Patents

Literature

67results about How to "Shorten the process chain" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

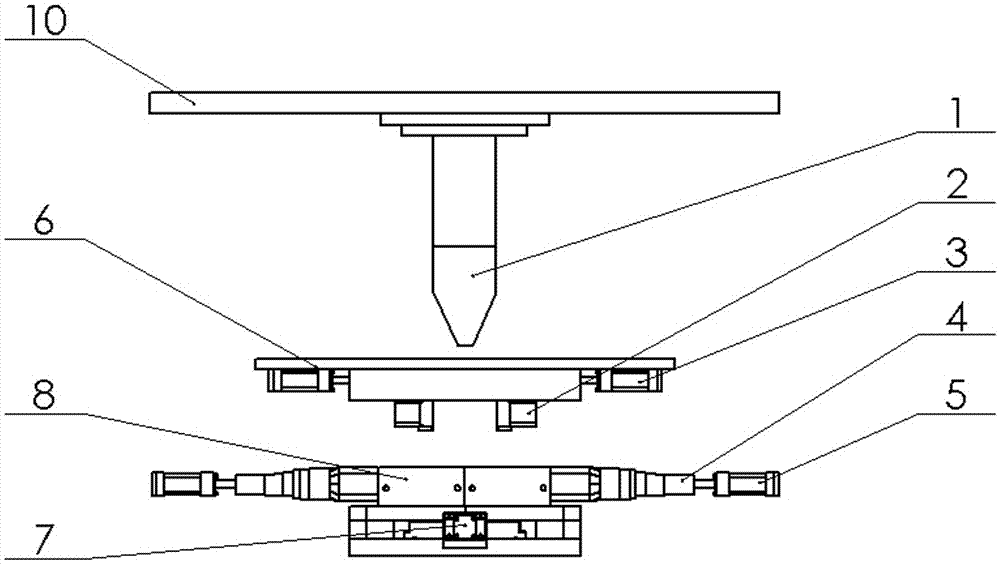

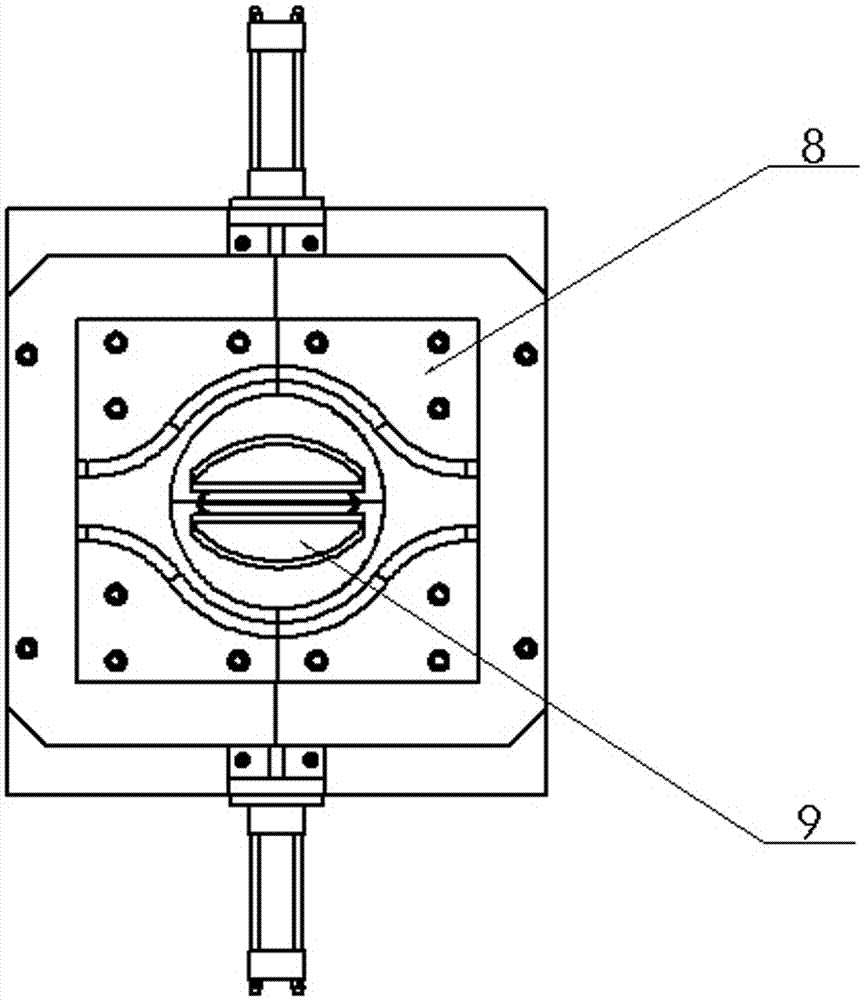

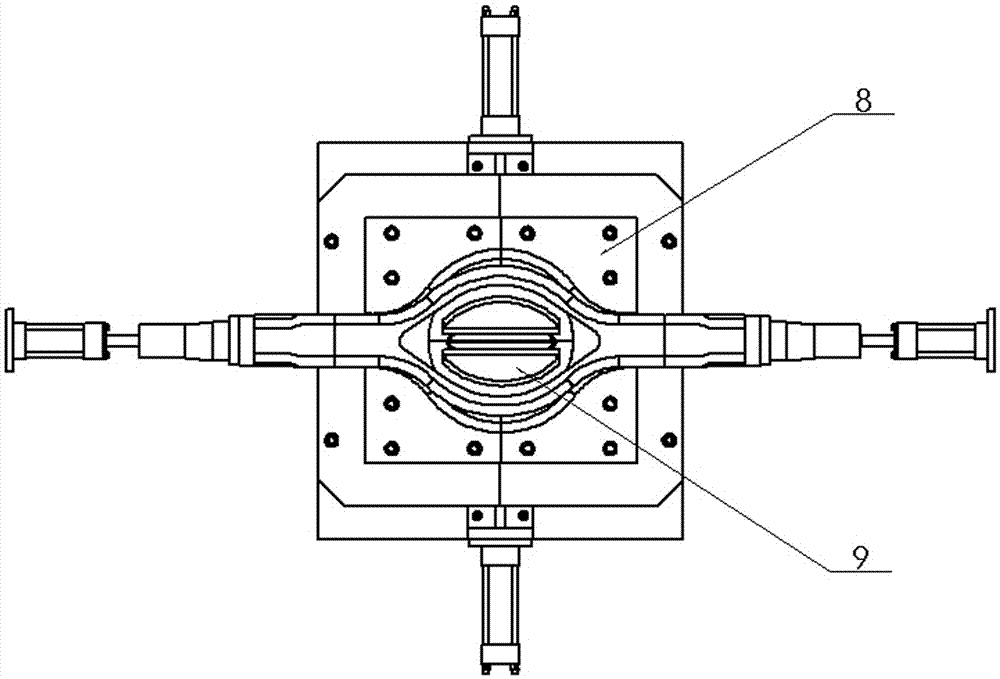

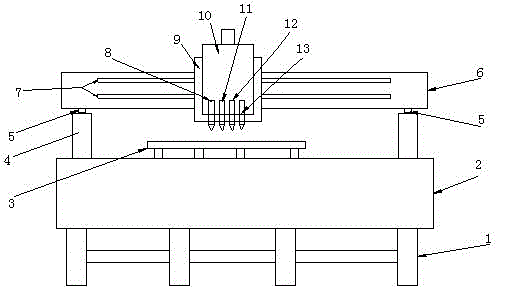

Forming method for banjo axle housing

ActiveCN105436350AEliminate product defectsImprove product qualityShaping toolsEngine componentsHydraulic cylinderEngineering

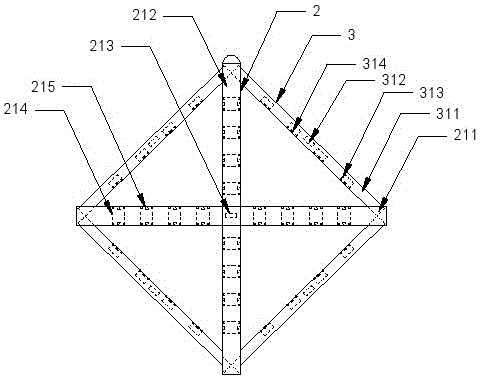

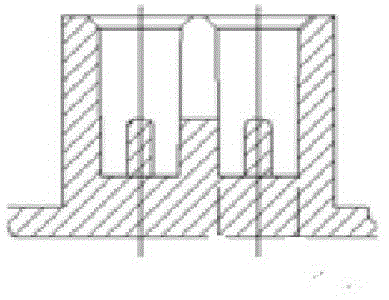

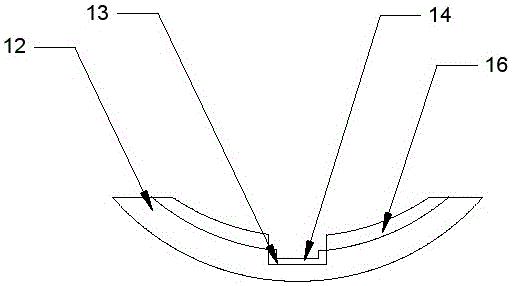

The invention discloses a forming method for a banjo axle housing. The forming method includes the following steps of (S1) blanking, (S2) extrusion of a shaft head, (S3) square pushing, (S4) manufacturing of a process groove, (S5) heating of a workpiece, (S6) radial expansion, (S7) shaping and (S8) upward resetting of a lower press sliding block and taking-out of the workpiece. According to the (S6), a wedge punch penetrates through a central hole of the lower press sliding block, pushes two radial expansion core molds to expand the radial direction of a workpiece central hole and axially squeezes the workpiece synchronously. According to the (S7), two axial shaping core molds are attached, the lower press sliding block moves downwards to enable the axial shaping core molds to be inserted into the position between two radial shaping core molds, an upper press sliding block moves downwards, and the wedge punch is inserted into the position between the two axial shaping core molds to shape the workpiece central hole and axially squeeze a hydraulic cylinder for axial limitation. The forming method integrates heat expansion and shaping, work procedures are reduced, a process chain is shortened, and the outline size accuracy is obviously improved.

Owner:吴志强 +1

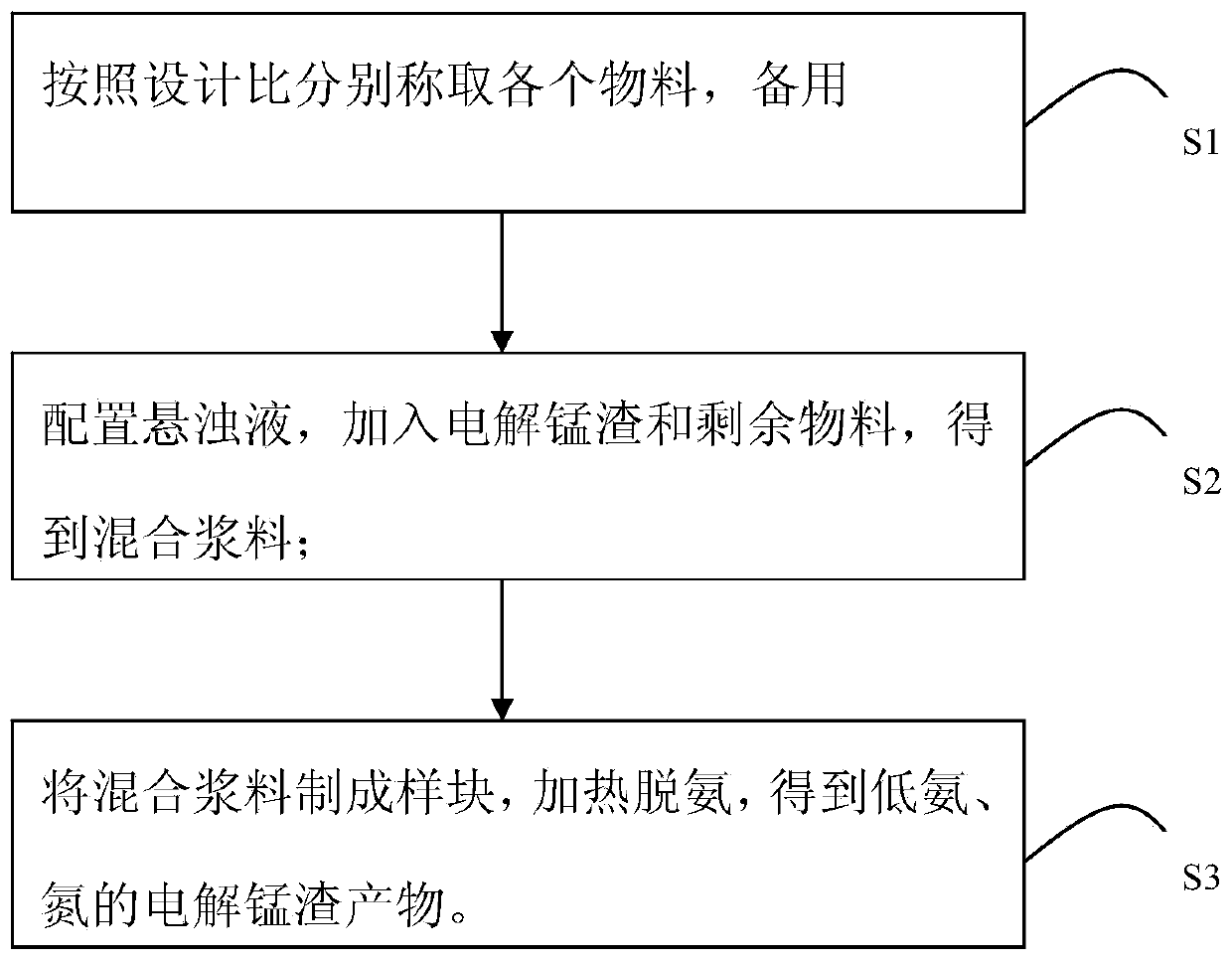

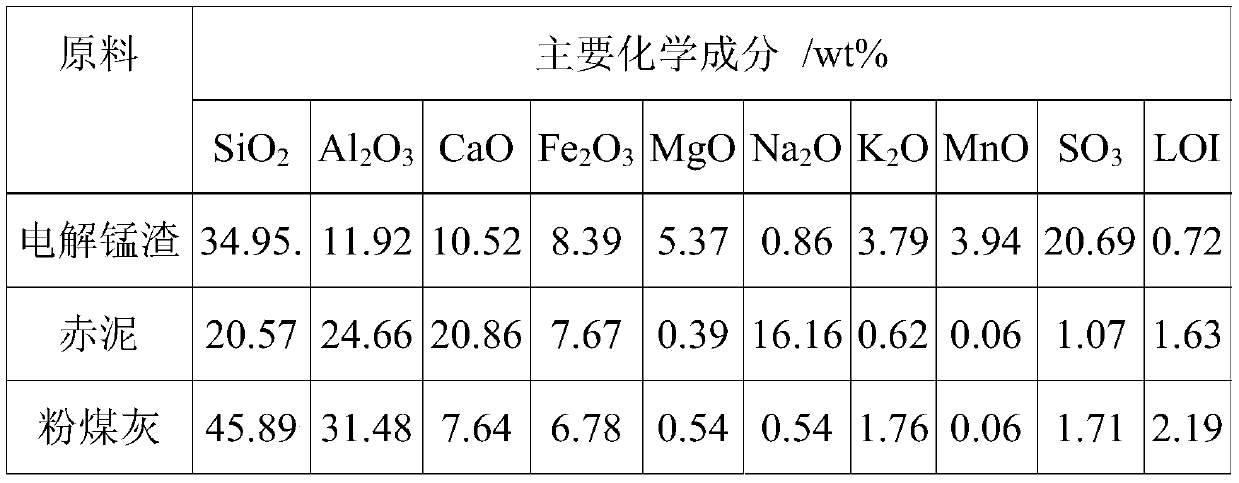

Additive for removing ammonia nitrogen in electrolytic manganese residues and removal method thereof

ActiveCN111592260ASimple processReduce energy consumptionSolid waste managementSolid waste disposalHydration reactionAmmoniacal nitrogen

The invention relates to an additive for removing ammonia nitrogen in electrolytic manganese residues and a removal method thereof. The additive comprises the following components in parts by weight:25-40 parts of an alkaline compound, 14-35 parts of fly ash, 25-46 parts of red mud, 85-100 parts of a solvent and 0.9-1.3 parts of a water reducing agent, wherein the alkaline compound comprises 15-35 parts of alkaline solid waste and 6-15 parts of a calcium-containing alkaline compound. Soluble ammonium salt in the electrolytic manganese residues with complex components can be converted into ammonia monohydrate which is easy to decompose, the ammonia monohydrate is converted into collected ammonia gas under the action of heat energy and mechanical energy, and a mixture obtained through a deamination treatment process can be directly mixed with materials such as slag and cement to prepare building materials meeting the national standard. According to the method, the purpose of efficientlyconverting the ammonia nitrogen unit in the electrolytic manganese slag is achieved, the electrolytic manganese slag product is prevented from emitting peculiar smell to harm the health of residents,and the purposes of comprehensively and cyclically utilizing resources and relieving the environmental pressure are achieved.

Owner:UNIV OF SCI & TECH BEIJING +1

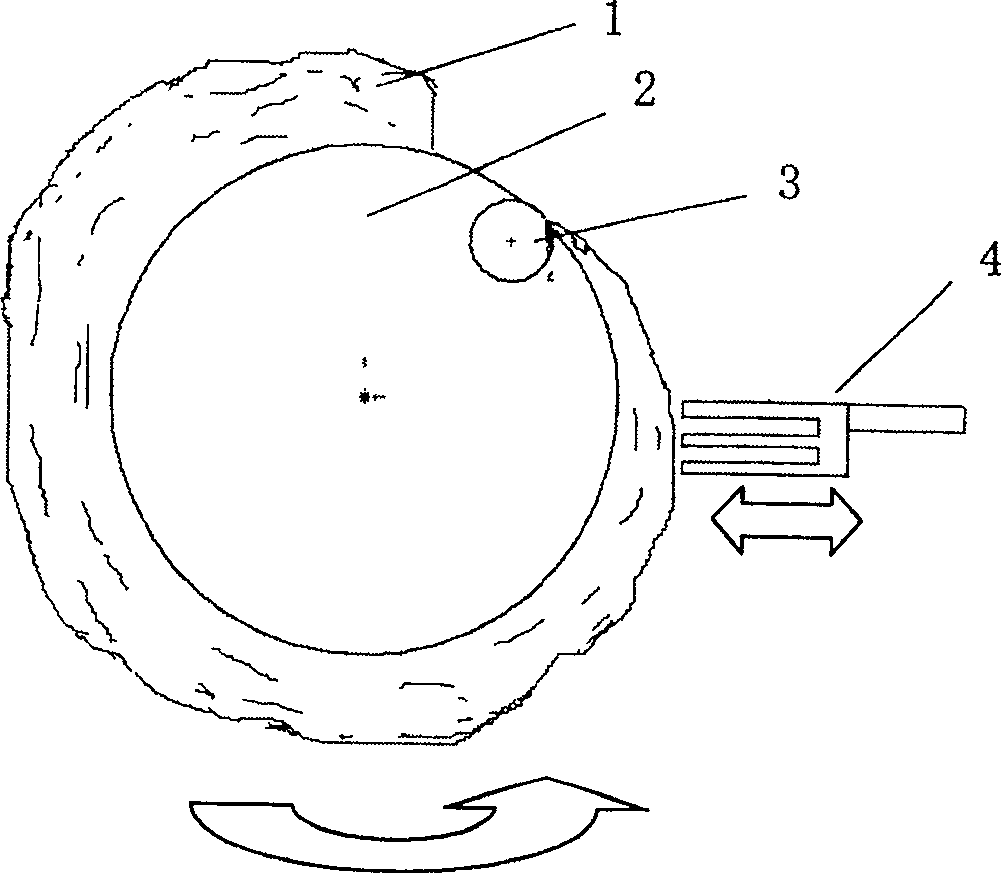

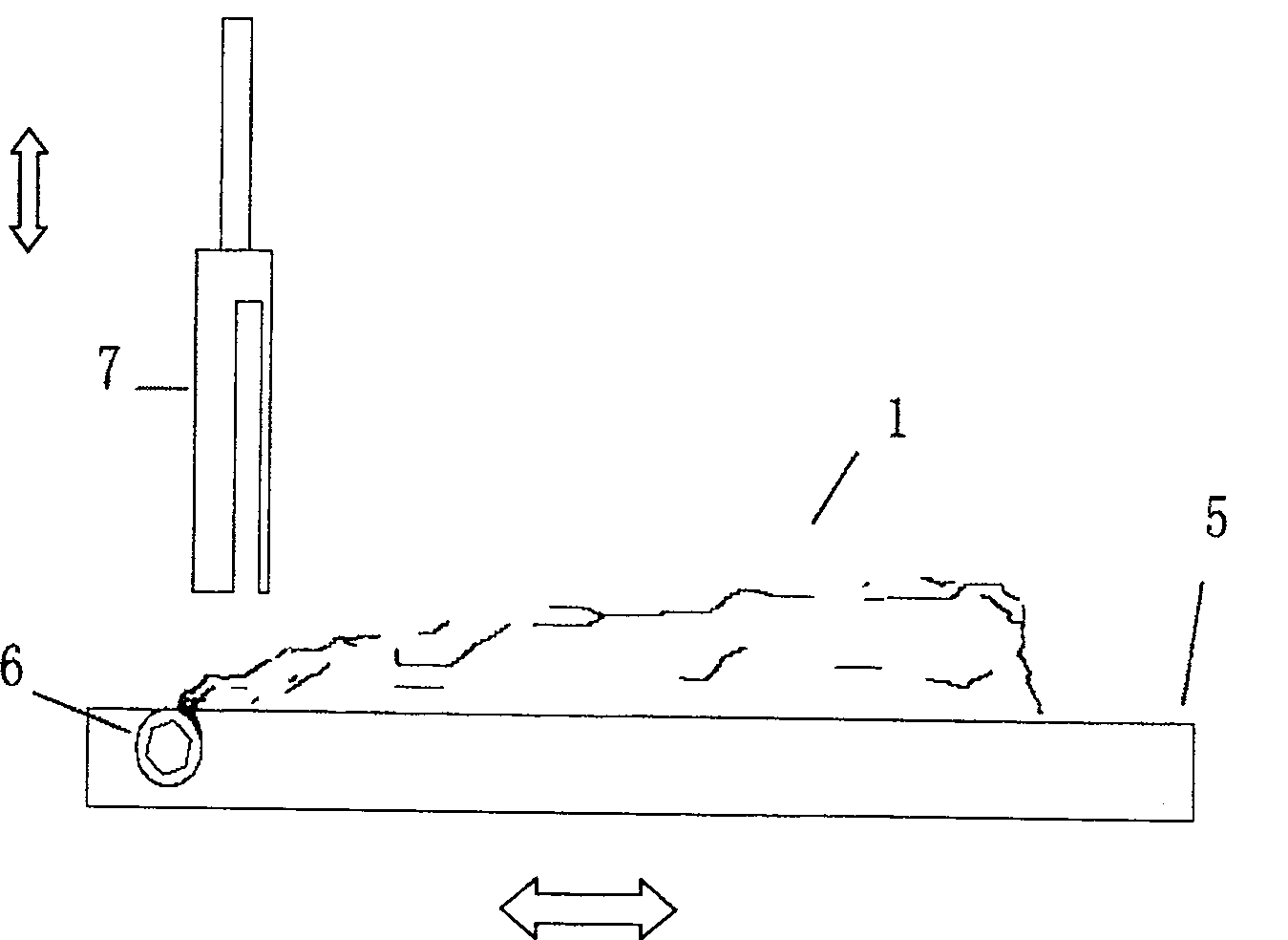

Method for separating fish meat and fishbone

The method of separating fish meat and fish bone includes the pre-treatment to eliminate large bones, setting the fish on a belt and hammering with kitchen knife to make fish meat become loose, scraping fish meat off to separate fish meat from fish bone and fish skin. The said process can separate fish bone effectively to obtain fish meat without fish bone and complete fish bones and fish skin.

Owner:李连斌

Multifunctional bamboo shoot cutting device

ActiveCN106313143AGuaranteed cutting effectImprove finishing effectFood shapingVegetable peelingCruciformBamboo shoot

The invention discloses a multifunctional bamboo shoot cutting mechanism. The multifunctional bamboo shoot cutting mechanism comprises a rack, a cutter and a clamp. The cutter comprises two same triangular blades which are arranged in a crossed manner to form a cross shape, and one ends of the two triangular blades face the same direction. Sliding grooves are formed in the two sides of the front face of each triangular blade and the two sides of the back face of each triangular blade, and a peeling blade is arranged between every two adjacent sliding grooves. A first cavity is formed in each triangular blade, the first cavities of the two triangular blades communicate, and each first cavity is internally provided with a first heating resistor connected with a power source. Each triangular blade is further provided with a plurality of through holes communicating with the corresponding first cavity, and each through hole is provided with a first fan blade connected with the power source. The clamp comprises a supporting base and supporting rods. The supporting base is provided with limiting grooves used for containing bamboo shoots. Each supporting rod is provided with a clamping arm. According to the scheme, the problems that time is consumed for bamboo shoot peeling, the hands are prone to getting hurt, and the bamboo shoot processing technology chain is long are mainly solved.

Owner:CHONGQING GUANGHENG FOOD DEV

Aluminium wire-contained motor joint and processing method thereof

InactiveCN104037517AImprove reliabilityPrevent Corrosion Short CircuitUnstripped conductor connection apparatusContact members penetrating/cutting insulation/cable strandsOxidation resistantAluminium

The invention discloses an aluminium wire-contained motor joint comprising an aluminium enameled wire and a wiring terminal. A clamp groove is formed in the motor and includes an aluminium enameled wire leading-out wire accommodation portion and a wiring terminal accommodation portion; an aluminium enameled wire leading-out wire is pressed into the aluminium enameled wire leading-out wire accommodation portion and penetrates the wiring terminal accommodation portion; and the wiring terminal is pressed into the wiring terminal accommodation portion with a pointed portion. When the wiring terminal is pressed into the wiring terminal accommodation portion, the pointed portion punctures the enamelling layer of the aluminium enameled wire, thereby completing condution with the aluminium wire. According to the processing method, the aluminium wire is compressed by using the wiring terminal and the clamp groove instead of using the traditional heat-shrinkable bush, thereby not only ensuring the oxidation-resistant capability and preventing phenomena of short circuit and poor contact at the joint but also improving the aluminium wire joint protection reliability. The motor running reliability is improved and easy production and operation are also realized.

Owner:SUZHOU SAMSUNG ELECTRONICS CO LTD +1

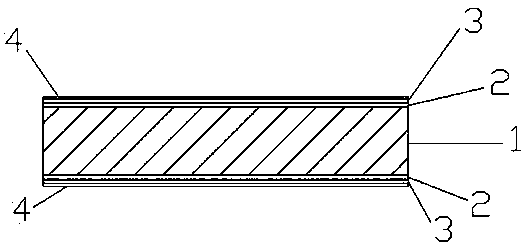

One-step forming process for special veneer glass fiber felt replacing plasterboard surface paper

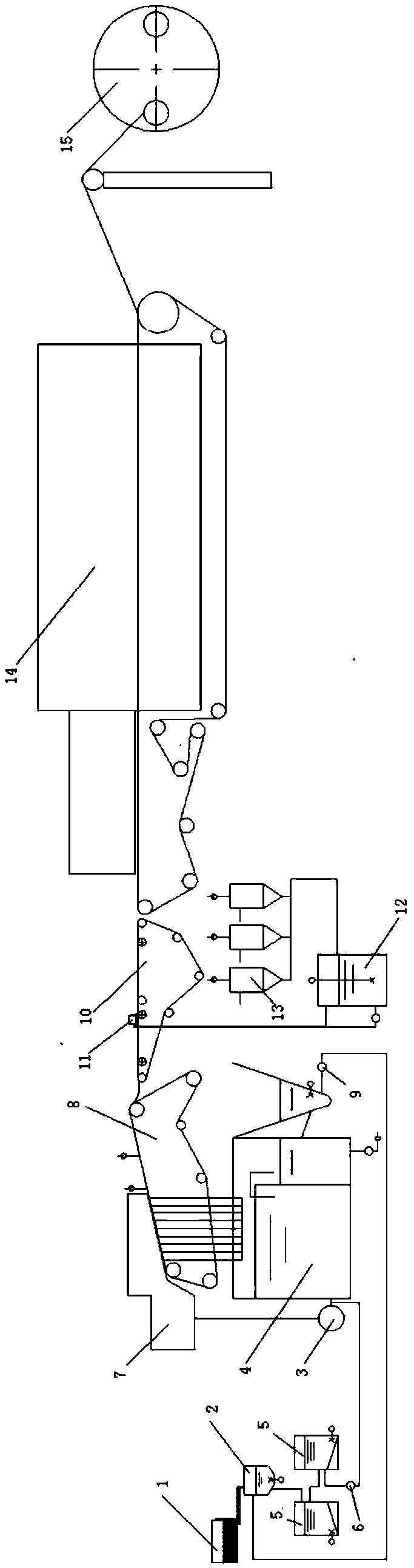

InactiveCN108824068AFlat surfaceShorten the process chainDefoamers additionMachine wet endGlass fiberSlurry

The invention discloses a one-step forming process for special veneer glass fiber thin felt replacing plasterboard surface paper. The forming process comprises the following specific steps: preparation of white water, preparation of slurry, forming of a wet felt blank, soaking in an adhesive solution, recovery of the adhesive solution, drying and curing, and winding to obtain a finished product. Existing equipment is fully utilized, production and 'coating' of the glass fiber felt can be completed through one step on a glass fiber wet felt line by adjusting the production process, and equipment investment is reduced, energy is saved and production efficiency is improved under the condition of meeting use requirements of customers.

Owner:CHANGZHOU ZHONGXIN TIANMA FIBERGLASS PROD

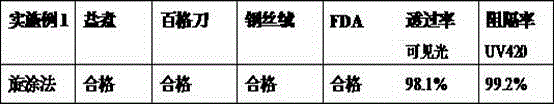

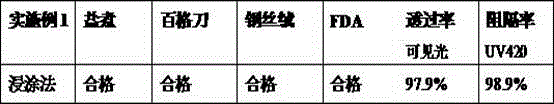

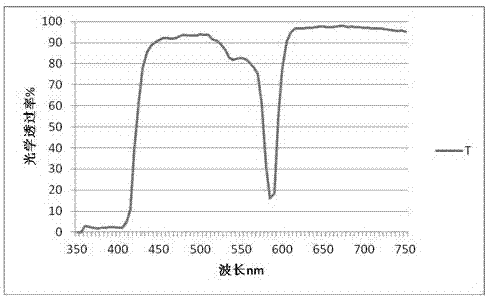

Manufacturing method of novel UV420 lens

The invention discloses a manufacturing method of a novel UV420 lens. The novel UV420 lens is different from a traditional UV380 and a traditional UV420 lens in that the blocking wavelength upper limit of the novel UV420 lens can be raised to 420nm. The manufacturing method mainly includes the steps of lens processing, solution preparation, curing, film coating and detection. According to the manufacturing method, an additive (UV420) is added into a hard coat, so that UV hardening of the lens can be realized, and therefore, a process chain can be shortened, and production cost can be reduced, and the UV blocking wavelength upper limit of the lens obtained through adopting the manufacturing method can be effectively improved to 420nm, and eyes can be better protected.

Owner:ZENNI OPTICAL

Cutting device for bamboo shoots

InactiveCN106985174AShorten the process chainImprove stabilityMetal working apparatusFood scienceElectrical resistance and conductanceBamboo shoot

The invention discloses a cutting device for bamboo shoots. The cutting device comprises a machine seat, a supporting mechanism, a limiting mechanism and a tool with a cavity are arranged on the machine seat, the supporting mechanism comprises a supporting table and two rotary shafts, and the supporting table is fixedly connected with the machine seat, a groove is formed in the middle of the supporting table, the two rotary shafts are arranged in the groove, and a sealing plate is rotatably connected to each rotary shaft; first pressing springs are arranged between the sealing plates and the bottom of the groove, limiting tables are arranged at the other ends of the sealing plates, through holes are formed in the ends, away from the sealing plates, of the limiting tables, and the through holes communicate with steam engines; the limiting mechanism comprises two supporting frames, the two supporting frames are arranged on the two sides of the supporting table correspondingly, a rotary arm is hinged to each supporting frame, and second pressing springs are arranged between the rotary arms and the supporting frames; an iron wire is arranged between the tool and a rack; and a heating resistance is arranged in the tool, and a plurality of heat dissipation holes communicating with a cavity of the tool are formed in the tool. According to the technical scheme of the cutting device for the bamboo shoots, the problems that a traditional technological chain for bamboo shoot processing is long, and the bamboo shoots on the surface of the tool need to be washed are mainly solved.

Owner:CHONGQING ZHOUYI FOOD CO LTD

Slicing device for bamboo shoots

ActiveCN106541426AIntegrated processing stepsImprove processing efficiencyMetal working apparatusFood scienceBamboo shootEngineering

The invention discloses a slicing device for bamboo shoots. The slicing device comprises a rack, a cutter and a clamping mechanism, wherein the cutter and the clamping mechanism are both arranged on the rack, and the cutter comprises a horizontal blade and a vertical blade which intersect to be cross-shaped; a plurality of pores are formed in both the horizontal blade and the vertical blade, and an exhaust fan blade connected with a power supply is arranged on each pore; a first cavity is formed in the horizontal blade, a second cavity is formed in the vertical blade, the first cavity and the second cavity communicate with each other, and a heating resistor connected with the power supply is arranged in each of the first cavity and the second cavity; and the clamping mechanism comprises a base and pillars fixedly connected to two sides of the base, a positioning groove for accommodating the bamboo shoots is formed in the base, a clamping arm is arranged in each pillar, and a groove allowing the horizontal blade to move therein is formed in each clamping arm. The invention mainly solves the problem that a traditional bamboo shoot handling process is troublesome in step and poor in positioning effect during cutting of the bamboo shoots.

Owner:NANTONG SHUANGHE FOOD

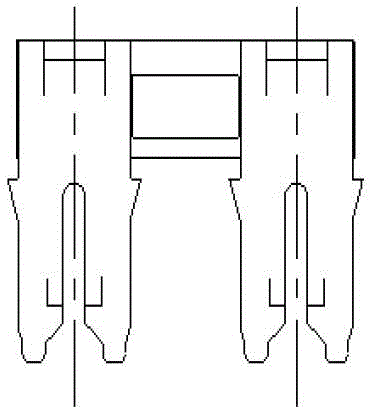

In-mould assembling and welding structure

InactiveCN106079264AReduce ultrasonic post-processing stepsShorten the process chainEngineeringMechanical engineering

The invention discloses an in-mould assembling and welding structure. The in-mould assembly and welding structure comprises a front mould core, a rear mould core, a pushing plate and a rear mould insert which are movably arranged on the upper surface of the rear mould core, an upper cover mould core which is arranged on the pushing plate for injection-molding an upper cover of a gas-liquid flow monitor and a main body mould core used for injection-molding a main body of the gas-liquid flow monitor; the rear mould insert is equipped with a lower forming cavity used for injection-molding a blade of the gas-liquid flow monitor; a lower assembly cavity is formed in the rear mould core; the lower assembly cavity is positioned at one side of the pushing plate and the rear mould insert; the front mould core is provided with a main body mould cavity used for injection-molding the main body of the gas-liquid flow monitor, an upper cover mould cavity used for injection-molding the upper cover of the gas-liquid flow monitor, an upper forming cavity used for injection-molding the blade of the gas-liquid flow monitor, and an upper assembly cavity used for assembling; the main body mould cavity, the upper cover mould cavity, the upper forming cavity and the upper assembly cavity correspond to the main body mould core, the upper cover mould core, the lower forming cavity and the lower assembly cavity respectively; and ejector pins are arranged underneath the rear mould core.

Owner:鸿利达模具科技(中山)有限公司

Internal joint process of aluminum wire motor

InactiveCN102594036AShorten the process chainIncrease productivityApplying solid insulationStatorAluminium

The invention discloses an internal joint process of an aluminum wire motor. Firstly, an aluminum enamelled wire and a copper lead-out wire are subjected to terminal press connection, during the press connection, the aluminum enamelled wire is placed at the bottom of a U-shaped terminal, and the copper lead-out wire is placed on the aluminum enamelled wire; then, a heat shrinkage sleeve is sheathed on the U-shaped terminal, at least 10mm of heat shrinkage sleeves are respectively exposed at two ends of the U-shaped terminal, a stator is placed on a heating air passage, the heat shrinkage sleeve is heated, and two ends of the heat shrinkage sleeve are sealed, fixed and formed; next, an insulation sleeve is sheathed outside the sealed sleeve; and finally, the stator is integrally immersed by insulation paint and is then baked, and during the process, the insulation paint is immersed inside the insulation sleeve. The internal joint process of the aluminum wire motor has the advantages that the heat shrinkage sleeves are sheathed outside the U-shaped terminal, the triple sealing protection is realized at the aluminum wire joint part through the sheathing of the insulation sleeve and the immersing of the insulation paint, the sealing effect at the U-shaped terminal part is better, and the motor insulation is more perfect, so the motor quality is improved, and the service life of the motor is prolonged.

Owner:ZHEJIANG JEAMO MOTOR

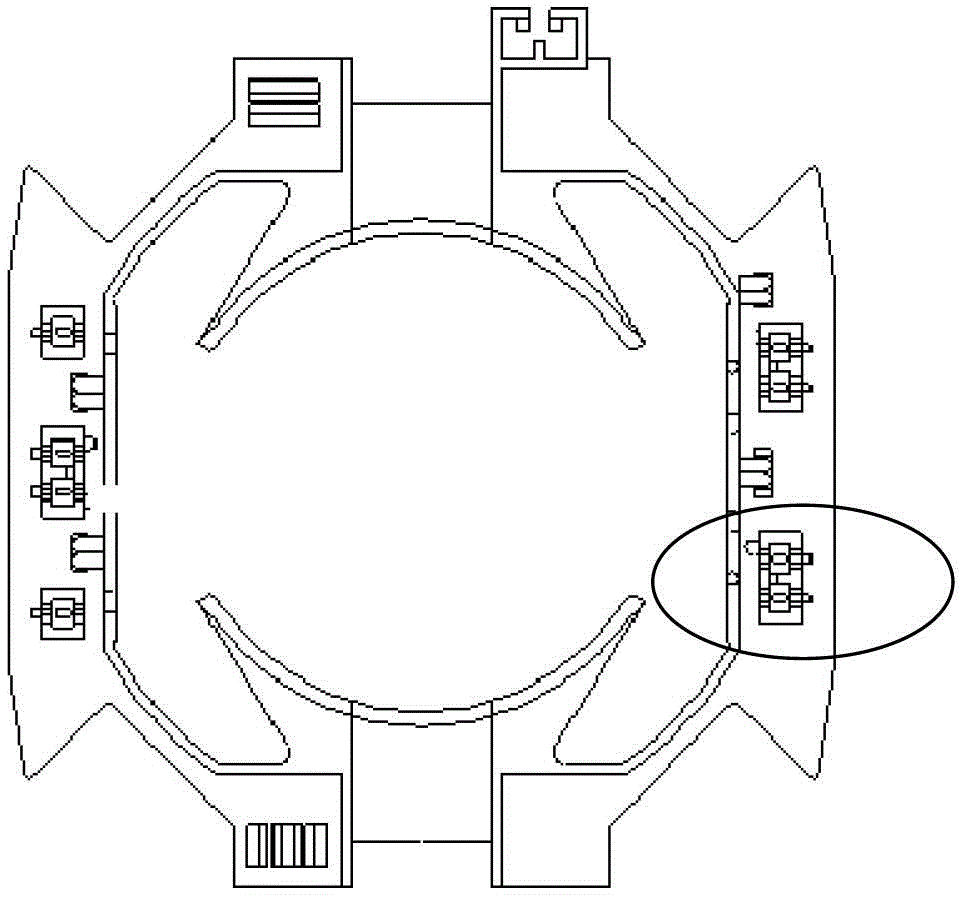

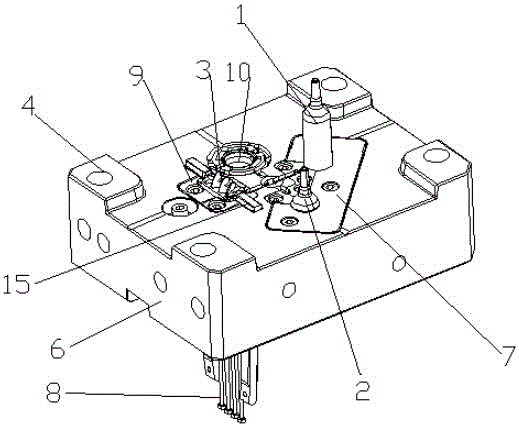

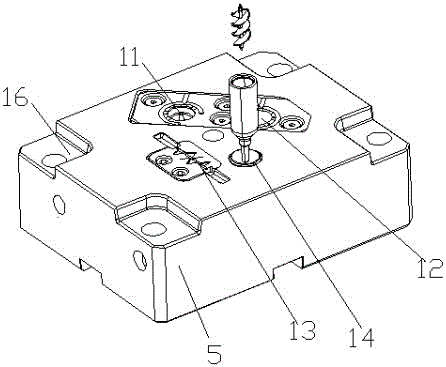

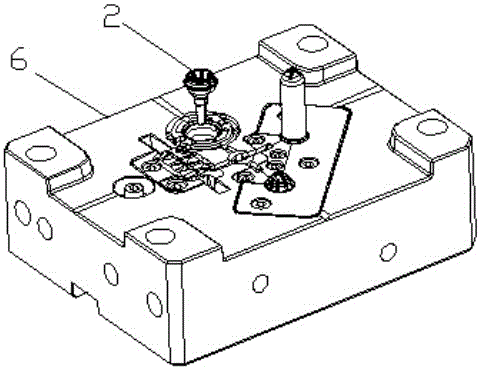

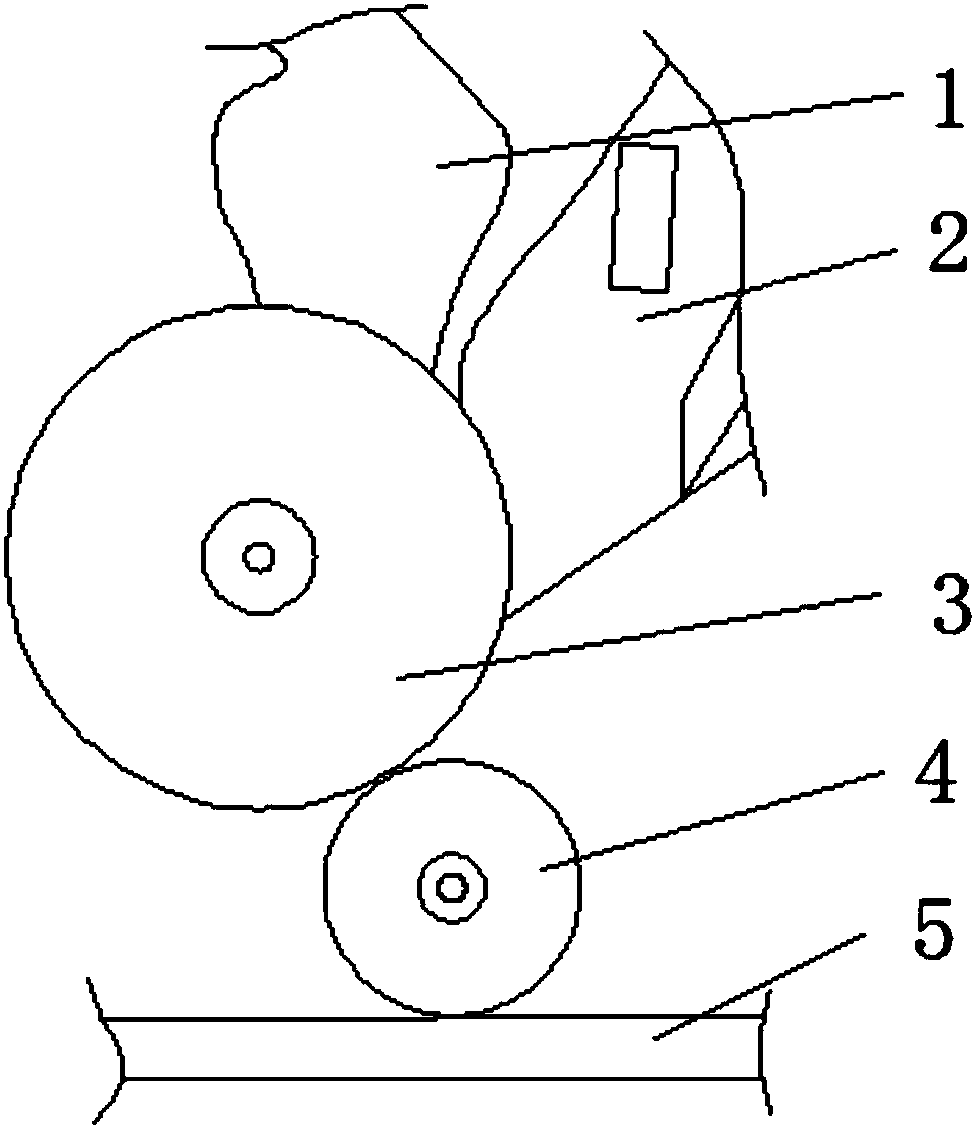

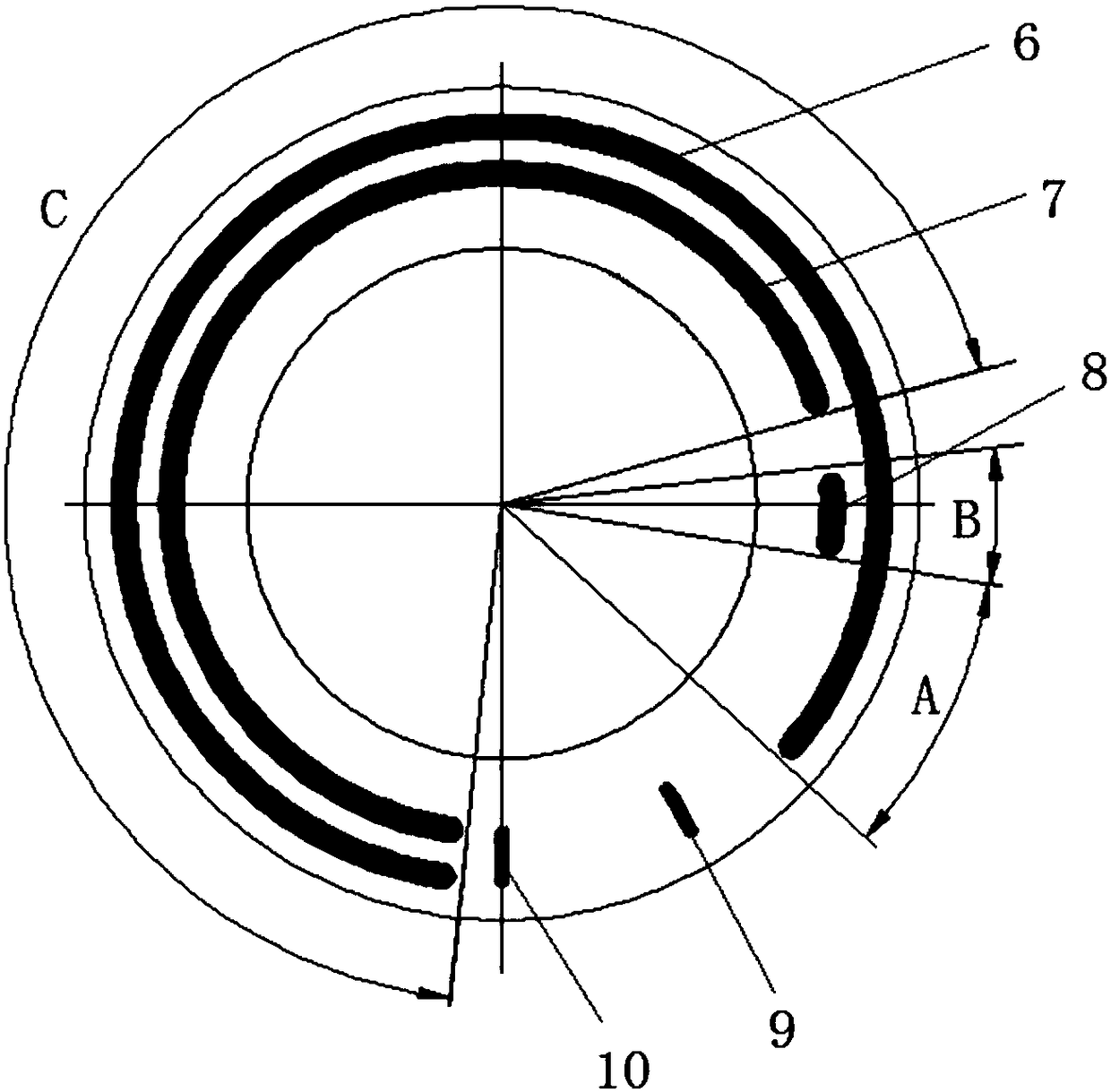

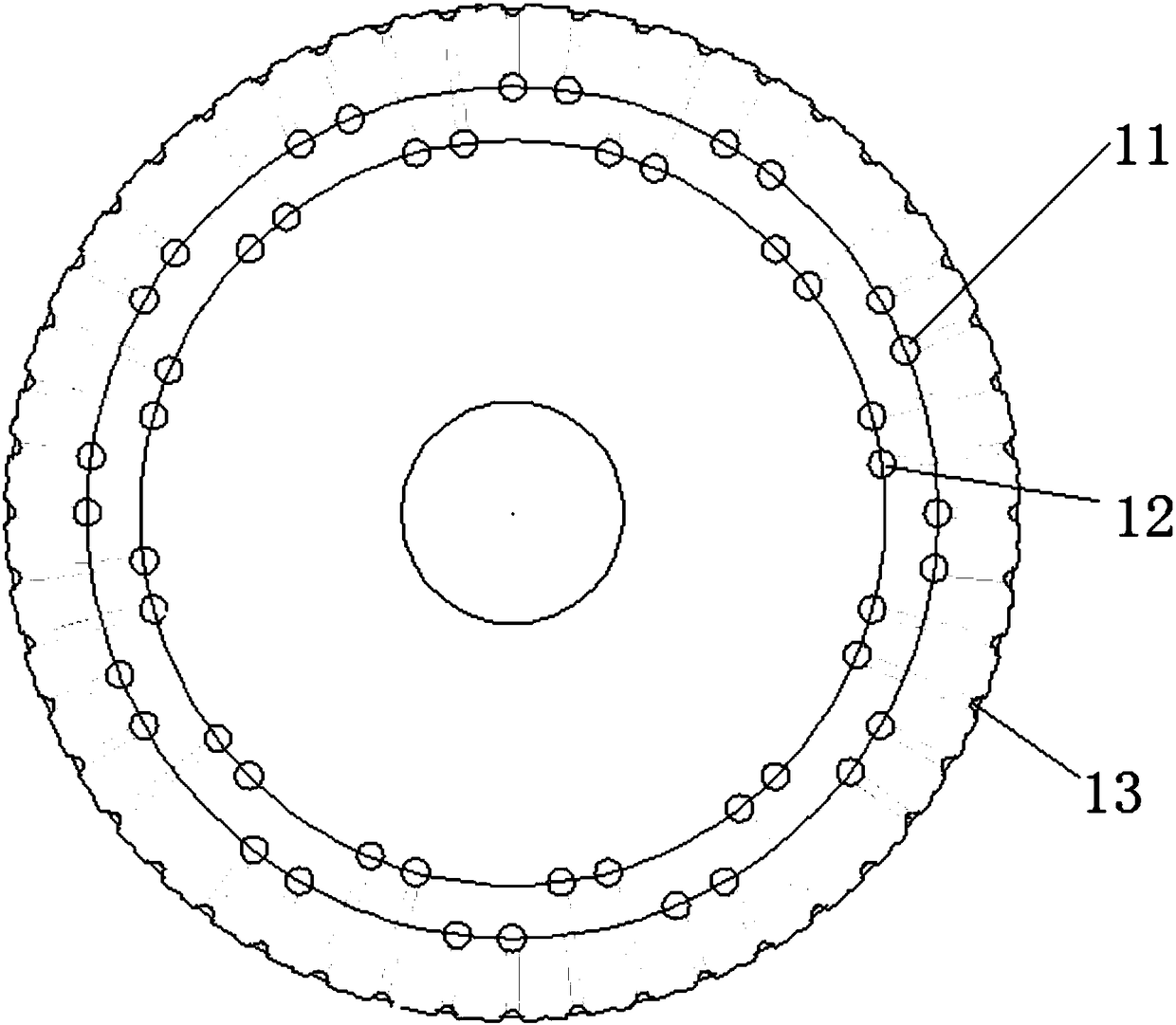

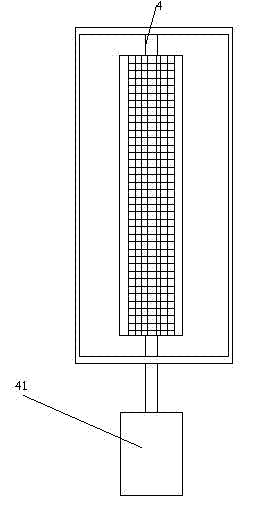

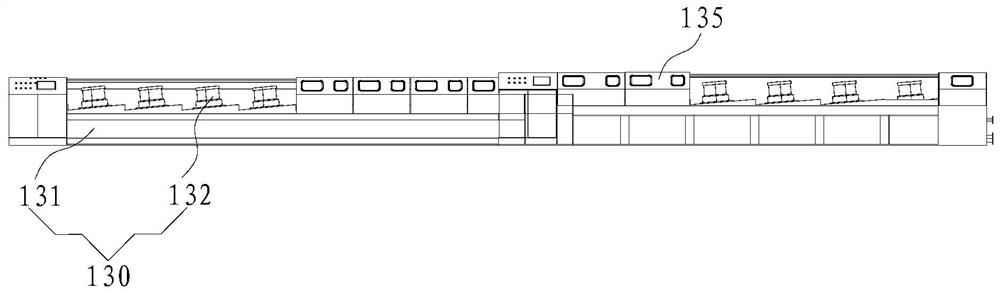

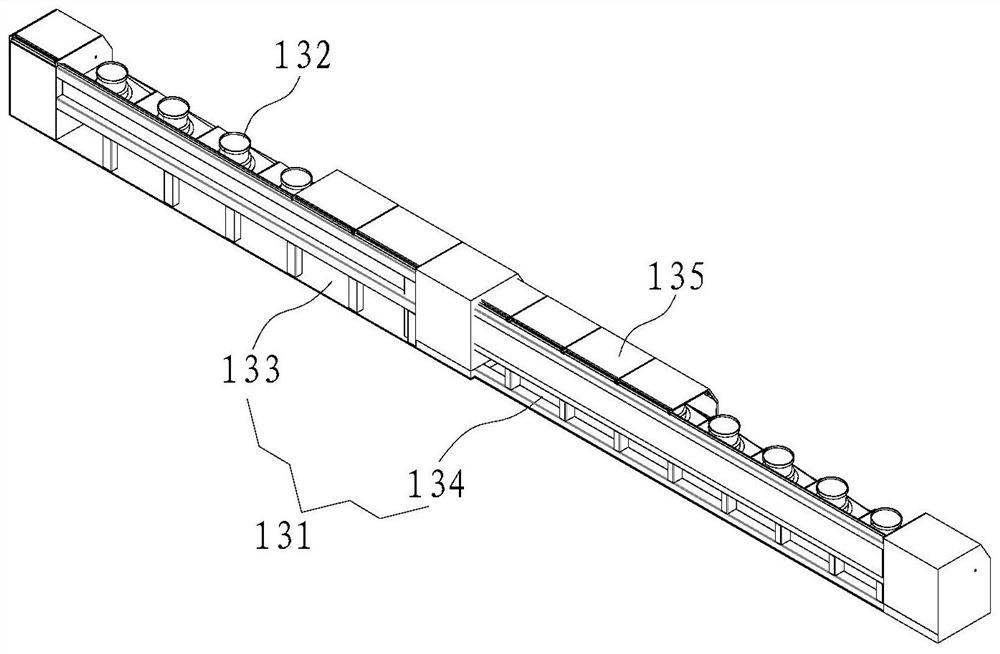

Air distribution plate for preparing double-filter-capsule filter rod and preparation device

The invention discloses an air distribution plate for preparing double-filter-capsule filter rod and a preparation device. The air distribution plate comprises a plate body, an inside suction slot, anoutside suction slot and an alternating air blowing structure, wherein the inside suction slot and the outside suction slot are both arranged on the plate body, an arc-shaped groove body is coaxial with the plate body, a radius of the inside suction slot is less than that of the outside suction slot, and one end of the inside suction slot is radially flush with one end of the outside suction slot; the central angle of the outside suction slot is 90-340 degrees, the central angle of the inside suction slot is at least 30 degrees, and at least 30 degrees smaller than that of the outside suctionslot; the alternating air blowing structure is arranged at one end of the inside suction slot radially flush with the outside suction slot; the inside suction slot and the outside suction slot are connected with a vacuum pump, the vacuum pump provides negative pressure for adsorbing negative pressure of a filter capsule; the alternating air blowing structure is connected with the air source, andprovides positive pressure for transferring the filter capsule to next process.

Owner:山东将军烟草新材料科技有限公司

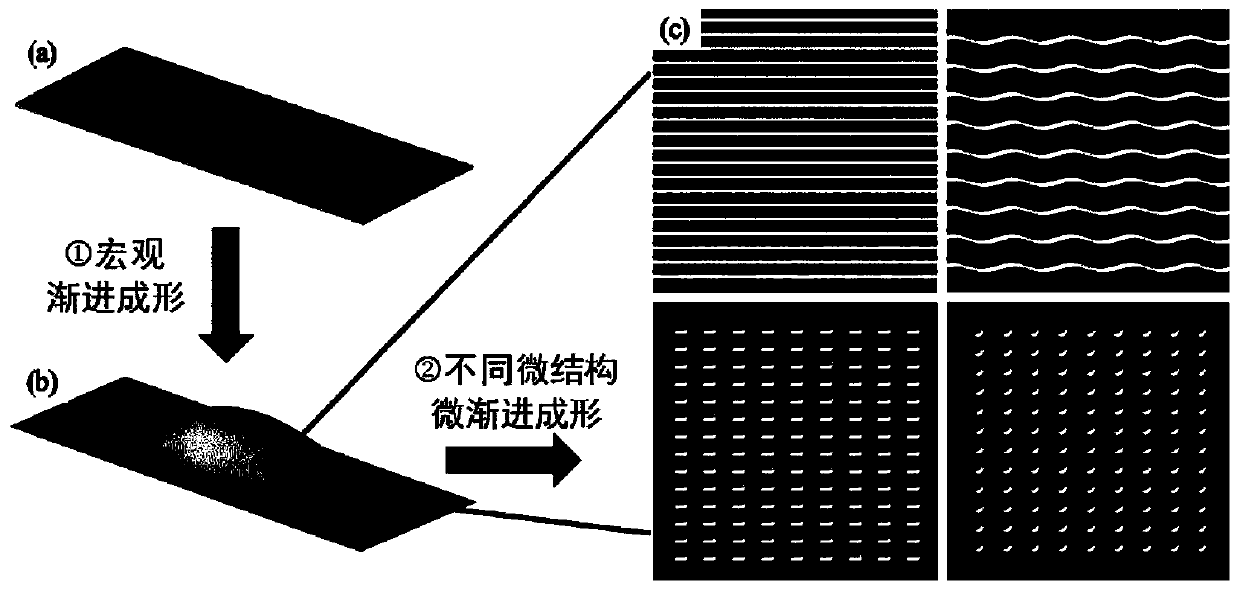

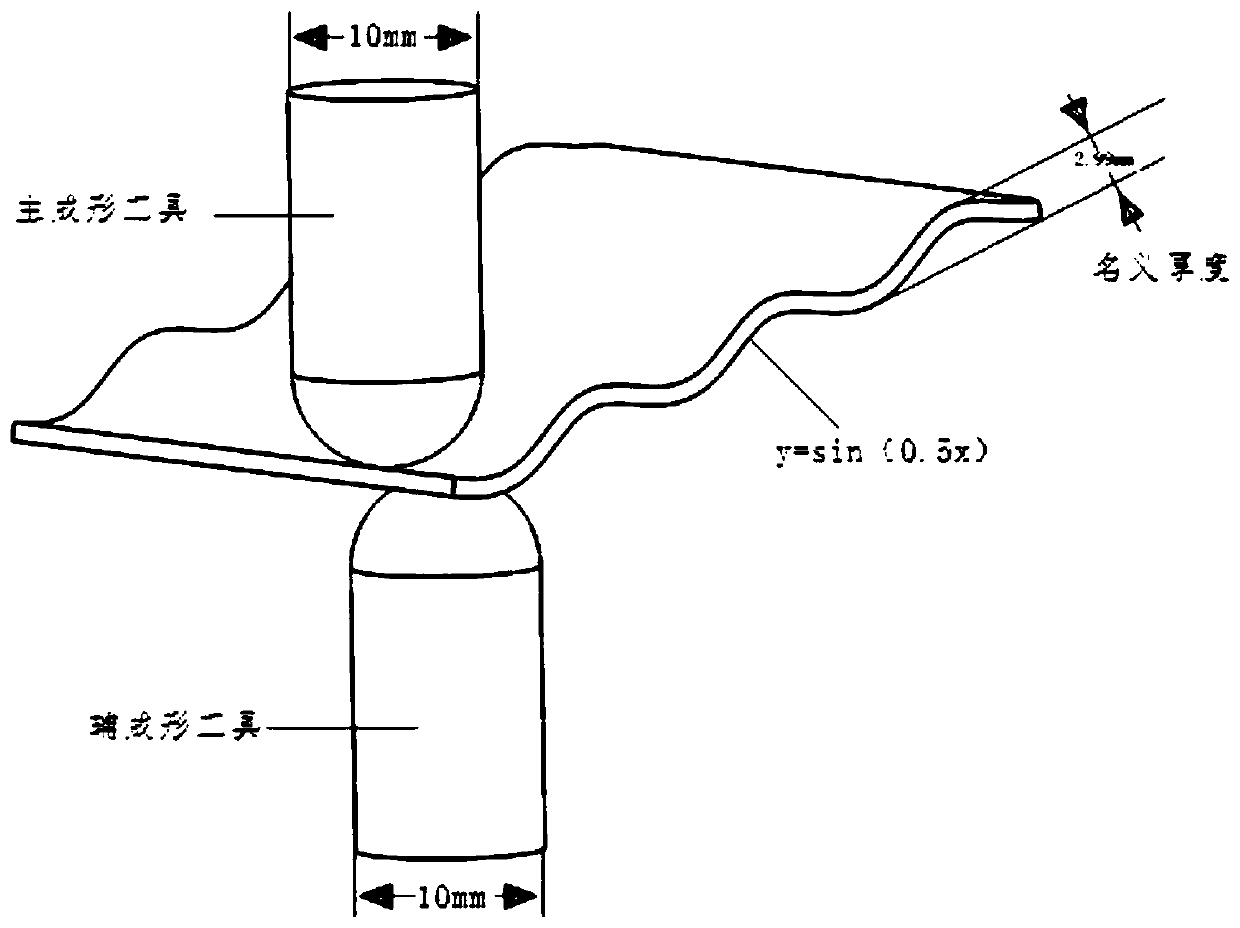

Implant macro-micro integrated incremental forming preparation method and obtained implant

ActiveCN110101488AShort manufacturing cycleShorten the process chainBone implantTomographyMicro structureEngineering

The invention discloses an implant macro-micro integrated incremental forming preparation method and an obtained implant. The method comprises the following steps that 1, the shape and mechanical property of the implant are determined according to the illness state of a patient, the needed shape is processed through a macroscopic incremental forming technology, and the local nominal thickness of the implant is increased during macroscopic incremental forming; 2, a microstructural type is selected, the surface of a macroscopically formed plate is modified through micro incremental forming, anda micro structure in the needed shape is obtained.

Owner:SHANDONG UNIV

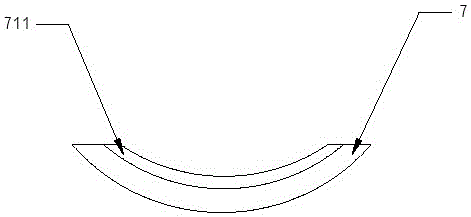

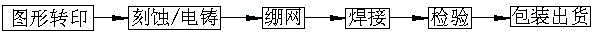

Metal mask plate integrated assembly detection center

InactiveCN104372290AImprove product qualityImprove efficiencyVacuum evaporation coatingSputtering coatingLaser cuttingLaser soldering

The present invention discloses a metal mask plate integrated assembly detection center, which comprises a laser welding device, a laser cutting device, a stretching-flattening component, a precision measurement device, a sag measurement device, a machine table and movement guide rails. The metal mask plate integrated assembly detection center of the present invention has five core functions of laser welding, laser cutting, automatic stretching-flattening, precision measurement and sag measurement. With the metal mask plate integrated assembly detection center, the original complex and lengthy process chain can be avoided, and only the one process laser cutting can affect the precision, such that the product precision is easy to control, and the process is simplified.

Owner:KUNSHAN THETA MICRO

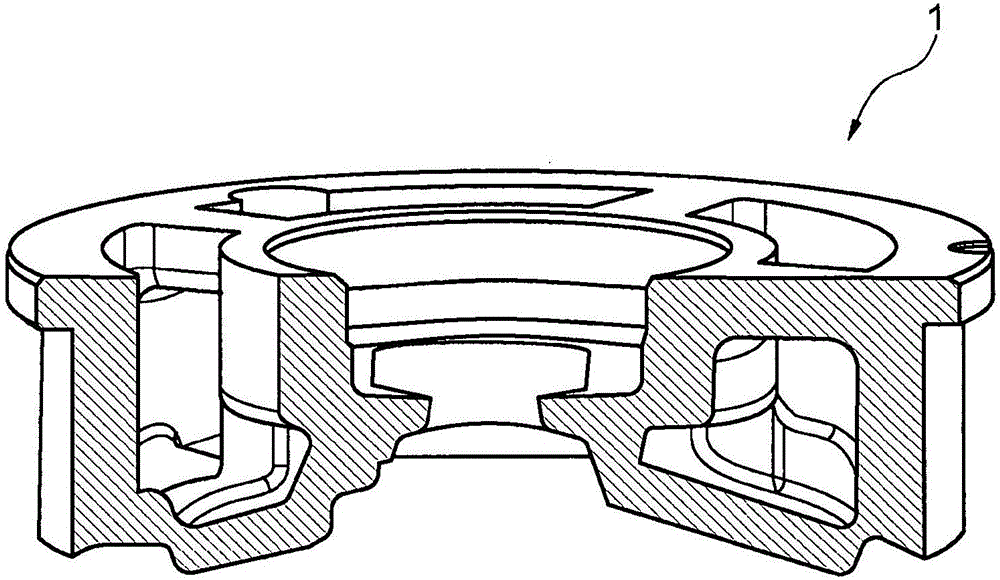

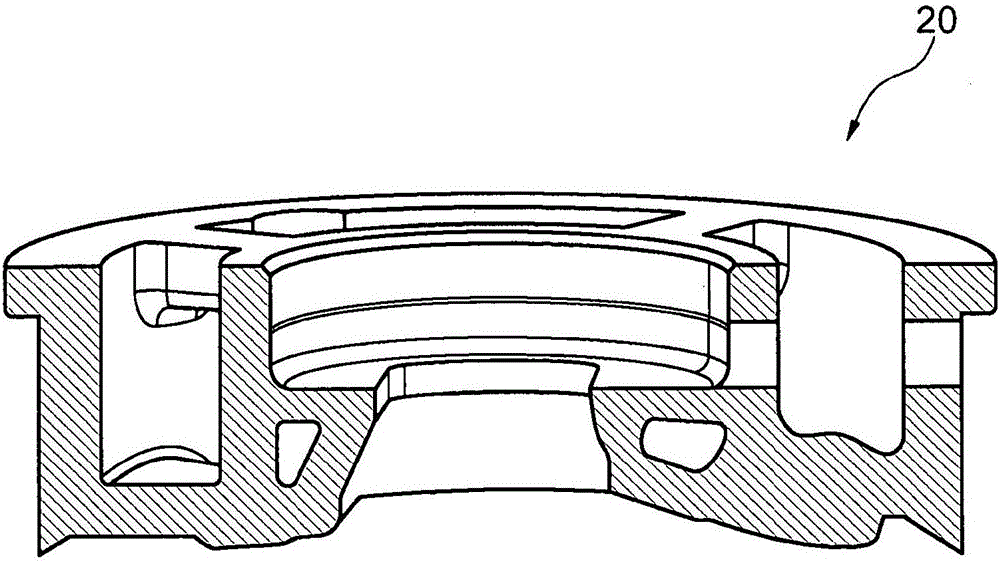

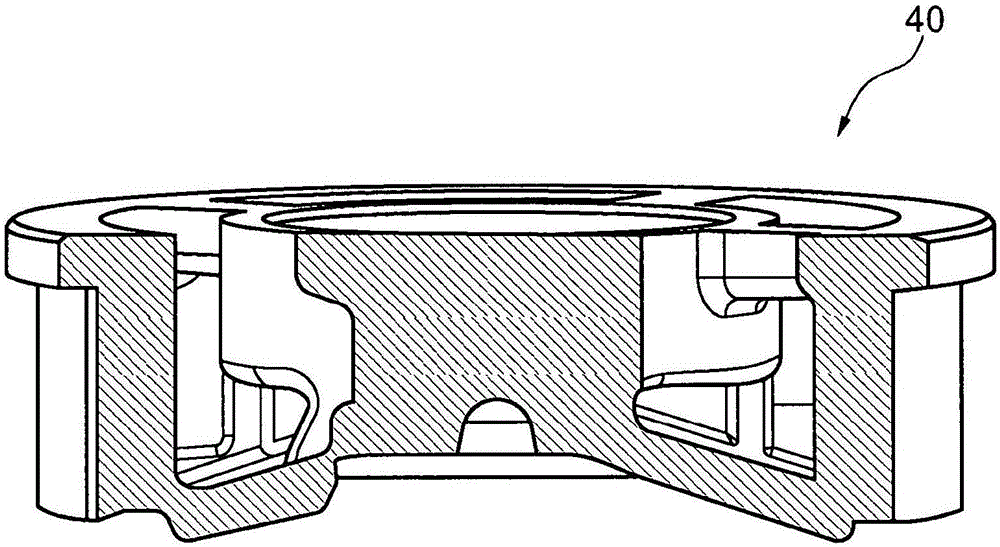

Layer-by-layer production method during laser melting (sls) in gravity die casting operations

InactiveCN106488817APrevent gaseous inclusionsCut costsAdditive manufacturing apparatusFoundry mouldsDirect metal laser sinteringCombustion

The invention relates to the use of direct metal laser sintering (DMLS) for the production of a casting mold, in particular a permanent mold, in order to avoid air pockets in internal combustion engine pistons manufactured in a gravity die casting process, wherein at least one portion of the casting mold has a plurality of small openings, in particular microscopic holes, for discharging air. The invention also relates to a method for producing a casting mold, in particular a permanent mold, for gravity die casting pistons for internal combustion engines.

Owner:KOLBENSCHMIDT AG

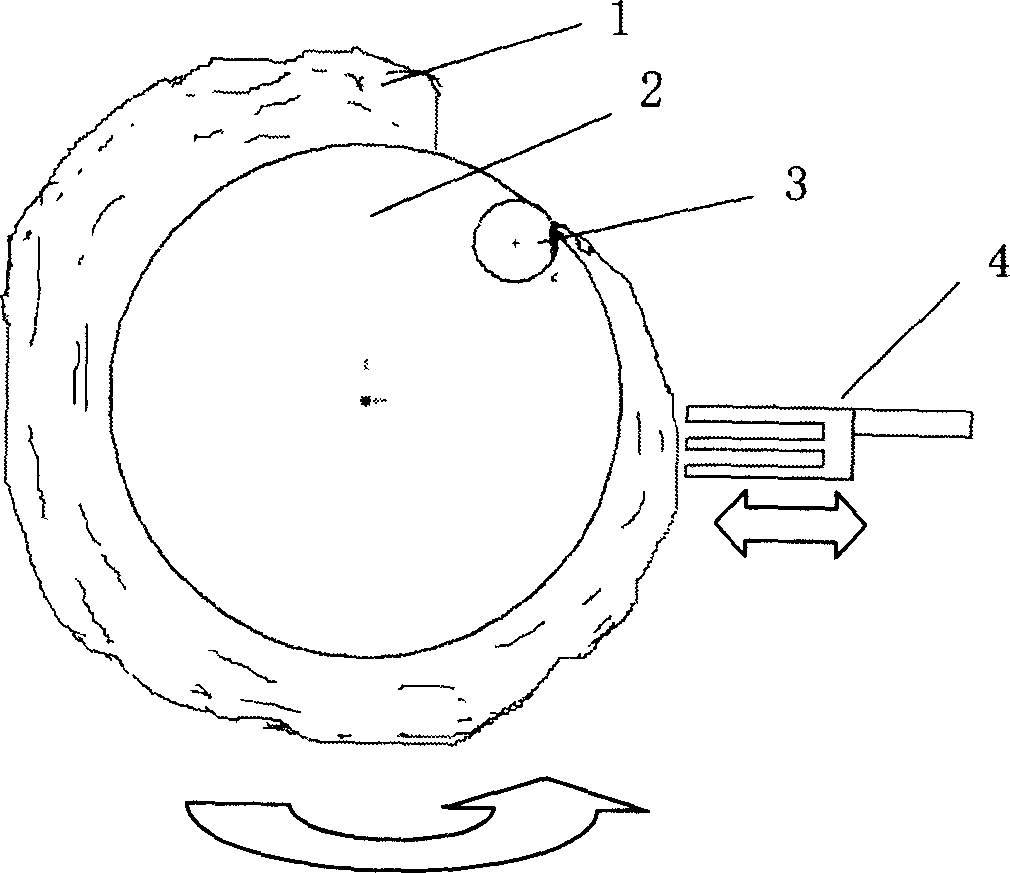

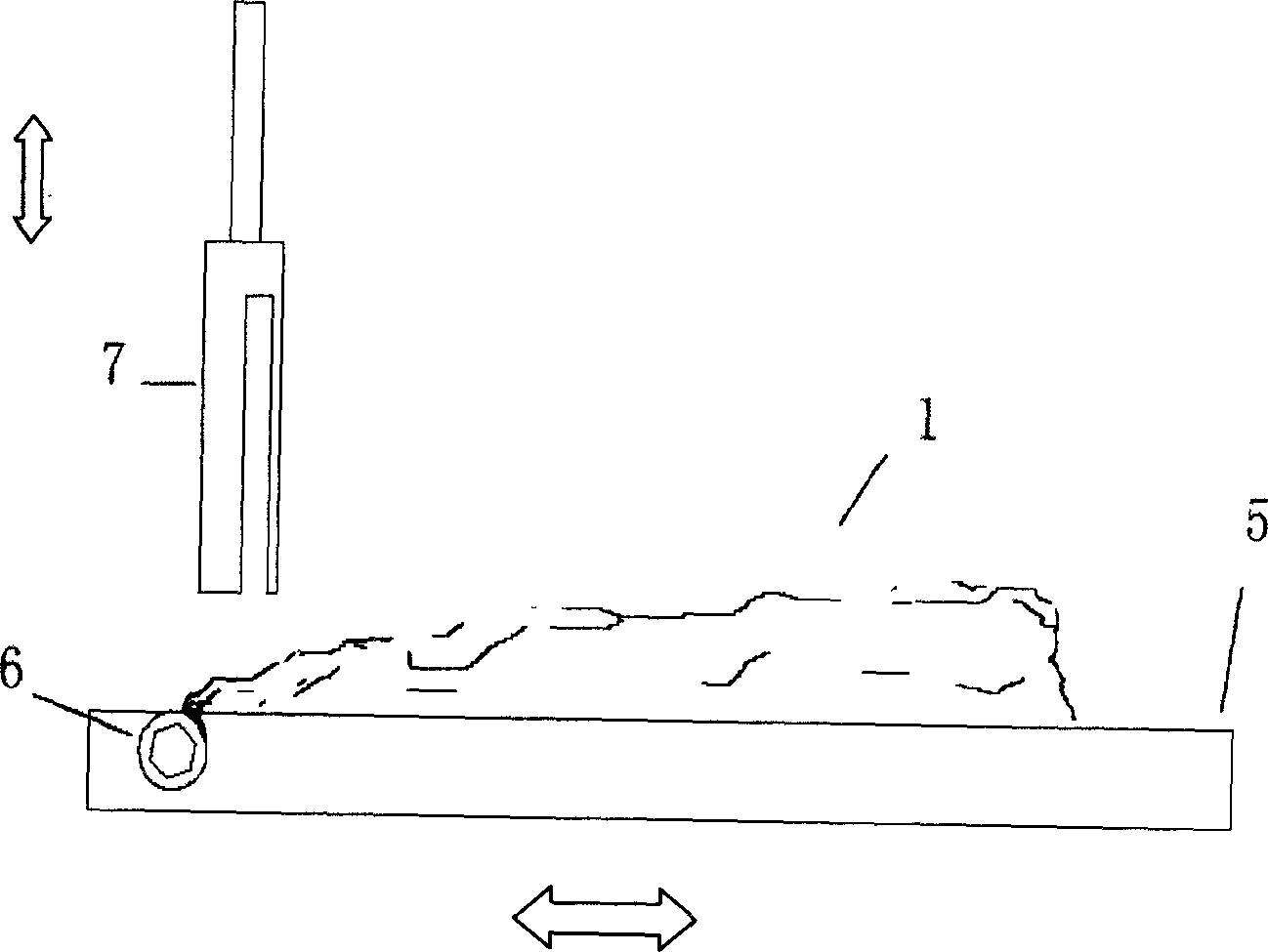

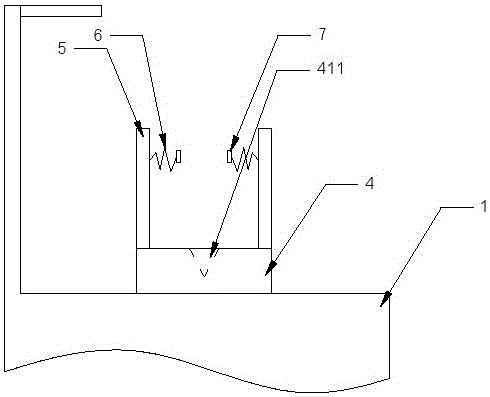

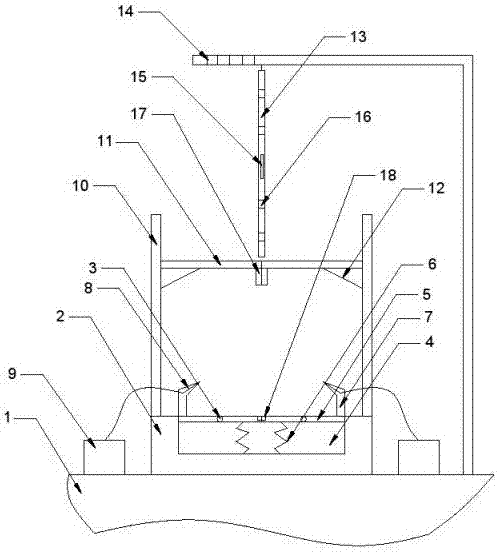

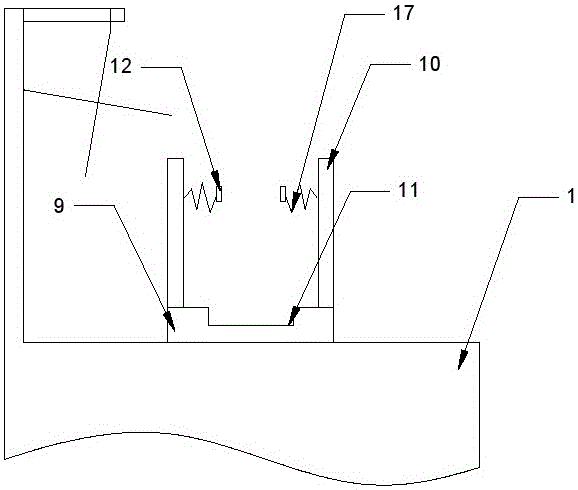

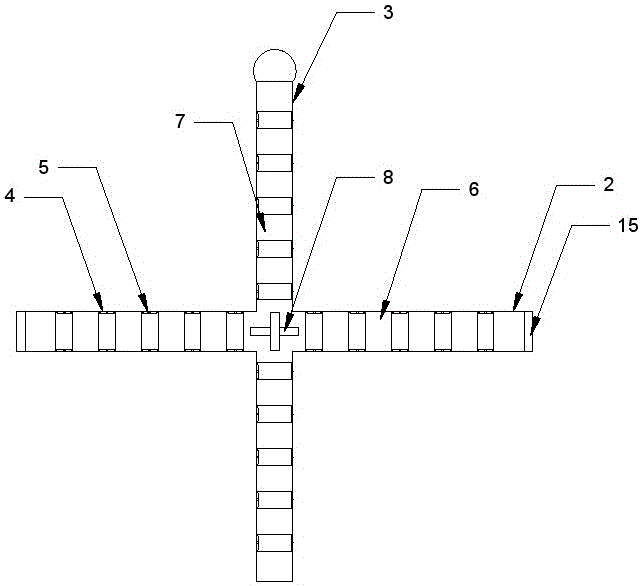

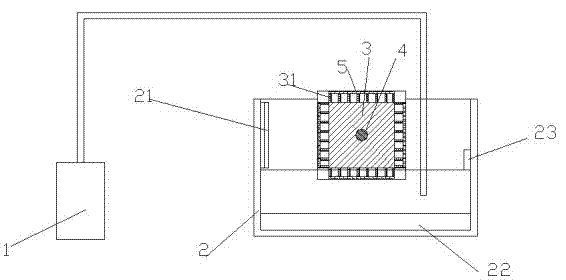

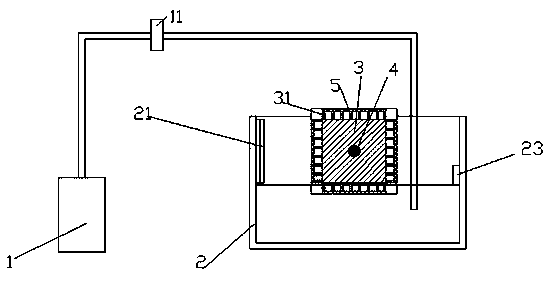

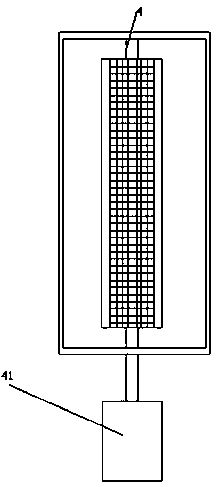

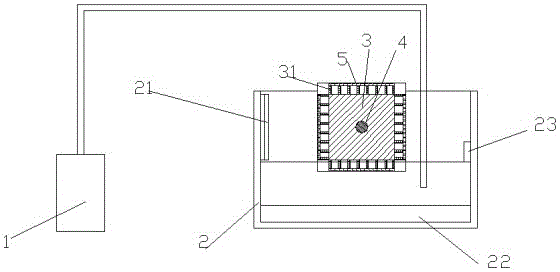

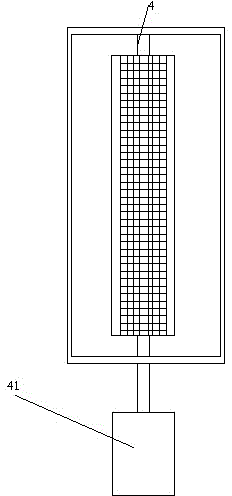

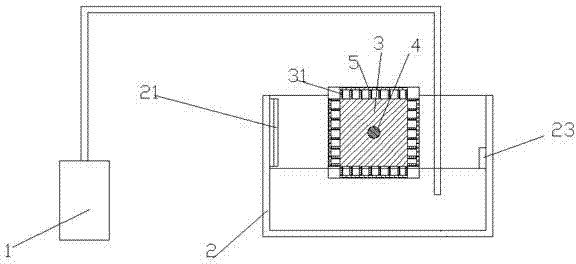

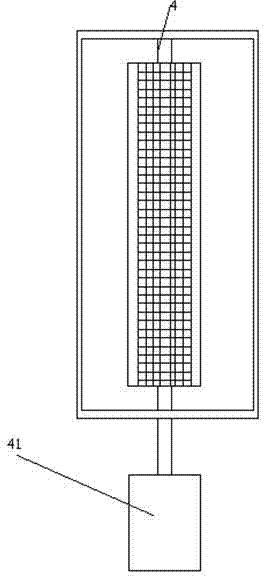

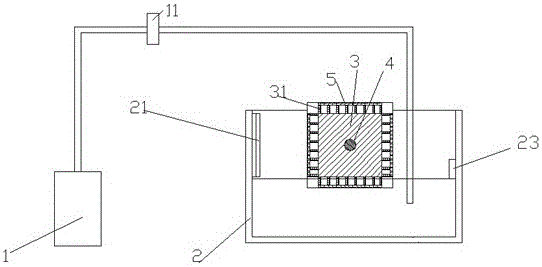

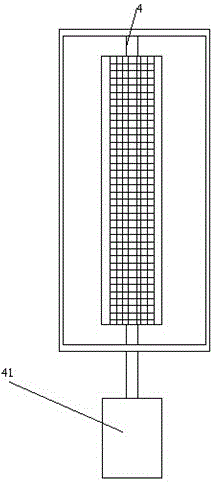

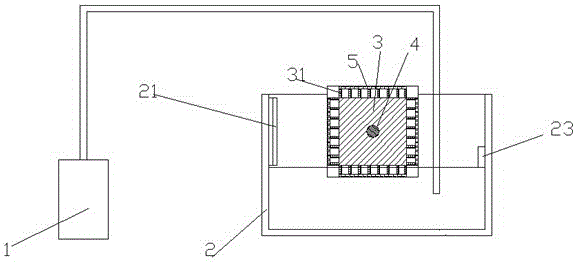

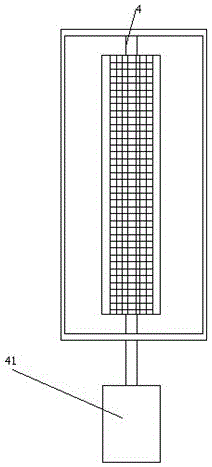

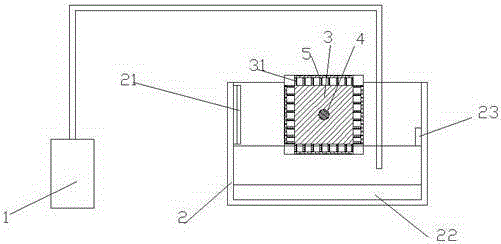

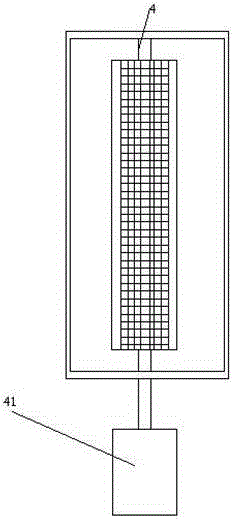

Medical cotton processing method utilizing temperature adjusting device and shaft height adjusting device

InactiveCN103655048AContinuous processingShorten the process chainMedical applicatorsAbsorbent padsSquare ShapeMesh grid

The invention provides a medical cotton processing method utilizing a temperature adjusting device and a shaft height adjusting device. A medical cotton processing device is utilized and comprises a liquid medicine container (2) which is of a cuboid structure, and two opposite short panels of the cuboid are rotatably provided with a shaft (4). A rotating body (3) is fixed on the shaft (4), and the shaft (4) is in power connection with an electromotor (41). The rotating body (3) is in a right pyramid shape and provided with a square cross section, and each side face of the right pyramid is provided with filtering net grids, wherein the filtering net grids are arranged in an array mode. The filtering net grids are in a square shape, side walls (31) of the filtering net grids are respectively composed of a filtering net and perpendicular to the plane where the side wall is located on the right pyramid, and each filtering net grid is used for containing the medical cotton.

Owner:HAIMEN THE YELLOW SEA ENTREPRENEURSHIP PARK SERVICE CO LTD

Anti-fatigue safety glasses and production method thereof

InactiveCN107356992AReduce manufacturing costShorten the process chainCoatingsOptical elementsAntistatic agentEngineering

The invention discloses anti-fatigue safety glasses and a production method thereof. The anti-fatigue safety glasses comprise a resin substrate and a special coating arranged on the surface thereof, a special antistatic agent and a special absorbent need to be added to the external coating, and the antistatic agent refers to one or more internal-mixing type antistatic agents. According to the antistatic glasses with the coating, static electricity on the resin glasses can be effectively, rapidly, and permanently led out, the usage is safer, and the surface of the glasses is more stain-resistant; two special absorbents are added to the external special coating, harmful blue light of the 420 nm can be blocked, narrowband visible light of the 585 nm, which causes visual fatigue, can be effectively absorbed, and eyes can be protected more comprehensively.

Owner:ZENNI OPTICAL

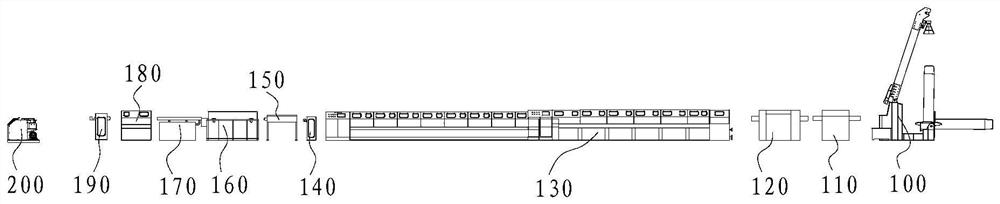

Full-process automatic welding wire production line

PendingCN112170532AHigh degree of automationIncrease productivityWelding/cutting media/materialsExtrusion cleaning devicesWire rodWinding machine

The invention discloses a full-process automatic welding wire production line. The full-process automatic welding wire production line comprises a pay-off machine around which a wire rod is wound. A husking machine, a derusting machine, a drawing all-in-one machine, a front tension box, a mixed cleaning machine, a high-speed plating tank, a high-speed cleaning tank, a high-speed polishing tank, arear tension box and a layer winding machine which allow the wire rod to penetrate through are sequentially arranged behind the pay-off machine. The drawing all-in-one machine comprises a box body andmultiple drawing rollers arranged on the box body, the multiple drawing rollers incline towards the same side of the box body and have the same inclination angle, and the multiple drawing rollers have the same height in the vertical direction. The drawing all-in-one machine in the scheme comprises the multiple drawing rollers so that the wire rod can be drawn into finished welding wires of various different specifications, the functions of a rough drawing machine and a fine drawing machine are integrated in the equipment, turnover of the wire rod between the rough drawing machine and the finedrawing machine can be avoided, thus, machine halt caused by frequent turnover of spools is avoided, and the stability of the product quality can be ensured.

Owner:德州市立尊焊丝有限公司

Method for treating medical cotton through intermittent opening valve and shaft height adjusting device

InactiveCN103706029AEnables continuous processingRealize handoverMedical applicatorsAbsorbent padsPrismShort face

The invention provides a method for treating medical cotton through an intermittent opening valve and a shaft height adjusting device. A medical cotton treatment device is adopted and comprises a liquid medicine container (2), the liquid medicine container (2) is of a cuboid structure, and shafts (4) are rotatably mounted on two opposite short face plates of the cuboid. Rotating bodies (3) are fixed to the shafts (4), and the shafts (4) are in power connection with a motor (41). The rotating bodies (3) are in the shape of a regular square prism and are provided with square sections, and filter screen boxes arranged in an array mode are arranged on each side face of the regular square prisms.

Owner:兴化市富强机械铸造有限公司

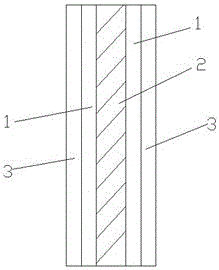

Intermediate-refractive index anti-blue-light impact-resistant lens and manufacturing process thereof

InactiveCN110632691ALow costShorten the process chainOptical filtersRefractive indexImpact-resistant lens

The invention provides an intermediate-refractive index anti-blue-light impact-resistant lens and a manufacturing process thereof. The intermediate-refractive index anti-blue-light impact-resistant lens comprises a resin lens; hardening layers are arranged on the front surface and rear surface of the resin lens respectively; impact-resistant layers are arranged on the surfaces of the hardening layers respectively; and surface coating layers are arranged on the surfaces of the impact-resistant layers. With the intermediate-refractive index anti-blue-light impact-resistant lens and the manufacturing process thereof of the invention adopted, the cost of the lens is effectively reduced; process chains are reduced; production efficiency is improved; and the functions of the blue light resistance, impact resistance and antireflection of the lens can be simultaneously met through the functional film layers; and since the functions of the lens are realized through the film layers, the lens isalmost free of chromatic aberration.

Owner:ZENNI OPTICAL

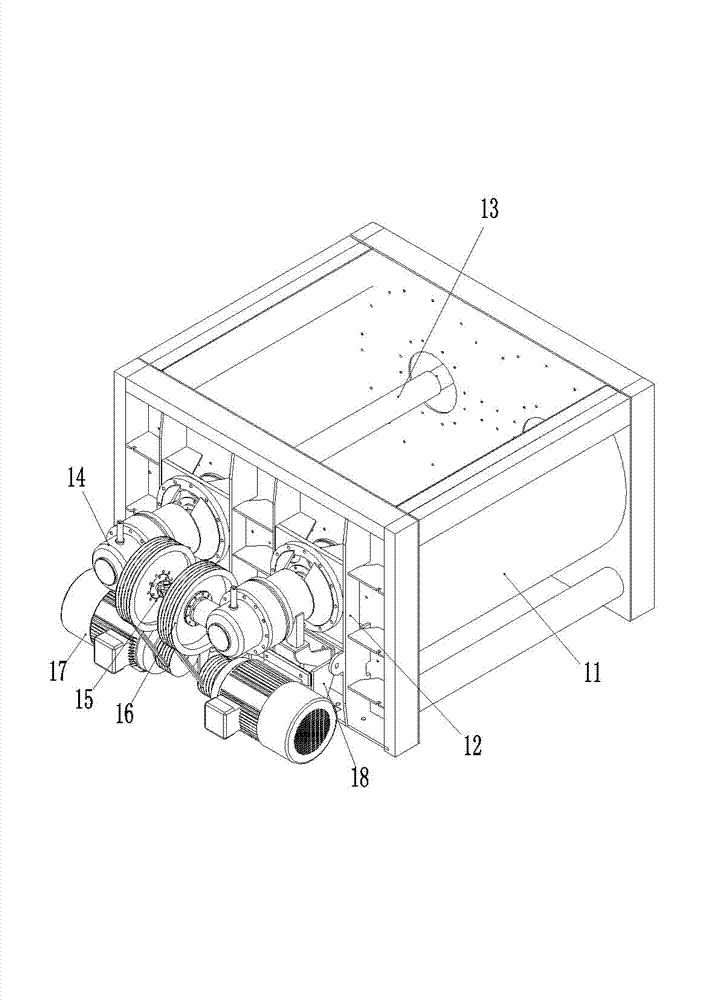

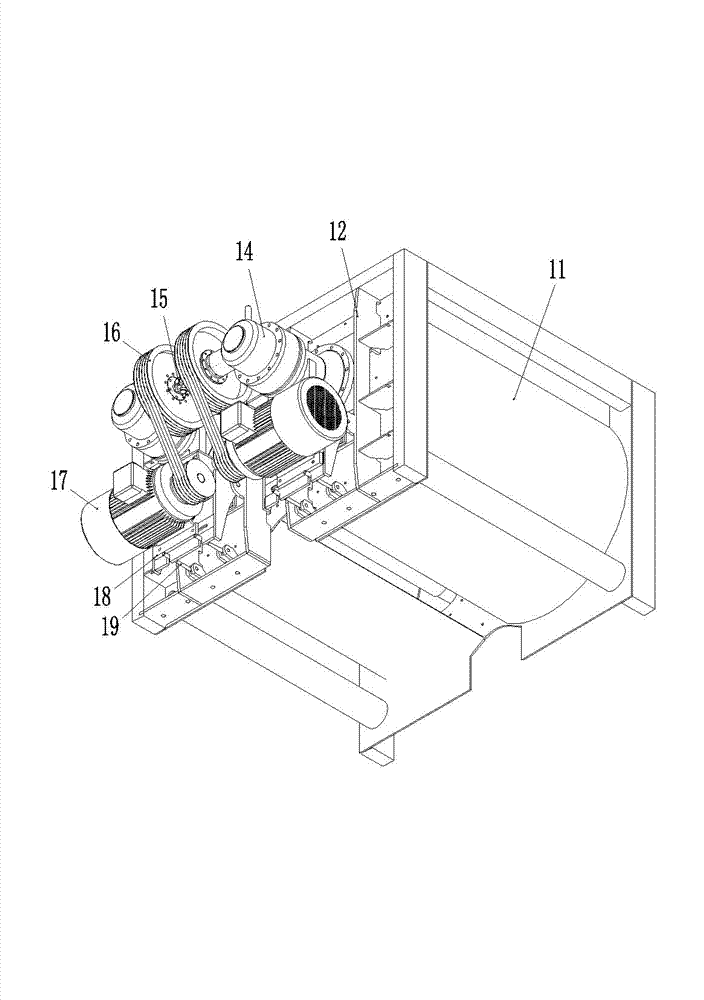

Low-noise double-shaft concrete mixer

InactiveCN102886821AReduce manufacturing costSolve the noiseCement mixing apparatusGearing detailsLow noiseCoupling

The invention relates to the field of concrete mixers and particularly relates to a low-noise double-shaft concrete mixer. The double-shaft concrete mixer comprises a mixing drum and two mixing shafts, wherein the two mixing shafts are respectively in transmission connection with a speed reducer, the two speed reducers are respectively provided with input shafts and output shafts, which are vertical to each other, the output rotation directions of the output shafts of the speed reducers are opposite, and the input shafts of the two speed reducers are in coaxial transmission connection through a shaft coupler; a synchronous gear on the conventional product is unnecessary, so that the noise generated by the engagement of the synchronous gear is eliminated, and the problem of high noise of the existing concrete mixer during the working process is solved; besides, the synchronous gear on the conventional product is omitted, so that the production cost of the mixer is reduced; and therefore, the low-noise double-shaft concrete mixer provided by the invention has the advantages that is the problem of high noise of the conventional concrete mixer during the working process is solved, but also the production cost of the double-shaft concrete mixer is lowered.

Owner:GREAT WALL MACHINE MFR

Medical cotton processing method utilizing temperature adjusting device and shaft height adjusting device

InactiveCN103655048BShorten the process chainReduce manufacturing costMedical applicatorsAbsorbent padsSquare cross sectionEngineering

The invention provides a medical cotton processing method utilizing a temperature adjusting device and a shaft height adjusting device. A medical cotton processing device is utilized and comprises a liquid medicine container (2) which is of a cuboid structure, and two opposite short panels of the cuboid are rotatably provided with a shaft (4). A rotating body (3) is fixed on the shaft (4), and the shaft (4) is in power connection with an electromotor (41). The rotating body (3) is in a right pyramid shape and provided with a square cross section, and each side face of the right pyramid is provided with filtering net grids, wherein the filtering net grids are arranged in an array mode. The filtering net grids are in a square shape, side walls (31) of the filtering net grids are respectively composed of a filtering net and perpendicular to the plane where the side wall is located on the right pyramid, and each filtering net grid is used for containing the medical cotton.

Owner:HAIMEN THE YELLOW SEA ENTREPRENEURSHIP PARK SERVICE CO LTD

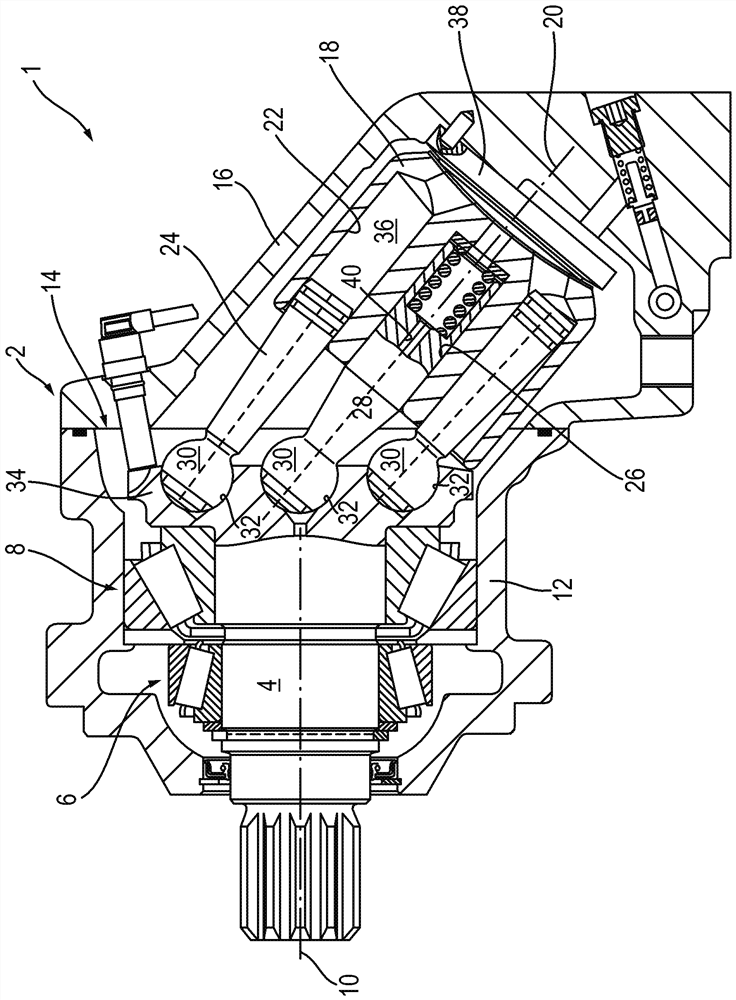

Method for producing clearance at drive shaft, drive shaft and axial piston machine

ActiveCN106862858BShorten the process chainReduce manufacturing costShaftsFurnace typesDrive shaftEngineering

A method for manufacturing an at least sectionally spherical-cap-shaped recess on a drive shaft for a hydrostatic axial piston machine includes whirling of the recess and heat treatment of the recess to form a wear layer. A drive shaft for a hydrostatic axial piston machine includes at least one recess manufactured according to the method. A hydrostatic axial piston machine includes a drive shaft with at least one recess manufactured according to the method.

Owner:ROBERT BOSCH GMBH

Detachable filtering net grid type medical cotton processing method utilizing shaft height adjusting device

ActiveCN103655047BShorten the process chainReduce manufacturing costMedical applicatorsAbsorbent padsSquare cross sectionEngineering

Owner:启东市天汾电动工具技术创新中心

Medicinal Cotton Treatment Method Using Intermittent Open Valve and Shaft Height Adjustment Device

InactiveCN103706029BShorten the process chainReduce manufacturing costMedical applicatorsAbsorbent padsEngineeringPrism

The invention provides a method for treating medical cotton through an intermittent opening valve and a shaft height adjusting device. A medical cotton treatment device is adopted and comprises a liquid medicine container (2), the liquid medicine container (2) is of a cuboid structure, and shafts (4) are rotatably mounted on two opposite short face plates of the cuboid. Rotating bodies (3) are fixed to the shafts (4), and the shafts (4) are in power connection with a motor (41). The rotating bodies (3) are in the shape of a regular square prism and are provided with square sections, and filter screen boxes arranged in an array mode are arranged on each side face of the regular square prisms.

Owner:兴化市富强机械铸造有限公司

Medicinal cotton processing method using position reading device and shaft height adjustment device

ActiveCN103706028BShorten the process chainReduce manufacturing costMedical applicatorsAbsorbent padsPrismEngineering

The invention provides a method for treating medical cotton through a position reading device and a shaft height adjusting device. A medical cotton treatment device is used and comprises a liquid medicine container (2), the liquid medicine container (2) is of a cuboid structure, and shafts (4) are rotatably mounted on two opposite short face plates of the cuboid. Rotating bodies (3) are fixed to the shafts (4), and the shafts (4) are in power connection with a motor (41). The rotating bodies (3) are in the shape of a regular square prism and are provided with square sections, and filter screen boxes arranged in an array mode are arranged on each side face of the regular square prisms. The filter screen boxes are square, each side wall (31) of the filter screen boxes is composed of a filter screen and is perpendicular to the faces of the regular square prisms where the filter screen boxes are located, and each filter screen box is used for containing the medical cotton.

Owner:海宁市钱塘新农村开发有限公司

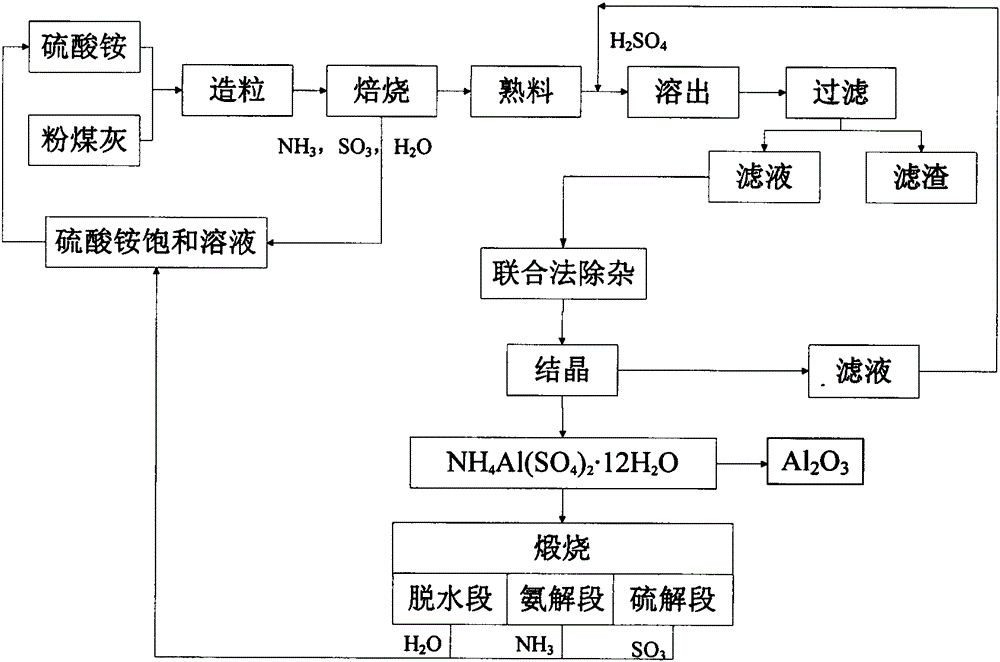

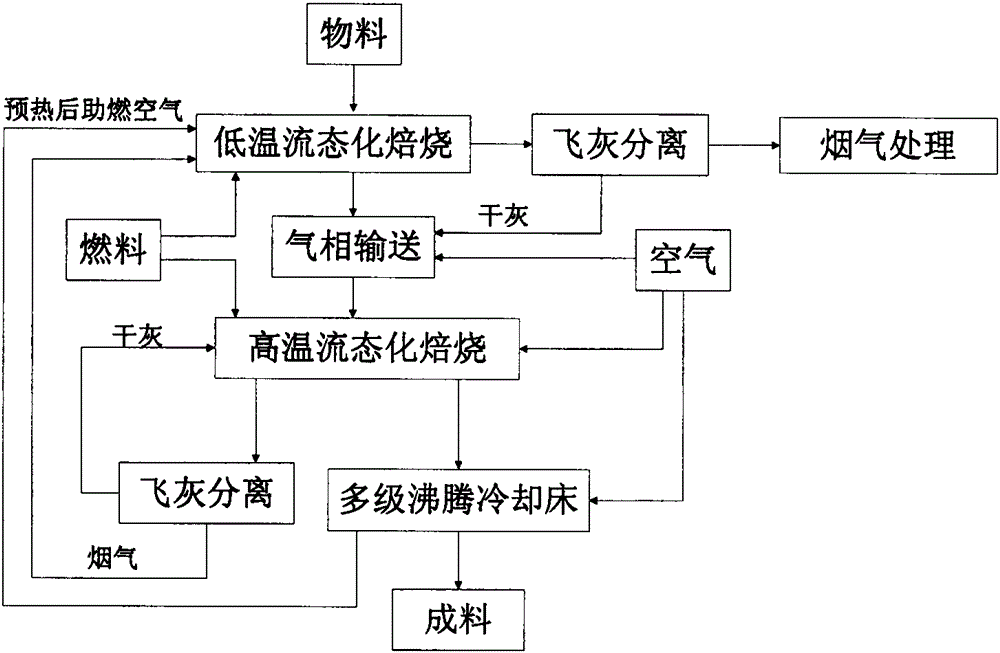

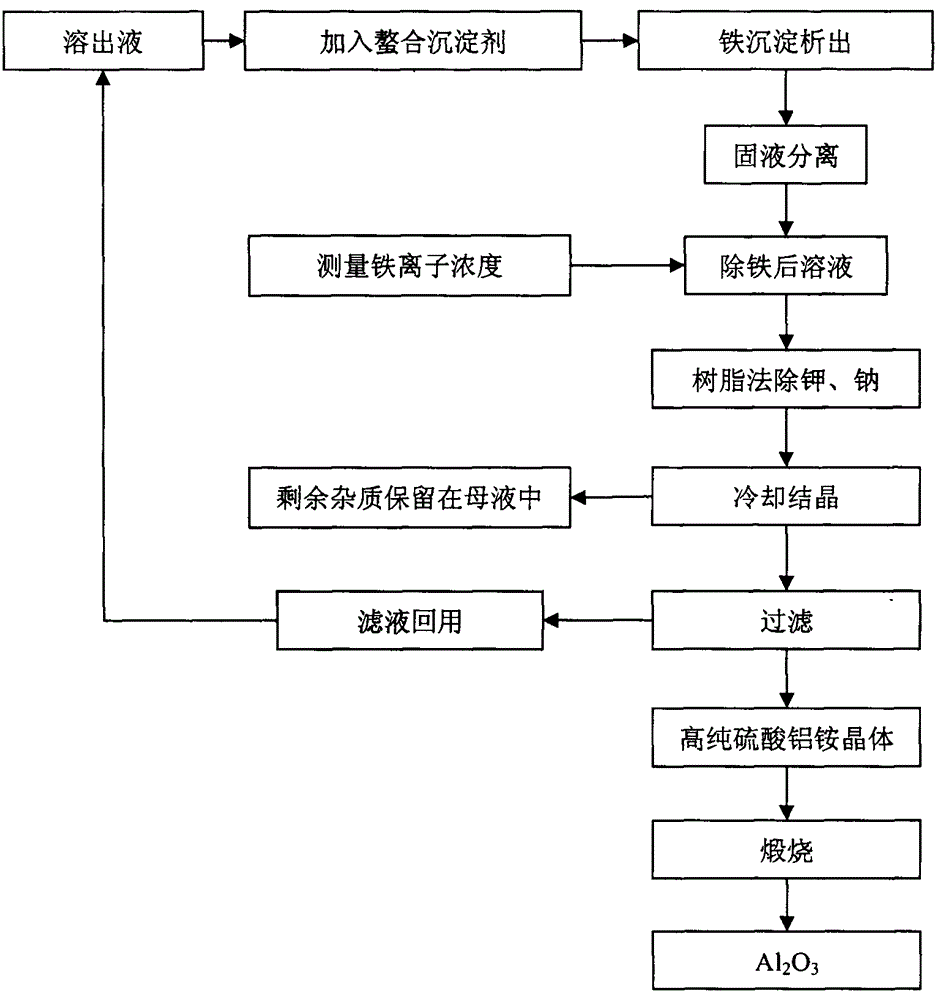

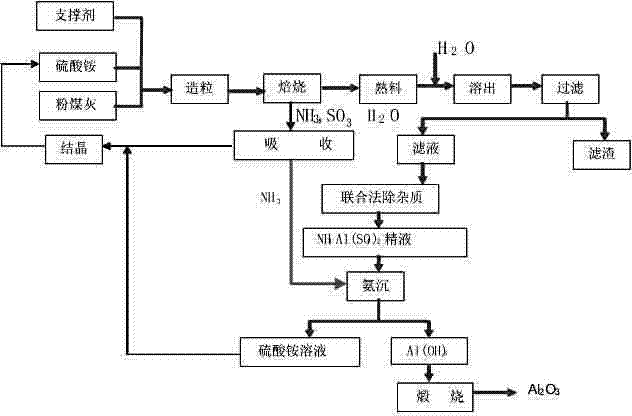

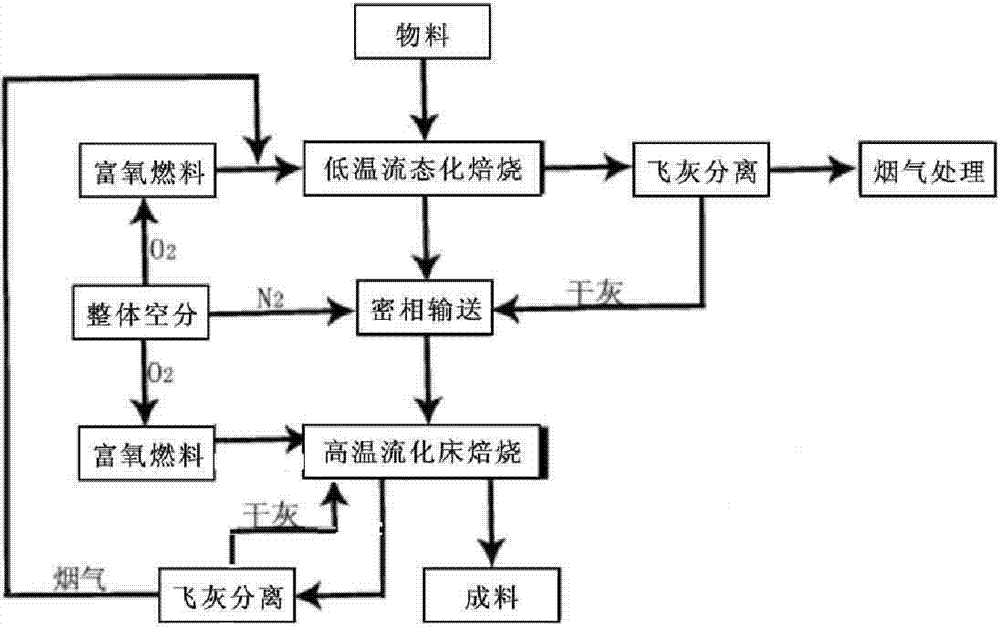

Method for extracting alumina from fly ash based on ammonium sulfate activation process

The invention relates to a method for extracting aluminum oxide from fly ash based on an ammonium sulfate activation process. By adopting roasting of the fly ash and ammonium sulfate, combined impurity removal and a two-section fluidized roasting system, the problem of high corrosion of equipment in the background technology is solved; a process chain of a main flow is shortened; through the roasting system, the roasting process is low in energy consumption, economic and low in cost by using methods such as two-section cyclic fluidized roasting and dense phase transportation; and the technical problem of material melting, wall sticking, caking or ring forming is solved.

Owner:CHINA SHENHUA ENERGY CO LTD +2

Method for extracting alumina from fly ash based on ammonium sulfate method

ActiveCN104150515BLess corrosiveImprove protectionEnergy inputAluminium oxide/hydroxide preparationAluminium hydroxideFluidized bed

The invention relates to a method for extracting alumina from fly ash based on an ammonium sulfate method. The prior art utilizing fluidized bed-based roasting activation of fly ash to realize alumina extraction produces the problems of material caking and adhesion to the wall so that industrialization is realized difficultly and crude alumina produced by the prior art needs resolution impurity-removal so that processes are more, efficiency is low and energy consumption is high. The method comprises that fly ash, ammonium sulfate and a propping agent are mixed, the mixture is subjected to granulation, the granules are subjected to two-section fluidized bed roasting, the clinker is heated and dissolved by water, the filtrate is subjected to combined impurity-removal and then ammonia precipitation crystallization, and the crystals are calcined to form alumina. The method utilizes mixing granulation of fly ash, ammonium sulfate and the propping agent, oxygen-rich two-section fluidized bed roasting and heating dissolution by water, changes the order of the impurity-removal processes, utilizes a technical scheme comprising impurity-removal and then ammonia precipitation crystallization for high-purity aluminum hydroxide production to solve the problems of equipment corrosion, roasting-caused adhesion to the wall, clustering and coking of the prior art, shortens the integral main process and greatly reduces energy consumption and a cost of extraction of alumina from fly ash.

Owner:CHINA SHENHUA ENERGY CO LTD +2

Medicinal cotton processing method using temperature regulating device and position reading device

InactiveCN103691053BShorten the process chainReduce manufacturing costMedical applicatorsPrismEngineering

The invention provides a method for treating medical cotton by utilizing a temperature regulating device and a position reading device. A medicinal cotton treatment device is used in the method and comprises a liquid container (2), the liquid container (2) is of a cuboid structure, and a shaft (4) is rotationally mounted on two opposite short panels of a cuboid. A rotator (3) is fixed on the shaft (4) which is in power connection with a motor (41). The rotator (3) is in the shape of a regular quadrangular prism and has a square section, and filter meshes in an array are arranged on each side face of the regular quadrangular prism. Each filter mesh is square, each side wall (31) of each filter mesh is composed of a filter screen and perpendicular to the corresponding face of the regular quadrangular prism, and each filter mesh is used for containing the medical cotton.

Owner:宋霞

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com