Mechanical stirring and blending equipment for colored lime slurry for decoration

A technology of mechanical stirring and lime slurry, which is applied in cement mixing devices, clay preparation devices, and sales of raw material supply devices, etc. It can solve the problems of heavy workload, long time-consuming, and low work efficiency of the mixing mechanism, and achieve the effect of reducing the work burden.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

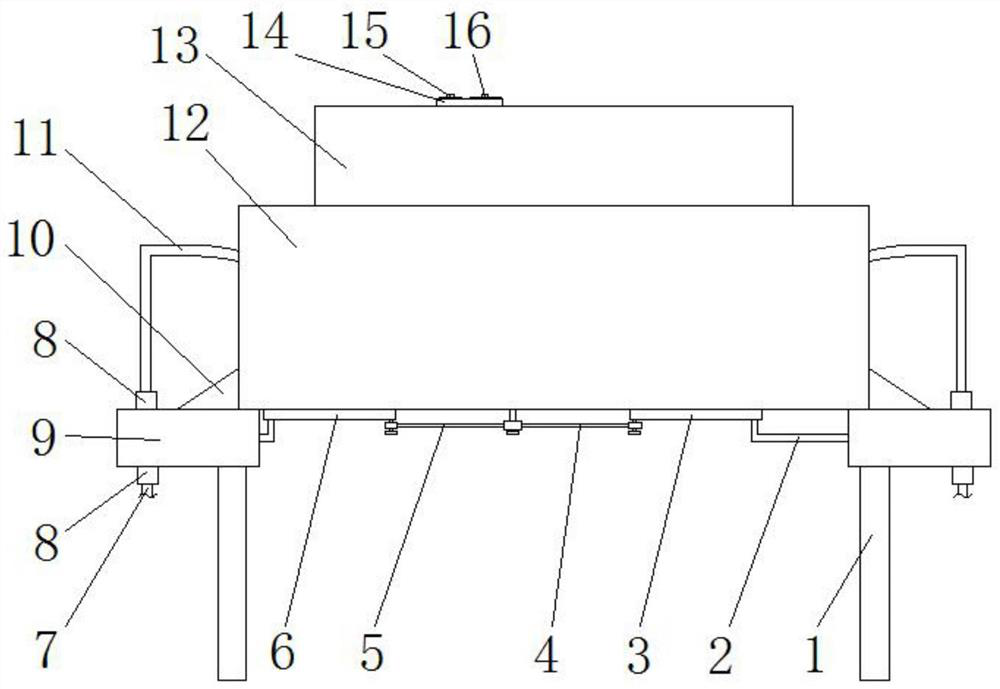

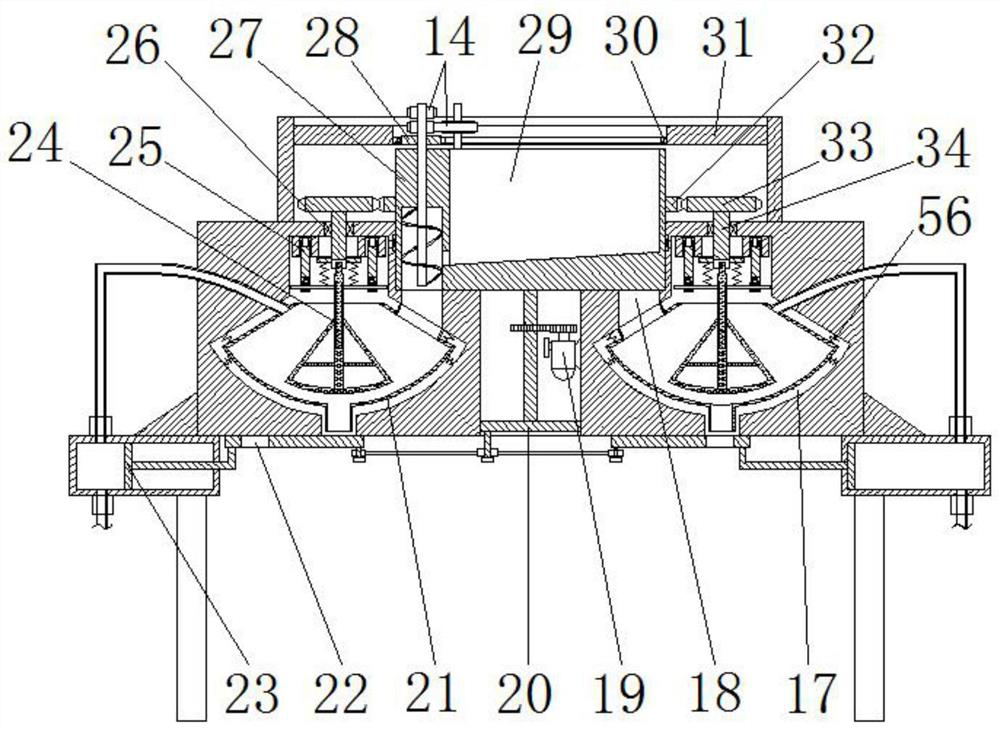

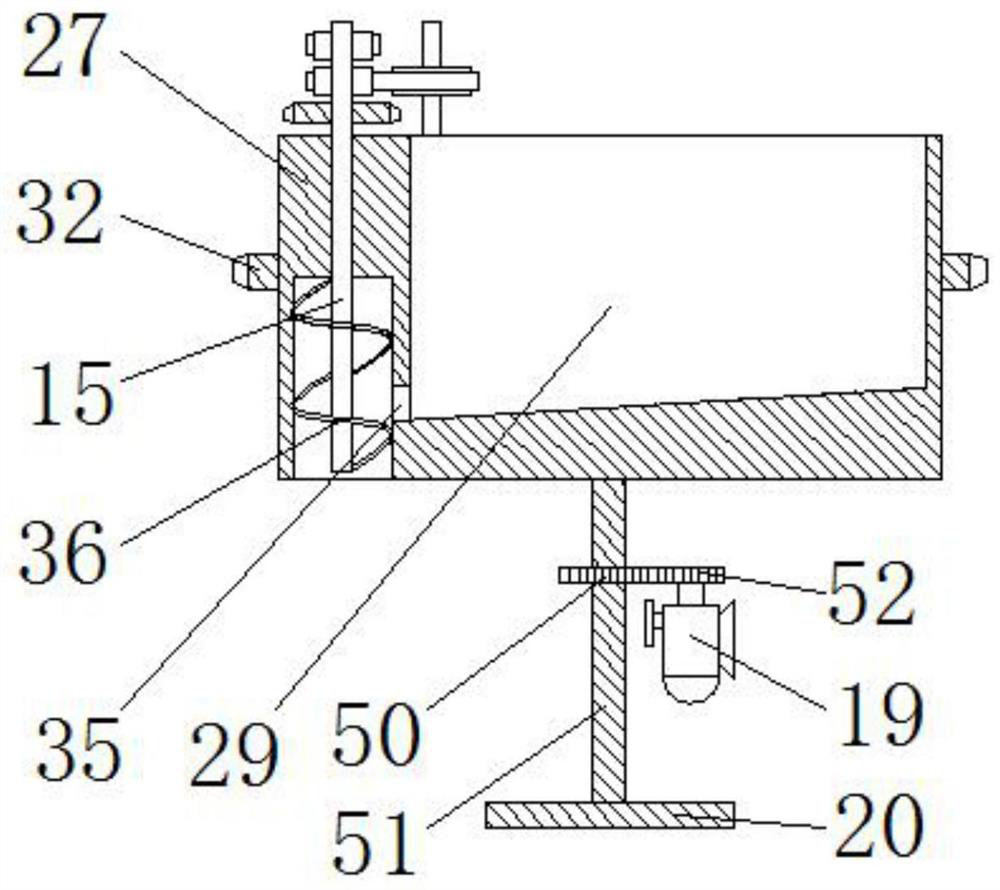

[0036] Such as figure 1 and figure 2 The shown mechanical mixing and blending equipment for colored lime slurry for decoration includes a stirring box 21 with a stirring assembly 24 inside; the stirring box 21 is installed in a fixed box 12, and the fixed box 12 passes through The supporting legs 1 are supported on the ground, and the center of the fixed box body 12 is provided with a vertically arranged straight-through opening, and the fixed box body 12 is provided with at least two ring-shaped and equidistantly distributed on the side of the straight-through opening for installation. The installation cavity 17 of stirring box 21 (only two installation cavities 17 located at two opposite sides are shown in the accompanying drawings), the peripheral side of said stirring box 21 is connected with equidistantly connected to the fixed box 12 The third spring 56, the center of the upper end side of the fixed box body 12 is embedded with a rotatable batching bucket 27, and the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com