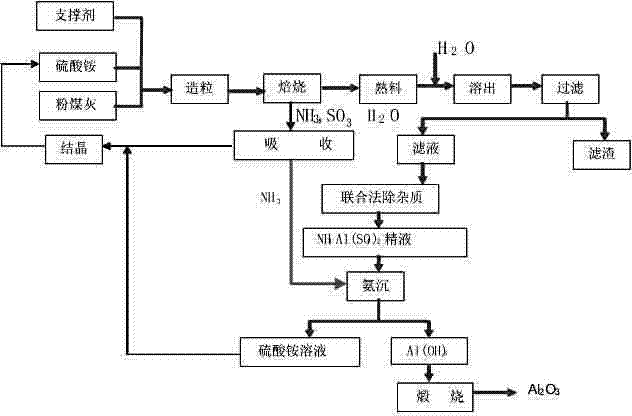

Method for extracting alumina from fly ash based on ammonium sulfate method

A technology of ammonium sulfate method and fly ash, applied in the direction of alumina/hydroxide preparation, energy input, etc., can solve the problems of shortening the main process process chain, high energy consumption, high corrosion, etc., and achieve environmental protection and energy efficiency Low consumption, less corrosive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0122] The method for extracting alumina from fly ash based on the ammonium sulfate method is characterized in that:

[0123] Achieved by the following steps:

[0124] Step 1: According to the molar ratio of fly ash and ammonium sulfate of 1:5, add ammonium sulfate to the fly ash; then add proppant according to the ratio of fly ash to proppant of 1:0.05; mix Granulation, the particle size of spherical mixed particles is 0.5-10mm in diameter;

[0125] The proppant is composed of two components mixed in a mass ratio of 1:0.5. The first component is selected from cement and yellow mud, and the second component is selected from sulfate (selected from sodium sulfate, potassium sulfate, ammonium sulfate, etc.);

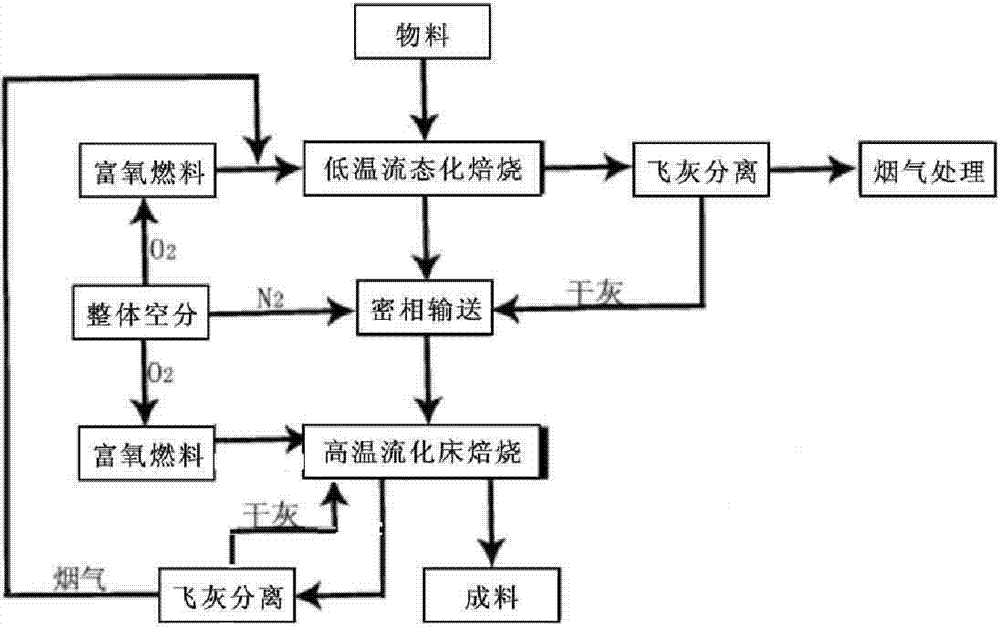

[0126] Step 2: Roast the particles in a two-stage fluidized roasting system:

[0127] A. Low-temperature drying and roasting of granulation:

[0128] The low-temperature drying system is used to dry and roast the granulation at a low temperature. The roasting temperatur...

Embodiment 2

[0152] Step 1: According to the molar ratio of fly ash and ammonium sulfate as 1:7, add ammonium sulfate to the fly ash; then add proppant according to the ratio of fly ash to proppant as 1:15; mix Granulation, the particle size of spherical mixed particles is 0.5-10mm in diameter;

[0153] The proppant is formed by mixing two components at a mass ratio of 1:1, component one is selected from water glass and bentonite, and component two is roasted clinker of ammonium sulfate and fly ash;

[0154] Step 2: Roast the particles in a two-stage fluidized roasting system:

[0155] A. Low-temperature drying and roasting of granulation:

[0156] Using a low-temperature drying system, the granulation is dried and roasted at a low temperature. The roasting temperature is 110°C and the roasting time is 10 minutes to remove free water on the surface of the granules;

[0157] In the low-temperature drying system, the bottom of the low-temperature roasting fluidized bed body is connected to...

Embodiment 3

[0180] Step 1: According to the molar ratio of fly ash and ammonium sulfate as 1:9, add ammonium sulfate to the fly ash; then add proppant according to the ratio of fly ash to proppant as 1:25; mix Granulation, the particle size of spherical mixed particles is 0.5-10mm in diameter;

[0181] The proppant is composed of two components mixed in a mass ratio of 1:1.5, component one is selected from phosphate (chosen from sodium phosphate, potassium phosphate, ammonium phosphate, etc.), aluminum ammonium sulfate, and the component Divided into one of the silicon slag;

[0182] Step 2: Roast the particles in a two-stage fluidized roasting system:

[0183] A. Low-temperature drying and roasting of granulation:

[0184] Using a low-temperature drying system, the granulation is dried and roasted at a low temperature. The roasting temperature is 160°C and the roasting time is 20 minutes to remove free water on the surface of the granules;

[0185] In the low-temperature drying system...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com