Die bending and forging finishing process of crank blank of low-speed diesel engine

A diesel engine and crank technology, which is applied in the field of roll bending hot die forging, can solve the problems of affecting the crank finishing size, high cost of tooling investment, and difficulties, so as to reduce machining allowance, avoid opening and folding, and reduce circulation time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in detail below with reference to the accompanying drawings. Concrete steps of the present invention are:

[0029] 1) Those qualified through steelmaking, steel ingot upsetting, elongation, upsetting, billet free forging, such as figure 2 Crank rough stock shown.

[0030] 2) Assemble the finishing mold.

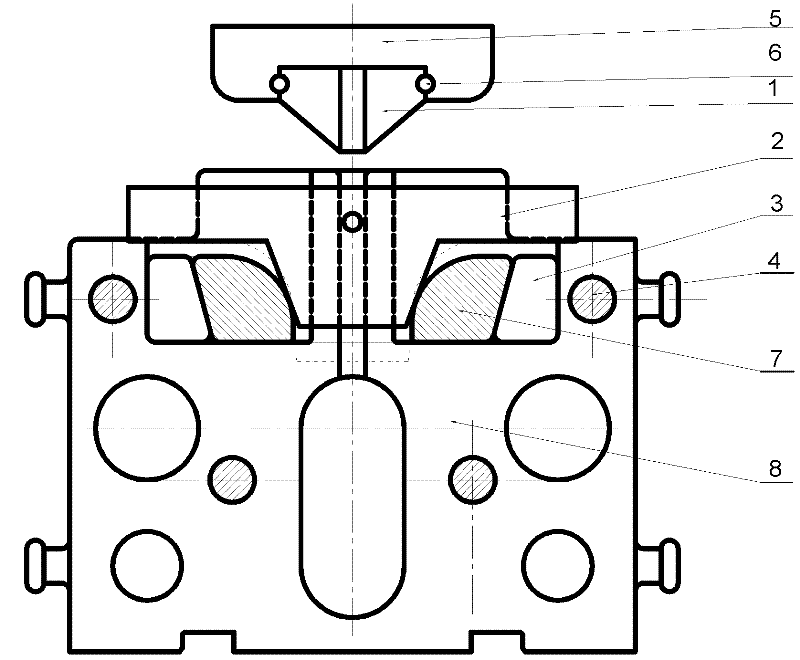

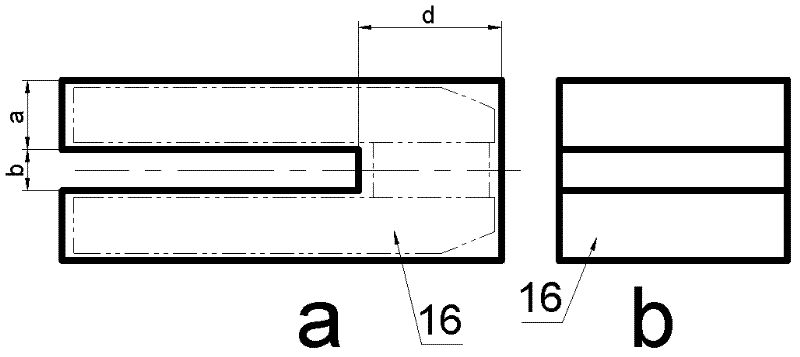

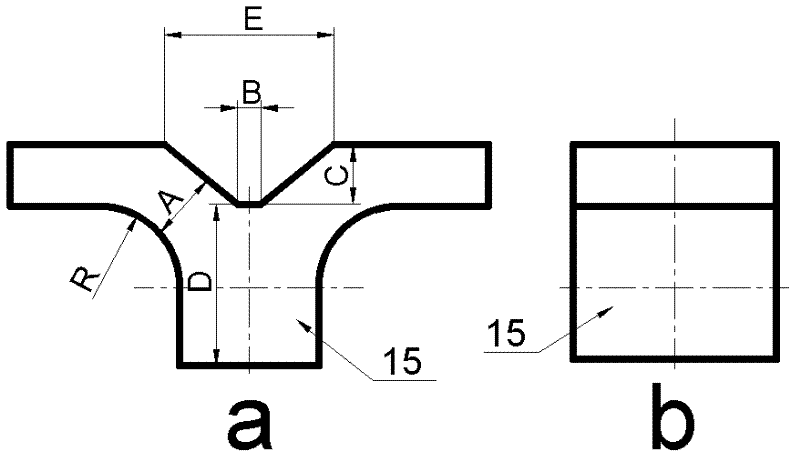

[0031] Two of the finishing molds such as Figure 4 , 5 The shown finishing bracket 8 has fixing bolt assembly holes 11, a card slot 9 for clamping the finishing bracket is arranged on the bottom surface, and a bottom assembly position 10 for adorning two arc forming blocks and four spacing control blocks is arranged on the bottom surface. There is a guide groove 14 for the finishing punch to move up and down. Will Figure 7 The arc forming block 7 shown in a and b, Figure 8 The spacing control block 3 shown in a and b is put into the lower assembly position 10, the arc surface of the arc forming block 7 is in contact wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com