Control method for controlling deformation of 3D printing thin and high part

A technology of 3D printing and control method, applied in the direction of additive manufacturing, additive processing, etc., can solve the problems of easy deformation of 3D printing thin and high parts, and achieve the effect of reducing the risk of waterway wall breaking, small deformation, and reducing the degree of deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Taking an automobile connector core mold as an example, the workpiece is characterized by a total height H=280mm, a bow-shaped cross section, a string=50mm, and a bow height=18mm, and it is formed by printing with Corrax powder.

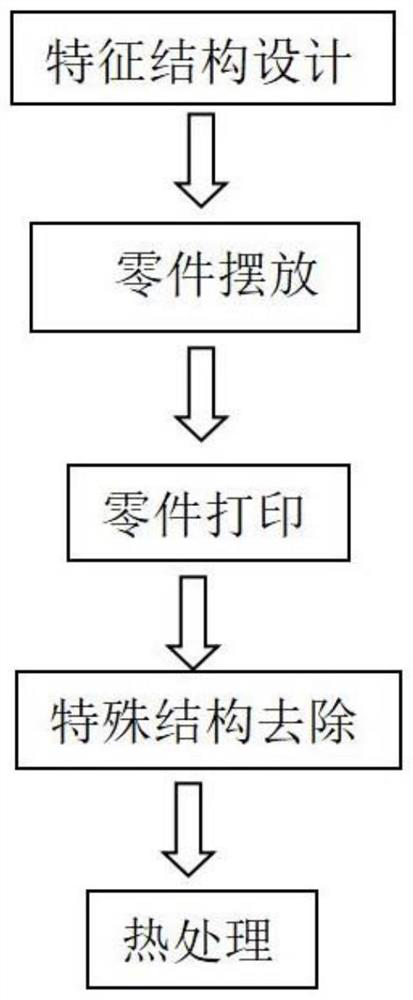

[0038] Step 1: Feature structure design;

[0039] The cross-section of the characteristic structure is still bow-shaped, the total height H=70mm, the bottom chord=46mm, the bottom bow height=17mm, the top chord=25mm, and the top bow height=8mm.

[0040] Step 2: Place the parts;

[0041] Place the string of the workpiece parallel to the blowing direction.

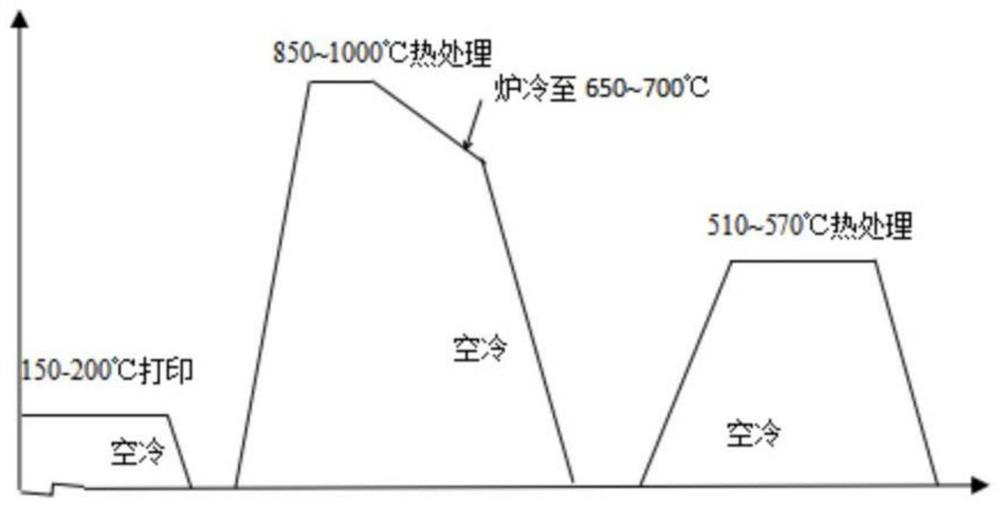

[0042] Step 3: Part printing;

[0043] The substrate is heated to 150°C, and a checkerboard printing method is adopted, where the width of the checkerboard is 6mm, the printing power is 230W, and the speed is 780mm / s.

[0044] Step 4: feature structure cut;

[0045] After the forming is completed, the feature structure is removed by wire cutting

[0046] Step 5: heat treatment;

[0047...

Embodiment 2

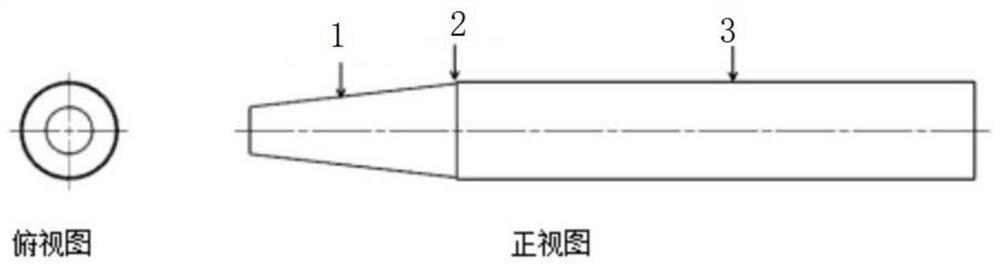

[0053] Taking a cosmetic eyebrow pencil packaged core mold as an example, the workpiece is characterized by a total height of H = 220mm, a circular cross section, and a diameter of 12mm, which is formed by printing with Corrax powder.

[0054] Step 1: Feature structure design;

[0055] The cross section of the characteristic structure is still circular, the total height H=60mm, the diameter of the bottom surface=11mm, the diameter of the top surface=8mm,

[0056] Step 2: Place the parts;

[0057] The cross-section of the workpiece is circular and placed normally

[0058] Step 3: Part printing;

[0059] The substrate is heated to 180°C, and a checkerboard printing method is adopted, where the width of the checkerboard is 6mm, the printing power is 280W, and the speed is 850mm / s.

[0060] Step 4: feature structure cut;

[0061] After the forming is completed, the feature structure is removed by wire cutting

[0062] Step 5: heat treatment;

[0063] The workpiece is subject...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com