A conical environmental protection stockyard

A stockyard and cone-shaped technology, which is applied in the field of storage and transportation facilities for bulk materials, can solve problems such as difficulty in meeting scale requirements, insufficient operating intensity, and small reserves, and achieve good wind and earthquake resistance, superior stress conditions, The effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0073] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

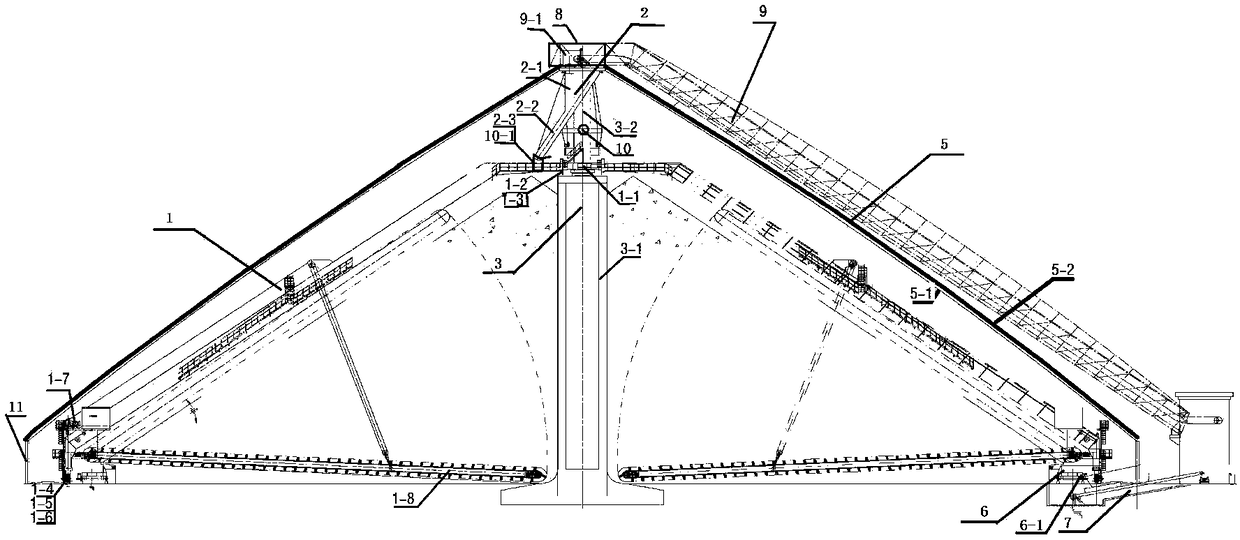

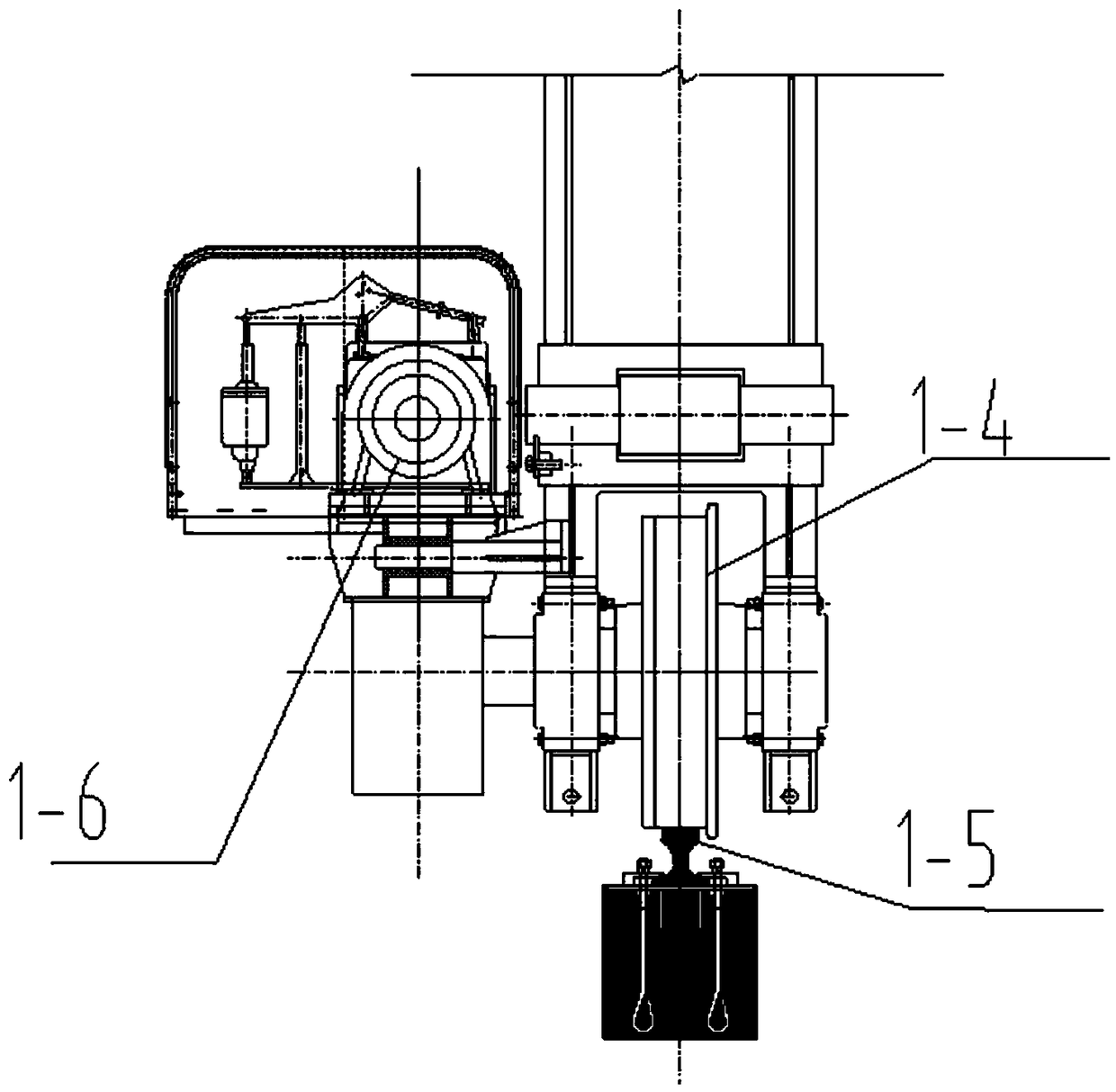

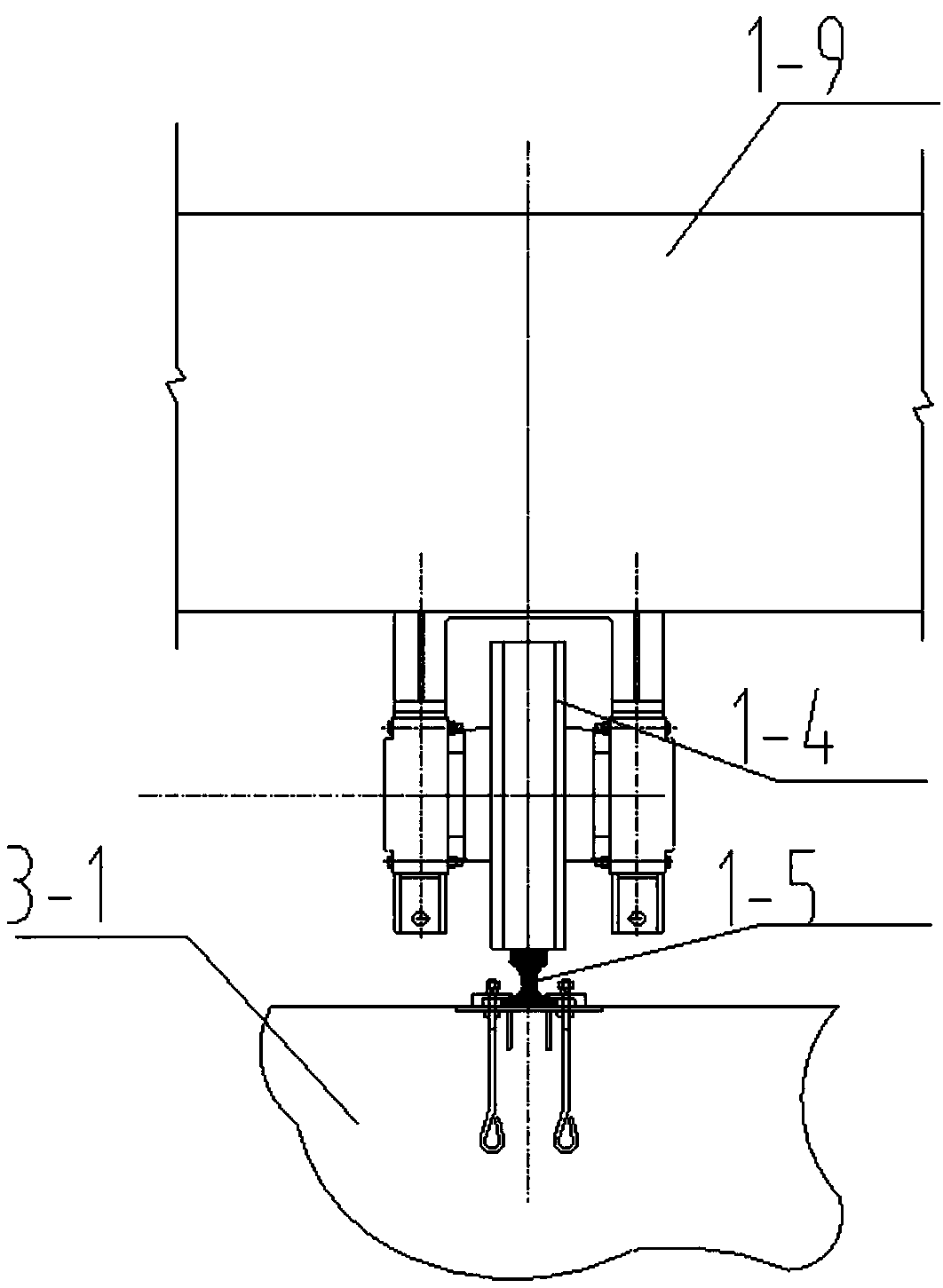

[0074] Such as Figure 1-4 As shown, the tapered environment-friendly material yard of the present invention comprises a scraper reclaimer 1, a rotary distributor 2, a central column 3, a closed cover 5, an annular transfer machine 6, an output belt conveyor 7, a transfer station 8, an input belt conveyor 9, Dry fog dust suppression device 10 and enclosure wall 11.

[0075] The center column 3 is located at the center of the stockyard, and the rotary distributor 2 is socketed and fixed with the upper steel pipe column 3-2 of the center column 3, and a transfer station 8 is arranged above the feeding port of the rotary distributor 2, and the input tape machine 9 The corridor is connected with the transfer station 8, and is connected with the external feeding equipment (not shown in the figure) with an inclination downwar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com