Gas-solid mixing combustion hot-air oven with double towers and double furnace cavities

A technology of hot blast stove and double furnace, which is applied in the direction of air heater, solid fuel combustion, combustion equipment, etc., which can solve the problem of increasing the cost of coal powder preparation for supporting facilities of pulverized coal combustion furnace, reducing combustion efficiency and equipment service life, and is not easy for long-term Problems such as storage and long-distance transportation, to achieve the effect of improving the level of automation technology, small heat exchange area and volume, and high temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

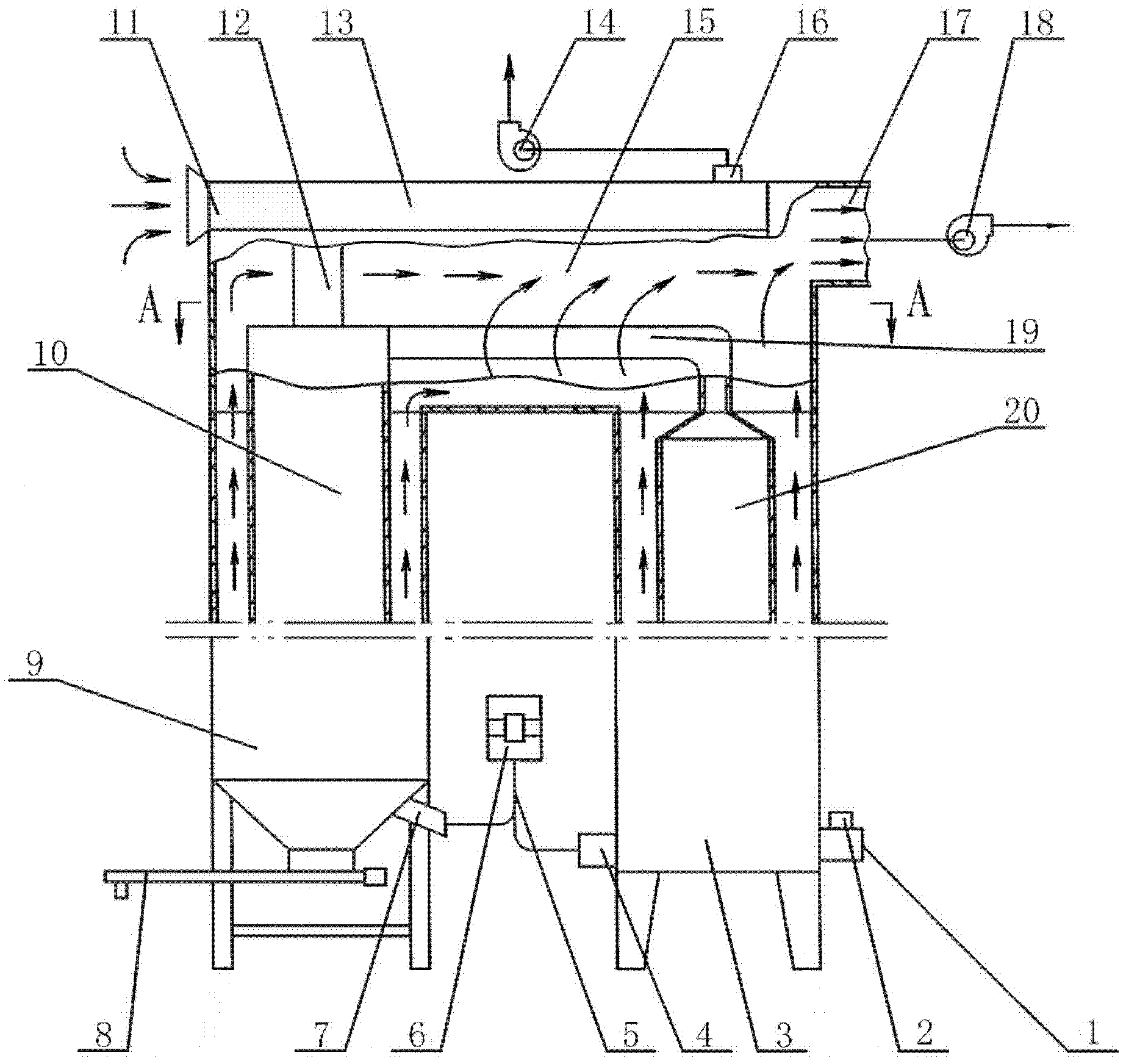

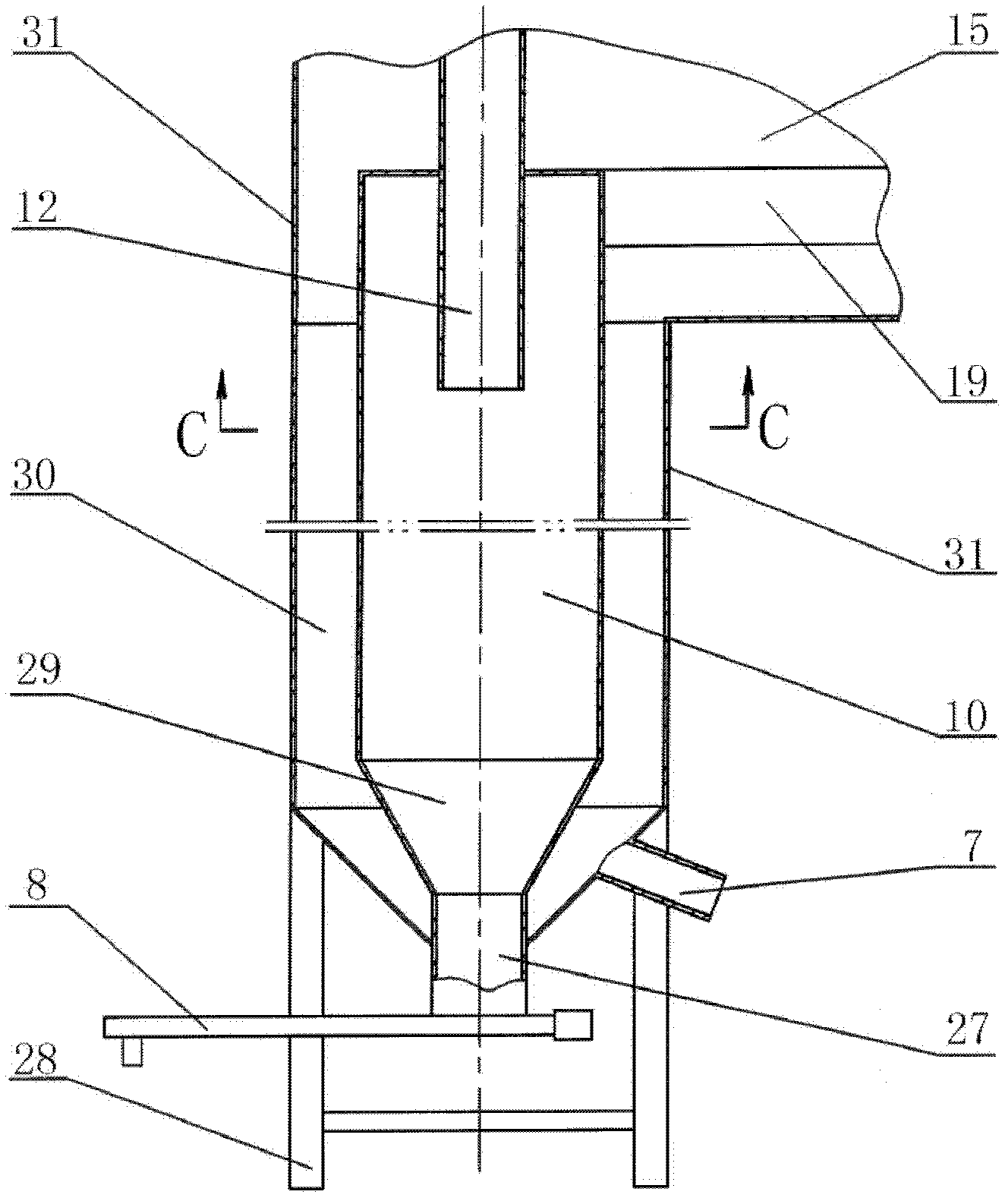

[0038] A gas-solid mixed combustion hot blast stove with double towers and double hearths, see figure 1 , the hot blast stove is composed of gasification tower (3), co-combustion tower (9), heat exchanger (13), hot air induced draft fan (18), cooling fan (6), exhaust fan (14) and igniter (2 ), cooling air duct (5), twin-tower cooling air collection duct (15), air mixing duct (17), guide tube (23), etc.;

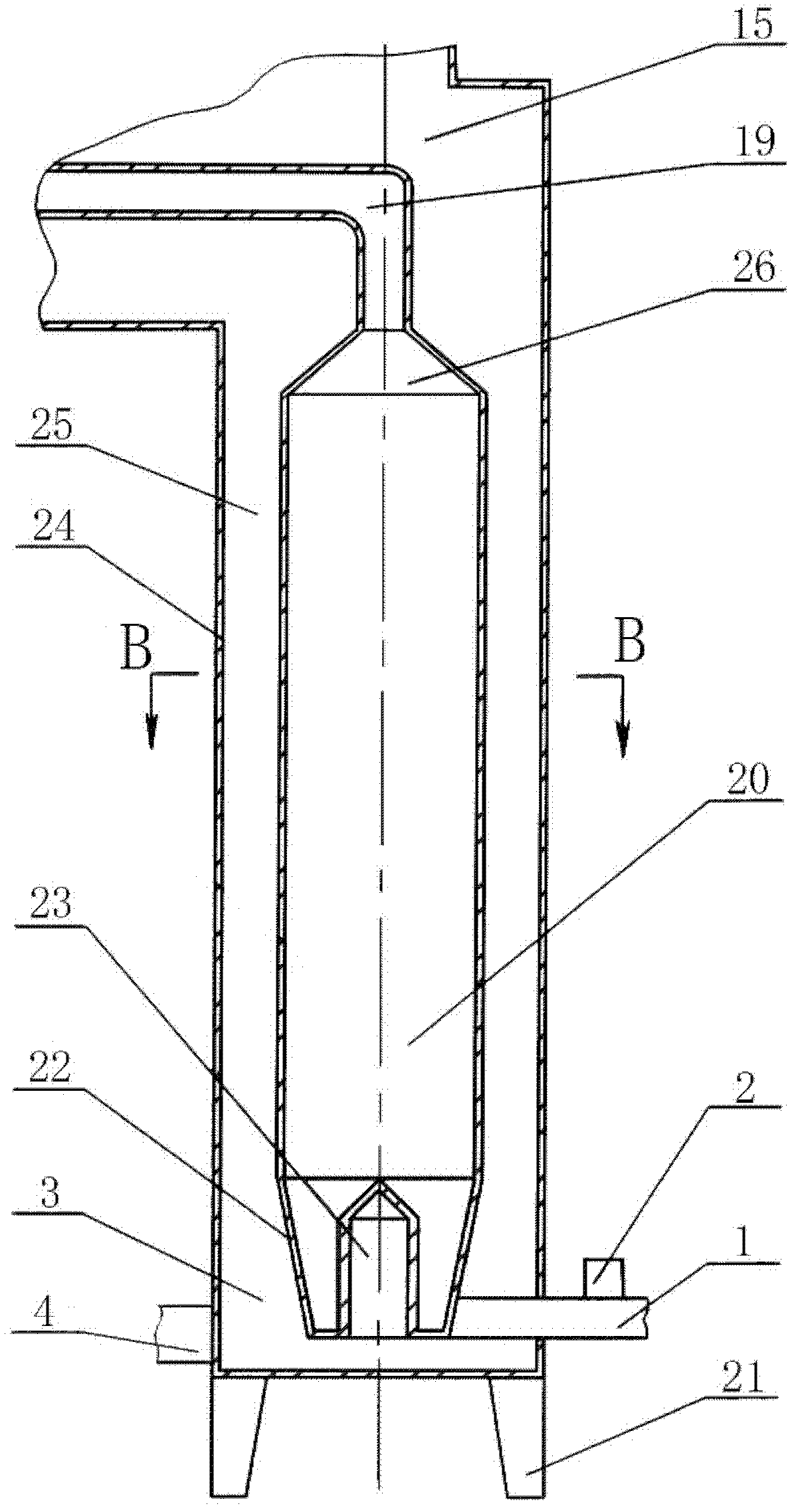

[0039] see figure 2 , the gasification tower is a jacket structure, and the ignition cone (22) at the lower part of the inner sleeve gasification furnace is an inverted cone, the diameter of the large end is the same as that of the gasification furnace (20), and the diameter of the large end of the ignition cone is the same as that of the small end. The ratio is 1.1 to 1.8; the ratio of the diameter of the big end to the height of the ignition cone is 0.8 to 1.2; the middle part of the ignition cone is provided with a guide tube (23), the lower part of the guide tube is a c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com