Method for preparing uranium carbide ceramic microspheres by taking carbon nanotubes as carbon source

A technology of carbon nanotubes and ceramic microspheres, applied in the field of nuclear engineering, can solve problems such as proportional effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042]A method for preparing uranium carbide ceramic microspheres using carbon nanotubes as a carbon source, comprising the following steps:

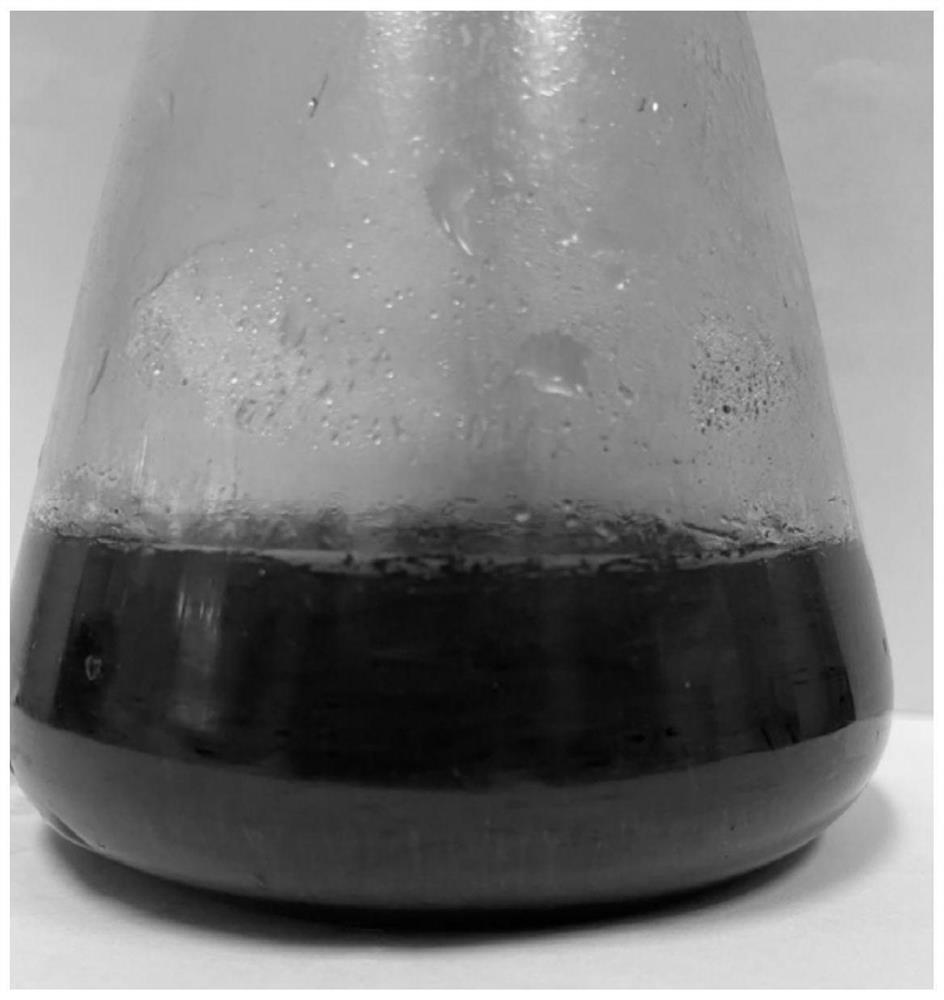

[0043] (1) At room temperature, add 5.522g of hexamethylenetetramine and 2.366g of urea into 10ml of carbon nanotube aqueous dispersion (containing 1g of carbon nanotube) to fully dissolve to make a carbon-containing solution, and carbon-containing The solution is cooled in a constant temperature water bath at 4°C to form the first mixed solution;

[0044] (2) Take 10ml of 2.8mol / L under-acid uranyl nitrate solution, place it in a constant temperature water bath at 4°C for cooling, and form the second mixed solution;

[0045] (3) Pour the second mixed solution into the first mixed solution to form a mixed glue, so that the molar ratio of carbon atoms and uranium atoms in the mixed glue is 3:1, and place it in a constant temperature water bath at 4°C for cooling, Constitute the third mixed solution, the third mixed solution can be used ...

Embodiment 2

[0052] A method for preparing uranium carbide ceramic microspheres using carbon nanotubes as a carbon source, comprising the following steps:

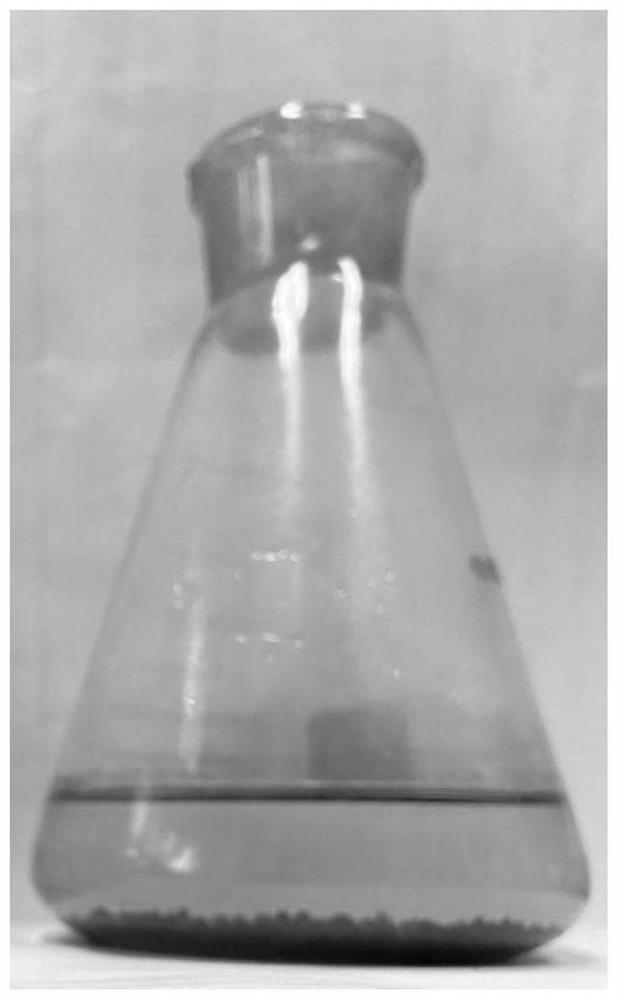

[0053] (1) At room temperature, add 5.405g of hexamethylenetetramine and 2.356g of urea into 10ml of carbon nanotube aqueous dispersion (containing 1g of carbon nanotube) to fully dissolve to make a carbon-containing solution, and carbon-containing The solution is cooled in a constant temperature water bath at 4°C to form the first mixed solution;

[0054] (2) Take 10ml of 2.8mol / L under-acid uranyl nitrate solution, place it in a constant temperature water bath at 4°C for cooling, and form the second mixed solution;

[0055] (3) Pour the second mixed solution into the first mixed solution to form a mixed glue, so that the molar ratio of carbon atoms and uranium atoms in the mixed glue is 2.90:1, and place it in a constant temperature water bath at 4°C for cooling, Constitute the third mixed solution, the third mixed solution can be u...

Embodiment 3

[0062] A method for preparing uranium carbide ceramic microspheres using carbon nanotubes as a carbon source, comprising the following steps:

[0063] (1) At room temperature, add 5.522g of hexamethylenetetramine and 2.366g of urea into 10ml of carbon nanotube aqueous dispersion (containing 1g of carbon nanotube) to fully dissolve to make a carbon-containing solution, and carbon-containing The solution is cooled in a constant temperature water bath at 4°C to form the first mixed solution;

[0064] (2) Take 10ml of 2.8mol / L under-acid uranyl nitrate solution, place it in a constant temperature water bath at 4°C for cooling, and form the second mixed solution;

[0065] (3) Pour the second mixed solution into the first mixed solution to form a mixed glue, so that the molar ratio of carbon atoms and uranium atoms in the mixed glue is 3.15:1, and place it in a constant temperature water bath at 4°C for cooling, Constitute the third mixed solution, the third mixed solution can be u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com