Automatic temperature control system for tank furnace

A technology of automatic control system and flue temperature, applied in vertical furnaces, furnaces, furnace types, etc., can solve the problems of refractory refractory life of retort furnace flue with great negative impact, untimely temperature adjustment, and high labor intensity. , to achieve the effect of improving production stability and product quality uniformity, prolonging service life, and preventing over-temperature phenomenon.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited by the embodiments.

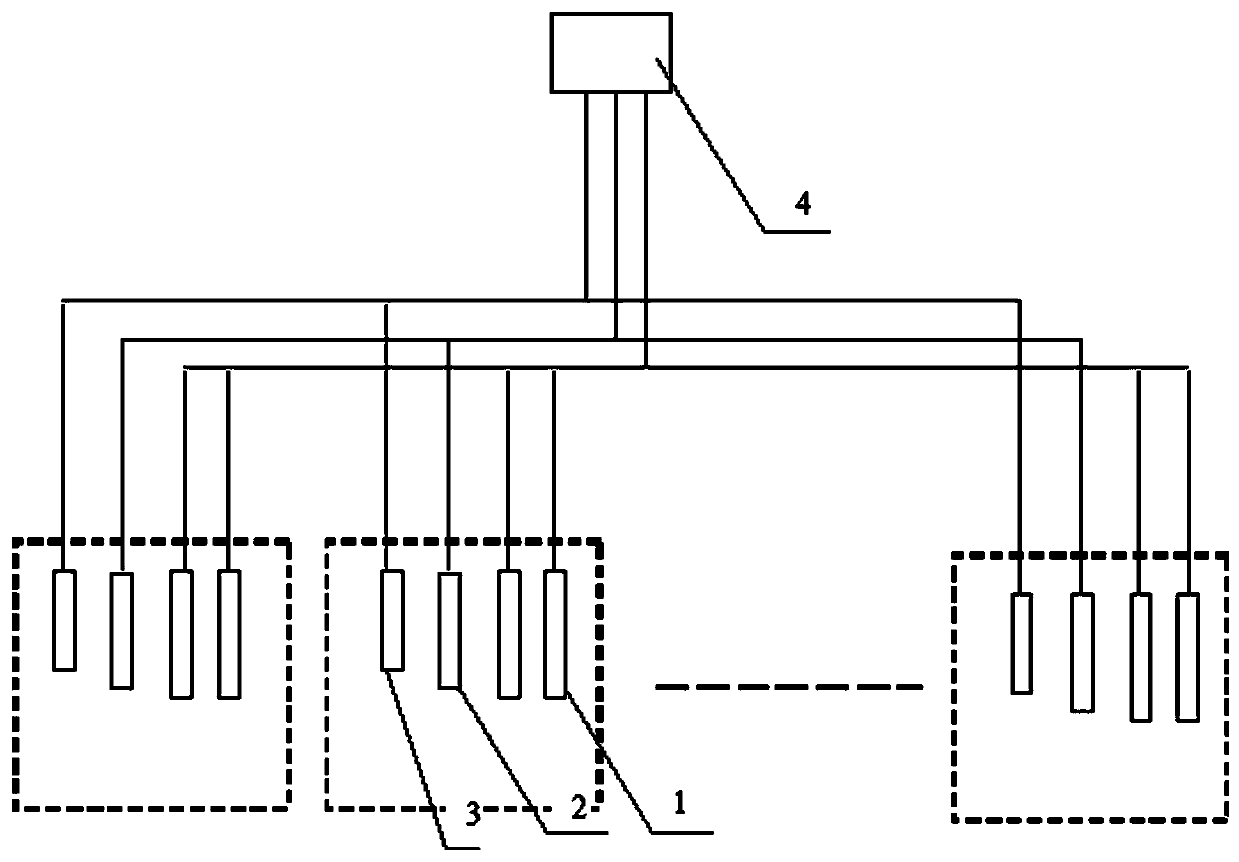

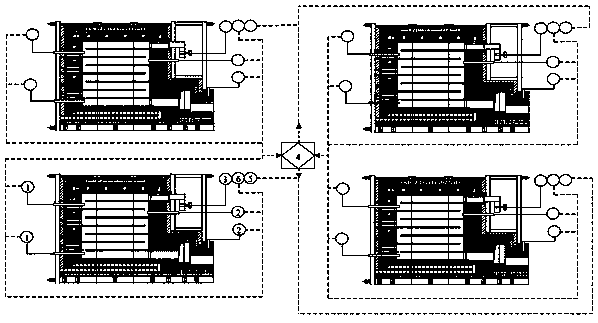

[0035] As shown in the figure, the automatic control system for the temperature of the fire channel of the tank furnace of the present invention includes the bottom local control system and the upper centralized control system. Each tank furnace in the calcining workshop is equipped with a set of local control system, and the local control system is through the network The communication system is connected to the upper-level centralized control system to realize unified management and control of the underlying system.

[0036] The local control system includes a temperature sensor to detect the temperature of the fire channel 1, a differential pressure transmitter to detect the pressure of the fire channel 2, a regulating valve 5 to control the air volume, an air volume ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com