preservation cylinders; mixing cylinders are arranged below the material tank; allocation covers are fixedly mounted on the mixing cylinders; feeding holes are formed in the upper ends of the allocation covers; the discharge holes of the preservation cylinders are communicated with the feeding holes of the allocation covers through allocation tubes; openings are formed in the lower ends of the mixing cylinders. According to the agricultural fertilizer mixing and throwing device, the mixing cylinders are arranged below the material tank, by adopting a mode that the mixing tanks are internally provided with stirring shafts, fertilizers can be mixed before seeding, the time difference between fertilizer mixing and seeding can be shortened, volatilization of the fertilizers is reduced, and maximum effects of the fertilizers can be ensured.

Owner:阜阳市卓创科技服务生产力促进中心

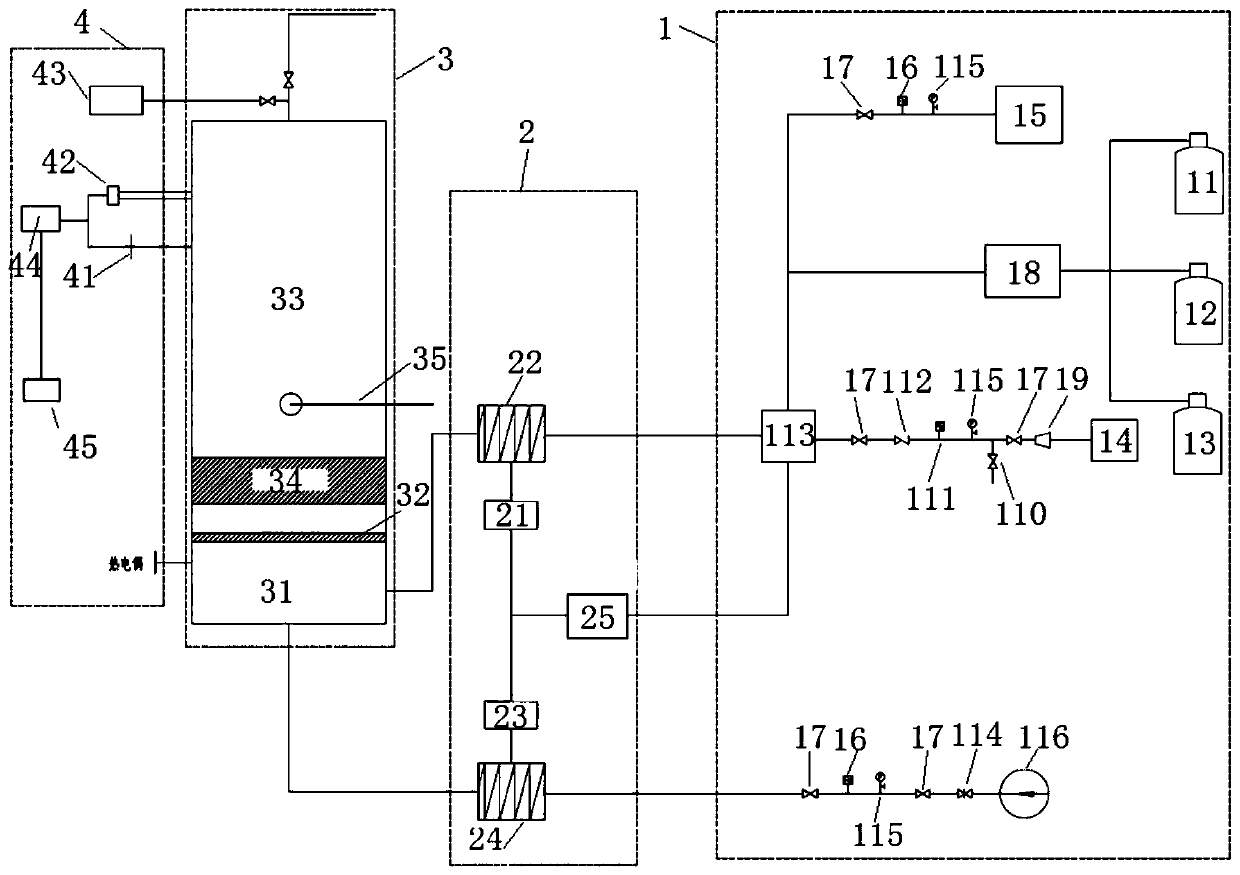

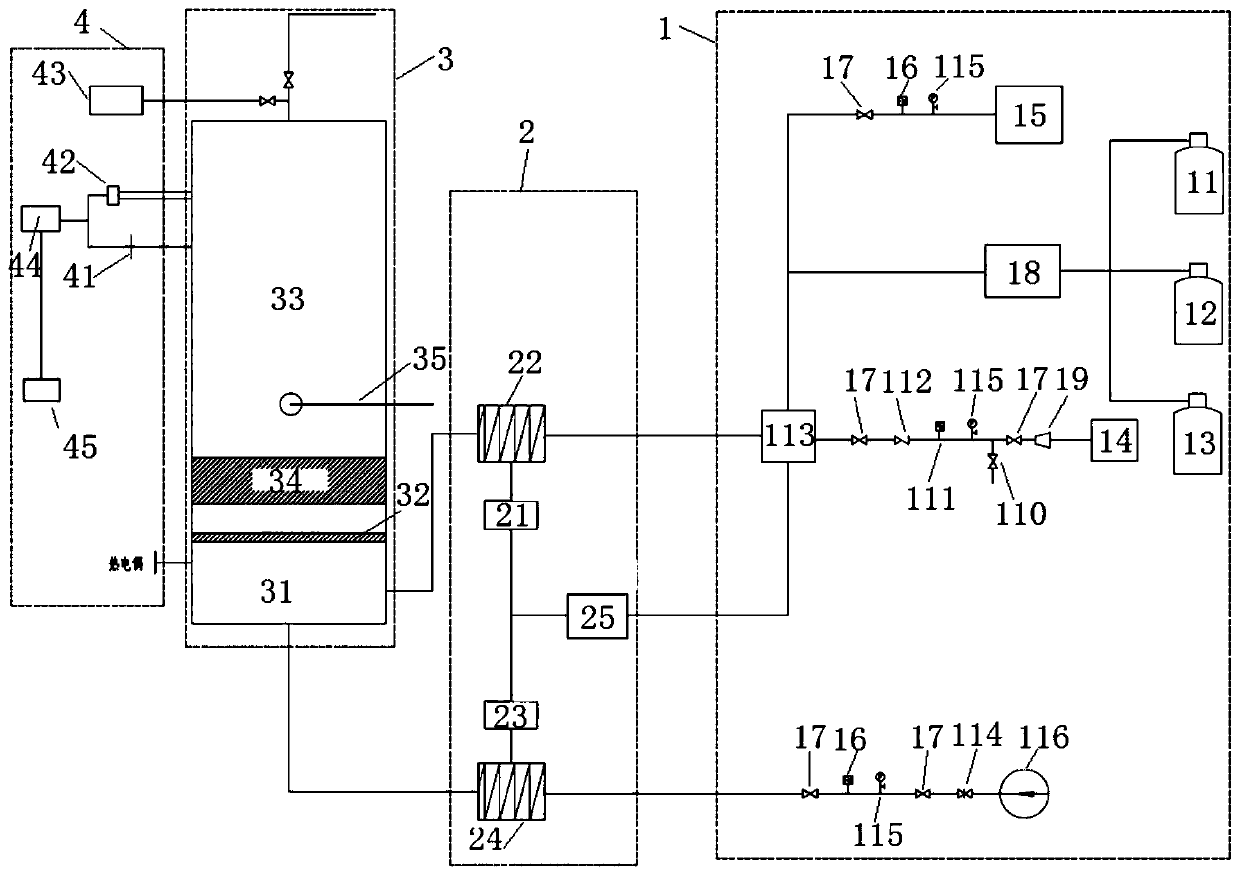

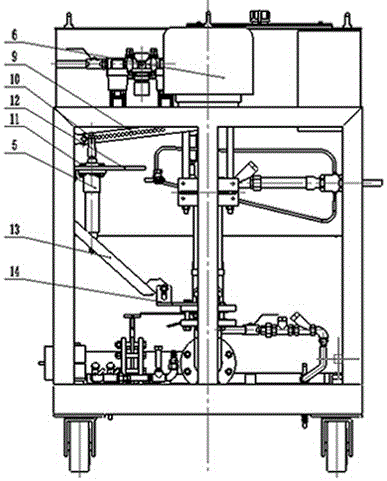

SOFC tail gas utilization research experiment system

InactiveCN111175345AAccurate measurementRealize simulationMaterial heat developmentFuel cellsCombustionProcess engineering

The invention relates to an SOFC tail gas utilization research experiment system which comprises a gas supply device, a heating device, a combustion device and a measurement device which are connectedin sequence. The gas supply device is used for generating compressed air and SOFC tail gas with different component contents; the heating device is used for heating the compressed air and the SOFC tail gas; the combustion device is used for mixing the SOFC tail gas and compressed air and carrying out combustion reaction; the measurement device is used for measuring technological parameters in theSOFC tail gas combustion reaction process. Compared with the prior art, different working conditions of an SOFC stack can be simulated, and the system has the advantages that parameters are easy to adjust, control is accurate, and SOFC tail gas components can be efficiently configured.

Owner:TONGJI UNIV

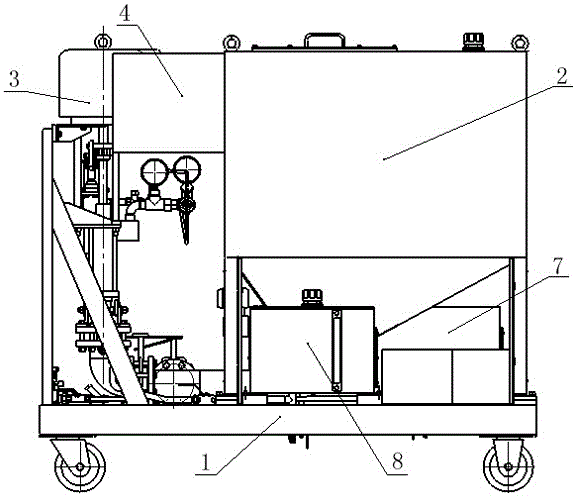

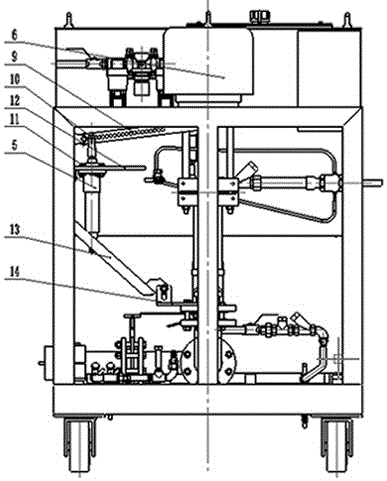

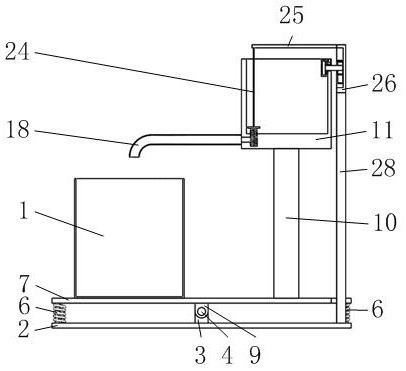

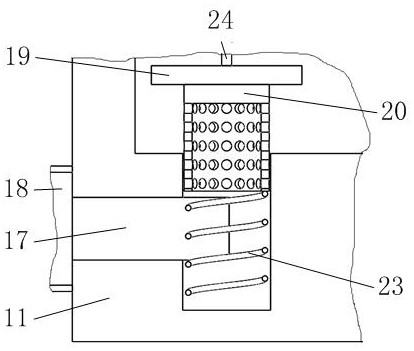

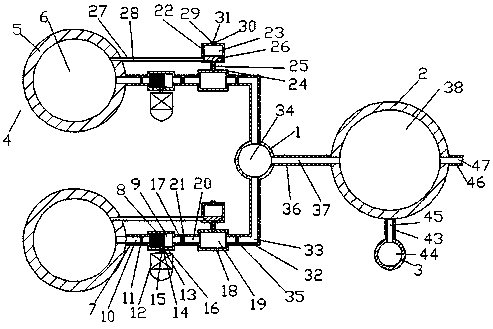

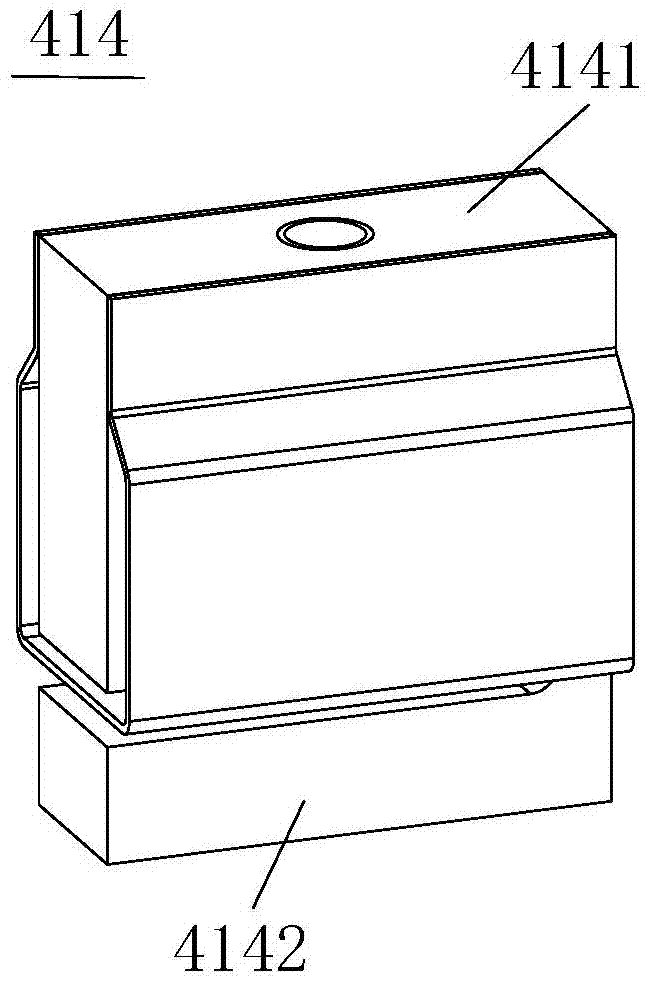

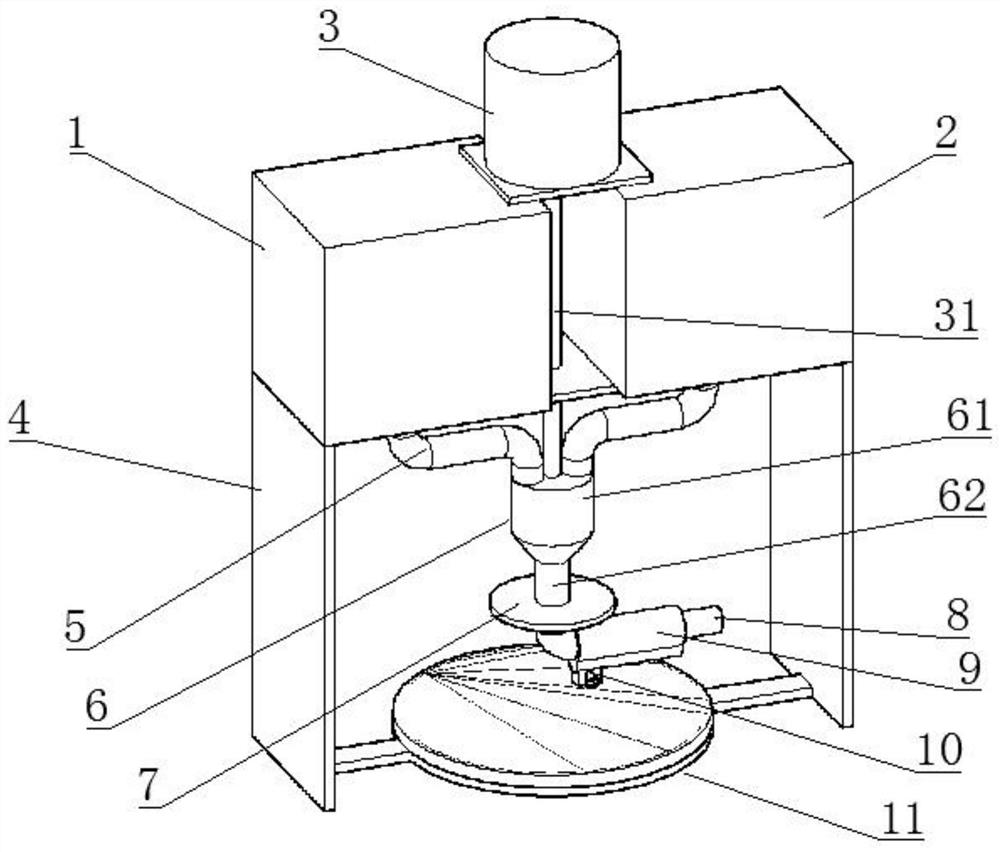

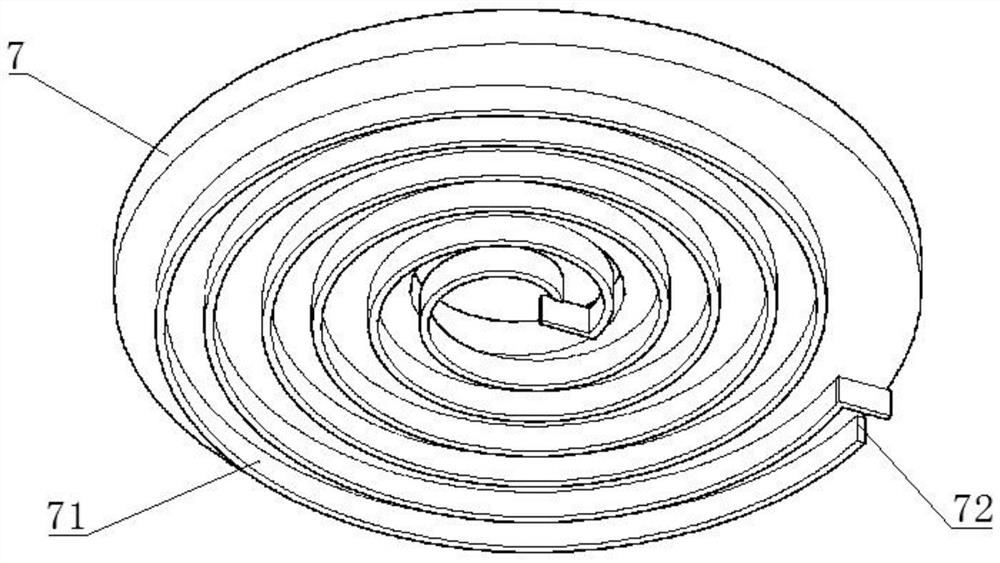

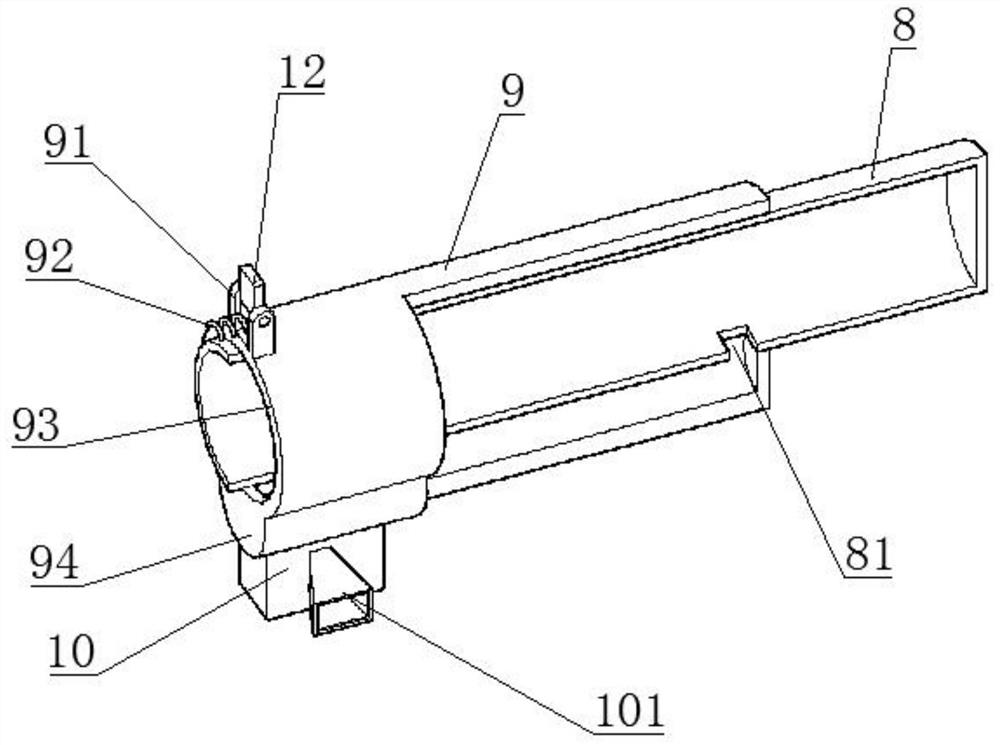

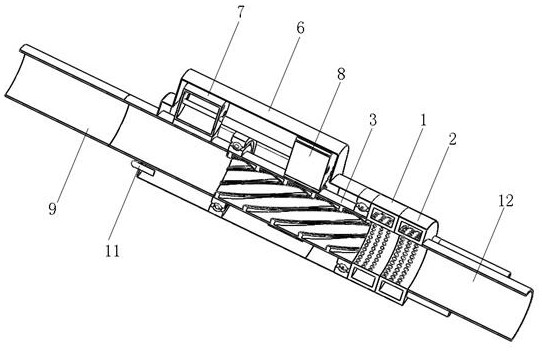

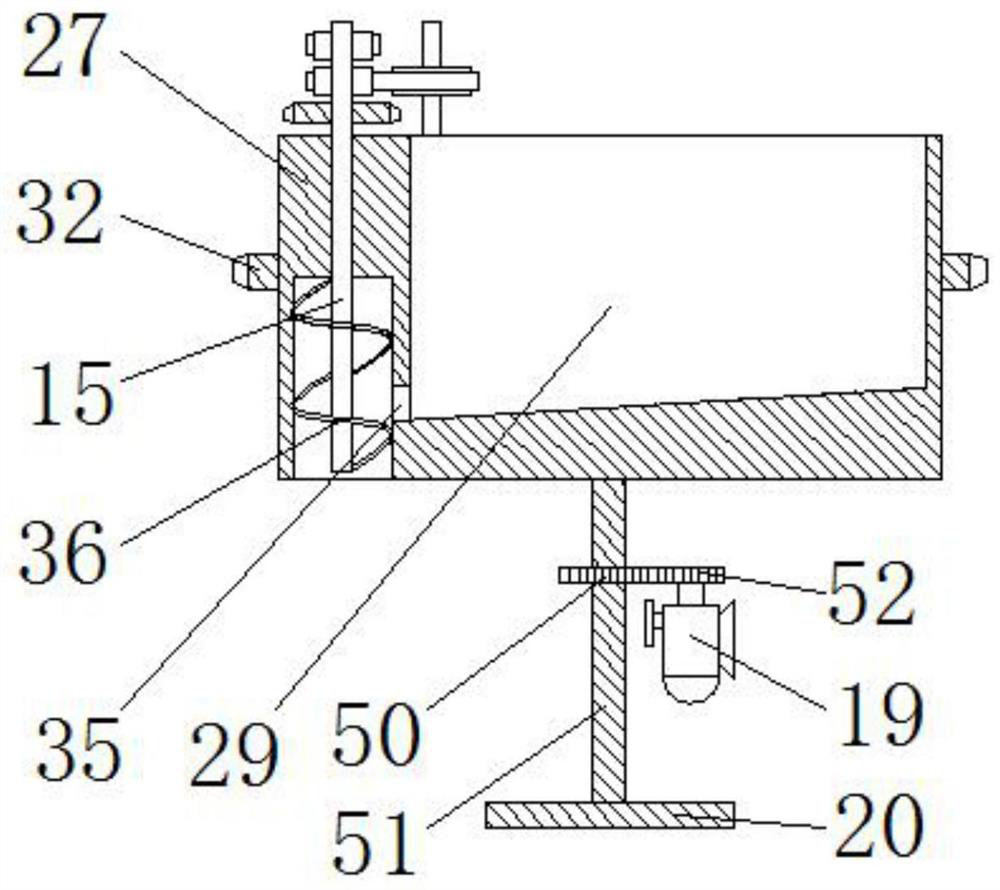

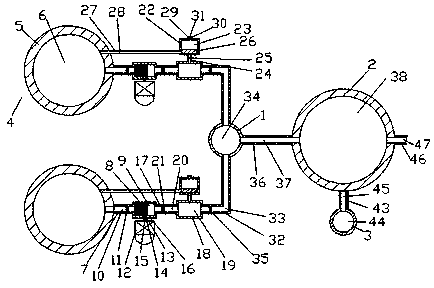

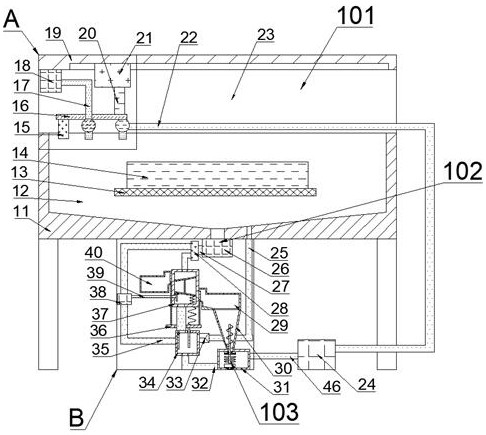

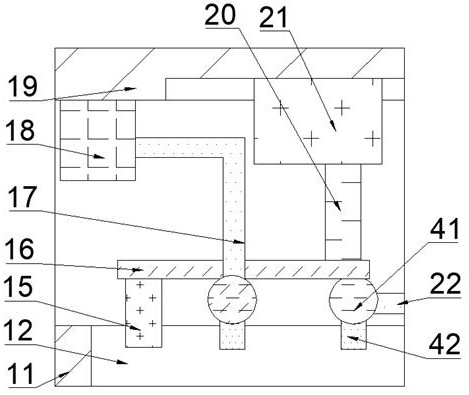

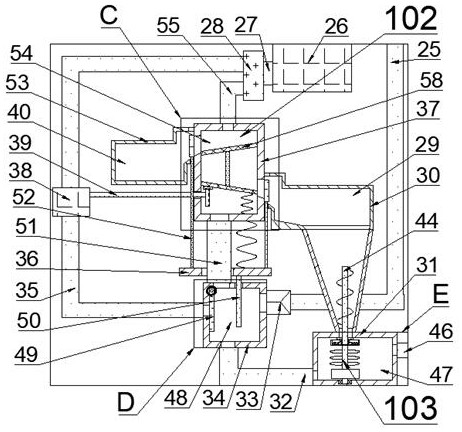

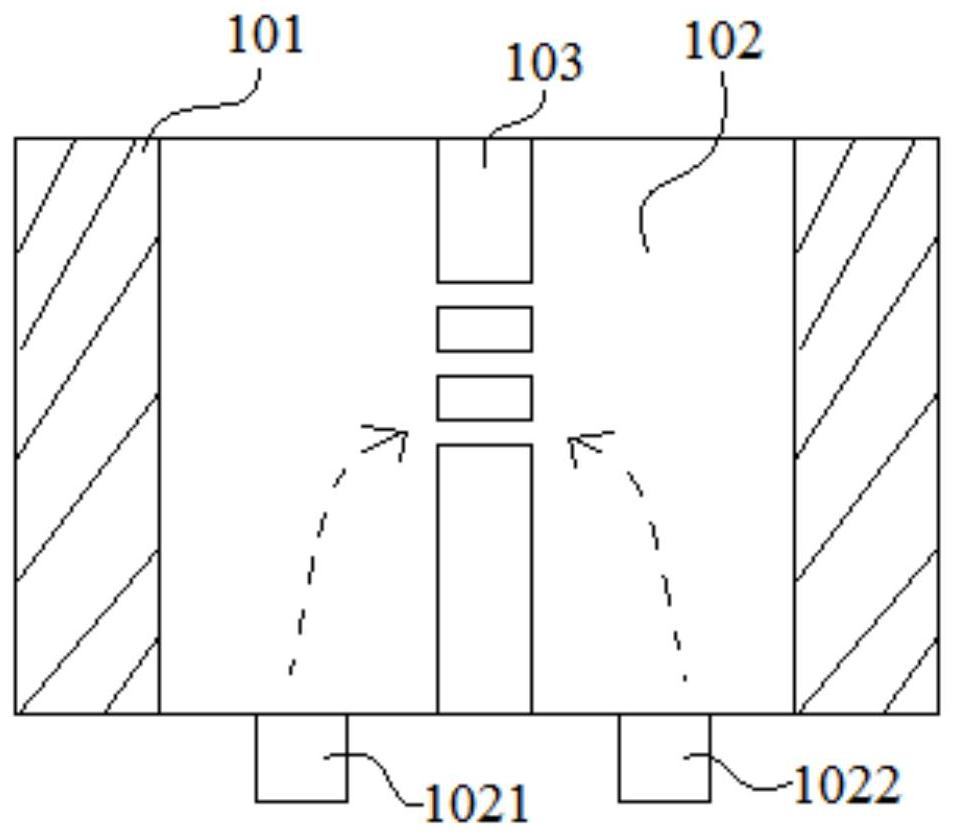

Scene explosive mixed loading equipment

The invention relates to scene explosive mixed loading equipment. The scene explosive mixed loading equipment comprises a chassis, a substrate cabin, a sensitizer box and a pumping system, wherein the substrate cabin and the sensitizer box are connected with the pumping system; the pumping system comprises a substrate pump, a sensitizer pump, a connecting rod, a pin shaft, a bracket, a connecting block, a mounting plate and a bolt; a piston rod of the substrate pump is connected with the connecting rod through the pin shaft; the other end of the connecting rod is connected with the bracket through the pin shaft; the connecting block is arranged at the middle part of the bracket; and the sensitizer pump is mounted on the connecting block. The scene explosive mixed loading equipment is simple in structure and continuous in feeding, and greatly reduces the labor intensity of workers when greatly improving the loading efficiency.

Owner:HUNAN KENON SCI & TECH

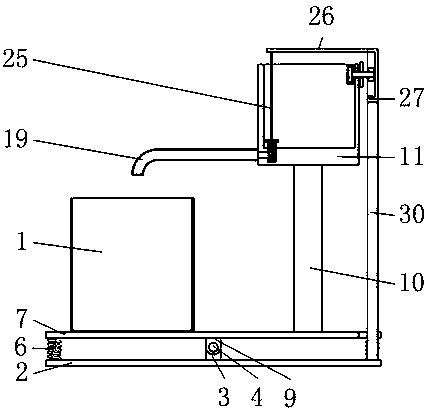

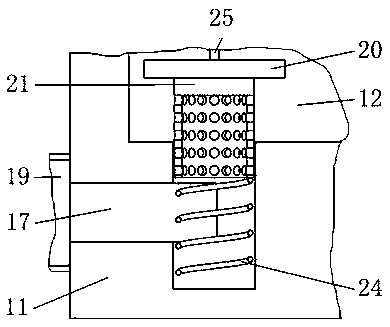

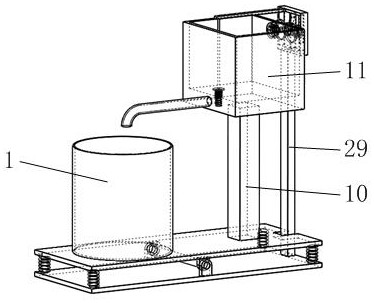

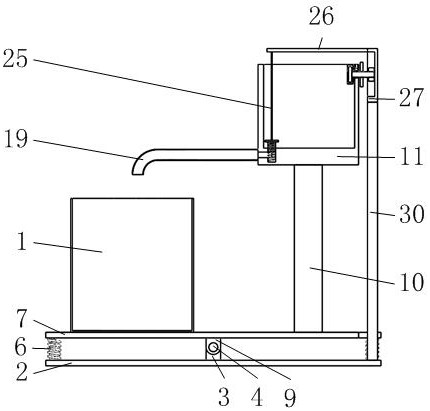

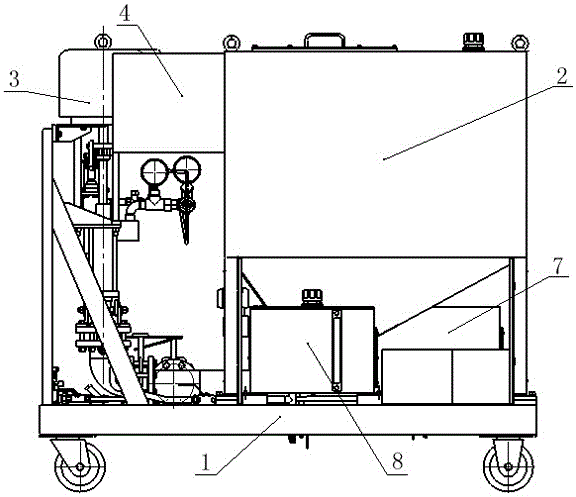

Putty powder automatic water injection equipment for indoor decoration

ActiveCN113289544AReduce maintenance costsQuality assuranceTransportation and packagingMixer accessoriesEnvironmental engineeringMechanical engineering

The invention belongs to the field of indoor decoration, and particularly relates to putty powder automatic water injection equipment for indoor decoration. The equipment comprises a barrel, a first horizontal plate, first hinge blocks, a water collecting tank, a driving rod, a flow limiting block and the like, wherein the first horizontal plate is put on the horizontal ground, two first hinge blocks are symmetrically installed at the centers of the two sides of the upper end face of the first horizontal plate, in the upward moving process of the water collecting tank, the driving rod located on the upper portion drives the flow limiting block to rotate by 45 degrees, and in the process that the water collecting tank moves from top to bottom, the driving rod located below drives the flow limiting block to continuously rotate by 45 degrees. The whole automatic water injection equipment can automatically match the mass of water according to the weight of putty powder in a barrel, and the mixing proportion of a mixture of the putty powder and the water is guaranteed, so that the quality of the mixture is guaranteed, and the quality of indoor decoration is further guaranteed; and the whole equipment is of a pure mechanical structure, precise small parts do not exist, the situation that the water injection equipment is polluted by putty powder dust and corroded does not exist in the using process, and therefore the maintenance cost of the water injection equipment is greatly reduced.

Owner:万洋建设集团有限公司

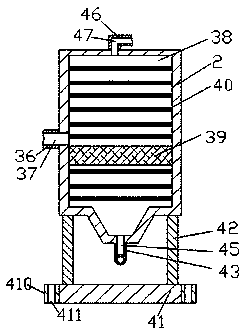

A high-efficiency filtration method for concentrate ore pulp

ActiveCN106362480BReduce moisture contentImprove filtration efficiencyFiltration separationControl systemFilter system

Owner:官景梁

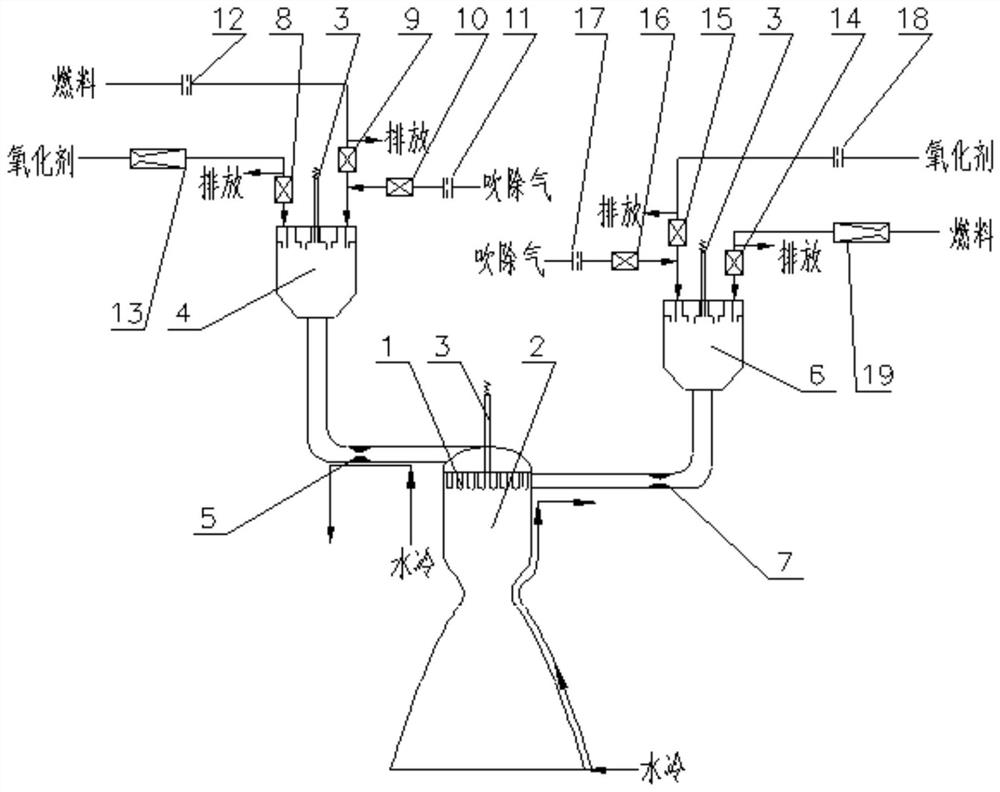

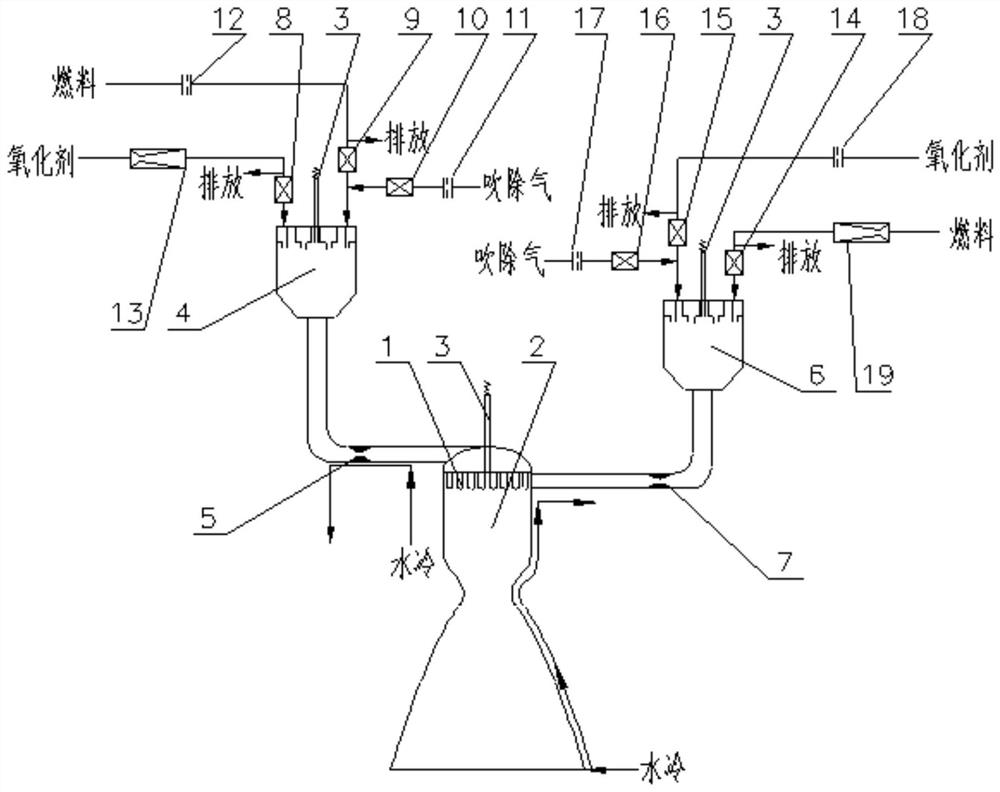

Gas-gas thrust chamber injector real supply condition thermal test device

ActiveCN112628026AFill in the gaps in hot test technologyRealize hot test simulationRocket engine plantsThrust chamberEngineering

The invention relates to the field of liquid rocket engines, particularly relates to a gas-gas thrust chamber injector real supply condition thermal test device, and aims to solve the problem that existing thrust chambers and injectors thereof are subjected to a thermal test aiming at liquid propellant blending combustion or gas-liquid blending combustion thrust chamber injectors, and both a test method and a test device cannot be used in a thermal test of a thrust chamber injector for gas-gas blending combustion. Both a test method and a test device cannot be used in a hot test of a thrust chamber injector for gas-gas blending combustion. The device comprises a thrust chamber test piece unit, an oxygen-enriched gas generator unit and a fuel-enriched gas generator unit, wherein the thrust chamber test piece unit comprises a thrust chamber test piece, the thrust chamber test piece is used for installing a tested injector, the oxygen-enriched gas generator unit comprises an oxygen-enriched gas generator, the fuel-enriched gas generator unit comprises a fuel-enriched gas generator, outlets of the oxygen-enriched gas generator and the fuel-enriched gas generator are connected with the thrust chamber test piece separately, and the oxygen-enriched gas generator and the fuel-enriched gas generator are used for supplying oxygen-enriched gas and fuel-enriched gas to the thrust chamber test piece.

Owner:XIAN AEROSPACE PROPULSION INST

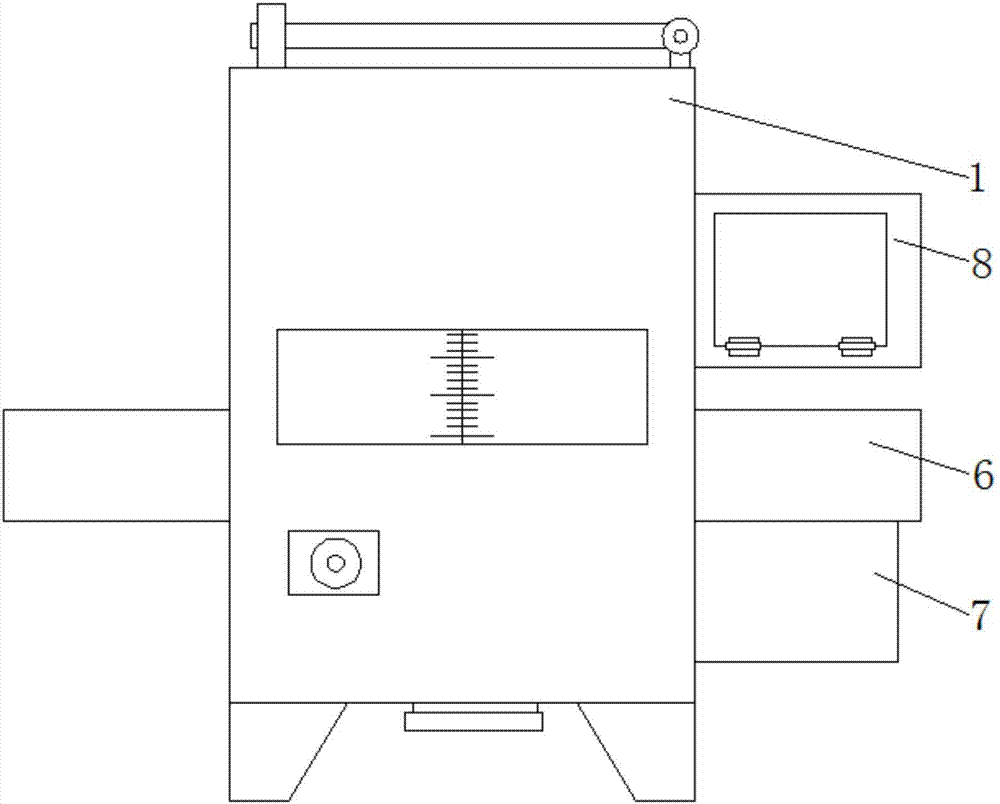

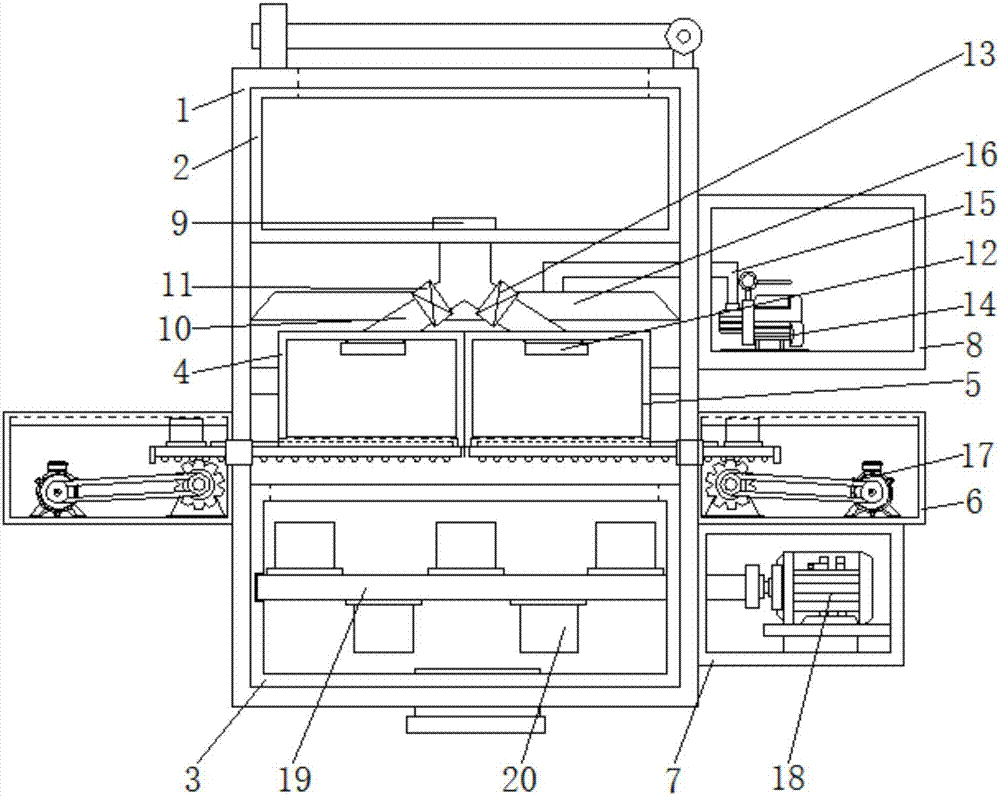

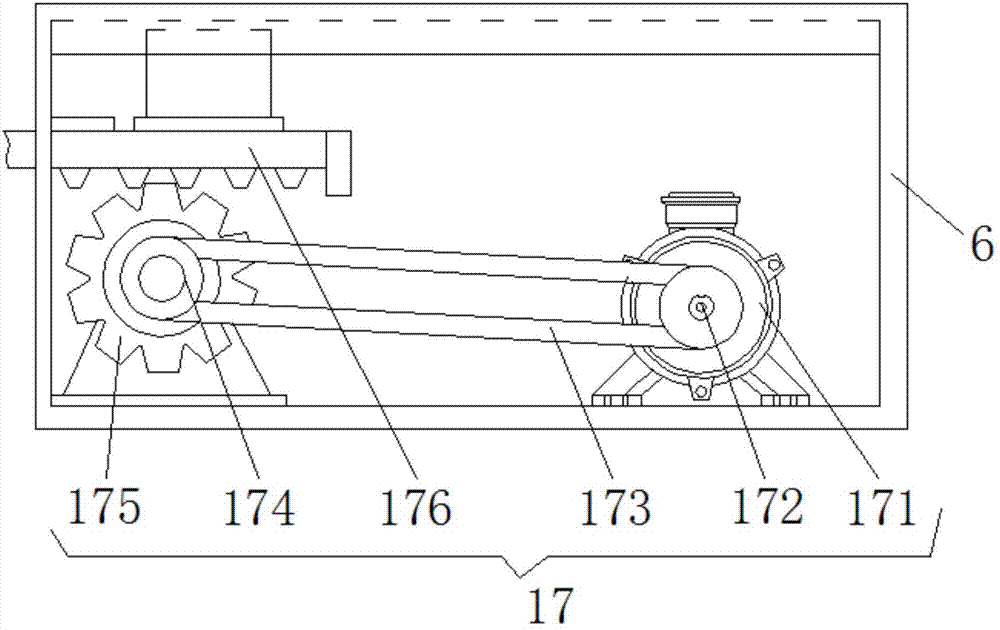

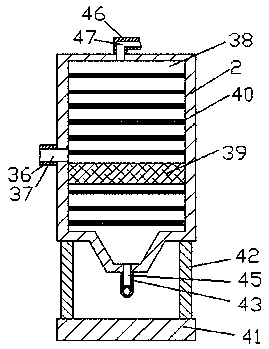

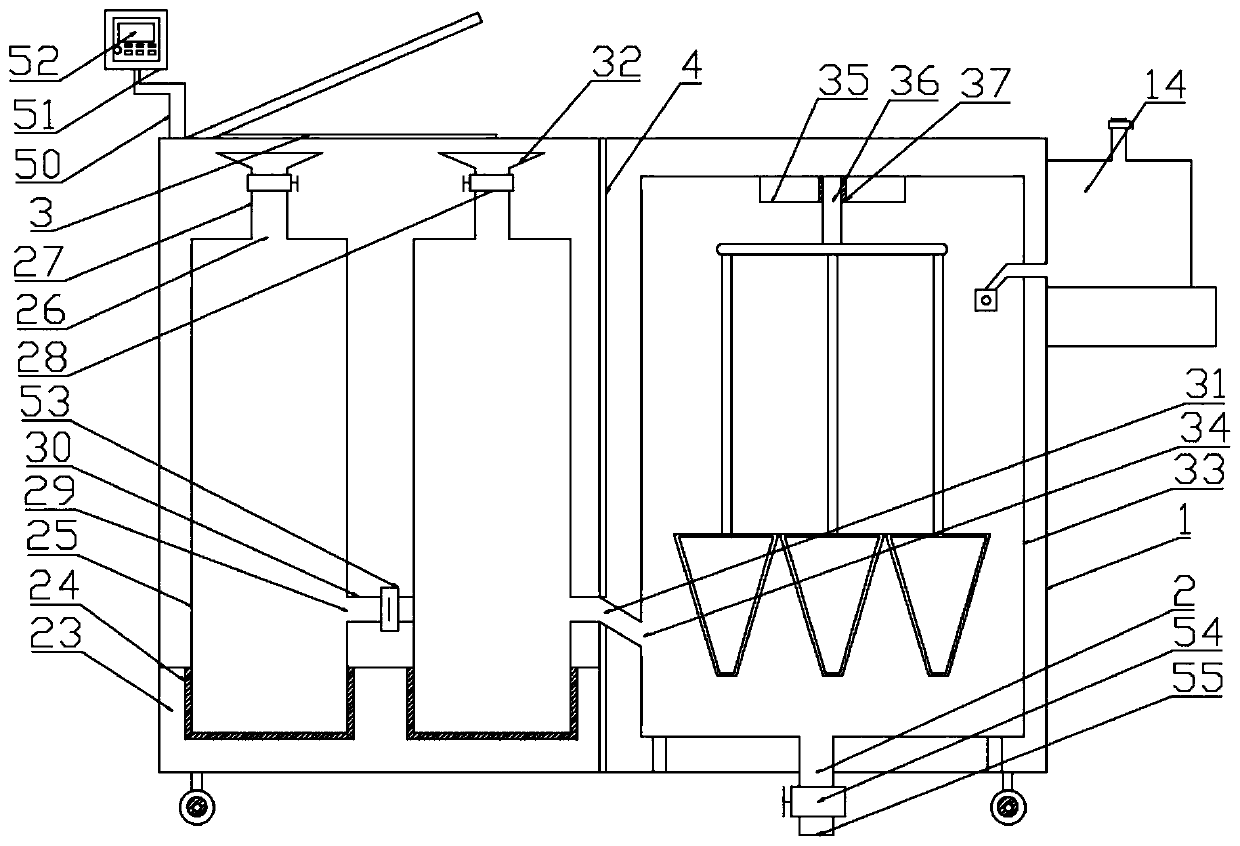

Concrete mixing device convenient to use and with quantitative function

The invention discloses a concrete mixing device convenient to use and with the quantitative function. The concrete mixing device comprises a box body; a top box is fixedly connected to the top of theinner wall of the box body; a mixing box is fixedly connected to the bottom of the inner wall of the box body; a first bottom box is fixedly connected to the left side of the inner wall of the box body through a connecting plate; a second bottom box is fixedly connected to the right side of the inner wall of the box body through a connecting plate and is located on the right side of the first bottom box; a motor box is fixedly connected to the bottom of the right side of the box body; movable boxes are fixedly connected to the two sides of the box body; a disinfection box is fixedly connectedto the top of the right side of the box body; and a vertical pipe penetrates through the bottom of the top box. The concrete mixing device relates to the technical field of concrete mixing equipment.According to the concrete mixing device convenient to use and with the quantitative function, materials can be added conveniently and quickly, the normal quantitative operation can be guaranteed, thematerials are then conveyed to the mixing position in time after being quantified, and therefore the concrete mixing device is convenient to use, the working efficiency can be greatly improved, and meanwhile, the device is simple in structure and high in practicability.

Owner:黄彬

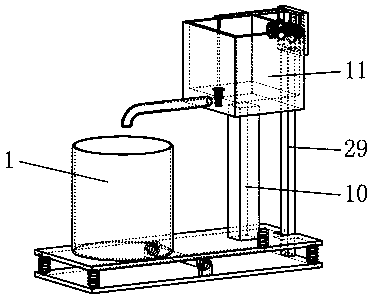

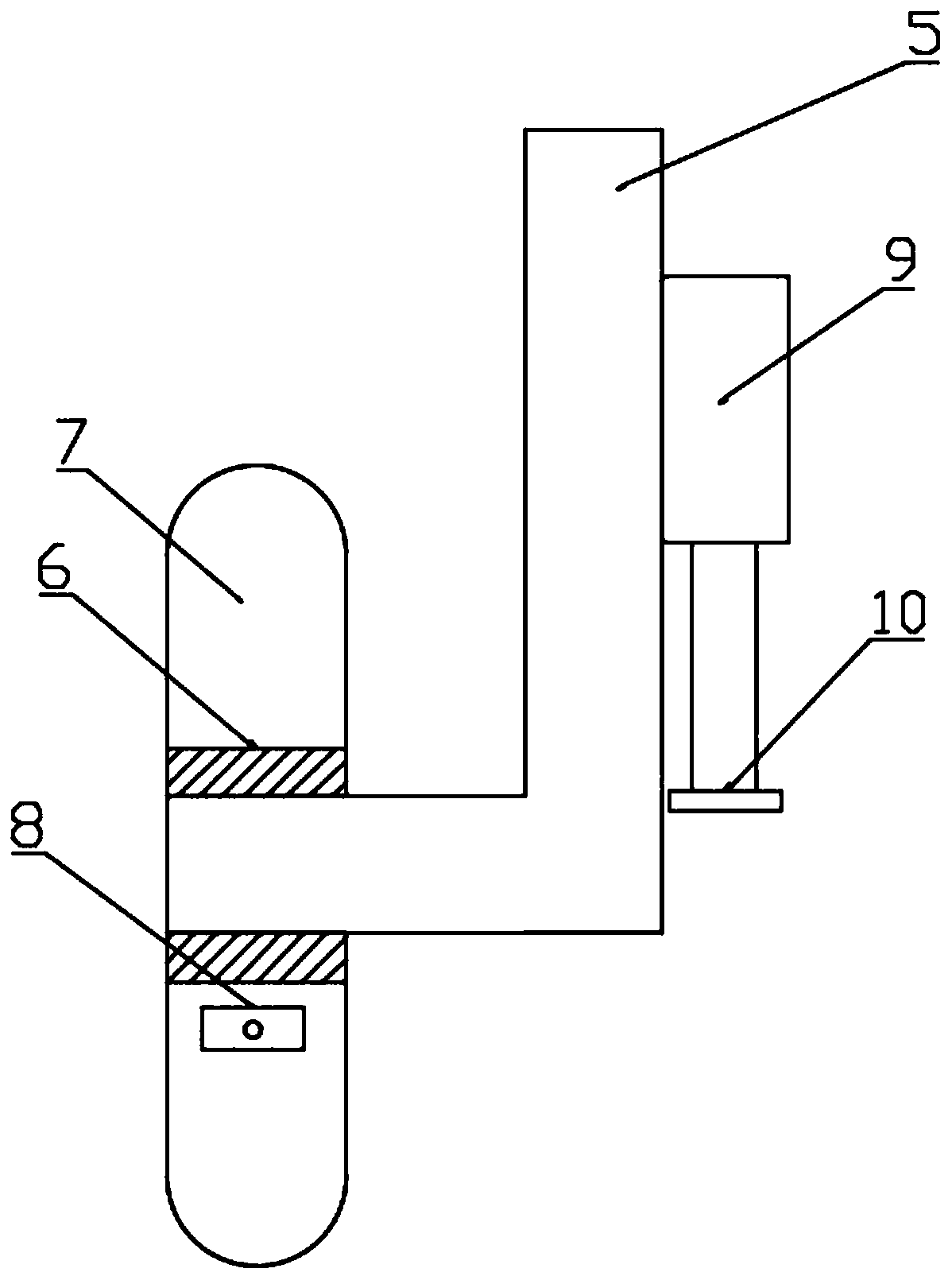

Automatic water injection device for putty powder used for interior finish and decoration

ActiveCN109603674AThere will be no collision and interferenceNo separation from each otherTransportation and packagingMixer accessoriesDrive wheelGear drive

The invention belongs to the field of interior decoration and particularly relates to an automatic water injection device for putty powder used for interior finish and decoration. The automatic waterinjection device comprises a putty bucket, a base plate, a water tank and the like, wherein the base plate is flatly placed on the horizontal ground; in the upward movement process of the water tank,a driving lever acts on a driving wheel to drive a valve element to rotate; in the process of from-top-to-bottom movement of the water tank, a third gear drives the valve element and the driving wheelto rotate under the action of a second one-way ring. The whole automatic water injection device can automatically prepare water amount according to the weight of putty power in the putty bucket, ensures the mixing ratio of the mixture of the putty powder and the water, forms a certain proportioning standard, ensures the quality of the mixture and thereby ensuring the quality of the interior decoration. Due to the fact that the whole device is of a pure mechanical structure and relatively precise small parts are not adopted therein, so that there is no putty powder dust contamination or rusting in the use process, and the maintenance cost of the water injection device is greatly reduced.

Owner:台州镘霓电子商务有限公司

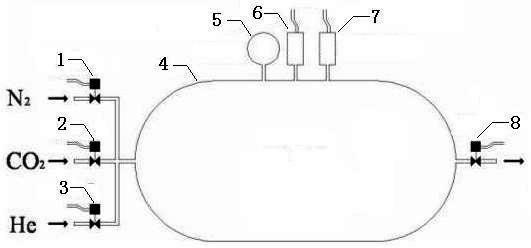

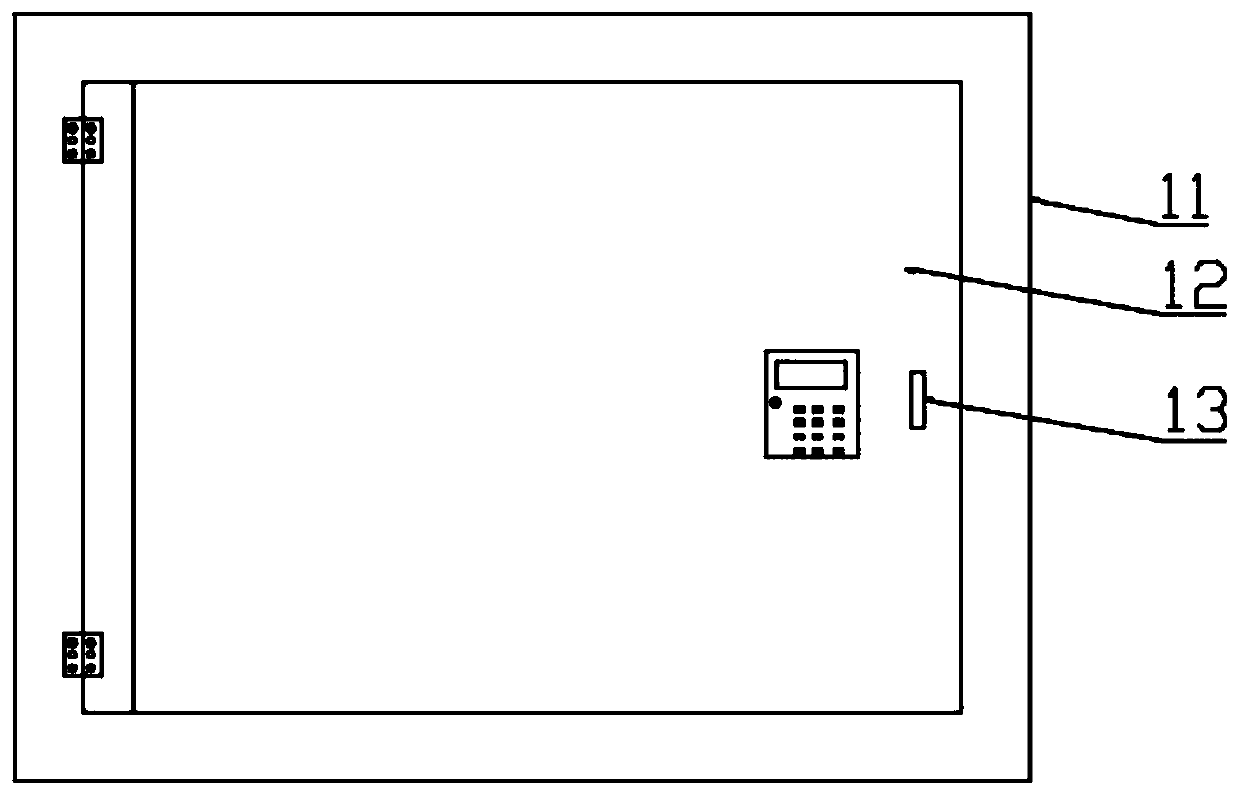

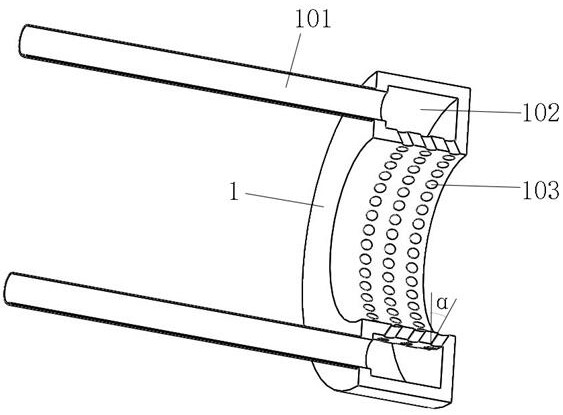

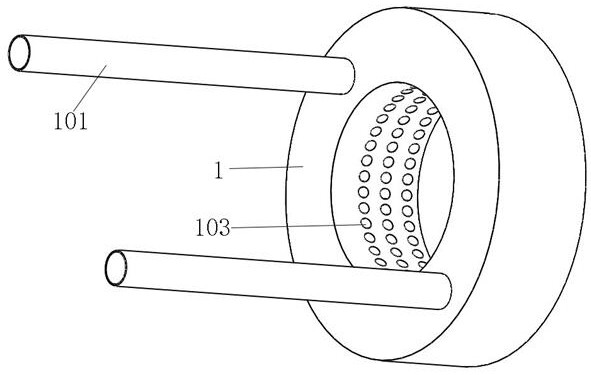

Air-conditioned cold store for garden stuff storage

InactiveCN109511731AGuaranteed mixing ratioGuaranteed low temperature conditionsFruit and vegetables preservationOperating energyEngineering

The invention discloses an air-conditioned cold store for garden stuff storage. The air-conditioned cold store for garden stuff storage comprises a store body. A plurality of gas conveying pipes are arranged in the top of the store body, a plurality of gas outlets are uniformly formed in each gas conveying pipe, each gas conveying pipe is connected a gas storage box through a gas supply pipe, a uniform mixing fan is also arranged between the inner wall of the top of the store body and the gas conveying pipes, the uniform mixing fan is located at the center of the store body, a placing shelf isarranged at the bottom of the store body, a plurality of labels are uniformly arranged on the placing shelf, a solar battery panel is arranged on the top out of the store body, a storage battery is arranged in the store body, and the solar battery panel is connected to the storage battery through a wire. The store can ensure a uniform mixing proportion of gas in the store body and the low temperature condition of the store body effectively, so that the operating energy consumption of the store body is reduced greatly and the cost needed for storage is lowered.

Owner:四川万良食品科技有限公司

A kind of organic synthesis catalyst equipment

ActiveCN108126745BGuaranteed mix ratioGuaranteed stabilityOrganic-compounds/hydrides/coordination-complexes catalystsLiquid carbonaceous fuelsOrganic synthesisFractionation

The invention discloses novel equipment for organically synthesizing a novel catalyst. The novel equipment comprises a mixing tank, a reaction tower and an MTBE storage tank, wherein stable input systems are symmetrically arranged at the front and rear ends of the left side of the mixing tank and comprise gas storage tanks; and a pressurizing tank is fixedly connected to the right end of each connecting pipe, a fixed motor is arranged outside the pressurizing tank, and a pressure maintaining space is formed in each pressure maintaining tank; and a reaction fractionation space is formed in a reaction tower, and a distilling pipe is fixedly connected to the center of the upper end surface of the reaction tower. When the novel equipment works and the flow rate of gas exceeds the standard, gaspushes a sealing plate to move backwards, and redundant gas flows back to the gas storage space through a decompression hole, so that the mixing proportion of gas is guaranteed; the mixed liquid of C4 and methanol is vaporized during the reaction by virtue of heat produced during the reaction, partial gas mixture is discharged through a distilling hole so as to bring away a large number of heat,so that the situation that equipment is burnt due to the over-high temperature in the reaction fractionation space is prevented.

Owner:扬州蒙飞环保科技有限公司

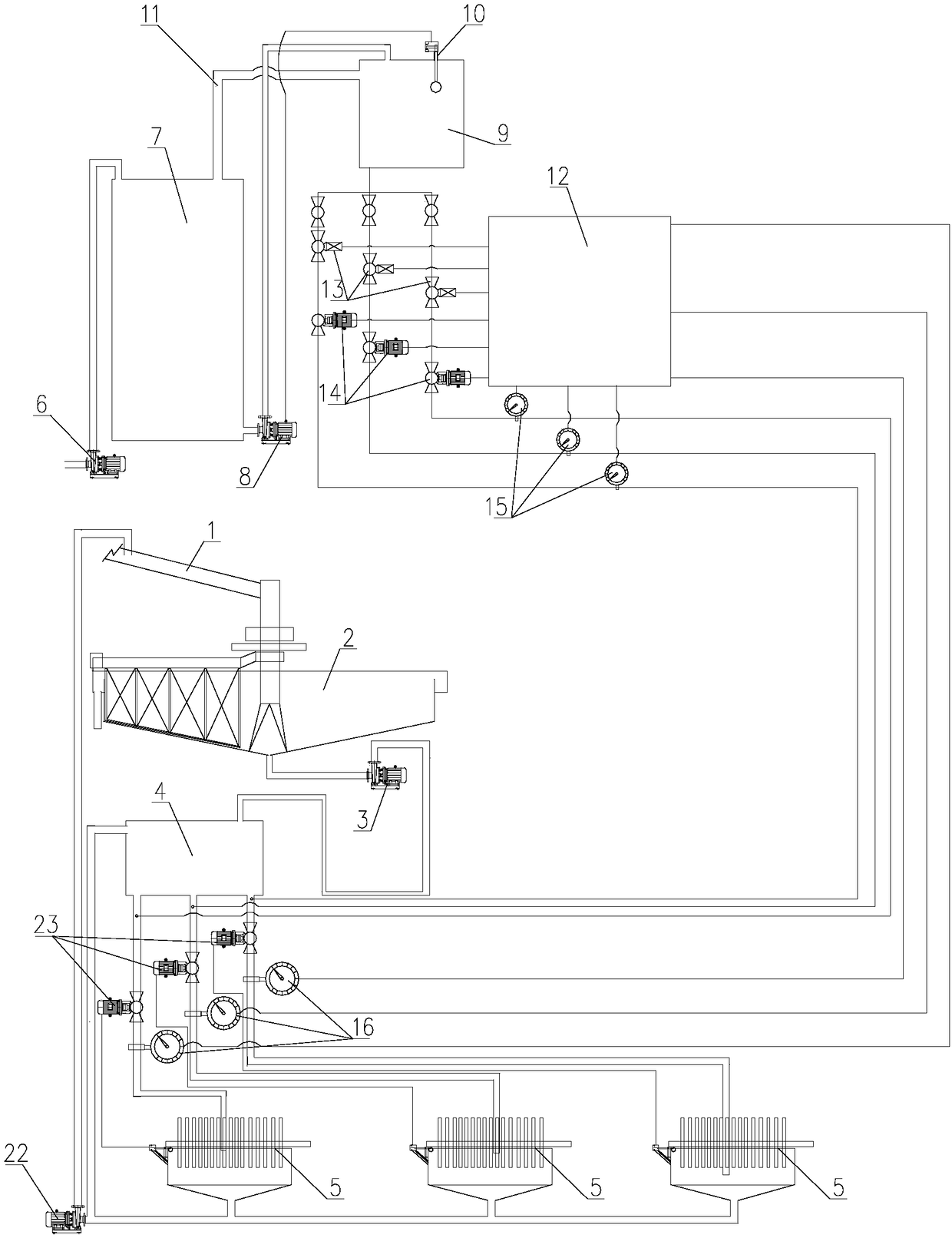

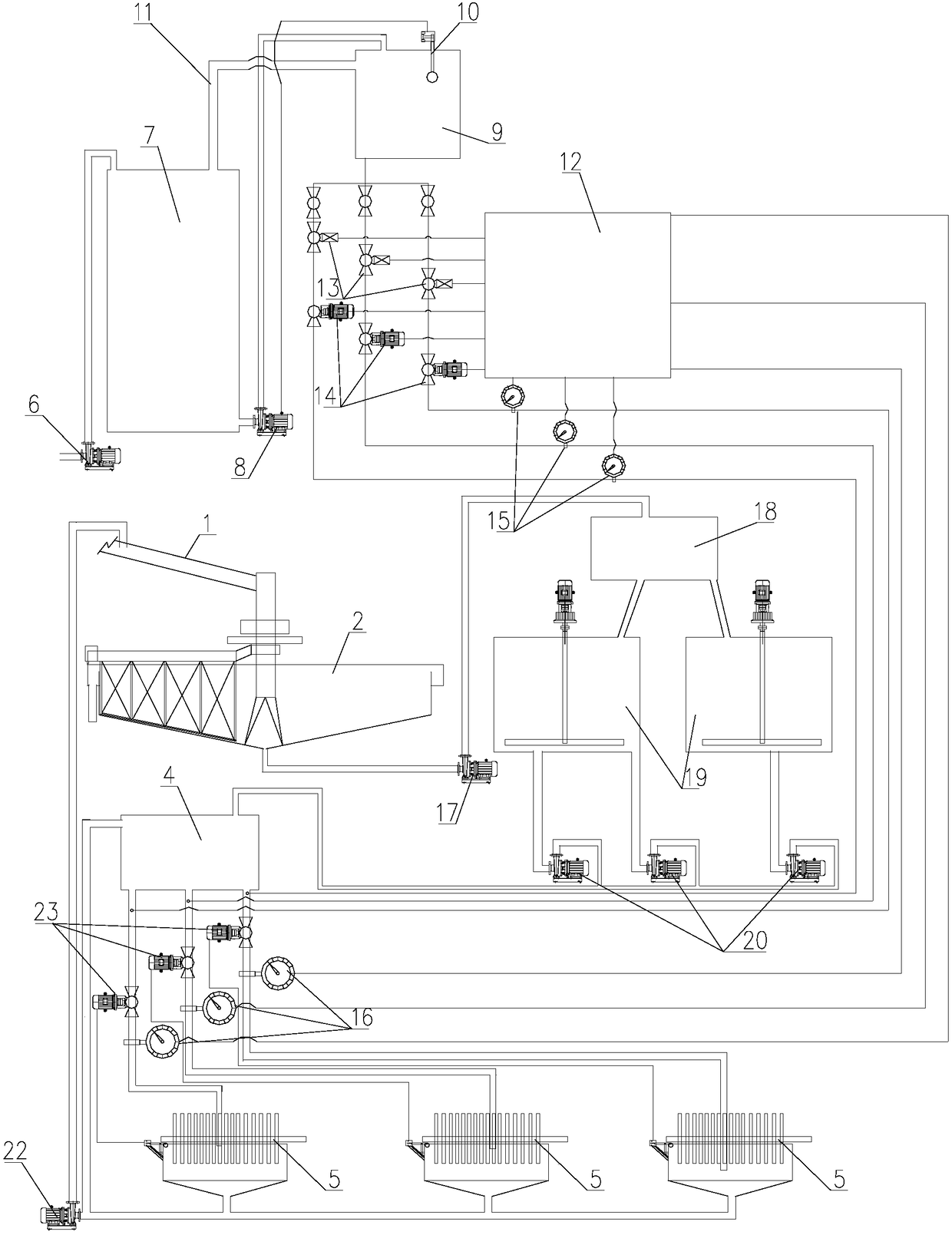

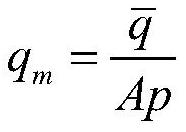

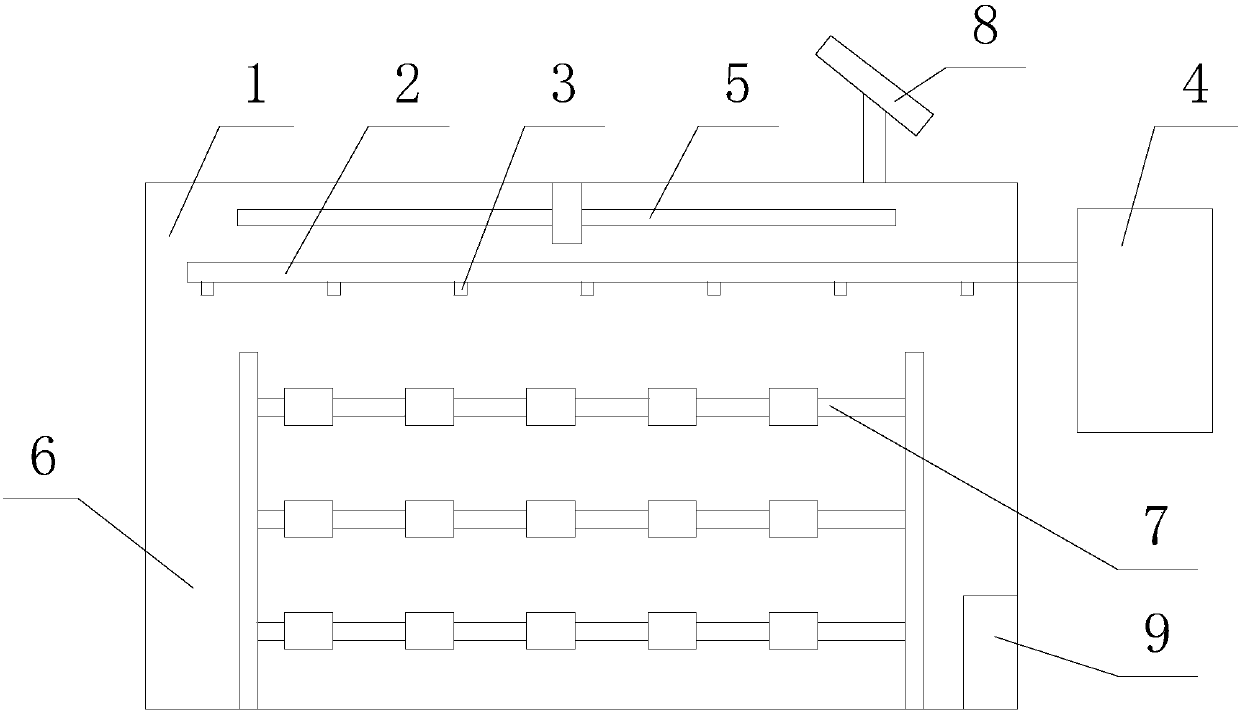

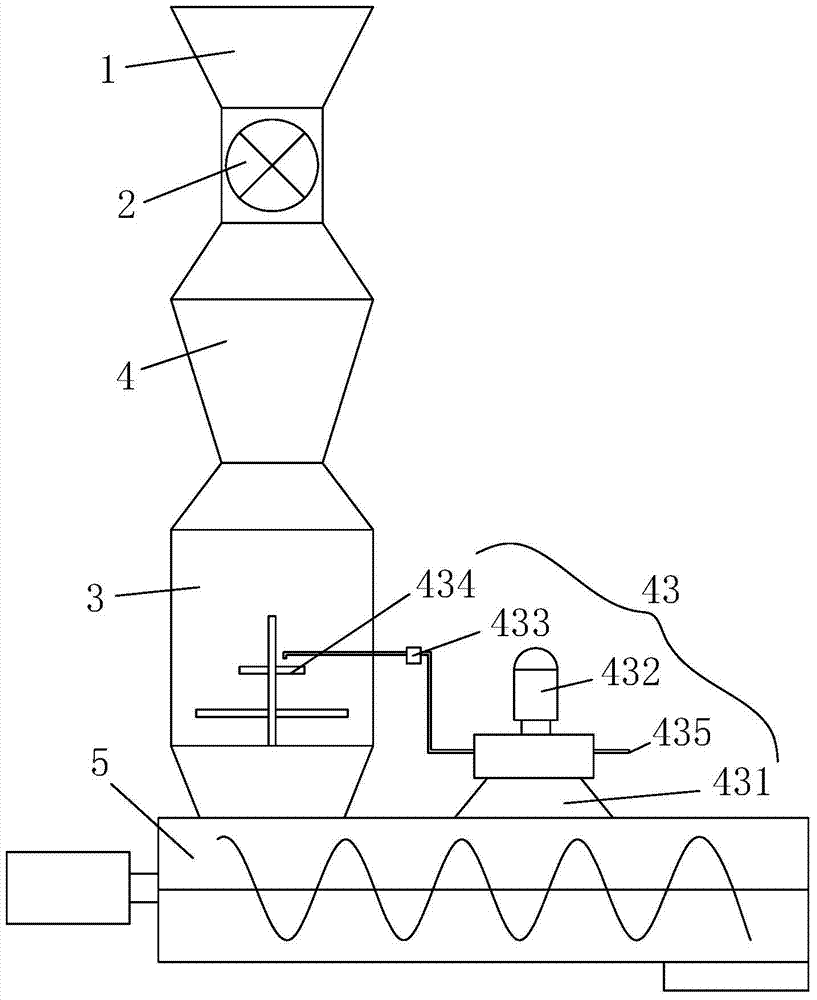

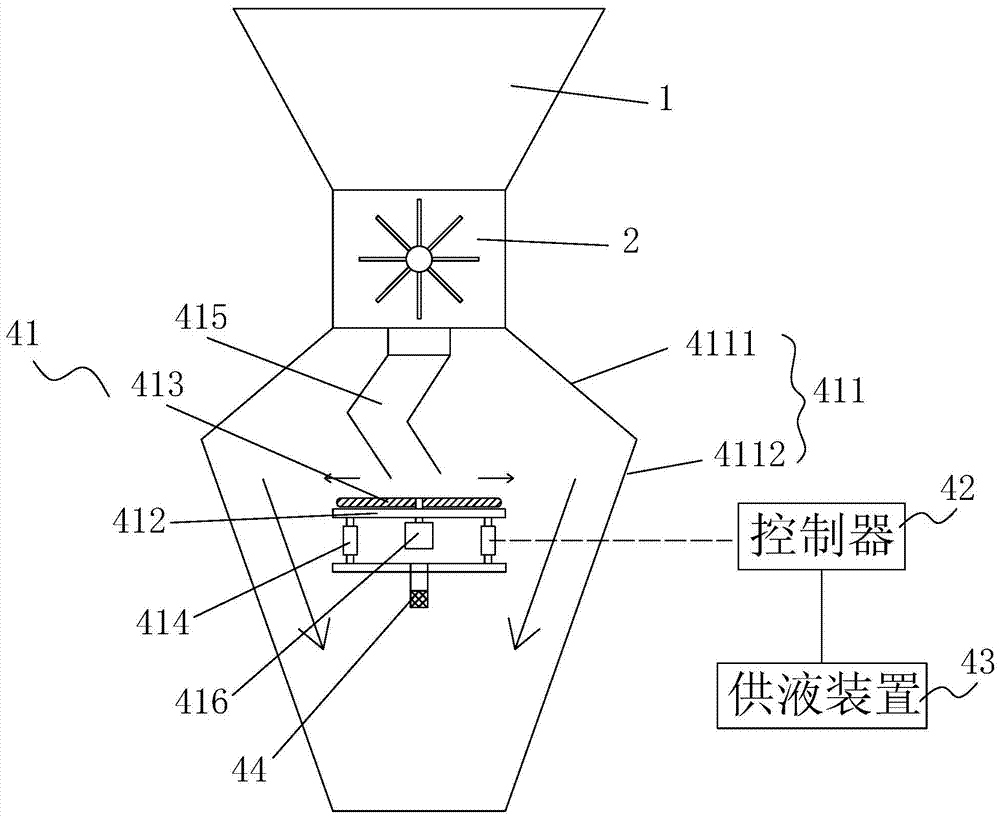

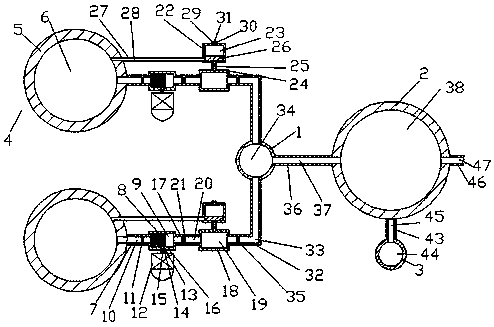

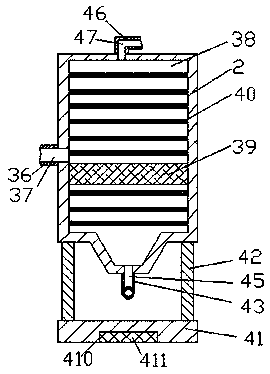

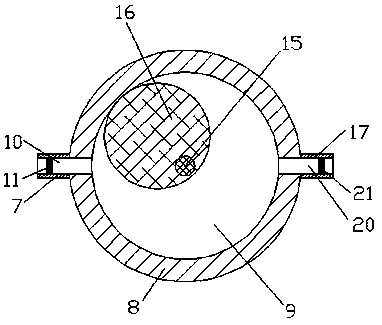

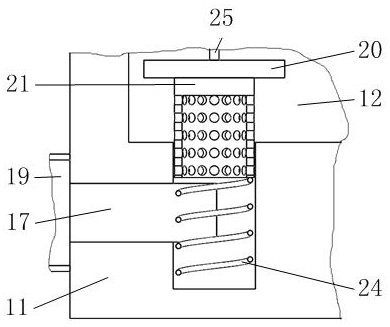

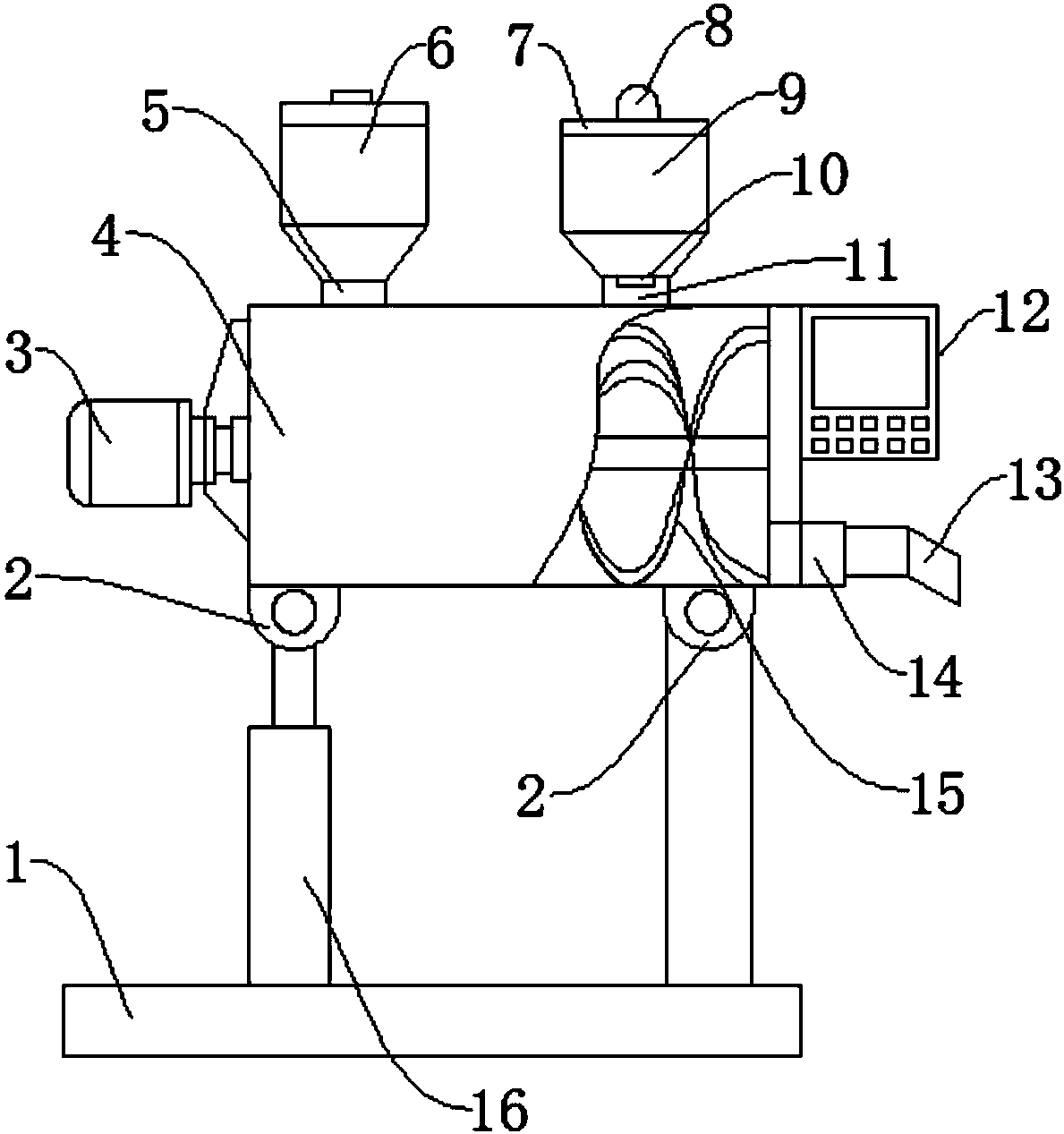

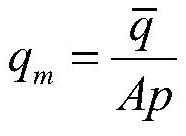

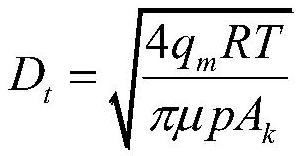

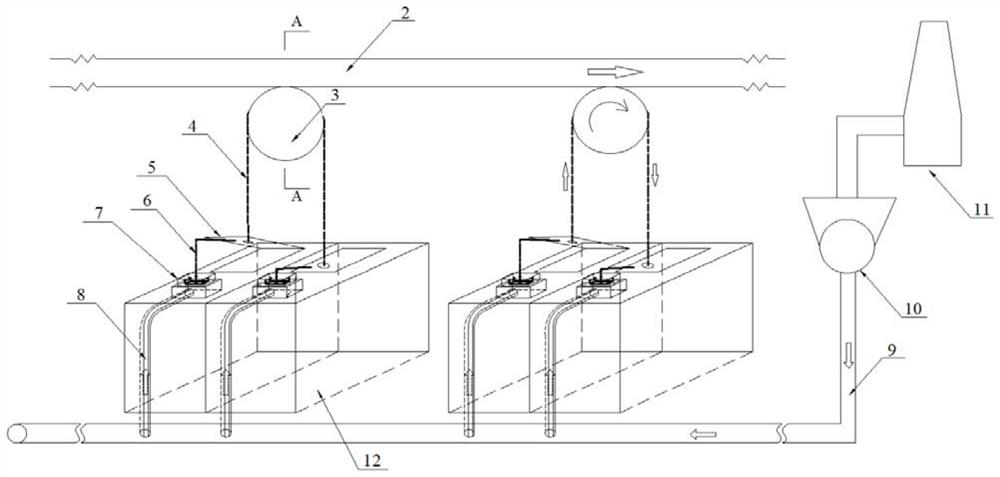

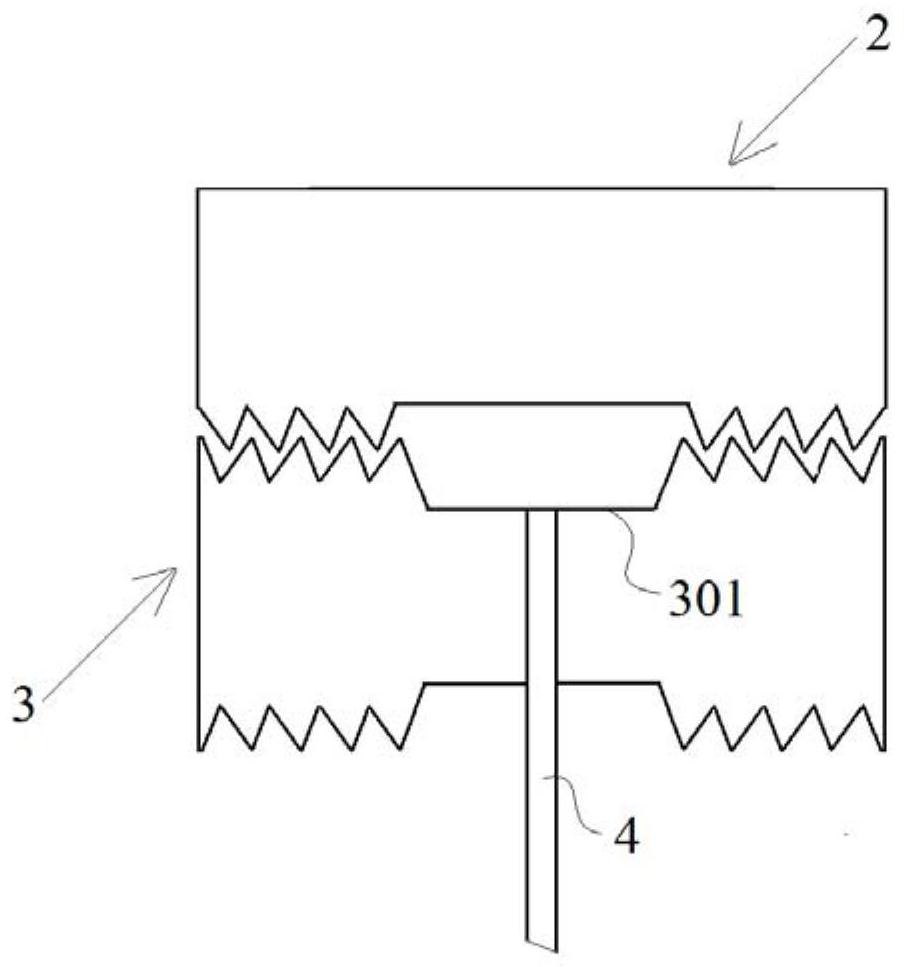

A seed coating machine and its on-line control device and method for seed medicine coordination

ActiveCN105075457BGuaranteed continuityGuaranteed mix ratioFlow control using electric meansSeed coating/dressingControl lineAgricultural engineering

A seed coating machine and its online control device and method for seed-drug coordination. The seed coating machine includes a storage bin, a feeder, a mixing chamber, a conveying device, and a seed-drug collaborative online control device. The seed-drug collaborative online control device The device is used to realize the cooperative supply of seed liquid, including a weighing and feeding device, which is connected between the feeder and the mixing chamber, and is used for real-time online weighing of the seeds flowing out of the feeder and outputting the The weight information of the seeds; the controller is connected with the weighing and feeding device, and is used to collect the weight information, perform data processing on the weight information, and calculate the weight of the seeds according to the set seed liquid mixing ratio. The supply amount of the required medicinal liquid; the liquid supply device is respectively connected with the controller and the mixing chamber, and is used to deliver the supplied amount of medicinal liquid to the mixing chamber. The invention also discloses a seed-drug synergy on-line control method using the above-mentioned seed-drug synergy on-line control device.

Owner:CHINESE ACAD OF AGRI MECHANIZATION SCI

Ceramic particle wet spraying equipment for surface treatment of electronic materials and spraying method thereof

ActiveCN112718309BSpray evenlyRealize integrationLiquid spraying apparatusElectronic materialsCeramic particle

The invention provides a ceramic particle wet spraying device for surface treatment of electronic materials and a spraying method thereof, and relates to the field of electronic material surface treatment. The connecting pipe is communicated with the mixing pipe, the mixing pipe is rotatably connected with a screw mixing shaft, the bottom end of the screw mixing shaft is fixedly connected with the spray pipe, the spray pipe and the mixing pipe are sealed and rotatably connected, and the spray pipe is connected to the mixing pipe. A material guide port is arranged on the pipe, and the material guide port is communicated with the spray head which is axially slidably connected on the spray pipe. The top of the spray head is connected with a limit rod, and the limit rod is fixedly connected with the limit plate outside the mixing pipe. Sliding connection, the bottom side of the limit plate is provided with a spiral limit groove, and a stage is provided under the nozzle. Making the nozzle spray the ceramic particles along the spiral trajectory can make the ceramic particles spray evenly.

Owner:翰贝摩尔表面技术(江苏)有限公司

A device for producing fertilizer

ActiveCN108249459BGuaranteed mix ratioGuaranteed stabilityAmmonium salt fertilisersAmmonia preparation/separationGas cylinderEngineering

The invention discloses a fertilizer production apparatus. The fertilizer production apparatus comprises a uniform stirring box, a reaction barrel and a collection and fetching box, wherein the frontend and the rear end of the left side of the uniform stirring box are symmetrically provided with a gas conveying apparatus, the gas conveying apparatus comprises a gas conveying bottle, the right endof a first connecting pipe is fixedly connected with an air pressure box, the outer side of the air pressure box is provided with a motor, a cavity is arranged in a pressure keeping box, a reaction cavity is arranged in the reaction barrel, and the center of the upper end surface of the reaction barrel is fixedly connected with a discharging pipe.

Owner:肇庆市绿泰美专业肥料有限公司

A road bridge crack reinforcement device

InactiveCN109989361BFully reinforcedWell mixedBridge erection/assemblyRoads maintainenceWater storageArchitectural engineering

The invention discloses a crack reinforcement device for roads and bridges. The device includes a reinforcement box, a mobile mechanism is installed on the lower portion of the reinforcement box, theright side of the lower portion of the reinforcement box is provided with a discharge hole, the upper portion of the reinforcement box is provided with a reinforcement and replacement opening, a reinforcement door mechanism is installed at the reinforcement and replacement opening, the middle in the reinforcement box is provided with a separation plate, the right side of the reinforcement box is provided with a water storage mechanism, the upper portion of the left side of the reinforcement box is provided with a control mechanism, the left side of the separation plate is provided with variousraw material storage mechanisms, and the right side of the separation plate is provided with a stable mixing mechanism. The device has the advantages that operation is convenient and the practicability is high.

Owner:SHAANXI TECHN INST OF DEFENSE IND

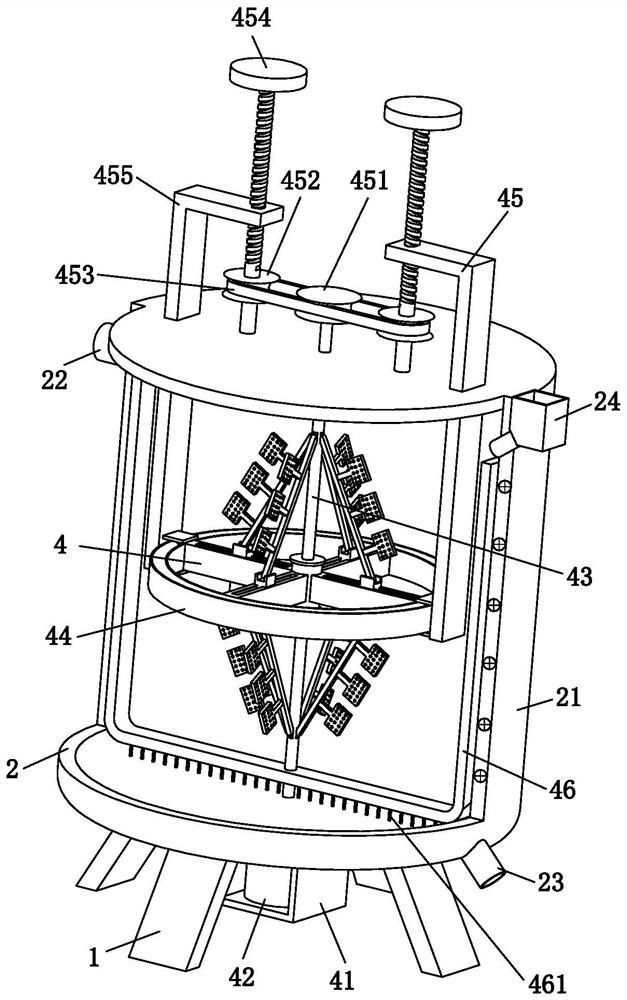

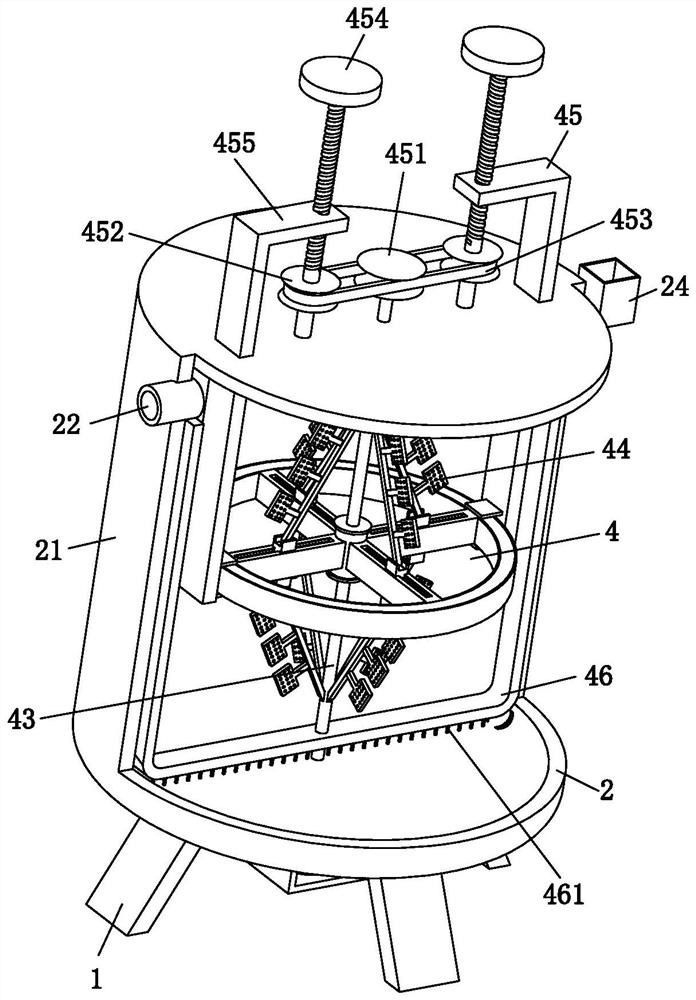

Industrial lubricating oil production and preparation equipment and preparation process thereof

PendingCN114288914AGuaranteed blending effectImprove production qualityShaking/oscillating/vibrating mixersTransportation and packagingProcess engineeringOil can

The invention relates to industrial lubricating oil production and preparation equipment and a preparation process thereof. The industrial lubricating oil production and preparation equipment comprises supporting legs, a stirring barrel, an upper end cover and a stirring device. The invention can solve the following problems in the blending process of the base oil of the existing industrial lubricating oil: a, the mixing effect of the base oil and the additive is reduced and the production quality of the lubricating oil is influenced due to insufficient stirring of the base oil and the additive because the stirring angle of the existing stirring and blending equipment cannot be adjusted; b. In the stirring and blending process of the existing stirring and blending equipment, the additive is easy to deposit at the bottom of the stirring and blending equipment, so that the additive and the base oil cannot be fully contacted, the additive and the base oil are not uniformly mixed, the quality of the lubricating oil is reduced, and the base oil is easy to adhere to the interior of a stirring drum in the stirring and blending process, so that the lubricating oil cannot be fully mixed. If scraping is not carried out, the component proportion of the lubricating oil can be influenced, and the use effect is reduced.

Owner:孙艳春

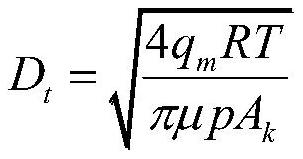

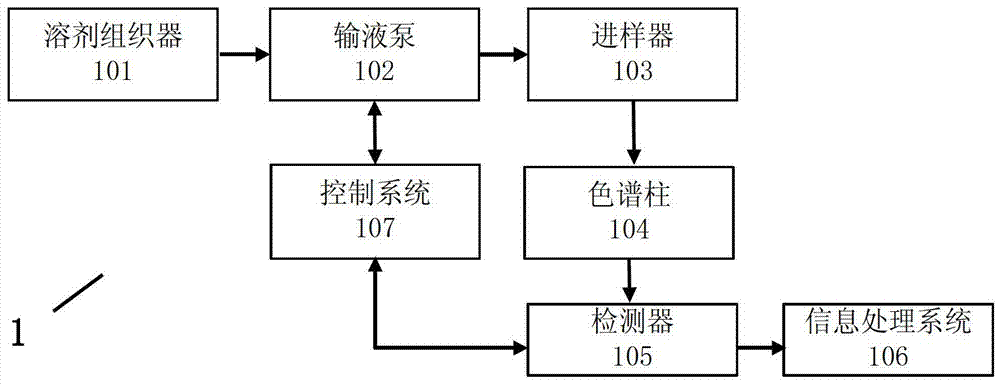

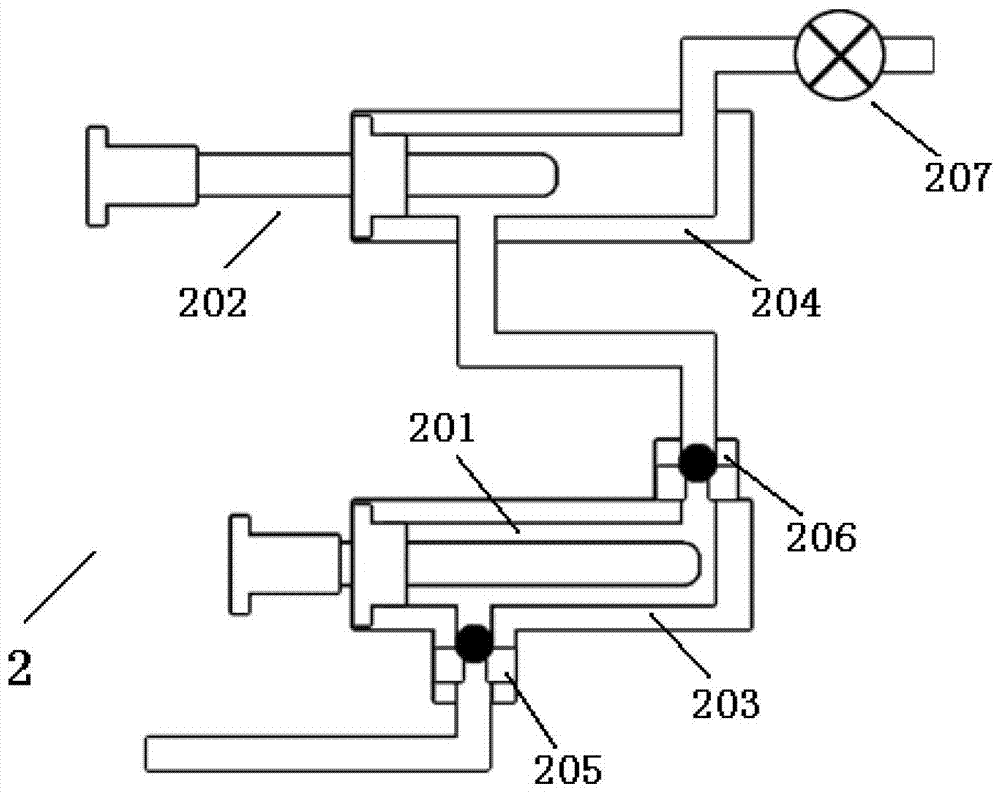

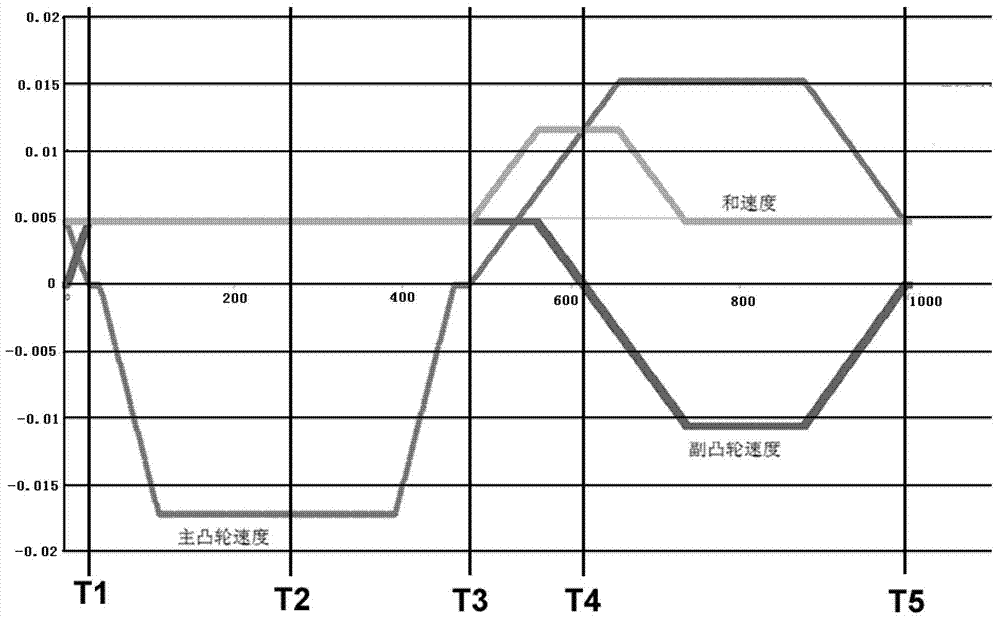

A high-performance liquid chromatograph capable of controlling the flow rate

ActiveCN104101658BGuaranteed mix ratioImprove accuracyComponent separationLoop controlControl system

The invention provides a high-performance liquid chromatograph capable of controlling the flow rate, comprising a double-pump plunger pump in series driven by a cam, a control system, and the series plunger pump including a main pump chamber and a main pump head plunger , an auxiliary pump chamber, an auxiliary pump head plunger, and an outlet check valve for connecting the main pump chamber and the auxiliary pump chamber, the control system is used to control the movement of the main pump head plunger and the auxiliary pump head plunger, The control system is also used to perform the following steps cyclically: obtain a calculated value of the opening point of the outlet check valve according to the system pressure and the configuration parameters of the liquid chromatograph; then obtain a calibration value of the opening point of the outlet check valve according to the system pressure ; Add the calculated value to the calibration value to obtain the actual value of the opening point of the outlet check valve; obtain a compression volume according to the actual value; and control the rotation speed of the cam according to the compression volume. The liquid chromatograph of the invention ensures the mixing ratio of the mobile phase and improves the accuracy of the measurement results.

Owner:苏州理瞳精密测量系统有限公司

An automatic water injection device for putty powder for interior decoration

ActiveCN109603674BReduce maintenance costsQuality assuranceTransportation and packagingMixer accessoriesGear driveTremella

The invention belongs to the field of interior decoration, in particular to a putty powder automatic water injection device for interior decoration, which includes a putty bucket, a bottom plate and a water tank, wherein the bottom plate is placed on a horizontal ground; during the upward movement of the water tank, The lever acts on the dial to drive the valve core to rotate; during the movement of the water tank from top to bottom, the third gear drives the valve core and the dial to rotate under the action of the second one-way ring; the entire automatic water injection device can be adjusted according to the putty bucket The weight of the putty powder in the machine is automatically proportioned to the quality of the water, which ensures the mixing ratio of the putty powder and water mixture and forms a certain proportion standard, thus ensuring the quality of the mixture and thus the quality of the interior decoration; because the whole device is Purely mechanical structure, there are no more precise small parts in it, so there is no pollution and corrosion by putty powder dust during use, thus greatly reducing the maintenance cost of the water injection device.

Owner:台州镘霓电子商务有限公司

A dry shotcrete spray gun with functions of intelligent positioning, pressure control and mixing

ActiveCN112554566BEffective moistureDifficult to divergeUnderground chambersBuilding material handlingTransceiverGear drive

The invention relates to a dry-sprayed concrete spray gun with functions of intelligent positioning, pressure control and stirring, and belongs to the technical field of concrete spraying tools. The feed pipe, quick-setting agent ring, pressure water ring, mixing chamber and discharge pipe are set in sequence and there is a shell on the outside. There are threads inside the stirring chamber, and there are fixed gears meshing with the transmission gear outside. The transmission gear is driven by a motor, and the shell There are multiple radar transceivers on it, and multiple radar transceivers are connected with the computer radar distance analysis system and the compressed air pressure control system for real-time data transmission. The invention avoids the generation of dust, avoids the waste of concrete, ensures the strength of the concrete, makes the concrete adhere firmly and is not easy to drop.

Owner:南京弘图华智科技有限公司

Mechanical stirring and blending equipment for colored lime slurry for decoration

InactiveCN112140345AReduce workloadSmooth entryCement mixing apparatusSold ingredients supply apparatusCircular discHydraulic cylinder

The invention discloses mechanical stirring and blending equipment for a colored lime slurry for decoration, and belongs to the field of lime slurry blending equipment. The mechanical stirring and blending equipment for the colored lime slurry for decoration comprises a blending barrel and a fixed box body, wherein a feeding groove and a discharging cavity are arranged on the blending barrel; a stirring box body and a feeding channel are arranged in the fixed box body; a crank-slider structure comprising a rotating disc, a swing rod and a switch plate and a hydraulic cylinder with a piston areconnected to the lower part of the blending barrel; rotating rods and a spiral blade plate are arranged in the discharging cavity; a transmission assembly is arranged between the rotating rods; a discharging through opening is formed in the switch plate; a stirring assembly comprises an inner sleeve rod, an outer sleeve rod and a stirring plate; a stirring strengthening assembly comprises a rotating shaft, an annular groove body and two walking rods; at least one group of convex block assembly is fixed onto the inner top surface of the annular groove body; and the thicknesses of the two convex blocks are different. The mechanical stirring and blending equipment for the colored lime slurry for decoration provided by the invention is light in workload, capable of guaranteeing the mixing ratio of materials, high in working efficiency, excellent in mixing and stirring effect and capable of preventing the materials from adhering to the wall.

Owner:长沙葡提科技信息有限公司

Automatic filling and stirring machine for producing sour and spicy starch noodles

InactiveCN108113039AModerate viscosityGuaranteed mix ratioFood shapingAutomatic controlControl valves

The invention discloses an automatic filling and stirring machine for sour and spicy starch noodles. The automatic filling and stirring machine comprises a base frame, a stirred tank, a powder charging hopper and a controller, wherein two hinge bases are mounted at the bottom of the stirred tank, one of the hinge bases is connected with the base frame by virtue of a hinge pin, an oil cylinder is mounted at the bottom of the other hinge base, a spiral stirrer is arranged in the stirred tank, a motor is mounted on one side of the spiral stirrer, a liquid charging hopper and the powder charging hopper are arranged at the top of the stirred tank, a metering valve is arranged at the bottom of the liquid charging hopper, an electric slip cover is arranged above the powder charging hopper, an alarm is mounted on the electric slip cover, a control valve is arranged at the bottom of the powder charging hopper, a weight sensor is arranged on the plug of the control valve, and the controller is mounted on one side of the stirred tank. The automatic filling and stirring machine for sour and spicy starch noodles has the beneficial effects: the automatic filling and stirring machine can automatically control the addition amount of water and a powder material, ensures the mixing proportion of the water and the powder material, enables the viscosity of the powder material to be moderate aftermixing and is convenient for noodle forming.

Owner:重庆自然红商贸有限公司

A Field Mixed Explosive Charging Equipment

ActiveCN104990468BReduce labor intensityReduce labor capacityBlastingPiston rodElectrical and Electronics engineering

The invention relates to scene explosive mixed loading equipment. The scene explosive mixed loading equipment comprises a chassis, a substrate cabin, a sensitizer box and a pumping system, wherein the substrate cabin and the sensitizer box are connected with the pumping system; the pumping system comprises a substrate pump, a sensitizer pump, a connecting rod, a pin shaft, a bracket, a connecting block, a mounting plate and a bolt; a piston rod of the substrate pump is connected with the connecting rod through the pin shaft; the other end of the connecting rod is connected with the bracket through the pin shaft; the connecting block is arranged at the middle part of the bracket; and the sensitizer pump is mounted on the connecting block. The scene explosive mixed loading equipment is simple in structure and continuous in feeding, and greatly reduces the labor intensity of workers when greatly improving the loading efficiency.

Owner:HUNAN KENON SCI & TECH

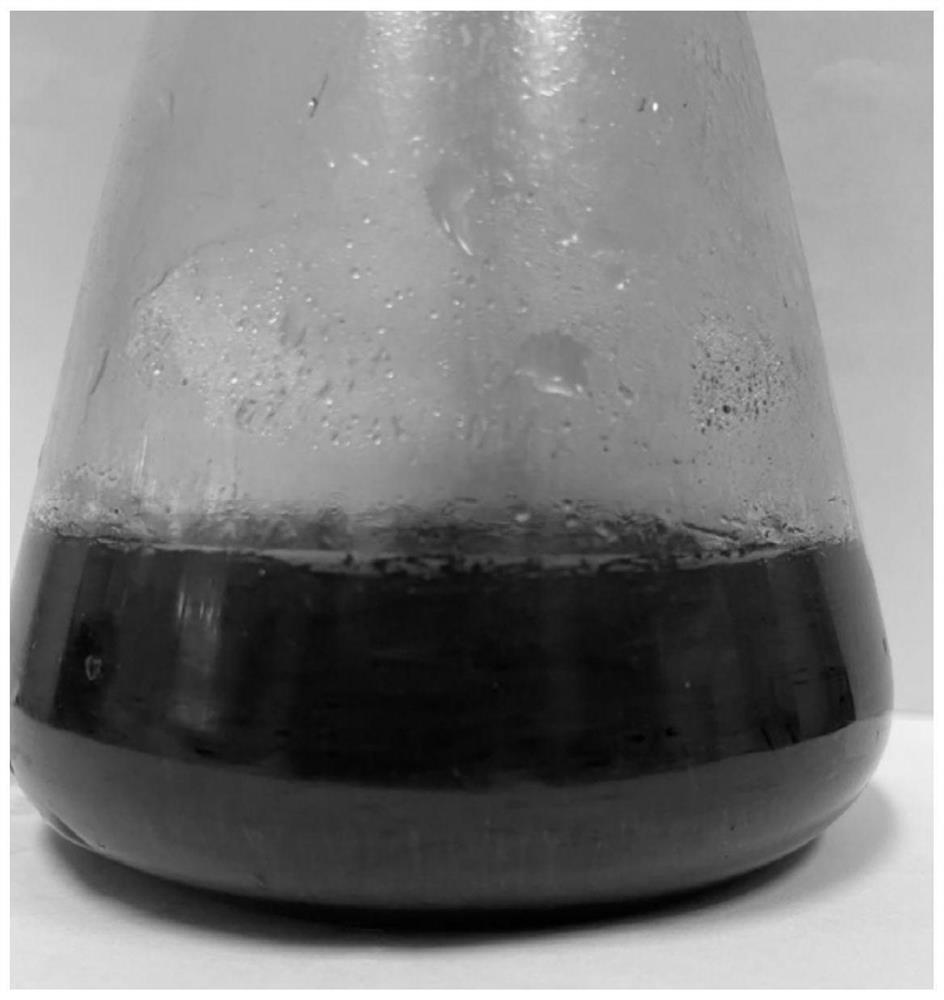

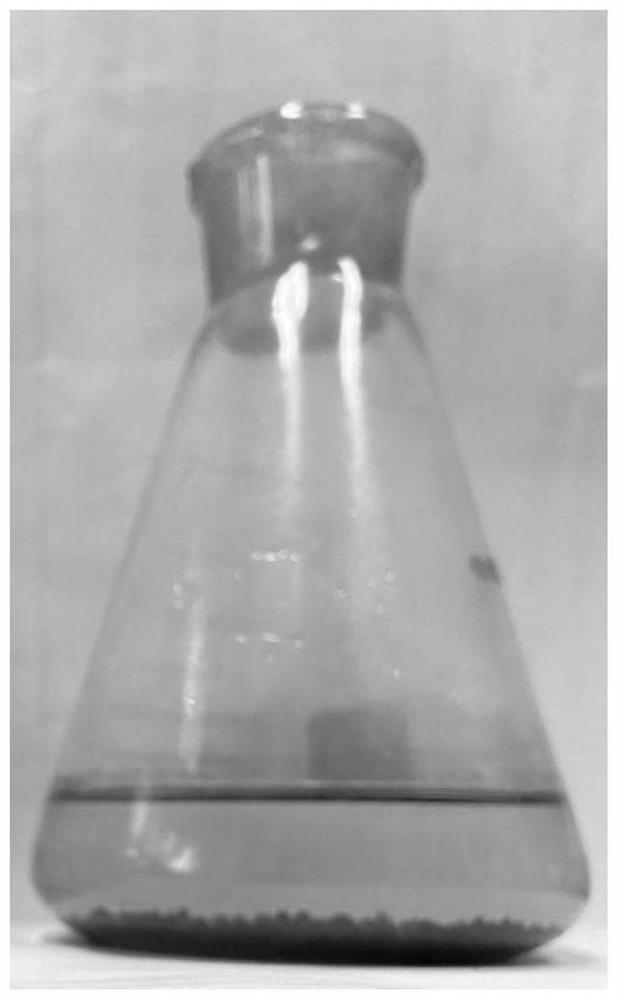

Method for preparing uranium carbide ceramic microspheres by taking carbon nanotubes as carbon source

ActiveCN112382425AReduce in quantityGuaranteed mix ratioNuclear energy generationReactors manufactureHexamethylenetetramineMicrosphere

The embodiment of the invention relates to a method for preparing uranium carbide ceramic microspheres by using carbon nanotubes as a carbon source, which comprises the following steps: mixing a carbon nanotube dispersion liquid, an acid-deficient uranyl nitrate solution, hexamethylenetetramine and urea, and preparing gel spheres by an internal gel method; aging, washing and drying the gel spheres; and calcining the dried spheres, carrying out carbon thermal reduction and sintering. The washing liquid during washing comprises ammonia water. According to the embodiment of the invention, the carbon source in the process of preparing the uranium carbide ceramic microspheres by an internal gel method is optimized, and after the inventor tries to use various carbon-containing substances, the inventor finds that the carbon-containing substances cannot be washed away by ammonia water when the gel spheres prepared by using the carbon nanotubes as the carbon source are washed after being aged in hot silicone oil, and an ammonia water washing solution is kept clear; and the mixing ratio of carbon to uranium during carbothermic reduction is effectively ensured.

Owner:TSINGHUA UNIV

Machine molding technology equipment

The invention discloses a machine molding technology equipment, which comprises a mixing box, a reaction box and a collection box, wherein the front end and the rear end of the left side of the mixingbox are symmetrically provided with a conveying device; each conveying device comprises a conveying tank; the right end of a first connecting pipe is fixedly connected with an air pressure box; the outer side of the air pressure box is provided with an electric rotation machine; a cavity is arranged in a pressure keeping box; a reaction cavity is arranged in the reaction box; the center positionof the upper end surface of the reaction box is fixedly connected with a discharge pipe.

Owner:ZHUJI CITY JIMAILUO IMPORT & EXPORT CO LTD

Thermal test device for real supply conditions of gas-pneumatic thrust chamber injectors

ActiveCN112628026BFill in the gaps in hot test technologyRealize hot test simulationRocket engine plantsThrust chamberEngineering

The invention relates to the field of liquid rocket engines, in particular to a thermal test device for real supply conditions of an injector of a gas-pneumatic thrust chamber, so as to solve the problem that the existing thermal tests of the thrust chamber and its injector are aimed at the mixed combustion of liquid propellants Or the thrust chamber injector of gas-liquid mixed combustion, the test method and test device cannot be used in the hot test of the thrust chamber injector of gas-gas mixed combustion. The device includes a thrust chamber test piece unit, an oxygen-rich gas generator unit and a fuel-rich gas generator unit. The thrust chamber test piece unit includes the thrust chamber test piece, the thrust chamber test piece is used to install the injector under test, the oxygen-enriched gas generator unit includes the oxygen-enriched gas generator, the fuel-rich gas generator unit includes the rich-burn gas generator, The outlets of the oxygen-enriched gas generator and the fuel-rich gas generator are respectively connected to the thrust chamber test piece, and are used to supply oxygen-enriched gas and fuel-rich gas to the thrust chamber test piece.

Owner:XIAN AEROSPACE PROPULSION INST

Maintenance system and maintenance method for spinning nozzle of melt-blowing machine for manufacturing melt-blown cloth

InactiveCN113089113AAvoid damageAutomatically adjust delivery volumeSpinnerette packsWater storageSpinning

The invention discloses a maintenance system and maintenance method for a spinning nozzle of a melt-blowing machine for manufacturing melt-blown cloth. The maintenance system comprises a working box; a water storage cavity with an upward opening is formed in the working box; a spray spinning nozzle blockage cleaning mechanism is arranged on the water storage cavity; an abrasive impurity separation mechanism is arranged on the lower side end face of the working box; and an abrasive mixing pressurization mechanism is arranged on the abrasive impurity separation mechanism. According to the invention, high-pressure water flow is mixed with low-hardness abrasive to dredge and clean spraying holes of the spinning nozzle of the melt-blown cloth, the capacity of cleaning and removing condensate in the spraying holes through the water flow mixed with the low-hardness abrasive is greatly improved, and therefore the requirement for water pressure can be greatly lowered; ultrahigh-pressure water flow equipment does not need to be adopted, so that the equipment cost is reduced; meanwhile, the low-hardness abrasive can avoid damaging the spinning nozzle of the melt-blown cloth; and the abrasive feeding amount can be automatically adjusted, so that the mixing proportion of the abrasive and water is guaranteed, and the dredging and cleaning effect is guaranteed.

Owner:刁柳平

A coke oven circulating flue gas double control pipe network device and its application method

ActiveCN106701108BGuaranteed mix ratioAdapt to alternate combustion conditionsCombustible gas coke oven heatingDispersed particle separationCombustion chamberThermodynamics

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com