A high-efficiency filtration method for concentrate ore pulp

A high-efficiency filtration and concentrate technology, applied in filtration and separation, separation methods, chemical instruments and methods, etc., can solve problems such as affecting filtration efficiency and loss of function, and improve filtration efficiency, reduce moisture content, and avoid delayed dosing. effect of the phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

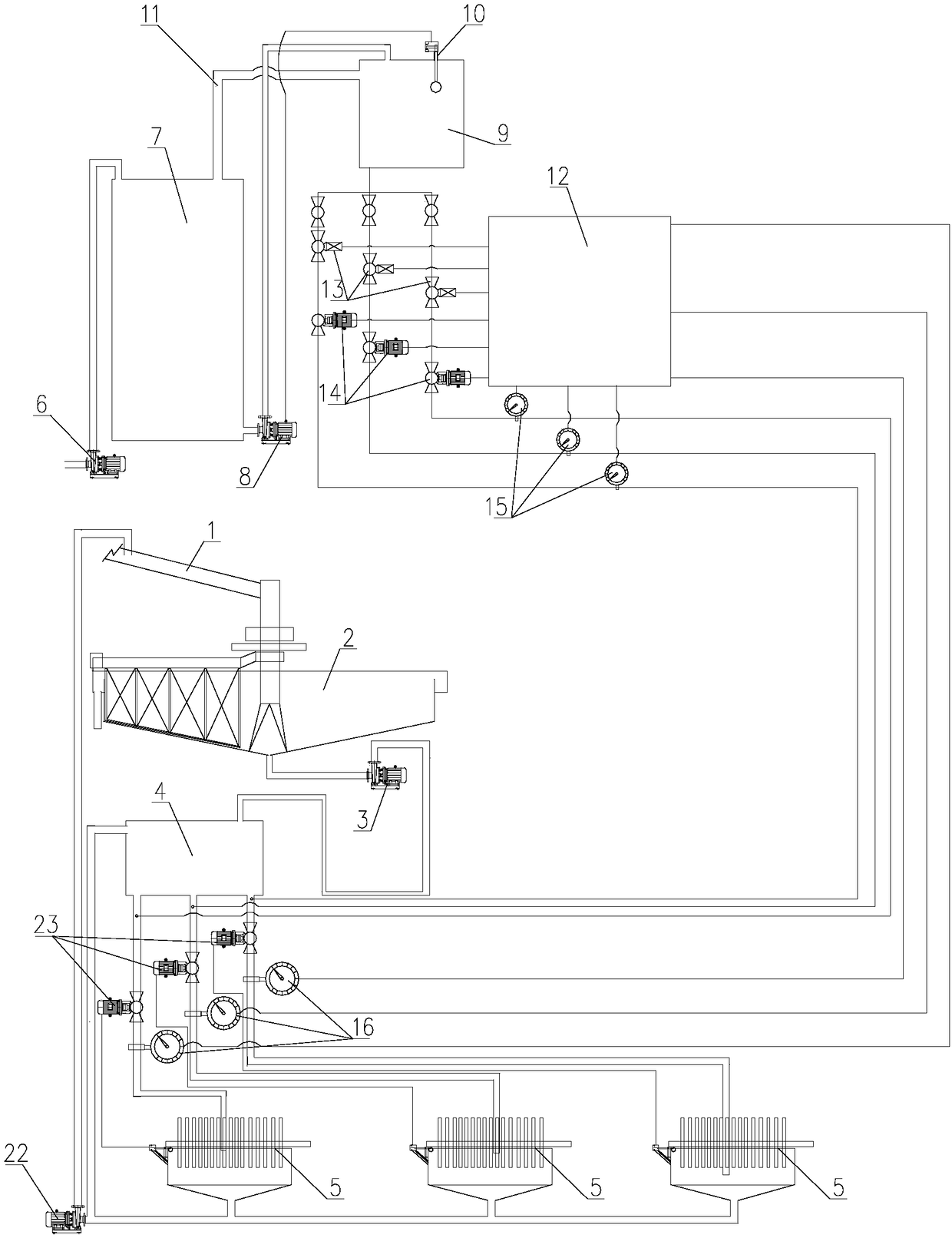

[0045] Such as figure 1 As shown, in the present embodiment, the concentrate pulp filtration system consists of a concentrate pulp launder 1, a concentrate thickening well 2, a concentrate thick slurry pump 3, a concentrate thick slurry filter separation box 4 and a vacuum filter connected in sequence. The vacuum filter 5 and the overflow port of the concentrated ore thick slurry filter sub-mine box 4 are connected to the concentrate ore slurry launder 1 through an overflow pipeline, and an overflow pump 22 is arranged on the overflow pipeline.

[0046] The iron ore concentrate slurry with an iron concentrate concentration of about 20% enters the concentrate concentration well 2 from the concentrate slurry flow tank 1, and in the concentrate concentration well 2, after overflow and dewatering treatment, the bottom flow of the concentrate concentration well 2 is obtained Concentrate pulp with a concentration of more than 60%, under the action of the concentrate pump 3, the conc...

Embodiment 2

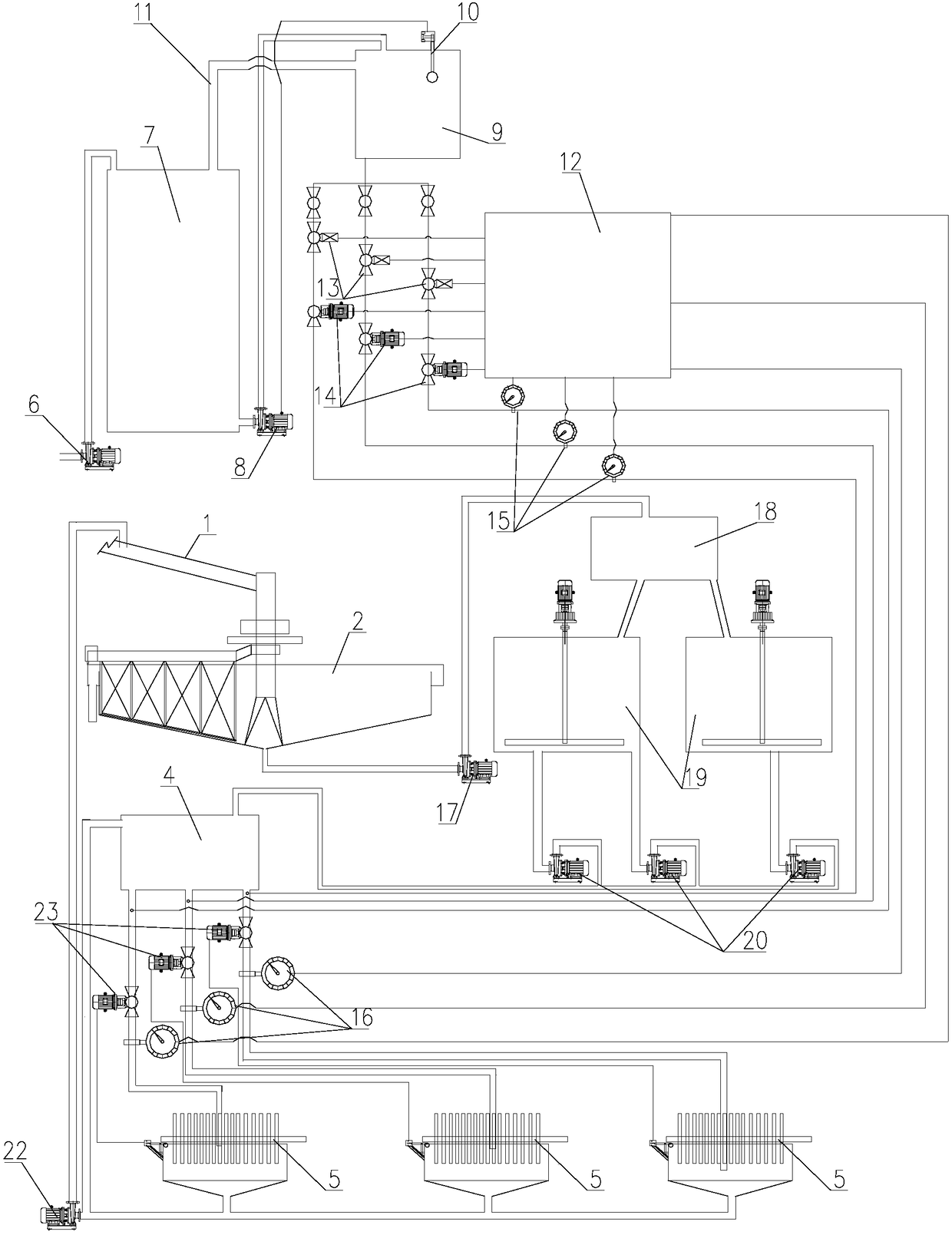

[0051] Such as figure 2 As shown, the concentrate pulp filtration system of the present embodiment is composed of the concentrate pulp launder 1, the concentrate thickening well 2, the concentrate thick slurry pump A17, the concentrate thick slurry mixing tank sub-ore box 18, the concentrate thick slurry The slurry mixing barrel 19, the concentrated ore thick slurry pump B20, the concentrate ore thick slurry filter separation box 4 and the vacuum filter 5 are composed; the overflow port of the vacuum filter 5 and the concentrate thick slurry filter separation box 4 passes through the overflow The flow pipe is connected to the concentrate ore slurry launder 1; in the present embodiment, two groups of concentrate ore thick slurry mixing barrels 19 and three groups of vacuum filters 5 are provided.

[0052] The iron ore concentrate slurry with an iron concentrate concentration of about 20% enters the concentrate concentration well 2 from the concentrate slurry flow tank 1, and i...

Embodiment 3

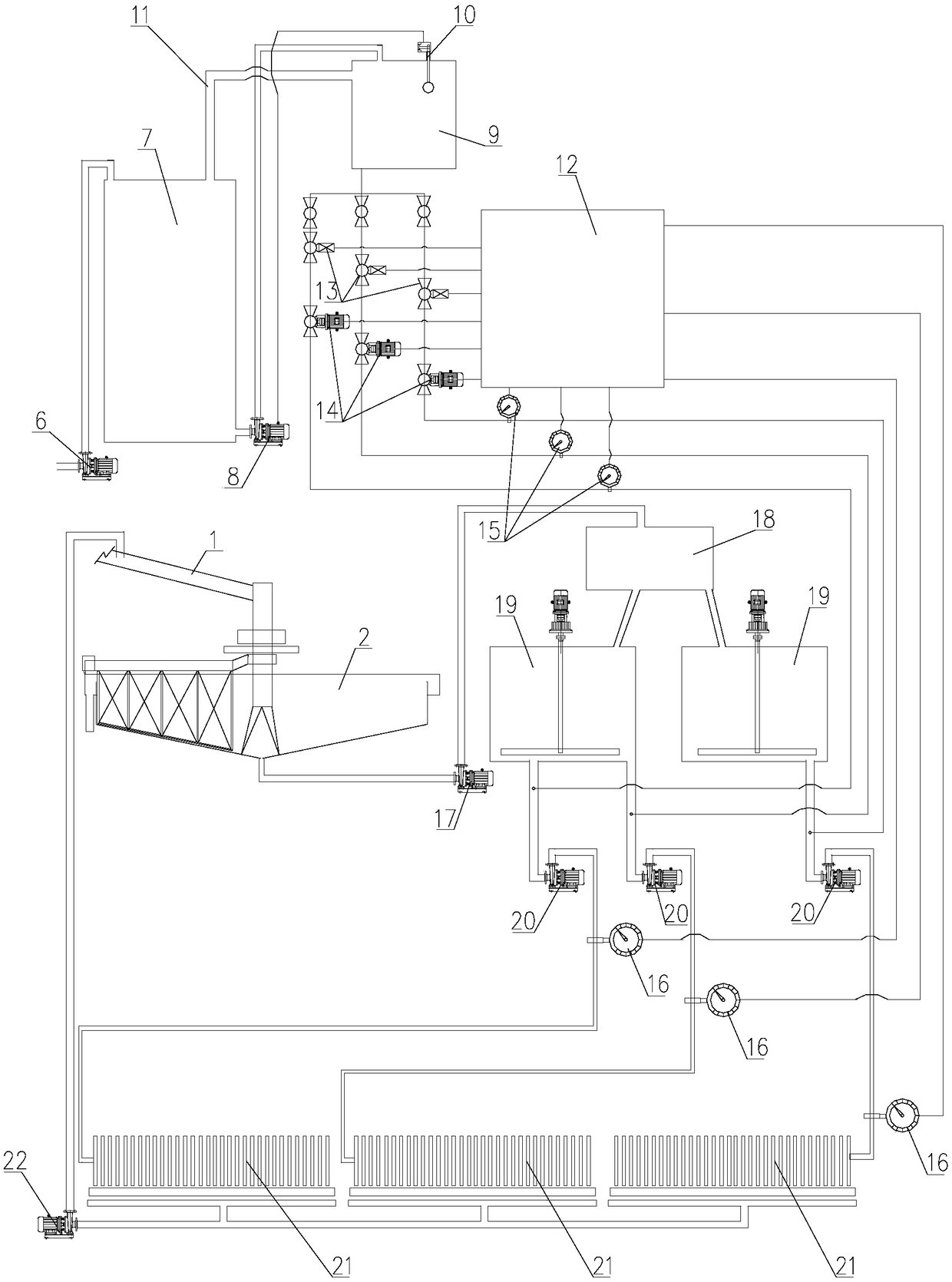

[0059] Such as image 3 As shown, in the present embodiment, the concentrate pulp filtration system is composed of the concentrate pulp launder 1, the concentrate thickening well 2, the concentrate thick slurry pump A3, the concentrate thick slurry mixing tank sub-ore box 18, the concentrate slurry, which are connected in sequence. Ore thick slurry mixing barrel 19, concentrated ore thick slurry pump B20 and plate and frame filter press 21 are composed; the overflow port of plate and frame filter press 21 is connected to concentrate ore slurry launder 1 by overflow pipeline; In the present embodiment, set There are 2 groups of concentrated ore thick slurry mixing barrels 19 and 3 groups of plate and frame filter presses 21, which are respectively connected through corresponding slurry conveying pipelines.

[0060] The iron ore concentrate slurry with an iron concentrate concentration of about 20% enters the concentrate concentration well 2 from the concentrate slurry flow tank...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com