Multi-screw extrusion device and refining method for refining and molding recycled rubber powder

A technology of recycled rubber and extrusion equipment, which is applied in the field of multi-screw extrusion equipment and refining, which can solve the problems of low-end safety hazards, low degree of automation, and low production efficiency, so as to reduce labor quota and labor intensity, and improve technology. Level, the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] A screw used for refining recycled rubber powder, including an extrusion conveying section, a shearing section and a shearing conveying section;

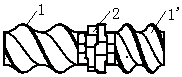

[0025] The extrusion conveying section includes the first conveying thread element 1, the second conveying thread element 1', and the third conveying thread element 1", and the pitch relationship of the three conveying thread elements is as follows: the first conveying thread element 1 pitch P1>the second The pitch P2 of the conveying thread element 1'>the pitch P3 of the third conveying thread element 1", at least one first shearing thread element 2 is arranged between the conveying thread elements;

[0026] The shearing section includes at least one second shearing screw element 2' and a fourth conveying screw element, and can optionally be combined with a reverse screw element 3, a mixing screw element 4, and a strong shearing screw element 5, the first Four conveying thread element pitch P4≤P3;

[0027] The shear conveyi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com