Manufacturing method of snowboard

A manufacturing method and technology of snowboards, applied to snowboards, skis, skating, etc., can solve the problems of low specific gravity of epoxy resin, poor mechanical properties of snowboards, and low toughness, so as to avoid less epoxy resin content and improve mechanical properties. Performance, the effect of improving ski performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

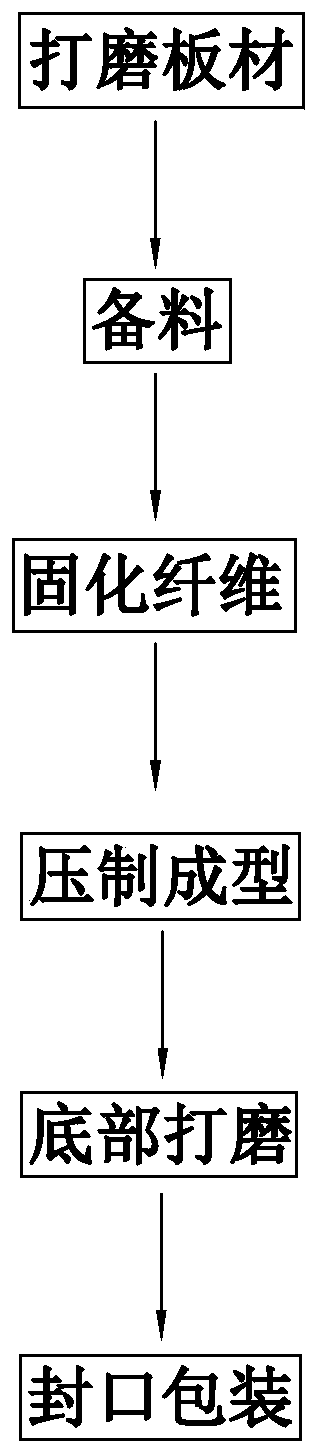

[0028] A method of manufacturing a snowboard, such as figure 1 As shown, the steps include:

[0029] Step 1: Grinding the board, grinding the base plate, core, and panel to the specified thickness according to the drawing, and then engraving and profiling the base plate, core, and panel according to the size of the drawing; making the bonding surface treatment of the base plate, core, and panel more perfect Smooth, easy for subsequent fitting and bonding;

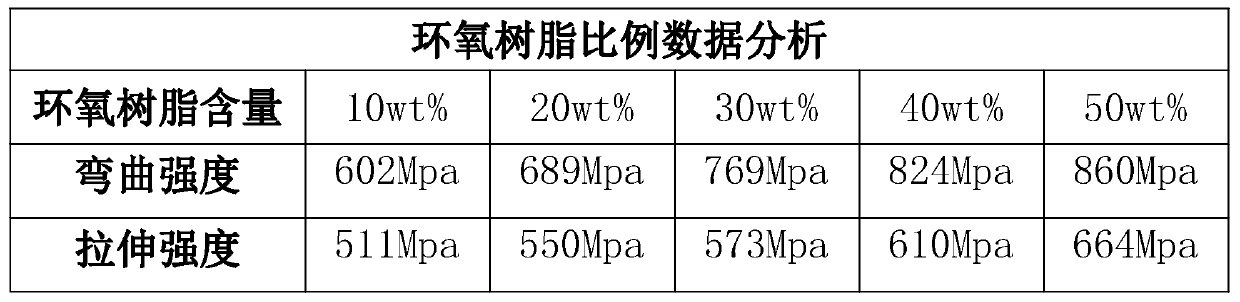

[0030] Step 2: Prepare materials, prepare glass fiber and epoxy resin. The glass fiber is prepared with two axes and the weight is not less than 600g / square meter; the glass fiber is cut according to the size of the core, and the cut The glass fiber is weighed, and the proportion of epoxy resin is weighed according to the ratio of epoxy resin: glass fiber = 13:7, and then the epoxy resin is evenly brushed on the glass fiber cloth, because the glass fiber and the ring Oxygen resin together constitutes the upper glass fibe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com