SOFC tail gas utilization research experiment system

An experimental system and exhaust technology, applied in electrical components, fuel cells, electrochemical generators, etc., can solve the problems of difficulty in obtaining, high temperature of SOFC system exhaust, ineffective utilization, etc., and achieve accurate experimental data, low cost, and heating speed. quick effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

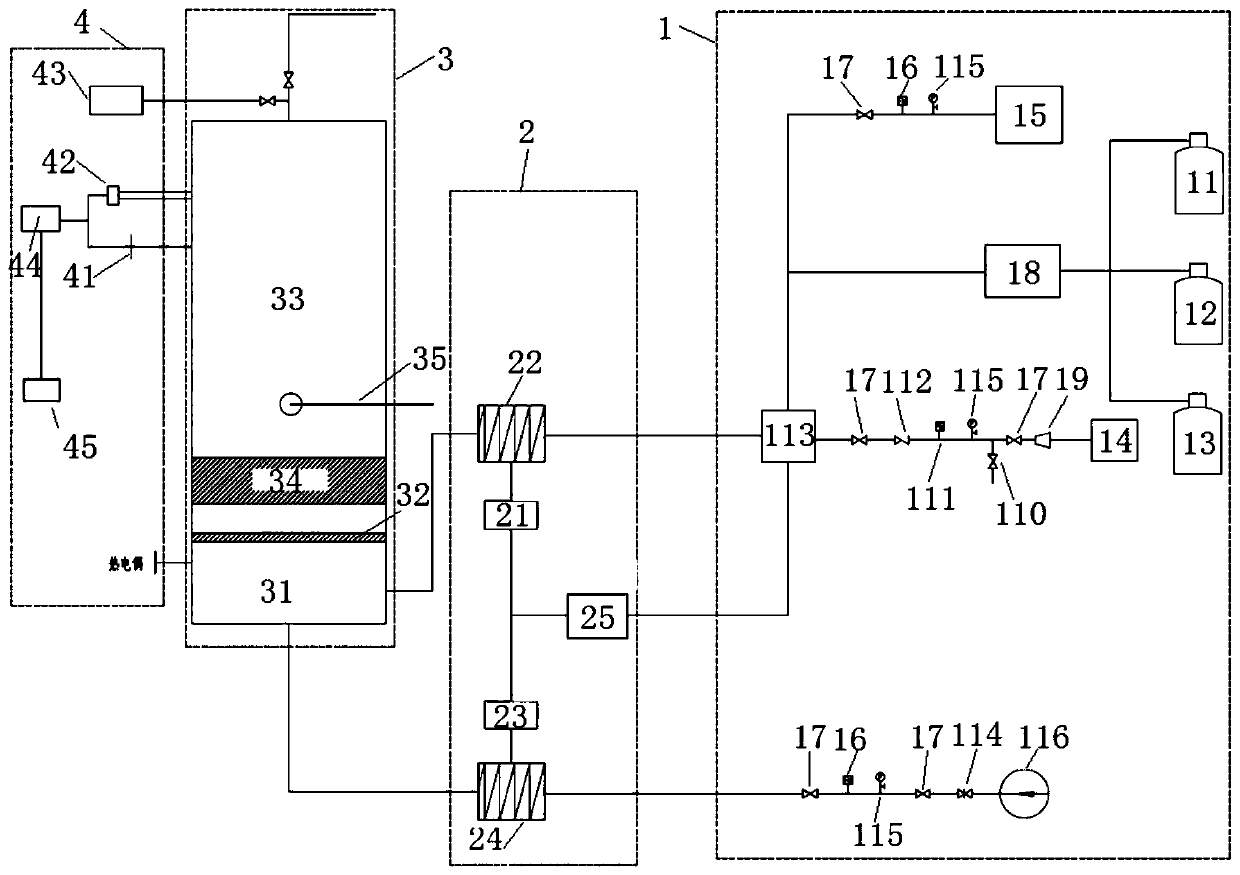

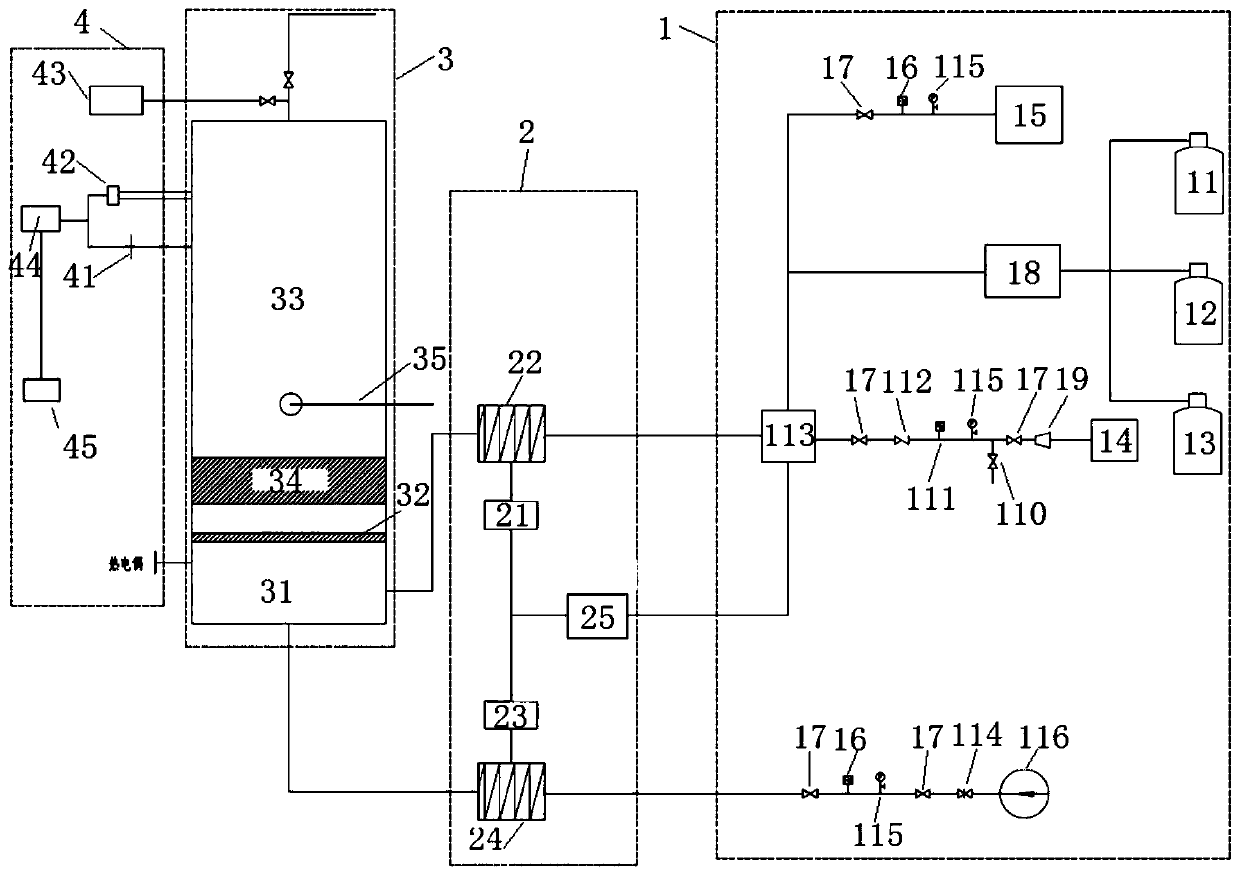

[0032] A kind of SOFC tail gas utilization research experimental system, such as figure 1 As shown, it includes a gas supply device 1 , a heating device 2 , a combustion device 3 and a measuring device 4 connected in sequence.

[0033] The gas supply device 1 is used to generate compressed air and SOFC tail gas with different component contents. The gas supply device 1 includes a gas supply mechanism, a water vapor supply mechanism, an air supply mechanism, and a The ejector 113 connected to the gas outlet pipeline of the gas mechanism; the gas at the gas outlet of the ejector 113 is SOFC tail gas; the air supply mechanism generates compressed air. The gas supply mechanism includes a natural gas pipeline connected to a natural gas source 15, a high-precision real-time gas distribution instrument 18, and a hydrogen gas storage cylinder 13, a carbon monoxide gas storage cylinder 12 and a carbon dioxide gas storage cylinder connected to the high-precision real-time gas distributi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com