Filtration-integration integrated plant and method for producing aluminum oxide by Bayer process

A technology of alumina and Bayer method, applied in the direction of alumina/hydroxide, etc., can solve the problems of low labor productivity, high labor cost, high production cost, etc., and achieve the effects of shortening the construction period, saving floor space, and reducing pipelines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

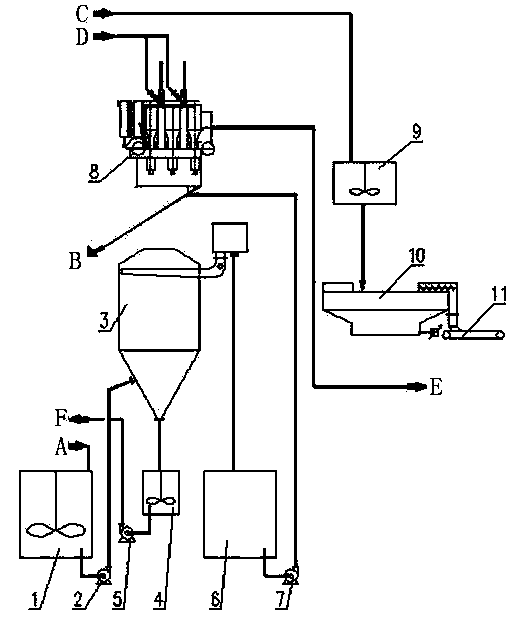

[0018] As shown in the drawings of the description, the main equipment of the present invention includes a crude liquid tank 1, a crude liquid pump 2, a leaf filter 3, a filter cake tank 4, a filter cake pump 5, a semen tank 6, a semen pump 7, and a vertical disc filter 8. Aluminum hydroxide slurry tank 9, horizontal disc filter 10 and belt conveyor 11.

[0019] Wherein the coarse liquid tank 1 is connected with the leaf filter 3 through the crude liquid pump 2, the bottom of the leaf filter 3 is connected with the filter cake tank 4, the upper part is connected with the semen tank 6, and the bottom of the semen tank 6 is provided with a semen pump 7 , the semen pump 7 is connected with the vertical disc filter 8; the filter cake tank 6 is arranged on a ▽5.000 plane, and the bottom of the filter cake tank 4 is provided with a filter cake pump 5; the aluminum hydroxide slurry tank 9 is arranged on Above the horizontal disc filter 10, the horizontal disc filter 10 is connected w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com