A low-cost cold-rolled magnetic pole steel with a yield strength of 450mpa and high magnetic induction and its manufacturing method

A technology of yield strength and manufacturing method, applied in the field of cold-rolled magnetic pole steel, can solve the problems that Si is not conducive to the surface quality control of hot-rolled strip steel, the magnetic properties need to be further improved, and the manufacturing cost is high, so as to achieve good coordination of magnetic induction intensity and excellent comprehensiveness. Good performance and surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be further described below in conjunction with embodiment.

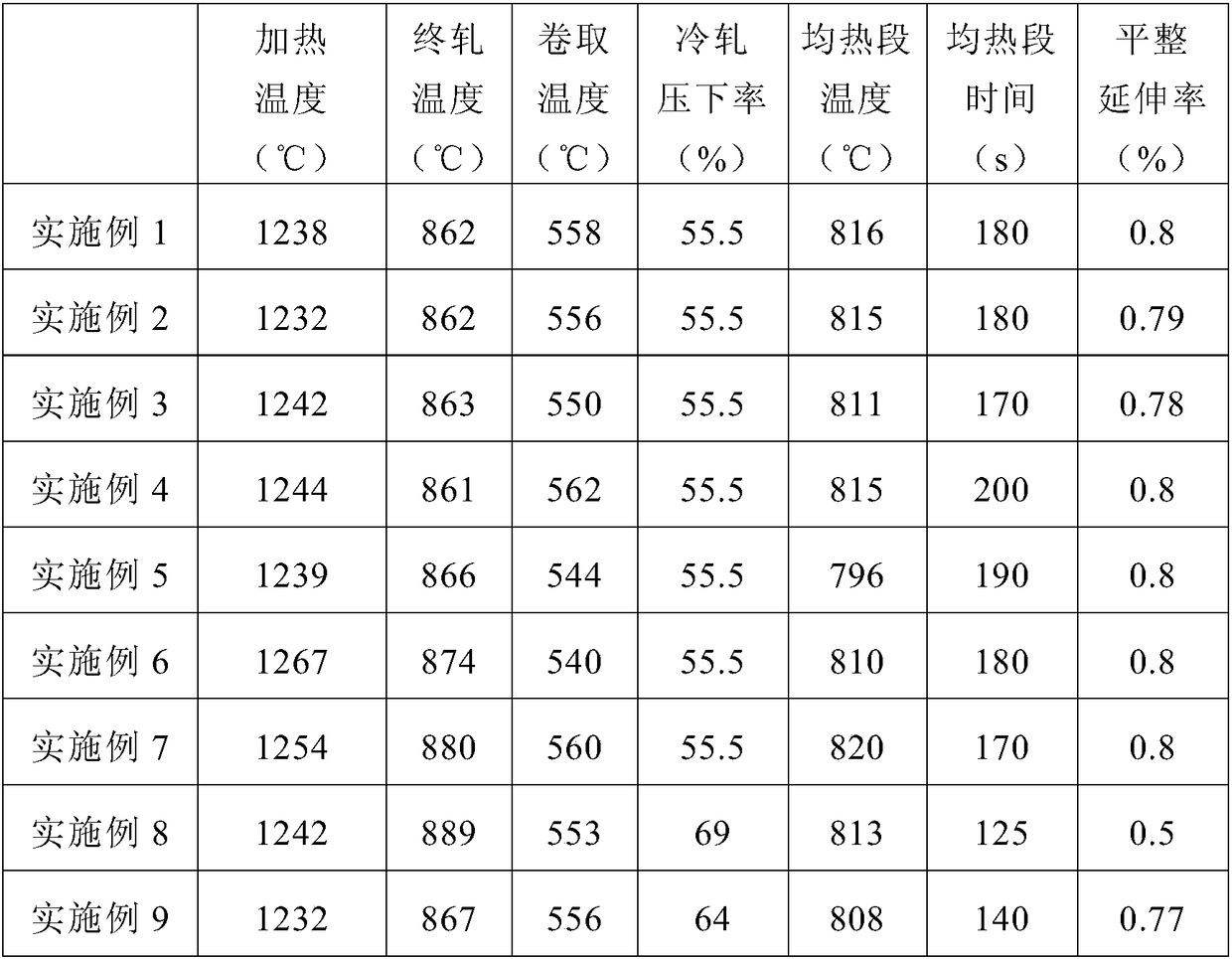

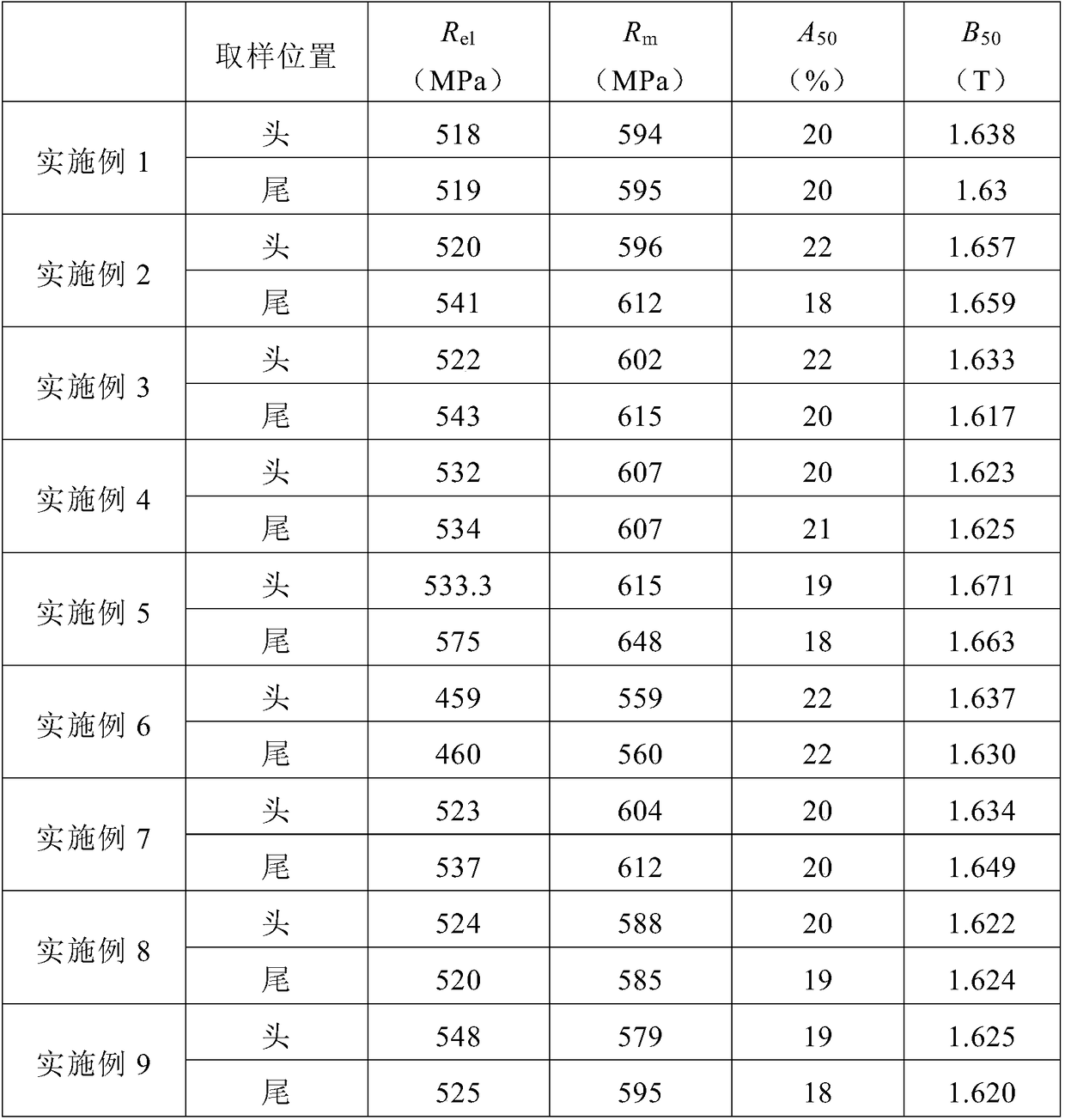

[0047] Table 1 shows the composition of the steel of the example of the present invention, Table 2 shows the manufacturing process of the steel of the example of the present invention, and Table 3 shows the mechanical properties and magnetic properties of the steel of the example of the present invention.

[0048] The manufacturing method of the embodiment of the present invention, concrete steps are as follows:

[0049] 1) The slab is heated, and the heating temperature is 1230-1280°C.

[0050] 2) Hot rolling: the final rolling temperature is 830-900°C; the deformation adopts 7-pass rolling, and the steel billet is finally rolled from 30mm into a thin steel plate with a size of 2-4mm. After rolling, it is cooled to 530-590°C by jet water cooling Do coiling.

[0051] 3) Air-cooling is used to cool the hot-rolled steel coil to 60-80°C for pickling.

[0052] 4) Cold rolling: the red...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com