A Catenary Conveying System for Anode Carbon Blocks

A technology of anode carbon block and conveying system, applied in the direction of conveyors, mechanical conveyors, conveyor objects, etc., can solve the problem of increasing road and car maintenance and maintenance costs, increasing production and operation costs of electrolytic aluminum enterprises, and not being able to connect together, etc. Problems, to achieve the effect of reducing project construction and production operation costs, reducing the labor quota of enterprises, and reducing transportation vehicles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

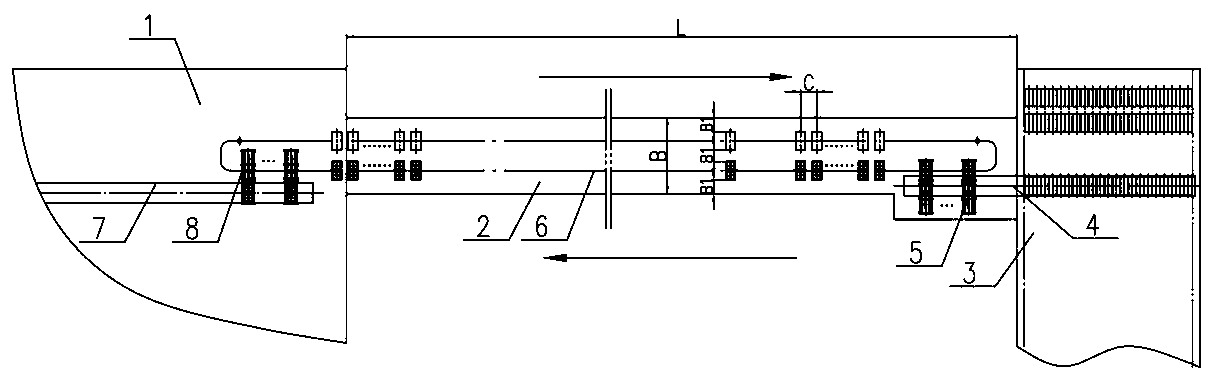

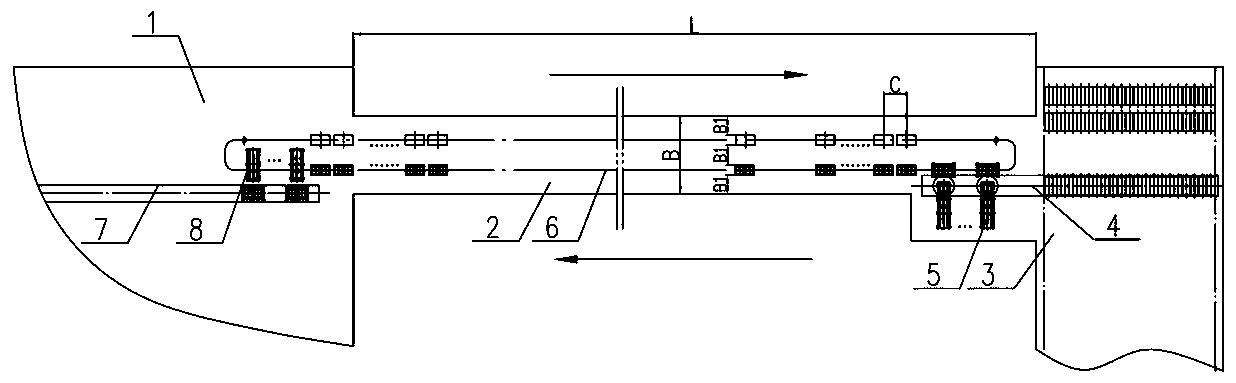

[0016] Below in conjunction with accompanying drawing, patent of the present invention is described further.

[0017] As shown in the figure, an anode carbon block catenary conveying system of the present invention has a carbon block conveying corridor 2 between the anode assembly workshop 1 and the anode carbon block warehouse 3; an assembly workshop carbon block conveyor is provided in the anode assembly workshop 7 and a carbon block push-out device 8, a carbon block conveyor 4 and a carbon block pushing device 5 are provided in the anode carbon block storehouse 3, and a suspended catenary conveyor 6 is provided in the carbon block conveying corridor 2, A spreader 9 is arranged below the suspended catenary conveyor 6 .

[0018] An anode tray is provided on the spreader 9 .

[0019] The distance between the anode assembly workshop 1 and the anode carbon block warehouse 3 should be less than 2000 meters, and the height difference between the anode assembly workshop 1 and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com