A coke oven circulating flue gas double control pipe network device and its application method

A technology for circulating flue gas and coke ovens, which is applied to coke ovens, separation methods, heating of coke ovens, etc., can solve the problems of difficult optimization and reconstruction of coke ovens, excessive nitrogen oxide emissions of coke ovens, etc., and achieves low construction difficulty, The effect of reducing the concentration of oxygen and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

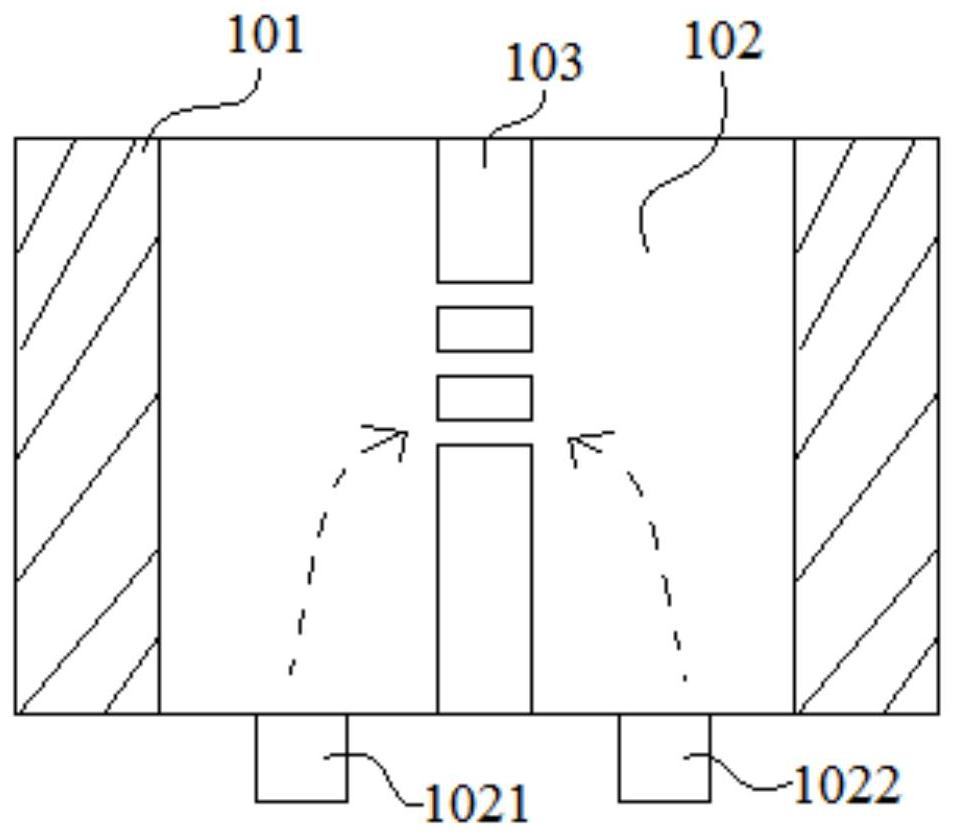

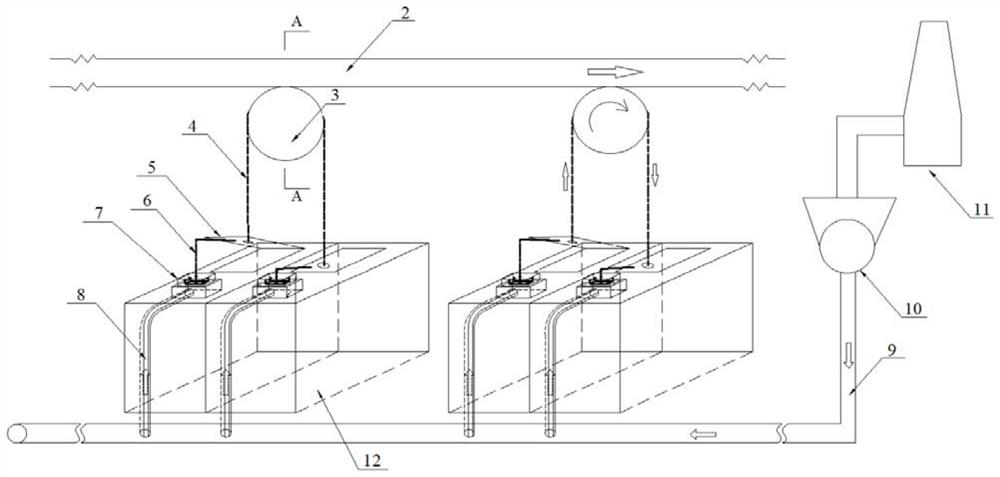

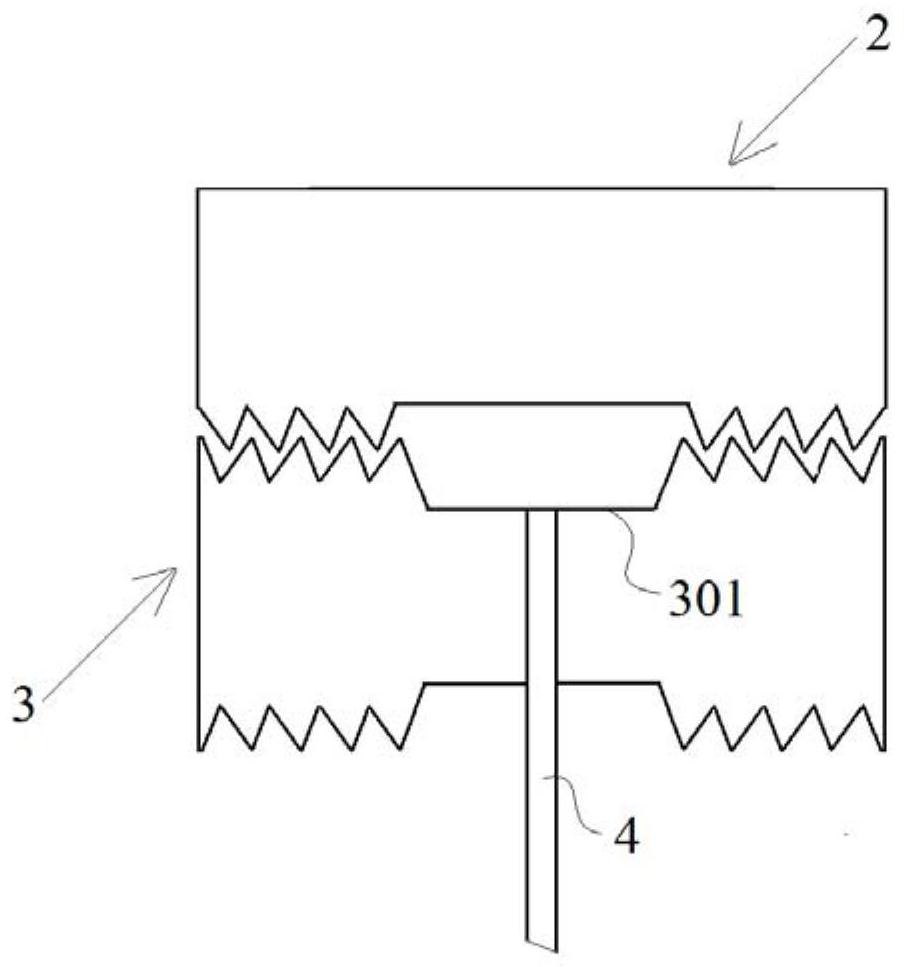

[0064] combine Figure 1-4 , the coke oven circulating flue gas dual control pipe network device in this embodiment includes a coke oven, the coking chamber 101 and the combustion chamber 102 in the coke oven are arranged alternately, and the combustion chamber 102 is separated into two parts connected to each other by a vertical fire channel 103 , the bottom of one part is provided with the combustion chamber port A 1021, and the bottom of the other part is provided with the combustion chamber port B 1022; it also includes the flue gas main pipe 9, the circulation fan 10 and the mixing box 12, the flue gas main pipe 9 and the coke oven The chimney 11 is connected, and a circulation fan 10 is installed on the flue gas main pipe 9; the mixing box 12 is divided into two disconnected spaces, and each space is connected to the flue gas main pipe 9 through a separate flue gas branch pipe 8; the combustion chamber port A 1021 is respectively connected with the chimney 11 , a space i...

Embodiment 2

[0084] combine Figure 6 , the coke oven circulating flue gas dual control pipe network device of this embodiment has basically the same structure as that of Embodiment 1, the difference is that in order to ensure that all the sub-transmission gears 3 are stably and synchronously driven, another The improved structure is specifically as follows: Compared with Embodiment 1, in this embodiment, the setting of the total transmission rack 2 is canceled, but the transmission between two adjacent sub-transmission gears 3 is carried out by a chain 13, and a certain sub-transmission gear The gear 3 is driven by a motor, so that when a certain sub-transmission gear 3 is driven by the motor, through the transmission of the chain 13 between two adjacent sub-transmission gears 3, all sub-transmission gears 3 have realized the same direction and synchronous rotation.

[0085] combine Figure 7 , the method for using the coke oven circulating flue gas dual control pipe network device of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com