Method for producing clearance at drive shaft, drive shaft and axial piston machine

A technology of axial piston machines and drive shafts, applied in shafts and bearings, reciprocating piston engines, manufacturing tools, etc., can solve cost-intensive and time-intensive problems, reduce manufacturing costs, improve process reliability, The effect of shortening the process chain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

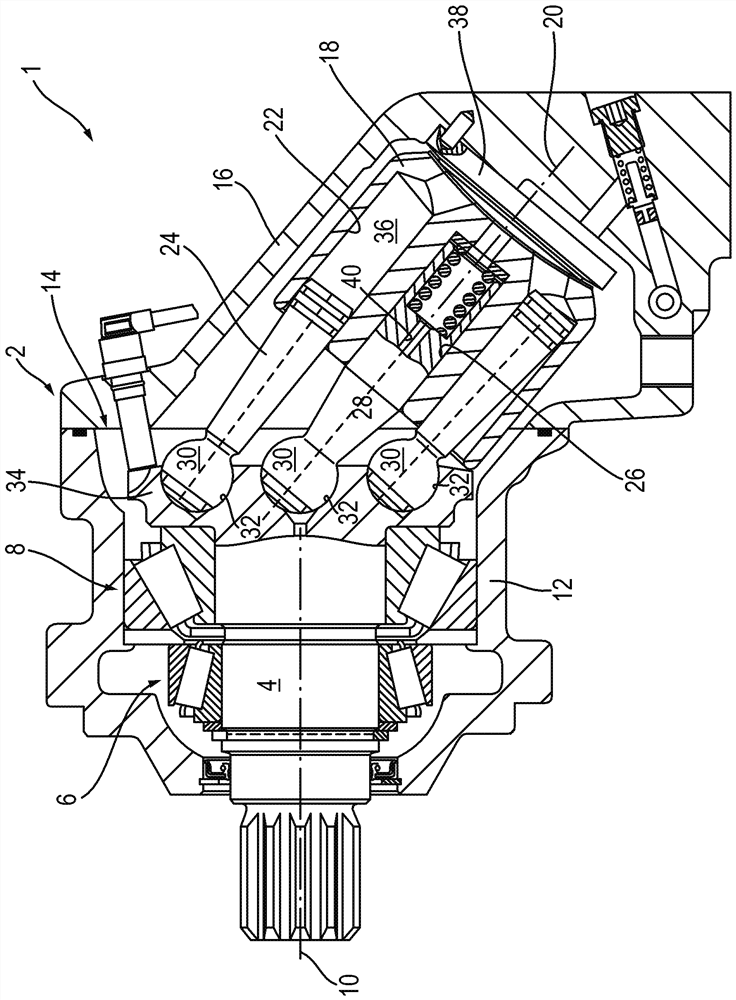

[0043] according to figure 1 An axial piston machine 1 constructed in an inclined-axis configuration has a two-part housing 2 in which a drive shaft 4 is rotatably mounted via two tapered roller bearings 6 and 8 , an axis of rotation 10 . Axial piston machine 1 according to figure 1 The exemplary embodiment of the present invention is designed as a constant machine, that is to say with a constant displacement, and can alternatively be configured with an adjustable displacement.

[0044] The drive shaft 4 is accommodated via bearings 6 , 8 in a pot-shaped first housing part 12 . At the mouth 14 of the housing, through which the drive shaft 4 can be mounted, abuts a second housing 16 inclined relative to the first housing 12 in which a rotation axis 20 The cylinder 18 is rotatably supported. In this case, the cylinder barrel 18 has a plurality of cylinder bores 22 on a pitch circle arranged concentrically to the axis of rotation 20 , in each case a working piston 24 is arranged...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com