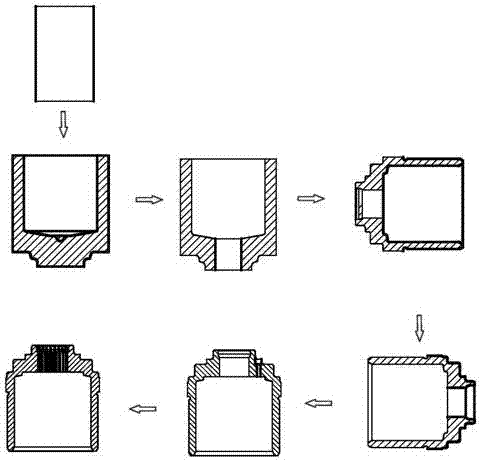

Cold forging process of clutch sleeve

A clutch sleeve and cold forging technology, which is applied in the field of cold forging of clutch sleeves, can solve the problems of affecting the accuracy of blank parts, warm forging is easy to produce forging, and the cost of coating heating is high, so as to improve cutting efficiency and product dimensional accuracy , Process energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] A cold forging process for a clutch sleeve, comprising the steps of:

[0023] Blanking: Using a circular saw, the blank is cut into bars of set length and weight.

[0024] Spheroidizing annealing: put the bar into the well-type resistance furnace, vacuumize to the air pressure ≤ -0.08MPa, keep the pressure for 20 minutes without rising, confirm that the tank of the well-type resistance furnace is airtight and heat it to 300-400 ℃, open the valve to remove the moisture in the furnace gas, and then fill nitrogen to 0.1MPa for the second time, then start heating. During heating, heat preservation and slow cooling, the pressure of the furnace tank is maintained at 0.1-0.2MPa, the heating temperature is 765℃, the holding time is 4.5 hours, and the furnace is released Temperature≤350℃.

[0025] Shot blasting: Shot blasting is performed on the surface of the bar. The shot blasting machine uses the motor to drive the impeller body to rotate, and throws the steel shot with a di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com