Integrated self-adaptive coordinated control system for flue gas denitrification, water-saving and coal-saving of cement plant

A technology for coordinating control systems and water-saving systems. It is applied in the direction of comprehensive factory control, comprehensive factory control, and electrical program control. It can solve the problems of inability to achieve the best energy-saving benefits in factories, information that cannot be communicated, shared, and waste of water. , to maximize energy saving benefits, reduce labor quota, and reduce labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

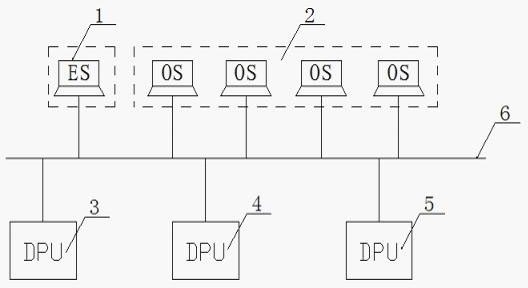

[0012] The whole system includes flue gas denitrification system, water-saving system, cement clinker production coal-saving system, and each system is connected to the industrial Ethernet where the central control DCS system is located. Through the same industrial Ethernet, each system can carry out effective communication of some data points and multi-domain coordinated control.

[0013] Field layer: the field intelligent bus device communicates with the CPU controller using the Profibus DP communication standard;

[0014] Control management layer: Industrial Ethernet TCP / IP protocol is used to realize the communication between the system controller and the operation station; each layer is independent and connected with each other, connected through the computer network system to achieve decentralized control of DCS and centralized management Purpose.

[0015] Taking the bus-type topology as an example, the engineer station, clinker cement central control DCS, flue gas den...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com