Method and device for mixing various gases according to specified proportion

A proportional mixing, gas technology, applied in mixing methods, gas and gas/vapor mixing, chemical instruments and methods, etc., can solve problems such as affecting the normal operation of the laser and changing the mixing ratio.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

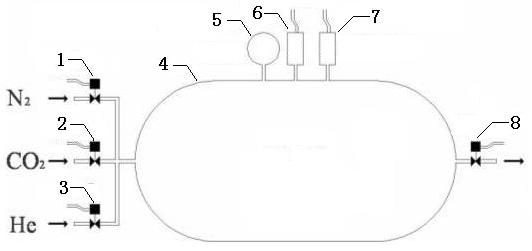

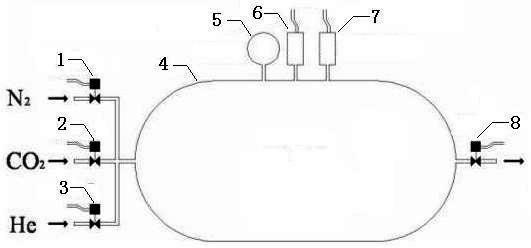

[0011] exist figure 1 Medium, N 2 Input solenoid valve 1, CO 2 The input electromagnetic valve 2 and He input electromagnetic valve 3 use the same type of electromagnetic valve, so that when they are opened, the flow rate is the same, and they are sent to the mixed gas storage tank 4, and the mixed gas in the mixed gas storage tank 4 is exhausted through the mixed gas storage tank. The valve 8 is sent into the resonant cavity; the mixed gas storage tank 4 is equipped with a mixed gas storage tank pressure upper limit detection pressure switch 6, a mixed gas storage tank pressure lower limit detection pressure switch 7 and a pressure gauge 5, and the pressure gauge 5 is used for Displays the pressure of the gas in the mixed gas storage tank.

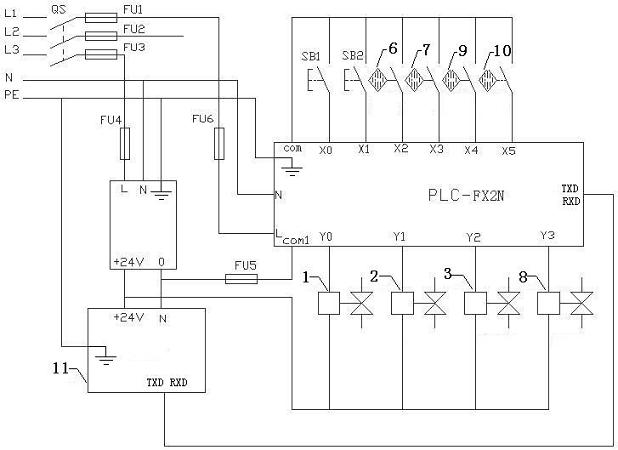

[0012] exist figure 2 Among them, the pressure switch 6 for the detection of the upper limit of the pressure limit of the mixed gas storage tank is used for feedback on the upper limit of the pressure of the mixed gas storage tank, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com