Integral thermal expansion manufacturing method for heavy-duty vehicle drive axle housing

A technology for driving axle housings and heavy-duty vehicles, which is applied in the field of metal processing, and can solve the problems of large machining volume, large welding workload, and low material utilization rate, so as to reduce production costs, increase material utilization rate, and improve product quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

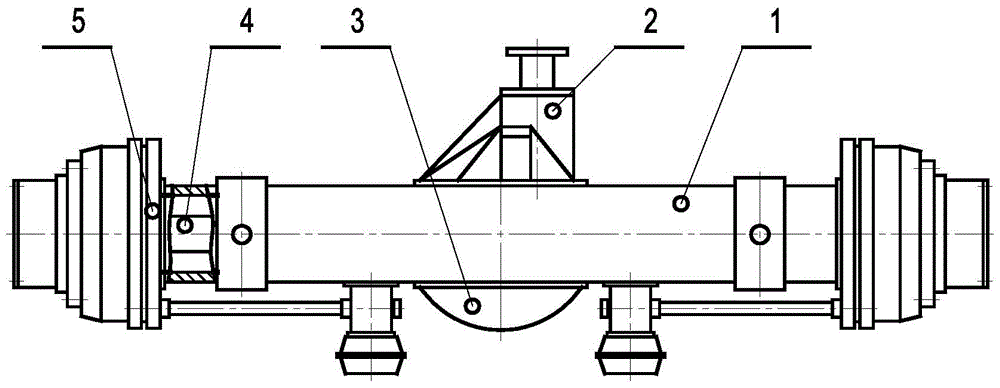

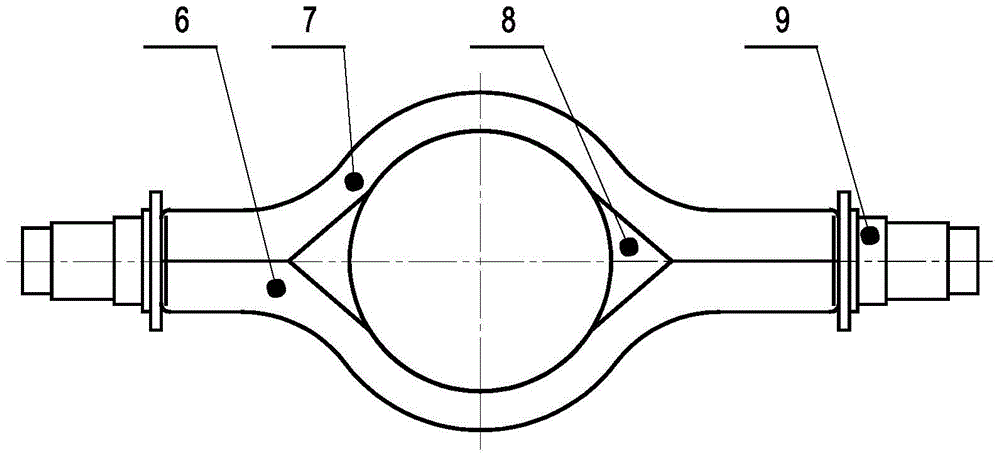

[0108] refer to figure 2 , for the 485 type load capacity shown in the figure is the driving axle housing of 13T car, adopt the step of the integral thermal expansion manufacturing method of heavy-duty vehicle driving axle housing of the present invention as follows:

[0109] 1. Determine the structural size of the tube blank used:

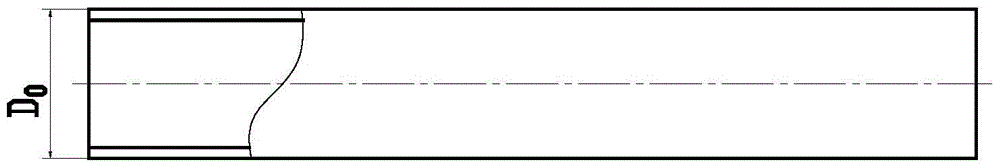

[0110] refer to image 3 , according to the geometric characteristics and size parameters of the drive axle housing, after selecting the appropriate bulging ratio, the specification of the tube blank is determined to be the diameter D 0 ,D 0 =219mm, wall thickness H 0 , H 0 = 16mm; and according to the principle of equal plastic deformation volume, the blanking length is determined through calculation, that is, the length of the tube blank L 0 =1295±2mm.

[0111] 2. Tube blank preforming before thermal expansion:

[0112] refer to Figure 4 , first perform two heat shrinking steps on the tube blanks on both sides of the bulging zone (abou...

Embodiment 2

[0122] refer to figure 2 , the present embodiment is a 498 type drive axle housing with a load capacity of 13T~15T that is one size larger than the 485 type drive axle housing model of embodiment 1. The steps of the overall thermal expansion manufacturing method of the heavy-duty vehicle drive axle housing according to the present invention are as follows:

[0123] 1. Determine the size specification of the tube blank used:

[0124] refer to image 3 , according to the geometric characteristics and size parameters of the drive axle housing, because the central pipa hole and the outer shell dimensions are larger than those of the 485 type axle housing, the size of the tube blank used should be determined after calculating the bulging ratio. Its outer diameter is D 0 ,D 0 =245mm, wall thickness H 0 , H 0 = 16mm; and according to the principle of equal volume of plastic deformation, the length of blanking is determined after calculation, that is, the length of the tube bla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com