A dry shotcrete spray gun with functions of intelligent positioning, pressure control and mixing

An intelligent positioning and concrete technology, which is applied in the direction of cement mixing device, earth square drilling, clay preparation device, etc., can solve the problems of reducing concrete strength, easy to block pipes, cement dust floating and waste of rebound materials, etc., to ensure uniformity , Guarantee the effect of continuity and strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

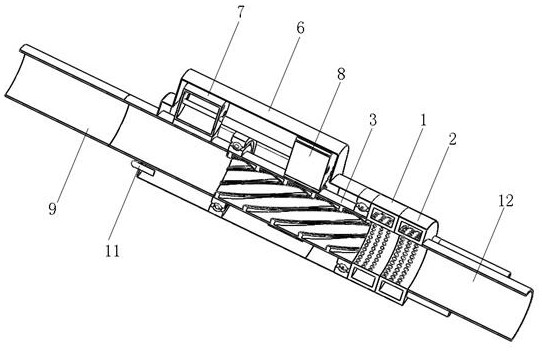

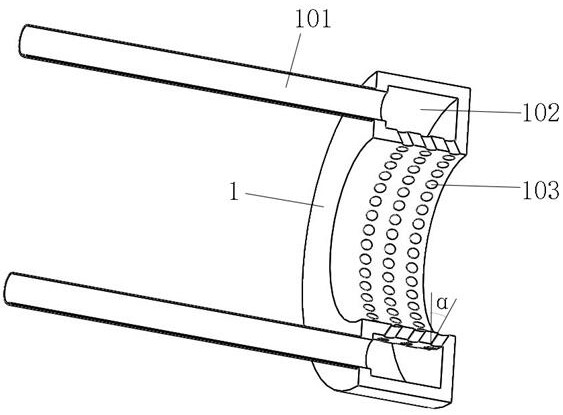

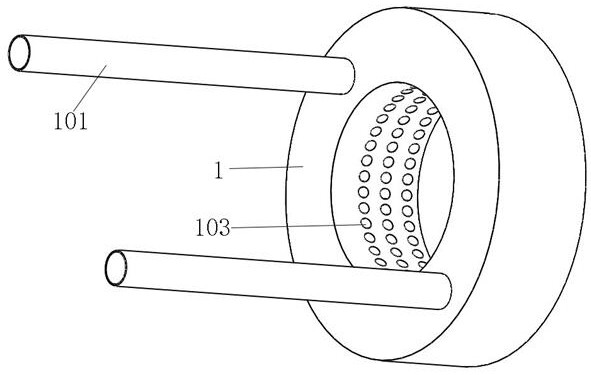

[0035] Specific implementation mode one: as Figure 1 to Figure 12 As shown, the present invention discloses a dry shotcrete spray gun with intelligent positioning, pressure control and stirring functions, including a pressure water ring 1, an accelerator ring 2, a mixing chamber 3, a fixed gear 5, a (metal) casing 6, Motor 7, transmission gear 8, discharge pipe 9, feed pipe 12 and multiple (three) radar transceivers 11; the middle part of described pressure water ring 1 is provided with annular water cavity 102 along its circumference, and One end face is provided with two water inlet pipes 101, and the water outlet ends of the two water inlet pipes 101 are connected with the annular water chamber 102. Quantity can change according to the property of engineering material; The discharge end of the agent pipe 201 is connected with the annular agent chamber 202, and the inner wall of the accelerator ring 2 is provided with several discharge holes 203, and one end surface of the...

specific Embodiment approach 2

[0036] Specific implementation mode two: as figure 2, 3 As shown, this embodiment is a further description of Embodiment 1, and the two water inlet pipes 101 are located on the same diameter of the pressure water ring 1 .

specific Embodiment approach 3

[0037] Embodiment 3: This embodiment is a further description of Embodiment 2. The two water inlet pipes 101 are provided with opening and closing valves to control the opening and closing of the pressure water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com