A detection method of raw anode carbon block based on machine vision

A machine vision, raw anode technology, applied in instruments, measuring devices, scientific instruments, etc., can solve problems such as decline, material waste, product quality, detection errors, etc., to achieve accurate detection results and reduce labor capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

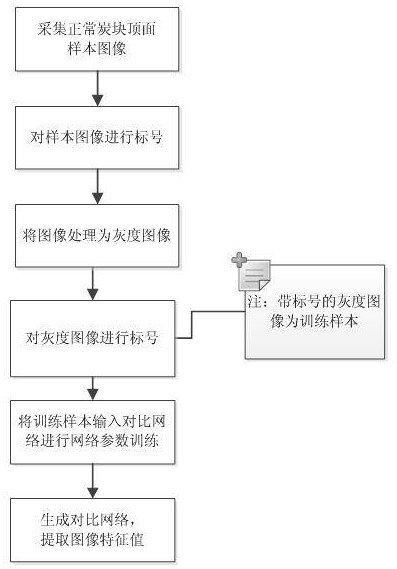

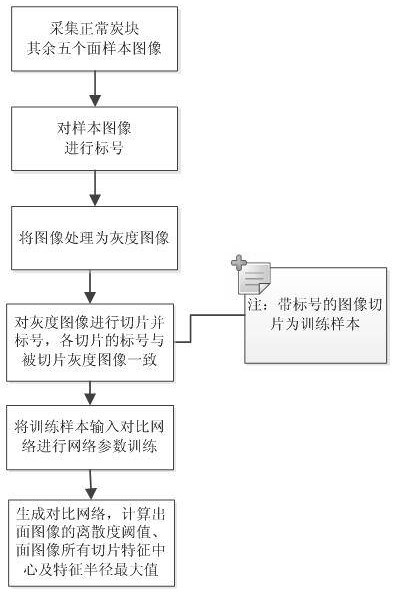

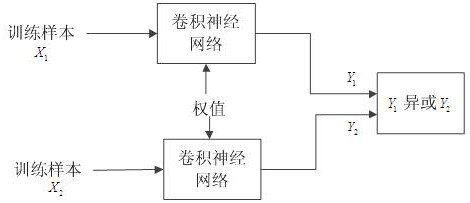

[0021] As shown in the figure, a method for detecting green anode carbon blocks based on machine vision in the present invention, cameras are installed at the exit of the carbon block forming machine at multiple angles to collect images of carbon blocks in the forming workshop, and the images of each surface of the carbon blocks are collected by the camera, and then carried out offline Modeling and online detection; offline modeling consists of modeling of the top surface of the carbon block and modeling of the remaining five surfaces; online detection includes detection of the top surface of the carbon block, detection of the remaining five surfaces of the carbon blo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com