Automatic filling and stirring machine for producing sour and spicy starch noodles

A technology of automatic filling and hot and sour powder, which is applied in application, food forming, food science, etc. It can solve the problems of high viscosity of powder, blockage of powder pulling machine, difficulty of pulling powder, etc., and achieve moderate viscosity and easy pulling powder effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

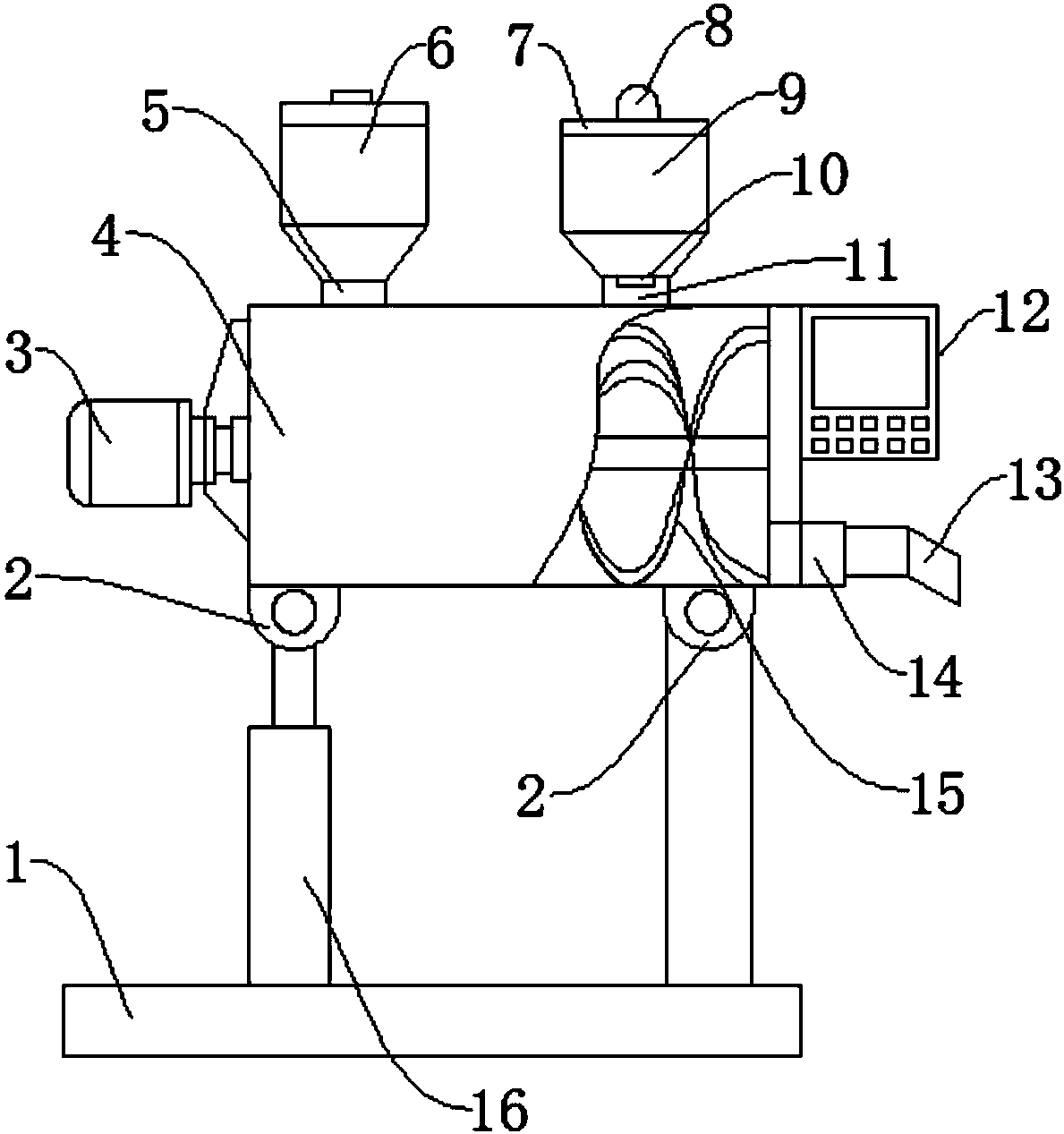

[0015] The present invention will be further described below in conjunction with accompanying drawing:

[0016] like figure 1 Shown, a kind of hot and sour vermicelli production automatic filling mixer, comprises bottom frame 1, mixing tank 4, powder adding hopper 9 and controller 12, two hinged seats 2 are installed on the bottom of mixing tank 4, wherein a hinged seat 2 It is connected with the bottom frame 1 through a pin shaft, so that the mixing tank 4 can rotate around the pin axis on one side, and an oil cylinder 16 is installed at the bottom of the other hinge base 2, and the oil cylinder 16 is used to lift up one side of the mixing tank 4, which is convenient for mixing. The powder is discharged from the discharge pipe 13, and the inside of the mixing tank 4 is provided with a helical agitator 15, which is used to stir the water and the powder, so that the two are fully mixed, and one side of the helical agitator 15 is equipped with a The motor 3, the motor 3 is used...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com